Second-hand machinery for sale (2,431)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auctions

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,163 km

Machining center

KIHEUNGCombi - U7

Condition: good (used), Year of construction: 2013, Functionality: fully functional, TECHNICAL DETAILS

Control: Heidenhain TNC 620

Speed: 4,000 rpm

Weight: approx. 12,000 kg

Max. Table load: 2,000 kg

Travel X: 1,600 mm

Travel Y: 750 mm

Travel Z: 900 mm

Clamping surface: 1,800 x 700 mm

MACHINE DETAILS

Gear spindle: 2-stage

Spindle power: approx. 38 kW

Dkslq Notuwkbolmvsl

Tool holder: SK 50

Spindle: manually swiveling

Tool magazine: 24-fold

EQUIPMENT

Chip conveyor with coolant system

Electronic handwheel

Auction

Auction ended

Bayern

Bayern

1,165 km

Laser cutting machine

Mercury1620

Condition: ready for operation (used), Year of construction: 2005, operating hours: 25,253 h, Functionality: fully functional, laser power: 300 W, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,620 mm, travel distance Z-axis: 80 mm, No minimum price - guaranteed sale at the highest bid!

Reason for selling: Space for new machine - machine must be collected by the end of September

Under power until 12.10. Bidders are obliged to collect the machine by the deadline of 18.10.24.

TECHNICAL DETAILS

Laser cutting system: Mercury 1620

Laser: Rofin SCx, water-cooled, cutting head with lens

Laser power: 300 W

Table: Anodized aluminium cutting base

Work surface: 1620 x 2000 mm

Clearance height: 70 mm

Material width: 1650 mm

Z-travel: 80 mm

Speed (X-Y axis): 2000 mm/s

Acceleration: 18 m/s²

Resolution (X-Y axis): 0.001 mm

Resolution Z axis: 0.1 mm

Accuracy: ± 0.05 mm on the entire work surface

Repeat accuracy: ± 0.025 mm

Laser system protection class: 1

Laser source: ROFIN ScX Series 300, closed and maintenance-free

Cooling circuit: closed incl. water recooler for laser

Cutting head: with lens, cutting nozzle, cutting gas supply

MACHINE DETAILS

Dimensions: 2390 x 4150 x 1550 mm

Weight: 2000 kg

Machine: 380 V, 50 Hz, 32 A 3P+N+T / 15 kW

Cooler: 380 V, 50 Hz, 16 A, 4 kW

Suction fan: not included in scope of delivery

Compressed air: 200 l/min, 7 bar, oil-free

EQUIPMENT

- Service set for optics

- ICARO software and user manual

- Shuttle table system

- 2 cutting tables positioned one above the other with motorized height adjustment

- Aluminum cutting base

- Vacuum / suction tray for small parts and dust; suction from below is through the tray. Extraction from above is through a specially designed slot in the upper part of the machine cover

- The cover closes/opens automatically before/after the job is completed

CONTROL

- Speed, acceleration, material thickness, laser power and frequency fully adjustable in the ICARO software

- Import HPGL, DXF, BMP, CF2 ...

- Execution of curves with constant speed

- Execution of curves with spline interpolation

Dslq Neuq I Inolmvokl

- Motor load control for all X, Y, Z axes

- Position and speed control using encoders

- Control system specially developed for laser technology

- Safety standards according to European standards (CE)

The extraction system with filter is not sold.

Auction

Auction ended

Bayern

Bayern

1,287 km

Automatic lathe

TraubTNL 12-7

Condition: excellent (used), Year of construction: 2000, operating hours: 49,274 h, Functionality: fully functional, machine/vehicle number: 247, turning length: 80 mm, spindle speed (max.): 12,000 rpm, feed length X-axis: 35 mm, feed length Y-axis: 37 mm, feed length Z-axis: 75 mm, bar diameter: 12 mm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Control: Mitsubishi TX-8i

Turning length: 80 mm

Main spindle

Technology: belt spindle

Speed: 12,000 rpm

Power: 4 kW

Torque: 7 Nm

Bar capacity: 12.7 mm

Travel path in Z1: 75 mm

Workpiece clamping: collet chuck

Counter spindle

Technology: belt spindle

Speed: 12,000 rpm

Power: 4 kW

Torque: 7 Nm

Travel path in X3/Z4: 222 mm / 139 mm

Rapid traverse in X3/Z4: 30 m/min

Workpiece clamping: collet chuck

Dkjlq Nljvrz E Homvol

Tool carrier I (X/Y)

Technology: turret with 6 stations (total drive)

