Used Itec for sale (201)

Remscheid

Remscheid Component

Meditec ML 4000 Laser mit Bedientafel

Korschenbroich

Korschenbroich Filter

KaeserFilter F9KE mit EcoDrain 30

Stolberg

Stolberg Double spindle milling machine

WissnerWITEC 2015 Economic Fräsmaschine

Trondheim

Trondheim UniControl 12

WEINIGUniControl 12 - UniTec + UniVar

Warburg

Warburg Screening plant

BinderBIVITEC ES/DD2500x5

Discover more used machines

Glinde

Glinde Chip conveyor Jung Do HI TECH 450

Jung Do Tech Co.HI TECH 450

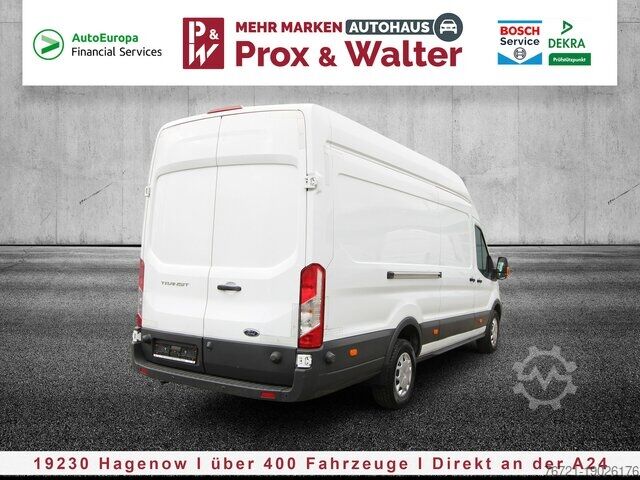

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L3 Trend KAMERA+TEMPOMAT

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L3 Trend KAMERA+TEMPOMAT

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L3 Trend KAMERA+TEMPOMAT

Hagenow

Hagenow High top van

FordTransit EcoBlue 350 L4 Trend KAMERA+TEMPOMAT+270°

Tatabánya

Tatabánya MSK hood shrink units

MSK (2665)KOMBI-MULTITECH Palettenschrumpfanlage

Germany

Germany CNC Milling Machine

Wissner MaschinenbauWitec 32 Performance

Deitingen

Deitingen CNC-Precision lathe

Schaublin102-N80 Combitec

Turkey

Turkey Crushing equipment

General MakinaDolomite Crushing and Screening Plant

Turkey

Turkey Crushing equipment

General MakinaBauxite Crushing and Screening Plant

Kežmarok

Kežmarok Set CNC Window tenoning+profiling centre

WeinigUnitec 10 + Univar 10

Kežmarok

Kežmarok Window profiling line Weinig UC Matic

WeinigUnimat 23EL + Unitec 10 + Univar 10 + Au

Kežmarok

Kežmarok CNC Window profile tenoning centre

WeinigUnitec 10

Wierzchowisko

Wierzchowisko Cnc turning and milling center

HWACHEONHi-TECH 100A

Sułkowice

Sułkowice Multispindle boring machine

SCMMultitech Plus

Zheng Zhou Shi

Zheng Zhou Shi Bauxite Granite Bentonite Barite Crusher

Mingyuan hard stone jaw crusher machineBauxite Granite Bentonite Barite Crusher

Maastricht

Maastricht Optical separator Titech Tomra

Maastricht

Maastricht Optical separator Titech Tomra

Maastricht

Maastricht Screening machine Binder Bivitec 19/95-1

Oradea

Oradea Nitech PolEko CLN53 laboratory incubator

Pol EkoCLN 53

Used Itec (201)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you