Insulating glass making machineGlaston-Bystronic

2300 x 3500 mm R-L

Insulating glass making machine

Glaston-Bystronic

2300 x 3500 mm R-L

Year of construction

2011

Condition

Used

Location

Lleida

Show images

Show map

Machine data

- Machine type:

- Insulating glass making machine

- Manufacturer:

- Glaston-Bystronic

- Model:

- 2300 x 3500 mm R-L

- Year of construction:

- 2011

- Condition:

- excellent (used)

- Functionality:

- fully functional

Price & Location

- Location:

- Lleida, Spain

Call

Technical details

- Working height:

- 2,700 mm

- Equipment:

- documentation/manual

Details about the offer

- Listing ID:

- A18356361

- Reference number:

- S-IGL-2276

- Update:

- 11.02.2026

Description

Double glazing line R-L

2300 x 3500

with gas press 2700 x 3500 mm cy 2012

ls.

Typical Components and Process

A standard Glaston Bystronic insulating glass line in this size range generally includes the following sequence of machines:

Vertical Infeed Conveyor Table: The initial loading point for the raw glass plates.

Washing Machine: Cleans the glass plates thoroughly, often using demineralized water (reverse osmosis).

Inspection System: Allows for visual quality control of the glass surface before assembly.

Spacer Application:

Conventional Spacer Lines: Feature a manual frame setting station or an automatic butyl extruder (Butylextruder) to coat pre-made spacer frames.

TPS® Lines: Utilize a robot for direct application of the Thermo Plastic Spacer (TPS®) material onto the glass plate, allowing for changes in spacer width during operation.

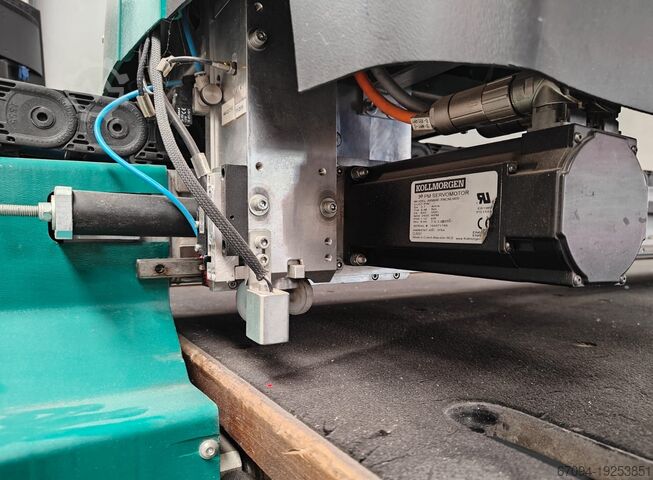

Assembly, Gas Filling, and Press Robot: This central unit assembles the glass panes with the spacer frames, presses them together, and simultaneously fills the unit with inert gas (e.g., argon) for enhanced insulation.

Sealing Robot: Automatically applies the secondary sealant (polysulphide or silicone) around the perimeter of the assembled unit to ensure durability and gas tightness.

Hfodpfxsvuhfls Aadsc

Outfeed/Conveyor System: Transports the finished I.G. units away from the main production area.

Configuration Details

The "R-L" designation indicates the flow of the glass through the line, starting from the right side and exiting on the left side when viewed from the operating side. The line features a modular design, and specific components (like the type of spacer system or additional turning stations) can be configured based on production needs.

These articles provide specifications for Bystronic insulating glass lines, detailing configurations for glass size, spacer application methods like TPS, and production capabilities:

2300 x 3500

with gas press 2700 x 3500 mm cy 2012

ls.

Typical Components and Process

A standard Glaston Bystronic insulating glass line in this size range generally includes the following sequence of machines:

Vertical Infeed Conveyor Table: The initial loading point for the raw glass plates.

Washing Machine: Cleans the glass plates thoroughly, often using demineralized water (reverse osmosis).

Inspection System: Allows for visual quality control of the glass surface before assembly.

Spacer Application:

Conventional Spacer Lines: Feature a manual frame setting station or an automatic butyl extruder (Butylextruder) to coat pre-made spacer frames.

TPS® Lines: Utilize a robot for direct application of the Thermo Plastic Spacer (TPS®) material onto the glass plate, allowing for changes in spacer width during operation.

Assembly, Gas Filling, and Press Robot: This central unit assembles the glass panes with the spacer frames, presses them together, and simultaneously fills the unit with inert gas (e.g., argon) for enhanced insulation.

Sealing Robot: Automatically applies the secondary sealant (polysulphide or silicone) around the perimeter of the assembled unit to ensure durability and gas tightness.

Hfodpfxsvuhfls Aadsc

Outfeed/Conveyor System: Transports the finished I.G. units away from the main production area.

Configuration Details

The "R-L" designation indicates the flow of the glass through the line, starting from the right side and exiting on the left side when viewed from the operating side. The line features a modular design, and specific components (like the type of spacer system or additional turning stations) can be configured based on production needs.

These articles provide specifications for Bystronic insulating glass lines, detailing configurations for glass size, spacer application methods like TPS, and production capabilities:

Seller

Note: Register for free or log in, to access all information.

Registered since: 2019

Send inquiry

Telephone & Fax

+32 89 53... show

These listings may also fit your interest.

Listing

Maasmechelen

Maasmechelen

780 km

Glass cutting table

Bottero353BKM-J

Bottero353BKM-J

Listing

Szczecin

Szczecin

1,182 km

Glass tempering furnace

TAMGLASS / GLASTONHTF ProE – 2448-ADS-R

TAMGLASS / GLASTONHTF ProE – 2448-ADS-R

Listing

Zamość

Zamość

1,845 km

MACHINING CENTRE ROTOX ZOR 941

RotoxZOR 941

RotoxZOR 941

Listing

HETEREN

HETEREN

717 km

Crane truck

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Mercedes-BenzArocs 3251 AROCS 3251 8x2 FASSI F820RA.2.28

Listing

Lleida

Lleida

1,560 km

Crane system

ABUS+Kappel500kg 10 x 7 m

ABUS+Kappel500kg 10 x 7 m

Listing

Furth im Wald

Furth im Wald

1,292 km

Shelf freezer / freezer for production

AGA

AGA

Listing

Lleida

Lleida

1,560 km

Glass grinding machine

LattuadaTLR 13 C

LattuadaTLR 13 C

Listing

Maulbronn

Maulbronn

1,093 km

Bar machining center

elumatecSBZ 150

elumatecSBZ 150

Listing

Estonia

Estonia

1,748 km

Machining centre

TeknaTKE783

TeknaTKE783

Listing

Velžys

Velžys

1,744 km

Glass tilting and transport table

TRIULZI-IGTilting table

TRIULZI-IGTilting table

Your listing has been deleted successfully

An error has occurred