Tool holder: Ø 25 mm

Tool drive: 8,000 rpm, 1.5 kW, 2.4 Nm

Travel path in X1/Y1: 35 mm / 37.5 mm

Rapid traverse in X1/Y1: 15 m/min

Front attachment

Number of stations: 4

Tool holder: Ø 28 mm

Pitch spacing: 32 mm

Tool drive: 12,000 rpm, 4 kW, 7 Nm

Number of driven stations: 4

Travel path in X3/Z3: 222 mm / 139 mm

Rapid traverse in X3/Z3: 30 m/min

Rear attachment

Number of stations: 4

Tool holder: Ø 28 mm

Pitch spacing: 32 mm

MACHINE DETAILS

Dimensions: 1,450 x 950 x 1,480 mm

Weight: 1,600 kg

Connected load: 16 kW

Installation dimensions: 7,943 x 1,430 x 1,480 mm

Control switch-on time: 96,171 h

Switch-on time: 100,147 h

Production time: 45,983 h

Spindle 1: 49,274 h

Spindle 2: 47,771 h

Spindle 5: 15,297 h

EQUIPMENT

- Chip management: Chip conveyor

- Coolant management: KSS pump

- Raw material feed: Bar loader, FMB minimag 3200

- Finished part removal: Workpiece removal device (pipe)

- Emulsion mist extraction: Interface mechanically prepared

- Tool holder: Various rigid and driven holders

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,170 km

5-axis machining center

Deckel MahoDMC 80 U duoBlock

Condition: good (used), Year of construction: 2005, operating hours: 29,839 h, Functionality: fully functional, machine/vehicle number: 11470000133, travel distance X-axis: 800 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 800 mm, rotational speed (max.): 8,000 rpm, number of slots in tool magazine: 120, TECHNICAL DETAILS

Control: Heidenhain iTNC 530

X-axis travel: 800 mm

Y-axis travel: 800 mm

Z-axis travel: 800 mm

Spindle technology: geared spindle

Spindle speed: max. 8,000 rpm

Spindle power: max. 28 kW

Spindle torque: max. 727 Nm

Swivel head: B-axis, 0.001°

Media feed-through: coolant + blast air

NC rotary table C-axis: 0.001°

Pallet clamping surface: Ø 800 x 630 mm

Table load: max. 1,200 kg

Workpiece clamping: interface clamping hydraulics prepared

Tool magazine: Chain magazine, 120-fold

Tool holder: SK 50

Rapid traverse X-axis: 60 m/min

Rapid traverse Y-axis: 60 m/min

Rapid traverse Z-axis: 60 m/min

MACHINE DETAILS

Switch-on time: 71,261 h

Spindle time: 29,839 h

Installation dimensions: 8,600 x 7,400 x 3,060 mm

Weight: approx. 17 tons

Connected load: 76 kVA

Operating voltage: 400 V, 50 Hz

EQUIPMENT

- Distance measuring system: Direct in all axes (glass scales)

- Chip management: Chip conveyor

Djlq Nlmeurky Njvekl

- Coolant supply: IKZ system with paper belt filter and high pressure, 80 bar

- Workpiece measurement: Infrared measuring probe, Hexagon

- Tool breakage monitoring: Interface prepared, mechanical

- Process monitoring: Operating mode 4

- Extraction: Electrostatic, ifs IFE 2000

- Number of pallets: 2 pieces

- Additional equipment: ROTO-Clear, rinsing gun

Auction

Auction ended

Bayern

Bayern

1,171 km

Jig

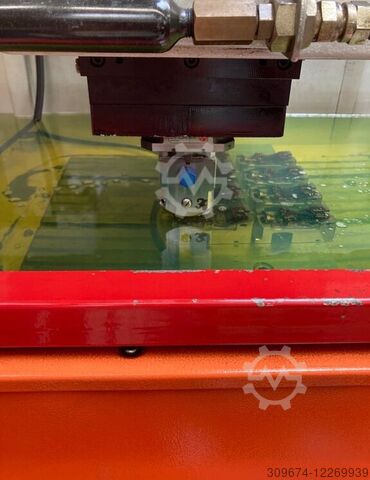

AGIE CHARMILLESHyperspark 3 HS (AT)

Condition: ready for operation (used), Year of construction: 2008, Functionality: fully functional, machine/vehicle number: 360, travel distance X-axis: 500 mm, travel distance Y-axis: 350 mm, travel distance Z-axis: 500 mm, workpiece weight (max.): 800 kg, TECHNICAL DETAILS

Travel X / Y / Z: 500 / 350 / 500 mm

Rotation: 0 - 60 rpm

Djlqsuh Tmie Nlmvjkl

Table dimensions: 800 x 600 mm

Automatically lowerable container: 200 - 700 mm

Workpiece weight: 800 kg

Internal dimensions of work bowl: 1,090 x 730 x 490 mm

MACHINE DETAILS

Weight: 5,000 kg

Installation dimensions: 3,200 x 2,400 x 2,700 mm

Operating voltage: 3 x 400 V

Frequency: 50 Hz

Connection: 8.3 kVA

Rated current: 12 A

Auction

Auction ended

Bayern

Bayern

1,171 km

Injection molding machine

NetstalSynErgy 2000-230/110

Condition: good (used), Year of construction: 2014, operating hours: 20,209 h, Functionality: fully functional, clamping force: 2,000 kN, Machine with exemplary maintenance and servicing

