Used Mobile Suction Unit for sale (36,953)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Symons cone crusher/mobile crusherSpring cone crusher PYB900, PYD900

Call

Condition: new, Year of construction: 2025, The PYB series spring cone crusher is a traditional cone crusher developed by introducing advanced technology from abroad. Here are some key features and information about the PYB spring cone crusher:

1. Structure and Working Principle:

- The crusher consists of an outer cone (mantle) and an inner cone (concave), with a crushing chamber in between.

- The outer cone is fixed, and the inner cone is eccentrically oscillated to crush the material.

2. Spring System:

- The crusher is equipped with a spring system to provide overload protection. When non-crushable materials enter the crushing chamber, the spring is compressed, allowing the material to pass through without causing damage to the crusher.

3. Adjustable Discharge Opening:

- The discharge opening can be adjusted to control the size of the crushed product.

4. Application:

- PYB spring cone crushers are widely used in industries like metallurgy, construction, road building, chemistry, etc.

- They are suitable for crushing hard and medium-hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase.

5. Advantages:

- Overload protection through the spring system.

Pedpfx Ahoq Nd Ndo Ueha

- Adjustable discharge opening allows for flexibility in the size of the crushed product.

- Simple structure and reliable performance.

6. Disadvantages:

- Compared to more modern cone crusher designs, the spring cone crusher may have limitations in terms of efficiency and energy consumption.

7. Maintenance:

- Regular maintenance is required to ensure optimal performance and longevity.

8. Model Names:

- Different models in the PYB series may have variations in specifications, such as PYB600, PYB900, PYB1200, etc., indicating the diameter of the cone.

9. Manufacturer:

- Various manufacturers produce PYB series spring cone crushers. It's important to choose a reputable manufacturer with a history of producing reliable and quality equipment.

Before selecting a crusher, it's advisable to consider the specific requirements of your project and compare the features of different models. Additionally, check the manufacturer's reputation and customer reviews to ensure the reliability and performance of the equipment.

Listing

Undoolya

Undoolya

15,082 km

Mobile concrete mixing plant

PROMAX Mobile Concrete Batching PlantMobile Concrete Batching Plant

Call

Condition: new, MOBILE CONCRETE BATCHING PLANT M100-TWN

GENERAL

Plant Type : MOBILE Concrete Plant with TWIN SHAFT MIXER

Plant Capacity : 100m³/hour freshly compressed concrete

Mixer Capacity : 3000/2000 lt (2m³ Compressed Concrete)

Total Motor Power : 143kw Standard Value can be changed depending on Equipment..

Voltage/Frequency : 380V/50Hz Standard Value.

The installation and startup of the plant is under our responsibility.

We provide excellent after-sales service.

Phodpfxowhybds Ah Usa

24/7 SERVICES. REMOTE CONTROL SERVICE.

Exporting more than 1000 Concrete Batching Plants to more than 90 Countries all over the world.

* HIGHLY EFFICIENT AND DUPLICATE PRODUCTION

* EASY TRANSPORTATION

* MINUMUM INVESTEMENT FOR FIELD GROUNDWORK

* QUICK INSTALLATION

DETAILS:

Crjbtuhm Njflz Hlo Aeb

Compacted concrete capacity: 100 m³/h

Air Compressor Capacity : 950 lt/min

Aggregate Hopper : 4 Bins : 4×11.25 = 45 m³

Mixer Type : TWIN Shaft (2 m³). 3000/2000 lt capacity

Mixer Converyor Band : 1000 mm * 13000 mm

Weighbridges: Aggregate/ Cement /Water/ Additives

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mobile / Stationary Rock Crushing Plant50-400 t/h stone crushing plant

Call

Condition: new, functionality: fully functional, Year of construction: 2025, For crushing dolomite and phonolite rocks, various types of rock crushing machines can be employed, depending on the characteristics of the rocks and the desired final product specifications. Here are some common types of crushers that may be suitable for processing dolomite and phonolite:

Pjdpfx Aheq Nyuvo Usha

1. Jaw Crusher:

- Jaw crushers are commonly used for primary crushing and can handle hard and abrasive materials. They are suitable for both dolomite and phonolite rocks.

