Used Eco Pharm for sale (5,688)

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010-ECO P TRAILER AXLE

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWSKHSF 9010 ECO-P

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWSKHZF 9008-15 ECO-P | MEGA AXLE | DISC

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P

Discover more used machines

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWECO Drum

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWSKHSF 9010 ECO-P

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWSKHSF 90210 ECO -P

Berkel en Rodenrijs

Berkel en Rodenrijs Flatbed

PactonPVG:97/3016 | Air suspension | BPW ECO P drum

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWSKHBE 9010 ECO-P | TRAILER AXLE DISC.

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSM10110-15 ECO-P|TRAILERAXLE.

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSM10110-15 ECO-P|TRAILERAXLE.

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P | TRAILERAXLE |DRUM.

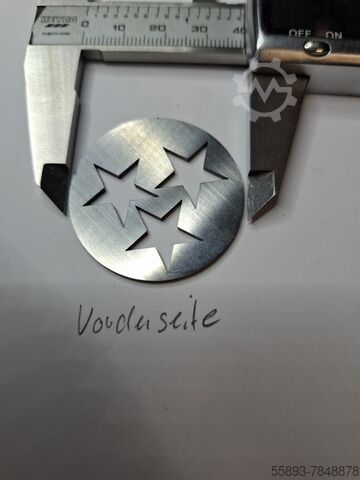

Oberperfuss

Oberperfuss Fitting drill machine

Verarbeitungstechnik Karl HeinzEco-Press Vario

Ahaus

Ahaus Screw compressor

BOGES 7 ECO DR - 10 bar

Ahaus

Ahaus Screw compressor

BOGES 5 ECO DR - 10 bar

Ahaus

Ahaus Screw compressor

BOGES 15 ECO DR - 10 bar

Germany

Germany DMG DECKEL MAHO DMC 635V eco

DMG DECKEL MAHODMC 635V eco

Berlin

Berlin CNC Milling Machine

Geiss AGFZ 1000x800 ECO

Hauzenberg

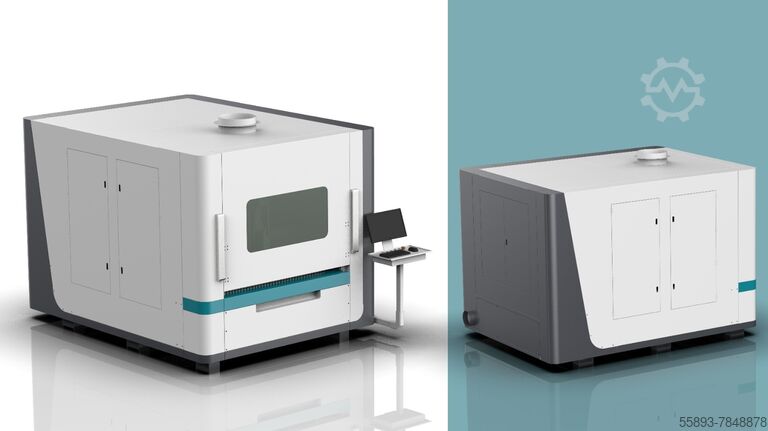

Hauzenberg Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Żychlin

Żychlin Climate chamber Memmert ICH 750 L eco

MemmertICH 750 L eco

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P | TRAILERAXLE |DRUM.

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P | TRAILERAXLE |DRUM. 10 PIECES.

Berkel en Rodenrijs

Berkel en Rodenrijs Axle

BPWHSF 9010 ECO-P | TRAILERAXLE |DRUM. 10 pieces.

Used Eco Pharm (5,688)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you