TECHNICAL DETAILS

Clamping force: 2000 kN

Cylinder size AG1: 20 mm

Cylinder size AG2: 16 mm

Machine drive power: 45 kW

Flow Box DETAILS

Type: LMP 105

Manufacturer: Max Petek

Serial number: S 140743

Year of manufacture: 2014

Robot DETAILS

Robot: Krauss - Maffei MH 50

Designation 6 -axis: Yaskawa

Type: DX 100

Operating hours: approx. 8900 h

Year of construction: 2014

MACHINE DETAILS

Weight: 13,300 kg

Length: 6,901 mm

Dkelqouh Tkzs Nlmvsl

Width: 2,075 mm

Height: 2,240 mm + 800 mm flow box

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,163 km

Machining center

DAEWOOACE - HP 500

Condition: good (used), Year of construction: 2004, Functionality: fully functional, TECHNICAL DETAILS

CNC control: FANUC 18i

Dkolqstuwhnj Nlmvjl

X-axis: 800 mm

Y-axis: 700 mm

Z-axis: 750 mm

B-axis: indexing axis

Spindle motor: 25 KW

Spindle speed: 8000 rpm

Distance from spindle nose to table center: 150 - 900 mm

Tool magazine: 60 places

Max. Table speed: 20 rpm

Tool changer: DIN SK50

EQUIPMENT

Chip conveyor

Without clamping angle

Auction

Auction ended

Bayern

Bayern

1,171 km

Automation system for injection molding

WITTMANNW833PRO

Year of construction: 2016, Condition: excellent (used), Functionality: fully functional, Automation system of the Wittmann brand was newly installed in 2016 and used on a Netstal Synergy 2000.

All documents, operating instructions, maintenance plans, measurement diagrams etc. included as well as control modules, power supply units and control panels.

The Wittmann Picker can be used as a stand alone.

TECHNICAL DETAILS

travel X / Y / Z: 900 / 1800 / 3000 mm

payload: 15 kg

Scope of delivery: robot, console, support V/2614-3104, adapter, conveyor system standard MB belt, SE protective enclosure incl. safety door with SIPA

MACHINE DETAILS

dimensions plant (LxWxH): 6560 x 4423 x 4154 mm

Robot weight: 560 kg

Mains connection: 3PH/N/PE

mains voltage: 400 V

tolerated voltage fluctuations: up to 10%

connected load: 11 kVA

frequency: 50-60 Hz

tolerated frequency fluctuations: up to 2%

supply line fuse: 16 A

Dkslq Nlopm Htgsmvjl

air pressure: max 6 bar

maintenance of system functions: up to min 5 bar

Auction

Auction ended

Bayern

Bayern

1,171 km

Jig

CHARMILLESRoboform 35 P Roboter Automation

Year of construction: 2001, Condition: good (used), Functionality: fully functional, Machine extensively overhauled worth EUR 18,000

Optional configuration QCRI 54/8: available, see pictures

placement automation: available, see video

Pressure flushing: 1 x through workpiece 1 x through electrode, 2 x lateral

Suction flushing: 1 x through workpiece

Central lubrication system automatically via NC in all axes

TECHNICAL DETAILS

Travel (X, Y, Z): 350, 250 300 mm

Max man. Feeding speed: 900 mm/min

Dslq Nen Arnxelmvjkl

Weight of electrodes: max. 20 kg

Weight of workpieces: max. 40 kg

Magazine configuration: 54/8

electrodes: 54 pieces

Electrode dimensions: 70 x 70 x 200

Plates: 8 pieces

workpiece dimensions: (4x) 320 x320 x 270 mm, (4x) 320 x 320 x 170 mm

work table: 500 x 400 mm

T-slots: 3 x 12 mm

distance of grooves: 125 mm

Available clamping systems: Erowa IST 3R Macro Megatool GPS 70

MACHINE DETAILS

Dimensions (H x L x W): 2400 x 1900 x 1690 mm

Auction

Auction ended

Mittelfinnland

Mittelfinnland

1,865 km

Double-end profiler

A. CostaKuadra 2 / 1200

Condition: ready for operation (used), Year of construction: 2000, Functionality: fully functional, working width: 1,200 mm, saw blade diameter: 80 mm, working height: 910 mm, workpiece height (max.): 180 mm, rotational speed (max.): 3,000 rpm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Working width: 1,200 mm

Working width with single belt: 70 mm

Working thickness: 180 mm

Working height: 910 mm

Driver spacing: 420 mm

Clearance between belt and column: 180 mm

Adjustable feed speed: 3 - 18 m/min

Adjustable speed of the movable column: 2 m/min

Electric spindle

Speed: 3,000 rpm

Power: 1 - 13 kW

Shaft diameter and length: 40 x 55/95/118 mm

Saw blade bore diameter for scoring saw and hogger: 60-80 mm

Belt drive

Speed: 6,000 rpm

Power: 2.2 - 9.2 kW

Dslev I S Udsq Nlmvekl

Spindle diameter and length: 40 x 55/95 x 118 mm mm

EQUIPMENT

- Saw unit

- Milling unit

- Soundproof enclosures

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,174 km

Punching machine

KAISERKSTU 1000 - 20 - 4 P

Condition: ready for operation (used), Year of construction: 2001, Functionality: fully functional, machine/vehicle number: 150204, table length: 2,000 mm, table width: 1,000 mm, pressing force: 100 t, ram stroke: 300 mm, Automatic punching press with automation