2. Impact Crusher:

- Impact crushers are versatile and suitable for both primary and secondary crushing. They work by impacting the material with hammers or blow bars, producing a high reduction ratio. Impact crushers can be effective for shaping the final product.

3. Cone Crusher:

- Cone crushers are often used for secondary or tertiary crushing. They are suitable for processing harder rocks and can produce well-shaped and fine-grained aggregates.

4. Gyratory Crusher:

- Gyratory crushers are used for large-scale primary crushing. They have a conical-shaped head and are well-suited for handling abrasive materials. However, they are less commonly used than jaw or cone crushers.

5. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are suitable for shaping and producing artificial sand. They operate by throwing the material against a set of anvils or impellers to break it down into finer particles.

6. Hammer Crusher:

- Hammer crushers are used for crushing softer materials and may be suitable for rocks like phonolite. They operate by applying force to the material, causing it to break along natural fault lines.

7. Roll Crusher:

- Roll crushers are used for reducing the size of friable materials. They consist of two counter-rotating rolls that compress the material between them.

8. Screening Equipment:

- After the initial crushing stage, screening equipment such as vibrating screens may be used to separate different sizes of crushed material.

9. Dust Suppression Systems:

- Crushing operations can generate dust, and dust suppression systems are used to minimize environmental and health impacts.

10. Mobile Crushers:

- Mobile crushers, including crawler mobile crushers, offer flexibility and mobility, allowing them to be used directly at the quarry or job site.

When selecting a crusher for dolomite and phonolite rocks, consider factors such as the hardness of the material, the desired final product specifications, and the production capacity required. Additionally, it's important to integrate the crushing process into an overall plant design that may include screening, conveying, and washing equipment depending on the specific needs of the application.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mobile stone crusher /Portable crusher50-350 t/h mobile stone crushing station

Call

Condition: new, power: 75 kW (101.97 HP), Year of construction: 2025, A mobile jaw crusher is a type of crushing machine that is equipped with a jaw crusher and is mobile in nature. This crusher is designed to be moved around and taken to various locations, especially those where processing materials are needed on-site. Mobile jaw crushers are widely used in industries such as mining, construction, and recycling for processing a variety of materials.

Here are the key features and components of a typical mobile jaw crusher:

1. Jaw Crusher:

- The primary crushing unit of the mobile jaw crusher is the jaw crusher itself. It consists of a fixed jaw and a movable jaw, with the material being crushed between them.

2. Mobile Chassis:

- The crusher is mounted on a mobile chassis, which may have tracks for mobility or be wheeled for easy transport. The mobility of the chassis allows the crusher to be easily moved between different work sites.

3. Feeder:

- A vibrating feeder is typically included to feed the material into the jaw crusher. It ensures a consistent and controlled feed of the material to the crushing chamber.

4. Engine or Power Source:

- Mobile jaw crushers are powered by diesel engines or electric motors. The choice of power source depends on factors such as the availability of electricity and the need for mobility.

5. Control Panel:

- A control panel is provided for operators to manage and monitor the crusher's operation. It may include controls for starting and stopping the crusher, adjusting the discharge setting, and monitoring various parameters.

6. Hydraulic System:

- Mobile jaw crushers often feature a hydraulic system to adjust the crusher's settings. This includes the adjustment of the jaw crusher's CSS (Closed Side Setting), which influences the product size.

Phjdpfxoq I N Ats Ah Usa

7. Conveyor Systems:

- Conveyors are used to transport crushed material from the jaw crusher to the next stages of the processing plant or for stockpiling. Some mobile jaw crushers have integrated conveyor systems.

8. Magnetic Separator (Optional):

- Some mobile jaw crushers come equipped with a magnetic separator to remove metal contaminants from the crushed material, preventing damage to downstream equipment.

9. Dust Suppression System (Optional):

- To control dust generated during the crushing process, some mobile jaw crushers may be equipped with dust suppression systems.

10. Remote Control (Optional):

- Remote control capabilities allow operators to control the crusher from a distance, enhancing safety and convenience.

11. Application:

- Mobile jaw crushers are used for primary crushing of various materials, including hard rock, construction and demolition waste, concrete, asphalt, and natural aggregates.