TECHNICAL DETAILS

Total pressing force: 100 t

Stroke: 300 mm

Adjustment: 125 mm

Stroke at bottom, adjustment at top: 600 mm

Number of strokes: 10 - 50 min-¹

Control system: Siemens S7

Dimensions

Distance between the uprights L-R: 2,020 mm

Distance between the uprights at the side: 620 mm

Table clamping surface: approx. 2,000 x 1,000 mm

Ram clamping surface: approx. 2,000 x 900 mm

Opening in the table: 1,700 x 300 mm

Table height above floor: 1,200 mm

MACHINE DETAILS

Power requirement: 39 kW

Height above floor: approx. 4,400 mm

Dimensions (L x W x H): 5,166 x 2,500 x 4,400 mm

Machine weight: approx. 38 t

EQUIPMENT

- Electrical overload protection

- Two-hand operation

- Schleicher straightener: width 650 mm, max. thickness 2.0 mm

- Wanzke decoiler: max. load 6 t

- Helmerding feed: width 600 mm, thickness 0.6 - 6.0 mm

Dkolqju Unmqe Nlmvel

Auction

Auction ended

Southwest Finland

Southwest Finland

1,662 km

CNC lathe

DOOSANPuma 2000 LSY

Condition: ready for operation (used), Year of construction: 2004, operating hours: 9,389 h, Functionality: fully functional, turning length: 760 mm, turning diameter: 330 mm, travel distance X-axis: 250 mm, travel distance Y-axis: 50 mm, travel distance Z-axis: 830 mm, TECHNICAL DETAILS

Max. turning length: 760 mm

Max. turning diameter: 330 mm

X-axis: 250 mm

Y-axis: ±50 mm

Z-axis: 830 mm

B-axis: 830 mm

Main spindle speed: 5,000 rpm

Counter spindle speed: 6,000 rpm

Bar capacity: Ø65 mm

Number of tool stations: 12

MACHINE DETAILS

Weight: 5,500 kg

Workpiece counter: 538,606 pieces

Switch-on time: 66,394 h

Cutting time: 9,389 h

EQUIPMENT

- Chip conveyor

- Tool measuring probe

- LNS Servo 2 bar loader

- Accessories as per pictures

Delq Njv D H Nuolmvskl

Auction

Auction ended

Oberösterreich

Oberösterreich

1,413 km

Press brake

EHTVarioPress 135 - 30

Condition: ready for operation (used), Year of construction: 2000, Functionality: fully functional, machine/vehicle number: 211431, pressing force: 135 t, bending length: 3,050 mm, power: 11 kW (14.96 HP), No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Working length: 3,050 mm

Pressing force: 1,350 kN

Oil quantity: 250 l

Control type: DNC 1200 HP

MACHINE DETAILS

Current type: 3~

Frequency: 50 Hz

Operating voltage: 400 V

Dkolqsvw Arfs Nlmvsl

Control voltage: DC 24 V

Rated current: 63 A

Rated current of the main fuse: 34 A

Power of the main motor: 11 kW

Electrical circuit diagram no.: 150.276

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

MIKRONVCP 800

Condition: good (used), Year of construction: 2000, Functionality: fully functional, machine/vehicle number: 107.33.99.021, travel distance X-axis: 800 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, controller manufacturer: Heidenhain, controller model: iTNC 426 / 430, table width: 590 mm, table length: 1,050 mm, TECHNICAL DETAILS

Machine type: 3-axis machining center

Manufacturer: MIKRON

Type: VCP 800

Control: HEIDENHAIN iTNC 426 / 430

Serial number: 107.33.99.021

Year of manufacture: 2000

Axes and table

Number of axes total: 3

Number of spindles: 1

Table length: 1,050 mm

Table width: 590 mm

Number of T-slots: 8

Distance between T-slots: 63 mm

T-slot width: 14 H7 mm

Max. Workpiece weight on the table: 400 kg

Longitudinal travel (X-axis): 800 mm

Transverse travel (Y-axis): 450 mm

Vertical travel (Z-axis): 450 mm

Tool changer

Type: TC 30

Tool diameter max.: 90 mm

Diameter with free secondary positions: 110 mm

Maximum tool length: 250 mm

Maximum tool weight: 6 kg

Tool change time: 5 seconds

Average chip-to-chip time: 7 seconds

Tool holder: HSK-A 63 DIN 69893

Spindle speed

Speed infinitely variable from: 100 rpm

to: 20,000 rpm

Feed speed: 1,500 mm/min

Rapid traverse: 22 m/min

Connections and power

Compressed air connection: 6-7 bar

Electrical connection: 400 V, 50 Hz, 3-phase

Dolq Nlou Dnc Hsmvekl

Total power requirement: 40 kW

Noise level: 75 dB(A)

Dimensions and weight

Machine weight approx.: 6,500 kg

Dimensions (L x W x H): 3,160 mm x 2,240 mm x 2,645 mm

EQUIPMENT

Coolant system 120 l

Paper filter system

Renishaw workpiece probe

Tool breakage control

Chip conveyor

Electronic handwheel

Lighting

Machine can be viewed assembled and, after consultation, can be energized for inspection.

Auction

Auction ended

Bayern

Bayern

1,182 km

Wire EDM machine

MitsubishiFA20P

Year of construction: 2002, Condition: used, Functionality: fully functional, machine/vehicle number: J20M0036, Wire EDM machine with automatic wire threading (AT)

TECHNICAL DETAILS

x-way: 500 mm

Djlqonh R Nke Nlmvskl

y-way: 350 mm

z-way: 300 mm

amps: 50 A

table length: 780 mm

table width: 630 mm

table feed: 1 - 1.300 mm/min

wire feed: 15,00 m/min

Control: W21F AP-2

workpiece size: 1050 x 800 x 295 mm

workpiece weight: max. 800 kg

MACHINE DETAILS

total power requirement: 12,00 kW

machine weight: approx. 4,50 t

space requirement: approx. 3.00 x 3.50 x 2.50 m

Auction

Auction ended

Zachodniopomorskie

Zachodniopomorskie

1,183 km

Cylindrical grinding machine

PALMARY EXTOMAXOCD-4240

Condition: like new (used), Year of construction: 2018, operating hours: 1,646 h, Functionality: fully functional, machine/vehicle number: GN4240001, Cylindrical grinding machine in special design and with automation

SPECIAL VERSION

- Tailstock as counter spindle with C-axis 0.001° (synchronized with workpiece spindle - optional)

- Center taper MT no. 4

- Stroke 25 mm (with CNC position control)

AUTOMATION

- Fanuc industrial robot, model M-10iA 10M with force sensor and Schunk gripper

- Rotating robot table

- Robot connected to the machine (ready for work)

TECHNICAL DETAILS

Djlqstr A Rhs Nlmvjkl

Distance between chuck and counter spindle: 300 mm (special version)

Center distance: 400 mm (without chuck)

Center height: 210 mm (radius)

External grinding diameter with / without tailstock: Ø 300 / 400 mm

Control: Fanuc 0I-TF

Grinding spindle

Grinding wheel dimensions: Ø 405 x 50 - 75 mm

Motor: 5.5 kW

Speed: 1783 rpm

Workpiece spindle

Workpiece chuck: Hainbuch Spanntop mini size 52

Motor: 2.7 kW

Spindle speed: 10 - 300 rpm

C-axis: 0.001°

Rotation angle: -30° / +90° (manual)

AUTOMATION

Robot: Fanuc M-10iA 10M

Number of axes: 6

Payload: 10 kg

Reach: 1422 mm

Mass: 130 kg

Equipment: Force sensor, Schunk gripper

MACHINE DETAILS

Switch-on time: 3914 h

Grinding time: 1646 h

EQUIPMENT

- Grinding sensor (Marposs)

- Balancing system (Marposs)

- Measuring probe for checking linear dimensions and the other for checking cylindrical dimensions - in progress (Marposs)

- Steady rest for grinding (Arobotech)

- Power clamping cylinder for workpiece spindle - pneumatic

- Cooling unit with filter system

- Grinding mist extraction

Auction

Auction ended

Salzburg

Salzburg

1,420 km

CNC turn-mill center

EMCOS65 TC

Condition: new, Year of construction: 2023, Functionality: fully functional, turning length: 680 mm, turning diameter over cross slide: 360 mm, turning diameter: 310 mm, spindle speed (max.): 4,200 rpm, travel distance X-axis: 210 mm, travel distance Z-axis: 610 mm, bar diameter: 65 mm, TECHNICAL DETAILS

Swing diameter over bed: Ø 540 mm

Swing diameter over cross slide: Ø 360 mm

Center distance (spindle nose-centre): 680 mm

Max. turning diameter: Ø 310 mm

Max. part length: 520 mm

Max. bar diameter: Ø 65 mm

Control: FANUC series 0i TF with Manual Guide dialog programming

Travel range

Travel path in X: 210 mm

Travel path in Z: 610 mm

Main spindle

Speed range: 60 - 4,200 rpm

Dkslq Nlsvwm Ahsmvsl

Drive power: 18 kW

Spindle connection DIN 55026: KK6

Tool changer

Number of tool positions: 12

Receiving compartment according to (DIN 69880): VDI 30 axial

Automatic Tailstock

Description: hydraulically operated, robust construction without quill,

Max. contact pressure: 8,000 N

Holder cone: MK4

MACHINE DETAILS

Machine footprint (W x D): 2,855 x 1,770 mm

Total weight: 4,300 kg

EQUIPMENT

- Hollow clamping cylinder including draw tube

- USB interface

- Network drive / Ethernet

- PCMCIA slot

- TFT color monitor 10.4"

- 3D simulation

- Machine light

- Coolant system

- Hydraulic unit

- Interface for chip conveyor

- Vibration-absorbing leveling shoes

- Screw-on bracket and high-performance anchor

- Documentation / CE certificate

- Warning light LED 3-way on the side

- Manual tool measuring system (S65)

- Foot switch

- BEF.-MAT. ET420/345/332 E45/65 MT45/65

Auction

Auction ended

Oberösterreich

Oberösterreich

1,415 km

Plasma cutting machine

Swift CutPro 3000

Condition: excellent (used), Year of construction: 2019, Functionality: fully functional, machine/vehicle number: PR4-3000-07190386, sheet thickness aluminum (max.): 20 mm, sheet thickness steel (max.): 22 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, No reserve price - guaranteed sale to the highest bidder!