12. Versatility:

- Mobile jaw crushers are versatile and can be used in various applications. They are suitable for both recycling and quarrying operations, offering flexibility in processing different types of materials.

Mobile jaw crushers are beneficial for operations that require frequent relocation or for processing materials in remote locations. They provide a cost-effective solution for on-site crushing and are widely used in the construction and mining industries. Operators should follow safety guidelines and manufacturer recommendations for proper operation and maintenance.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mingyuan Small mobile jaw crusherMobile Diesel jaw crusher 250x400

Call

Condition: new, functionality: fully functional, power: 11 kW (14.96 HP), Year of construction: 2025, A diesel jaw crusher PE250X400 with a screen typically refers to a mobile jaw crusher equipped with a diesel engine that can be used for primary crushing of various raw materials, and it includes a screening system for separating the crushed material into different sizes. Here are key features and information about such a configuration:

1. Diesel Engine:

- The diesel engine provides the power for the jaw crusher, making it suitable for locations where electric power may not be readily available or practical. Diesel engines are known for their durability and reliability.

2. Jaw Crusher (PE250X400):

- The "PE250X400" indicates the opening size of the jaw crusher in millimeters. In this case, the jaw crusher has an inlet opening of approximately 250mm x 400mm, allowing it to crush various materials with different sizes.

3. Screening System:

Psdpfx Ahsq Nfu Es Usha

- The inclusion of a screen allows the crushed material to be separated into different sizes based on particle size. This is particularly useful for producing various grades of final products.

4. Mobile Configuration:

- A mobile jaw crusher with a diesel engine and screen is often mounted on a mobile chassis, making it easy to move from one location to another. This mobility is especially beneficial for applications in construction sites or quarry operations.

5. Material Handling:

- The raw material is fed into the jaw crusher, where it is crushed by the reciprocating motion of the movable jaw against the fixed jaw. The crushed material then passes through the screen, and different-sized particles are discharged accordingly.

6. Adjustable Output Size:

- The jaw crusher typically has an adjustable discharge setting, allowing operators to control the size of the final crushed material.

7. Applications:

- Diesel jaw crushers with screens are commonly used in construction, mining, and quarrying applications for processing various materials such as concrete, gravel, rock, and other aggregates.

8. Maintenance and Operation:

- Regular maintenance of the diesel engine, jaw crusher components, and the screen is necessary to ensure optimal performance and longevity.

9. Fuel Efficiency:

- Diesel engines are generally known for their fuel efficiency, making them suitable for applications where a reliable power source is required without access to electrical grids.

When considering a diesel jaw crusher with a screen, it's important to evaluate factors such as the required capacity, material hardness, and the desired final product specifications. Additionally, choose a reputable manufacturer known for producing reliable and high-quality mobile crushing and screening equipment.

Discover more used machines

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mobile / Stationary stone crusher plantSand & aggregate production plant

Call

Condition: new, Year of construction: 2025, A sand aggregate production plant is a facility where various types of aggregates (such as sand, gravel, crushed stone, or recycled concrete) are produced for use in construction and other applications. These plants typically include various stages of processing, from raw material extraction to the final product.

Here are the key components and processes typically involved in a sand aggregate production plant:

1. Raw Material Extraction:

- Quarrying or Mining: Aggregates are often extracted from quarries, mines, or riverbeds. Depending on the type of aggregate, the extraction process may involve drilling, blasting, or dredging.

2. Primary Crushing:

- Jaw Crusher or Gyratory Crusher: The extracted raw material is usually transported to the plant and fed into a primary crusher, where large rocks are broken down into smaller pieces.

3. Secondary Crushing:

- Cone Crusher or Impact Crusher: The crushed material from the primary crusher may undergo further reduction in size through secondary crushing.

4. Screening:

- Vibrating Screens: After crushing, the material is often screened to separate different sizes of aggregates. This process ensures that the final product meets the required specifications.

5. Washing:

Pjdpfeq Ngb Dex Ah Ujha

- Sand Washers: In some cases, especially for sand production, washing is done to remove impurities, clay, and fines from the aggregates, ensuring a cleaner and higher-quality product.