TECHNICAL DETAILS

Cutting area: 3000 x 1500 mm

Drives: 400 W AC OMRON servo motors

Plasma source Hypertherm: Powermax 105

Duty cycle: 80%

100% duty cycle: 94 Amps

Maximum piercing capacities

Mild steel: 22 mm

Stainless steel: 20 mm

Aluminium: 20 mm

MACHINE DETAILS

Space requirement: 5.50 x 2.80 m

Machine dimensions: approx. 3.7 x 2.0 m

Transport dimensions: 3780 x 2115 x 1500 mm

Weight: 1.1 t

Dkjlq Nljvw Amcemvjl

Box software: included

Operating hours: 265 arc hours

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

MIKRONVCP 600

Condition: good (used), Year of construction: 2001, operating hours: 13,305 h, Functionality: fully functional, machine/vehicle number: 212.30.73.101, travel distance X-axis: 600 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, controller manufacturer: Heidenhain, controller model: iTNC 530, table width: 530 mm, table length: 850 mm, TECHNICAL DETAILS

Dkolq Nou Dncaelmvjl

Switch-on time: 93,951 hours

Operating time: 41,735 hours

Spindle running time: 13,305 hours

Total number of axes: 3

Control: Heidenhain iTNC 530

Table and axes

Table length: 850 mm

Table width: 530 mm

Number of T-slots: 6

Distance between T-slots: 63 mm

T-slot width: 14 mm

Centering hole diameter: 30 mm

Max. Workpiece weight on the table: 400 kg

Longitudinal travel (X-axis): 600 mm

Transverse travel (Y-axis): 450 mm

Vertical travel (Z-axis): 450 mm

Tool changer

Number of tools: 30

Tool diameter max.: 90 mm

Diameter with free secondary positions: 110 mm

Maximum tool length: 250 mm

Maximum tool weight: 6 kg

Tool change time: 5 seconds

Average chip-to-chip time: 7 seconds

Tool holder: ISO 40 DIN 69871

Pull stud: DIN 69872 Form B

Spindle speed

Speed infinitely variable from: 50 rpm

to: 12,000 rpm

Work feed: 15 m/min

Rapid traverse: 22 m/min

Max. Feed force: 5,000 N

Connections

Compressed air connection: 6 bar

Electrical connection: 400 V, 50 Hz, 3-phase

Spindle power: 12 / 16 kW

Total power requirement: 15 kW

Noise level: 75 dB(A)

Machine weight approx.: 6,500 kg

Machine dimensions

Length: 2,500 mm

Width: 1,600 mm

Height: 2,600 mm

EQUIPMENT

Water cooler

Electronic handwheel

Lighting

Machine can be viewed assembled and, after consultation, can be energized for inspection.

Auction

Auction ended

Bayern

Bayern

1,182 km

Horizontal machining center

Deckel MahoDMC 60 H

Year of construction: 2002, Condition: used, Functionality: fully functional, Horizontal machining center with double chain magazine.

TECHNICAL DETAILS

x-way: 600 mm

y-way: 560 mm

z-way: 560 mm

control: Siemens Sinumerik 840D

B - axis: 360 x 0,001 °

spindle speed - stepless: 8.000 rpm

feed X/Y/Z/ axis: 1 - 60.000 mm/min

feed B axis: 9.250 °/min

rapid traverse X/Y/Z: 60.00 m/min

feed force X/Z: 9.600 N

Feed force Y: 8,000 N

drive power 40 % ED: 20,00 KW

driving power 100% ED: 13,00 kW

Tool holder: SK40

Torque at 40% / 100% ED: 191 / 124 Nm

Pallet size: 2x 400 x 500 mm

workpiece weight: max. 600 kg

tool magazine: 180

tool diameter: 90 mm

tool diameter with 2 free places: 160 mm

tool length: max. 350 mm

Tool weight: max. 3.50 / 12.00 kg

MACHINE DETAILS

total power requirement: 65,00 kW

machine weight: approx. 16,00 t

space requirement: approx. 9.00 x 4.50 x 3.50 m

EQUIPMENT

Coolant system with IKZ

Double chain magazine with 180 places

Chip conveyor

BLUM tool laser measurement

electronic handwheel

Dkjlq Nsnh Rn Aslmvsl

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

HERMLEU 740

Condition: good (used), Year of construction: 2003, operating hours: 27,804 h, Functionality: fully functional, machine/vehicle number: 16165, travel distance X-axis: 915 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 500 mm, controller manufacturer: Heidenhain, controller model: iTNC 530, rotational speed (max.): 12,000 rpm, TECHNICAL DETAILS

Machine type: Machining center

Manufacturer: HERMLE

Type: U 740

Control: HEIDENHAIN iTNC 530

Serial number: 16165

Year of manufacture: 2003

Dkelq Nsu Dnitslmvsl

Production times

Switch-on time: 86,672 hours

Working time: 34,362 hours

Spindle running time: 27,804 hours

Axes and table

Total number of axes: 5

Table length: 900 mm

Table width: 500 mm

Number of T-slots: 8

Distance between T-slots: 65 mm

T-slot width: 14 mm

Max. Workpiece weight on the table: 700 kg

Longitudinal travel (X-axis): 915 mm

Transverse travel (Y-axis): 500 mm

Vertical travel (Z-axis): 500 mm

Workpiece size max.

Length: 900 mm

Width: 500 mm

Height: 500 mm

Tool changer

Number of tools: 16

Tool diameter max.: 125 mm

Diameter with free secondary positions: 180 mm

Maximum tool length: 300 mm

Maximum tool weight: 6 kg

Milling head

Swivel range: -5° to +95°

Tool holder: SK 40

Spindle

Speed infinitely variable from: 20 rpm

to: 12,000 rpm

Feed rates

Rapid traverse lengthwise: 30 m/min

Rapid traverse: 30 m/min

Vertical rapid traverse: 20 m/min

Connections and power

Compressed air connection: 6 bar

Electrical connection: 400 V, 50 Hz, 3-phase

Spindle power: 32 kW

Total power requirement: 26 kVA

Noise level: 78 dB(A)

Dimensions and weight

Machine weight approx.: 7,300 kg

Dimensions (L x W x H): 2,760 mm x 2,390 mm x 2,370 mm

EQUIPMENT

Three-jaw chuck Ø 200 mm

Workpiece probe: HEIDENHAIN TS 640

Dividing head 4th axis: HOFMANN, type RW/NC-160

Rinsing gun

RS 232 interface

Ethernet interface

Control cabinet Air conditioning unit

Machine can be inspected assembled and energized for inspection after consultation.

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

KITAMURAMyCenter-2XiF

Condition: good (used), Year of construction: 2004, Functionality: fully functional, machine/vehicle number: 07577, travel distance X-axis: 510 mm, travel distance Y-axis: 355 mm, travel distance Z-axis: 460 mm, controller manufacturer: Fanuc, controller model: Series 16i-MB, workpiece length (max.): 510 mm, workpiece width (max.): 355 mm, workpiece height (max.): 460 mm, TECHNICAL DETAILS

Machine type: 4-axis machining center

Manufacturer: KITAMURA

Type: MyCenter-2XiF

Control: FANUC Series 16i-MB

Serial number: 07577

Year of manufacture: 2004

Axes and table

Total number of axes: 4

Table length: 900 mm

Table width: 355 mm

Number of T-slots: 3

Distance between T-slots: 110 mm

T-slot width: 14 mm

Max. Workpiece weight on the table: 240 kg

Longitudinal travel (X-axis): 510 mm

Transverse travel (Y-axis): 355 mm

Vertical travel (Z-axis): 460 mm

Dksleu Dngrsq Nlmvsl

Workpiece size max.

Length: 510 mm

Width: 355 mm

Height: 460 mm

Tool changer

Number of tools: 24

Maximum tool diameter: 80 mm

Maximum tool length: 300 mm

Maximum tool weight: 8 kg

Tool holder: BT 40

Distance between spindle nose and table: 160 - 620 mm

Spindle

Speed infinitely variable from: 0 rpm

to: 10,000 rpm

Feed rates

Feed speed: 0 - 36,000 mm/min

Rapid traverse lengthwise: 50 m/min

Rapid traverse: 50 m/min

Vertical rapid traverse: 36 m/min

Power data

Total power requirement: 25 kVA

Dimensions and weight

Machine weight approx.: 4,400 kg

Dimensions (L x W x H): 2,565 mm x 2,470 mm x 3,000 mm

EQUIPMENT

Vice: 2 pieces

Vice jaw width: 145 mm

Coolant device

Dividing head 4th axis: NIKKEN CNC202

Machine can be inspected assembled and can be energized for inspection after consultation.

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

MIKRONVCP 1000

Condition: good (used), Year of construction: 1997, operating hours: 1,564 h, Functionality: fully functional, machine/vehicle number: 7015, travel distance X-axis: 1,000 mm, travel distance Y-axis: 750 mm, travel distance Z-axis: 750 mm, controller manufacturer: Heidenhain, controller model: TNC 426, table width: 700 mm, table length: 1,150 mm, rotational speed (max.): 24,000 rpm, TECHNICAL DETAILS

Machine type: 4-axis machining center

Manufacturer: MIKRON

Type: VCP 1000

Control: HEIDENHAIN TNC 426

Serial number: 7015

Year of manufacture: 1997

Operating times

Switch-on time: 21,859 hours

Operating time: 7,308 hours

Spindle running time: 1,564 hours

Axes and table

Total number of axes: 4

Table length: 1,150 mm

Table width: 700 mm

Turret stations: 60

Longitudinal travel (X-axis): 1,000 mm

Transverse travel (Y-axis): 750 mm

Vertical travel (Z-axis): 750 mm

Tool changer

Type: TC 30

Number of tools: 30

Tool diameter max.: 77 mm

Diameter with free secondary positions: 115 mm

Maximum tool length: 305 mm

Tool holder: HSK A63

Distance between vertical spindle and table: 115 mm

Spindle

Speed infinitely variable up to: 24,000 rpm

Feed rates

Feed speed: 1,500 mm/min

Rapid traverse: 22 m/min

Connections and power

Connection: 400 V, 50 Hz, 3-phase

Total power requirement: 40 kW

Dkelq Nlju Dngfomvol

Dimensions and weight

Machine weight approx.: 10,500 kg

Dimensions (L x W x H): 5,220 mm x 3,100 mm x 2,840 mm

EQUIPMENT

Tool changer with 30 tools

Coolant through the spindle (IKZ)