6. Grading and Sorting:

- Classifiers or Graders: After washing and screening, the aggregates may go through additional processes to separate them based on size or quality.

7. Stockpiling:

- Stockpiles: The final aggregates are usually stockpiled for storage before being transported to construction sites or other end-users.

8. Aggregate Storage and Handling:

- Storage Bins or Silos: Larger production plants may have storage facilities, such as bins or silos, to store different types and sizes of aggregates before distribution.

9. Quality Control:

- Laboratory Testing: Regular quality control testing is performed on aggregates to ensure they meet specifications for strength, size, gradation, and other properties.

10. Environmental Considerations:

- Water Management: Some plants incorporate water management systems to recycle and reuse water used in the washing process, minimizing environmental impact.

11. Transportation:

- Conveyors or Trucks: Aggregates are typically transported from the production plant to construction sites by conveyors, trucks, or other means.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Tracked mounted mobile crushing stationCrawler mobile stone crusher

Call

Condition: new, functionality: fully functional, Year of construction: 2024, A crawler mobile stone crusher is a mobile crushing device that has a tracked chassis, which allows it to move around the site and be transported from one location to another. This type of crusher is generally used in areas where there are space restrictions and the stones need to be crushed directly at the site, making it a versatile and flexible option for various applications. Here are some key features and aspects of crawler mobile stone crushers:

1. Mobility:

- The primary advantage of a crawler mobile stone crusher is its mobility. The tracked chassis enables it to move easily on different types of terrain, making it suitable for a wide range of applications, including construction sites, quarries, and demolition projects.

2. Crushing Mechanism:

- Crawler mobile stone crushers are equipped with a primary crusher to break down the large rocks into smaller pieces. Common types of primary crushers include jaw crushers, impact crushers, or cone crushers.

3. Versatility:

- These crushers are versatile and can handle various types of materials, including hard rocks, ores, and recycled concrete. They can be used for primary, secondary, or tertiary crushing depending on the specific requirements of the application.

4. Remote Control Operation:

- Many crawler mobile crushers are equipped with remote control systems, allowing operators to control the equipment from a distance. This feature enhances safety and efficiency, especially in challenging or hazardous environments.

5. Compact Design:

- Crawler mobile stone crushers typically have a compact design, making them suitable for working in confined spaces or on construction sites with limited available space.

6. Hydraulic System:

- The crushers are often equipped with a hydraulic system to facilitate quick and easy adjustment of the crusher settings. This includes adjusting the crusher's discharge opening and controlling the feed rate.

7. High Production Capacity:

- Despite their compact design, crawler mobile stone crushers can have high production capacities. This is crucial for efficiently processing large volumes of material on construction sites or in mining operations.

8. Screening Unit (Optional):

- Some crawler mobile crushers come with an integrated screening unit, allowing the production of multiple particle sizes in a single pass. This can be particularly useful in applications where a specific range of sizes is required.

9. Power Source:

- Crawler mobile stone crushers are typically powered by diesel engines, providing the flexibility to operate in remote areas where electrical power may not be readily available.

Phedpeq Nxpgjfx Ah Uja

10. Easy Maintenance:

- Many crawler mobile crushers are designed with ease of maintenance in mind, with features such as access panels and service points to simplify routine inspections and repairs.

Crawler mobile stone crushers have become popular in the construction and mining industries due to their flexibility, mobility, and ability to crush a variety of materials on-site. They offer a solution for efficient and convenient mobile crushing operations in diverse working environments.

Listing

Dianalund

Dianalund

940 km

Pallet inverter / pallet changer

ToppyMobile / stationary

Call

Year of construction: 2025, condition: new, NEW MACHINES

Phsdpfx Aohmfcteh Uja

We have a large selection of new pallet inverters and pallet changers, both mobile and stationary models. We have machines for all types of products that need to be turned or replaced pallets. Semi-automatic or fully automatic.

We deliver and install throughout the EU.