Chip conveyor

Dividing head 4th axis

Set of tool holders: 45 pieces

Tool cabinet: LISTA

Remark: Few spindle hours, spindle has been replaced

Machine can be inspected assembled and can be energized for inspection after consultation.

Auction

Auction ended

Bern

Bern

1,181 km

Machining center

MIKRONHSM 400

Condition: good (used), Year of construction: 2002, operating hours: 16,516 h, Functionality: fully functional, machine/vehicle number: 107.84.00.070, travel distance X-axis: 400 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 350 mm, feed rate X-axis: 40 m/min, feed rate Y-axis: 40 m/min, feed rate Z-axis: 40 m/min, controller manufacturer: Heidenhain, controller model: iTNC 530 M, rotational speed (max.): 42,000 rpm, TECHNICAL DETAILS

Machine type: High-speed center

Manufacturer: MIKRON

Type: HSM 400

Control: HEIDENHAIN iTNC 530 M

Serial number: 107.84.00.070

Year of manufacture: 2002

Cycle times

Switch-on time: 25,671 hours

Operating time: 22,211 hours

Working time: 10,475 hours

Spindle running time: 16,516 hours

Axes and table

Total number of axes: 3

Number of spindles: 1

Max. Workpiece weight on the table: 200 kg

Longitudinal travel (X-axis): 400 mm

Transverse travel (Y-axis): 450 mm

Vertical travel (Z-axis): 350 mm

Pallet changing device

Quantity: 10

Length: 240 mm

Width: 240 mm

Dkjlsu Dndkeq Nlmvol

Tool changer

Number of tools: 36

Tool change time: 10 seconds

Average chip-to-chip time: 12.5 seconds

Tool holder: HSK E40

Spindle

Speed infinitely variable from: 100 rpm

to: 42,000 rpm

Feed rates

Work feed: 1-40 m/min

X-axis: 0-40 m/min

Y-axis: 0-40 m/min

Z-axis: 0-40 m/min

Rapid traverse: 42 m/min

Connections and power

Connection: 400 V, 50 Hz, 3-phase

Spindle motor power: 12.5 kW

Noise level: 75 dB(A)

Dimensions and weight

Machine weight approx.: 6,500 kg

Dimensions (L x W x H): 2,100 mm x 2,400 mm

EQUIPMENT

Set of tool holders (without tools)

Set of collets

Water cooler (manufacturer: BURN)

Infrared measuring probe (manufacturer: m&h)

Tool breakage control (manufacturer: BLUM)

Chip conveyor

Electronic handwheel

Lighting system

Hot air shrink unit (manufacturer: HOT SHOT)

Machine can be inspected assembled and energized for inspection after consultation.

Auction

Auction ended

Bern

Bern

1,181 km

Milling machine

MIKRONUMS 710

Condition: good (used), Year of construction: 1996, Functionality: fully functional, machine/vehicle number: 5.49.10.07, feed length X-axis: 15,000 mm, feed length Y-axis: 15,000 mm, travel distance X-axis: 710 mm, travel distance Y-axis: 630 mm, travel distance Z-axis: 500 mm, table width: 600 mm, table length: 1,200 mm, TECHNICAL DETAILS

Machine type: CNC milling machine

Manufacturer: MIKRON

Type: UMS 710

Control: HEIDENHAIN TNC 426

Serial number: 5.49.10.07

Year of manufacture: 1996

Table and axes

Table length: 1,200 mm

Table width: 600 mm

Longitudinal travel (X-axis): 710 mm

Transverse movement (Y-axis): 630 mm

Vertical travel (Z-axis): 500 mm

Spindle

Spindle speed up to: 6,300 rpm (42,000* rpm with high-frequency spindle)

Tool changer

Number of tools: 20

Feed rates

Longitudinal: 0 mm/min to 15,000 mm/min

Transverse: 0 mm/min to 15,000 mm/min

Vertical: 0 mm/min

Milling spindle motor

Delq Nlsu Dnaremvekl

Power: 11 kW

Weight and dimensions

Machine weight: approx. 4,690 kg

Dimensions (L x W x H): 4,700 mm x 2,100 mm x 2,700 mm

EQUIPMENT

Rigid angled table

High-frequency spindle with 42,000 rpm (make: FISCHER)

Set of tool holders

Coolant / mist extraction system (make: FIBARON)

Machine can be inspected assembled and energized for inspection after consultation.

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

This may be of interest to you

Find out now

+44 20 806 810 84

+44 20 806 810 84

Create listing

*per listing / month