Listing

Wakefield

Wakefield

228 km

Double wire binder

James BurnBB/43H Wire-O Closing Unit

Call

Condition: excellent (used), Year of construction: 2001, Ref:11046 . 2001 JBI James Burn BB/43H Wire-O Closing Unit

Double wire booklet binder

Equipped with:

Pjdpfx Ahex Nfp No Uoha

Hand feed area with foot operated control

Auto closing unit with 2 x closing tools

Fully enclosed Perspex guarding

Hand feed & delivery table

Specification:

Product size, Max: 430 x 610 mm

Listing

United Kingdom

United Kingdom

147 km

800mm x 915mm Stainless Steel Niro Mobile Minor Spray Dryer

NiroMobile Minor

Call

Condition: used, Used Niro Mobile Minor stainless steel laboratory spray dryer. This unit has an approximate evaporation rate of 1 to 7 kg/hr depending on product. Has stainless steel chamber approximately 800mm diameter x 915mm straight side. Chamber is lagged and clad. Has electric heater, cyclone and pipework. Unit is mounted on mobile frame. Includes stainless steel Niro centrifugal air operated atomiser.

Click on the link below to see a video of the machine running.

Phsdpfxox Hv Tyo Ah Uja

Listing

United Kingdom

United Kingdom

0 km

Control unit

AGIE CHARMILLESSP3

Call

Condition: good (used), Agie Charmilles SP3 EDM Die Sink Machine

S/No. MON30 NR-001014. With Filtermist. Rolls-Royce Approved Contractor (PIC) will need to remove item. Please contact PIC for a quote, contact details can be found in the Essential Information section.

Pjdpfxox H Rxko Ah Usha

BIDDING NOTE: All Top Closing Bids received either through Auction or via Make Offer function will be presented to Rolls Royce for final approval. Buyers will be notified by email and/or by Invoice if their bid is successful. COLLECTION NOTE: Rolls-Royce Approved Contractor (PIC) will need to remove item. Please contact PIC for a quote, contact details can be found in the Essential Information section.

Listing

Moneymore

Moneymore

219 km

Paint spraying unit

MakorStart One

Call

Condition: used, Year of construction: 2016, Used Makor START ONE spray coating machine suitable for low-volume woodworking production. Designed for applying water-based or solvent-based paints and glues to veneered components and PVC panels. Ideal for companies moving from manual finishing to automatic spray coating.

Equipped with PLC control system with intuitive interface and automatic panel detection to optimise paint usage. Features a self-cleaning paper transport system, reducing maintenance and downtime.

Spraying unit includes an electronically controlled oscillating arm with capacity for up to 4 spray guns, 2 high-pressure feed circuits, and quick-change coupling system.

Phedpfx Ajx Iggysh Uja

Efficient air-flow and filtration system ensures clean operation and environmental compliance.

Technical Data:

• Feed speed: 1–4.5 m/min

• Air capacity: 10,000 m³/h

• Installed power: 7 kW

• Working height: approx. 900 mm

Listing

Nottingham

Nottingham

309 km

Crushing unit

McIntyreM20 Can Baler

Call

Condition: reconditioned (used), Year of construction: 2008, functionality: fully functional, The McIntyre M20 Baler is cost effective for cans and can also be used for many other applications where automatic volume reduction or product destruction is required. The M20 Baler will accept cans up to 250mm x 480mm and will produce up to 750kg of 20g aluminium drink cans per hour. When fed with aluminium drinks cans, these machines crush and lock the material together to produce dense 274mm cubes, weighing approximately 9 – 11kgs. Such dense bales means that no tying or strapping is needed. The cubes are simply ejected from the machine and are ready for transportation.

Pedpfxewl I Hvj Ah Ueha

Listing

Dromore

Dromore

272 km

Mobile crane

Sennebogen735E

Call

Condition: ready for operation (used), functionality: fully functional, power: 231 kW (314.07 HP), overall weight: 43,900 kg, Year of construction: 2017, operating hours: 14,647 h, machine/vehicle number: Serien Nr: 0907, Sennebogen 735E used wheeled log loader. This machine was bought recently for our business and is running well. It's just to big for the job we want it to do and would like to move it on.

Pedpfxjx Ngiws Ah Ueha

Listing

Duxford

Duxford

436 km

Agilent 34970A Data Aquisition Switch Unit

Agilent34970A

Call

Condition: used, This listing is for the Agilent 34970A Data Aquisition Switch Unit

Psdpfxsx Npy Ej Ah Ujha

The unit is in full working condition and is ready for immediate release.

The Agilent 34970A Data Acquisition/Switch Unit is a modular test and measurement instrument designed for data logging, signal measurement, and flexible switching in lab, production, and automated test environments

Listing

Suffolk

Suffolk

442 km

Dust extraction unit for crumbing line

GEA CFSOPA OptiAir

Call

Condition: excellent (used), OptiAir unit to extract dust when predusting food products with fine flour.

Phodpfox Hamqox Ah Uja

Listing

United Kingdom

United Kingdom

0 km

Sandblasting unit

WheelabratorTTX2

Call

Condition: excellent (used), Year of construction: 2014, Wheelabrator TTX2 Dry Blasting Line With Siemens Simatic Touchscreen PLC

Semi-Automated Abrasive Blast Cell With Cyclone & Extraction System. Donaldson Torit DCE Extractor. Cyclone. YOM: 2014. S/No. 602498. Included with The Purchase Of The Machine is An Upgrade Package Purchased In 2020 But Not Fitted That Includes: Media Dosage System, Automatic Media Refill, Dust Collector Bag Weight Monitoring, Cyclone Replacement, Additional Maintenance Platform, Additional Blowoff Air Nozzle, Machine ‘Self-Cleaning’ System, Removable Door Ledge, Media Sampling System Upgrades, Improved Door Opening System.

With Spare (New) Cyclone and Extractor. BIDDING NOTE: All Top Closing Bids received either through Auction or via Make Offer function will be presented to Rolls Royce for final approval. Buyers will be notified by email and/or by Invoice if their bid is successful. COLLECTION NOTE: Due to Rolls Royce Company Policy, ONLY Approved Removal Contractors are Permitted to Operate on this Site. Please See Collection Details for Contact Information.

Pedpfx Asx Ah Dgsh Uoha

Listing

Wiefelstede

Wiefelstede

785 km

Suction slide

Stahl500 mm

Call

Condition: good (used), Extraction slides, ventilation duct slides, slides for filter systems, chip extraction, dust extraction, extraction systems, ventilation ducts and fittings

Phodpfxscba Txo Ah Uea

-Length: 470 mm

-Connection: Ø 500 mm

-mechanical: flap

-Material: Steel sheet

-Quantity: 1x slider available

-Price: per piece

-Dimensions: 550/470 mm

-Weight: 22 kg

Listing

Vuren

Vuren

685 km

Standard-SZM

DAFXF 480 2X TANK CARRIER UNIT

Call

Condition: used, mileage: 697,309 km, power: 353 kW (479.95 HP), first registration: 01/2019, fuel type: diesel, tire size: 385/65R22,5, axle configuration: 4x2, fuel: diesel, color: other, driver cabin: sleeper cab, gearing type: automatic, number of gears: 12, emission class: euro6, suspension: steel-air, total length: 6,220 mm, total width: 2,550 mm, total height: 3,560 mm, Year of construction: 2019, = Further Options and Equipment =

- Digital tachograph

- Fixed

- Space Cab

= Notes =

Number of axles: 2, Configuration: 4x2, Twin tires, Unladen weight: 8,313 kg, Gross weight: 19,500 kg, Fifth wheel: Fixed, Suspension type: Air suspension, Cab type: Space Cab, Digital tachograph, Colour: Multicolour, Heated mirrors, Mirror camera, Lighting type: Halogen lamp, Speed limiter, Lane departure warning system, Heated seat, Engine output: 353 kW (473 hp), Euro 6, Transmission type: AS-Tronic, Speed limiter, Gears: 12, PTO type: 1, Starter battery, Seat adjustment: Manual, CARRIER POWER UNIT

= Additional Information =

Axle configuration

Brakes: Disc brakes

Axle 1: Tyre size: 385/65R22.5; Steering; Tyre tread left: 6 mm; Tyre tread right: 6 mm; Suspension: Leaf springs

Axle 2: Tyre size: 315/70R22.5; Twin tyres; Inner left tyre tread: 20 mm; Outer left tyre tread: 20 mm; Inner right tyre tread: 20 mm; Outer right tyre tread: 20 mm; Suspension: Air suspension

Weights

Kerb weight: 8,313 kg

Payload: 11,187 kg

Gross vehicle weight: 19,500 kg

Phsdjw Rku Eepfx Ah Uea

Condition

General condition: very poor

Technical condition: very poor

Optical condition: very poor

Damages: none

Number of keys: 2

Financial Information

Leasing price: €373 per month (default, 60 months); Please ask for further information and terms

Identification

Registration number: KLEYN1

= Company Information =

Kleyn Trucks is one of the world’s largest independent dealers of used vehicles. Here, you can choose from a constantly changing stock of 1,200 used trucks, tractor units and trailers. Our range includes all European brands, model years and price categories.

Why buy from Kleyn Trucks? Simple!

• Large, fast-changing selection

• Recognisable quality

• Competitive prices

• Professional business conduct

• Multilingual support

• We understand our customers

• Assistance with import and transport

• (Export) registration plates arranged quickly

• Expert technical services

• The security of ‘recognisable quality’

• And much more....

Please visit our website for special offers and our full inventory:

Leasing through Kleyn Trucks is possible in most European countries!

Quickly calculate your leasing rate and submit your request via our website.

Ask directly about our European warranty package.

Listing

Tadley

Tadley

474 km

Control unit

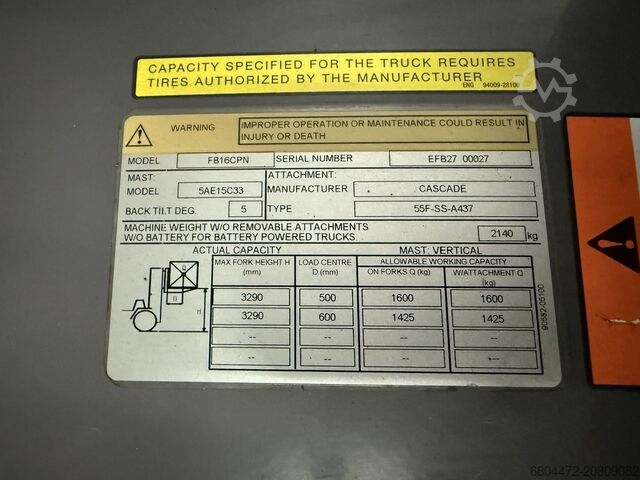

MitsubishiMitsubishi FB16CPN Electric Folklift

Call

Condition: used, Year of construction: 2012, operating hours: 554 h, functionality: fully functional, Mitsubishi FB16CPN Electric Forklift truck.

In very good condition and working order.

Year 2012

1 pervious owner from new! Have original purchase receipt of £20k plus.

Truck is registered With the UK DVLA to be able to drive truck on the road.

Digital Display allows you to see what speed you are doing and also displays the weight you are lifting.

Comes complete with Single Phase Battery charger, Spare keys and Handbook.

See last photo of trucks Features.

Podpfx Aox Nbn Ijh Uoha

Collection and inspection is Tadley UK (Near Reading)

Specification:

Mitsubishi FB16CPN Electric Folklift truck

Capacity: Nominal 1600kg at 500mm Load centre

With sideshift: 1600kg at 500mm Load centre at full height

With sideshift: 1425kg at 600mm Load centre at full height

Mast: Simplex 2 stage clear view

Lift height: 3290mm

Closed height: 2125mm

Tyres: Solid Pneumatic profile

Folks: 1000mm Long

Single phase battery charger

Listing

Honselersdijk

Honselersdijk

628 km

Standard tractor unit

DAFXF 460 FT SSC 2x TANKS 881.000 KM NL TRUCK

Call

Condition: used, mileage: 999,999 km, power: 340 kW (462.27 HP), first registration: 01/2016, fuel type: diesel, overall weight: 20,500 kg, axle configuration: 2 axles, gearing type: automatic, emission class: euro6, Year of construction: 2016, Equipment: ABS, air conditioning, parking heater, Additional features:

* Aluminium fuel tank

* Anti-lock braking system (ABS)

* Traction control (ASR)

* Automatic transmission

* Brake booster

* Roof spoiler

Podexpz Dyepfx Ah Usha

* Differential lock

* Dual fuel tanks

* Electric windows

* Electronic braking system (EBS)

* High beam headlights

* Cruise control

* Camera

* Air conditioning

* Refrigerator

* Steering axle

* Air horn

* Fog lights

* Parabolic suspension

* Radio/CD player

* Disc brakes

* Sleeper cab

* SemCollection

* SemStars

* Sideskirts

* Spoiler

* Parking heater

Semtrade B.V.

Contact | Martin Klaaijsen | Tel: | Whatsapp: | Email:

Export charges | Please enquire in advance about costs and procedures specific to your country

Location | Maasdijk (NL) | 140 km from the border | 20 km from Rotterdam The Hague Airport

Disclaimer:

Subject to change, prior sale, and errors.

Trust Seal

Dealers certified through Machineseeker

Listing

Sassenheim

Sassenheim

629 km

Mobile crane

LiebherrLTM 1150-5.3

Call

Condition: good (used), functionality: fully functional, Year of construction: 2023, Basic information

Capacity: 150 tons

Type: Hydraulic all-terrain crane

Year of manufacture: 2023

Main boom: 66 m

Jib: 19 m mechanical

Stock number:

Details

Mileage: 43,382 km (as of 06-12-2025)

Lower structure operating hours: 1,319 (as of 06-12-2025)

Carrier engine: Liebherr Stage V and Tier 4 Final

Upper engine:

Upper structure operating hours: 3,225 (as of 06-12-2025)

Gearbox: ZF

Tire size: 16.00 R25

Axle configuration: 10 x 8

Phodox Nqq Eepfx Ah Usa

Suspension: Hydro-pneumatic

Chassis: Liebherr

LMI system: Liccon 2

Load chart: 75% metric

Hook blocks: 1 x 3-sheave block and 1 x ball hook

Winch: 1 (prepared for second winch)

Counterweight: Full set

Manuals: Yes

Availability:

Serial number:

Additional information:

Listing

Wiefelstede

Wiefelstede

785 km

Mobile dust extractor

SchukoVacomat 200 XPE

Call

Condition: good (used), Year of construction: 2011, Compact dust extractor, dust extractor, dust extraction blower, extraction, dust blower, extraction system, dust blower, dust extraction device, separator, filter system

Cartridge dust extraction system, clean air system, clean air dust extractor

Pedpoxu Dybofx Ah Usha

-Filter system: Höcker Polytechnik Vacomat 200 XPE mobile dust collector

-Nominal flow rate: 2260 m³/h

-Exhaust fan: 3.7 kW

-Intake manifold: Ø 200 mm

-Individual components: electric filter cleaning, 3 chip containers, see photos

-Dimensions: 890/2620/H2120 mm

-Weight: 440 kg

Listing

Wiefelstede

Wiefelstede

785 km

Hydraulic unit 55 kW/1460 rpm

AEG55 kW/1460 U/min

Call

Condition: good (used), Hydraulic power unit, hydraulic pump, universal power unit, hydraulic station, injection molding machine, plastic injection molding machine, plastic injection molding press

-Manufacturer: AEG, hydraulic unit from Krauss Maffei KM 250-1200 B injection molding machine

-Motor: Bauknecht type AJ 225 MV4 Q4 55 kW / 1460 rpm

-Individual components: see images

-Dimensions: 1340/650/H760 mm

Phodpfx Aheg Azpto Uoa

-Weight: 557 kg

Listing

Wiefelstede

Wiefelstede

785 km

Hydraulic unit 30 bar

Integral Hydraulik6 l/min

Call

Condition: good (used), Hydraulic power unit, hydraulic pump, universal power unit, hydraulic station

-Manufacturer: Integral Hydraulik, hydraulic power unit with pressure switch

-Pressure: up to 30 bar

Pedpowmax Hofx Ah Ueha

-Flow rate: 6 l/min

-Pressure switch: Telemecanique XMG-B140

-Hydraulic reservoir: with pressure accumulator and level indicator

-Individual components: see photos

-Dimensions: 465/260/H510 mm

-Weight: 48 kg

We make it easier for you to find: "mobile suction unit"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Mobile Suction Unit (36,953)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month