Used Robi for sale (384)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Riederich

Riederich

1,152 km

Pick-up van

MERCEDES-BENZVARIO 816 D DOKA 7-Sitzer Plane 3 m*AHK

Call

Condition: used, mileage: 314,800 km, power: 115 kW (156.36 HP), first registration: 08/2007, fuel type: diesel, overall weight: 7,490 kg, color: blue, gearing type: mechanical, emission class: euro4, number of seats: 7, loading space volume: 14 m³, loading space length: 3,060 mm, loading space width: 2,260 mm, loading space height: 2,049 mm, Year of construction: 2007, Equipment: ABS, * VARIO 816 D DOKA 7-seater tarpaulin/tarpaulin, 3 m, with tow bar ball head

* 3-entry door on the right

* Tarpaulin labeled, can be removed for an additional charge

* Vehicle number For customer inquiries: 4292

* Passenger compartment (double cab)

* Environmental sticker (green)

* Reinforced cross member without trailer hitch

* Low-profile ball-head trailer hitch

* Double seat for right passenger compartment

* Double seat for left passenger compartment

* Two-seater passenger seat

* Hydraulic driver's seat "Isringhausen"

* Transmission G 56-6/6.29-0.78

* Electric windows for driver and passenger doors

* Braking system, anti-lock braking system (ABS)

* Electric windows for driver and passenger doors

* Right-hand revolving entry door with window

* Anti-lock braking system (ABS)

* Reinforced rear parabolic springs, Stage I

Hjdpfx Aswc E N Ajddjfb

* Platform 3060 x 2260 x 400

* Engine OM 904 LA 115 kW (156 hp) 2200 rpm

* Air-operated engine brake

* Main tank 90 liters, right

* Digital tachograph, EC type

* Wheelbase 3700 mm

* Passenger-side mirror, electrically adjustable

* 7-pin trailer socket

* Reinforced shock absorbers

* Reinforced rear axle stabilizer under frame

* 13-pin trailer socket

* BlueTec 4 (Euro 4)

* Seven-seater

* Hydraulic 2-circuit brakes/Compressed air 2-circuit brakes

* Weight variant 7.49 t (2.5/5.6)

* Driver-side mirror, electrically adjustable

* 2/3 doors

No liability for printing or typographical errors

Sale to businesses only

Subject to errors and prior sale* Changes, prior sale, and errors are expressly reserved. The description serves to identify the vehicle and does not constitute a warranty under sales law. The description in the purchase contract is decisive.

* TOP SERVICE + QUALITY

* We are happy to provide you with a LEASING, FINANCING, or HIRE PURCHASE offer.

Warranty insurance available upon request from the insurer.

* TÜV / UVV LBW / tachometer inspection and OBU device installation by our local partners.

* Customs license plate valid for 30 days.

All customs documents for export are available, but must be requested separately.

* Toll Collect can be booked in-house.

* Free transfer from Stuttgart Airport or Metzingen (Württemberg) train station.

* ARRIVAL STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

--- Visit us on our website at

* Over 200 vehicles always in stock.

Listing

Heidenheim an der Brenz

Heidenheim an der Brenz

1,194 km

Welding robot

LorchCobot UR10e im Set

Call

Condition: used, Year of construction: 2024, functionality: fully functional, Cobot Universal Robots UR10e incl. Control Unit and Lorch S5-RoboMIG XT + Kemper VacuFil Compact Extraction System

For sale is a used Cobot UR10 including welding system and extraction unit as a package, fully operational. The machine/package is offered on behalf of a client.

COBOT + S5-ROBOMIG XT:

The Lorch S5-RoboMIG XT welding unit is equipped with a special cobot interface and a water cooling system with increased cooling capacity. The interface/control panel as well as the wire feeder are housed in a separate feeder case (1m intermediate hose package). The package comes with an LMR 450 W EVO torch with a 3.5m cable length.

The package includes a full feature set with the following licenses:

• Motion (enables control of turntable and linear axis)

• Assistant+QuickPoints (enables programming via multi-flange)

• Weaving (oscillation – linear and radial)

• Seamtracking (seam tracking to compensate for tolerances)

• Smartcopy (enables easy copying of programs)

• TouchSense (enables component position detection via probing with the gas nozzle)

• Fume Extraction (enables control of torch extraction system)

The package also includes a Cobot Move 2400 linear axis with a travel range of 2m, extending the working area to 4.5m. The travel speed can be set between 2 and 160 mm per second. Both the cobot and the Move linear axis are collaborative.

Additional accessories: jib boom, balancer 1–2 kg, cable holder, Lorch Connect Gateway

KEMPER VACUFIL COMPACT:

The high-vacuum extraction device VacuFil Compact is designed for high volumes of welding fume and dust and is also included. It features a large, cleanable filter and easy one-button operation—even while wearing gloves. Numerous additional features are available, such as automatic airflow control. The side channel blower for negative pressure generation ensures robust performance for industrial users. For further technical data, please refer to the data sheet.

SIEGMUND BRIDGE:

The package is completed with a bridge from Siegmund. Cross beams, machine stands, and the rotary device are also included.

The total package price is as follows:

Cobot UR10e incl. welding machine = €67,500

Kemper VacuFil Compact extraction = €4,200

Bridge by Siegmund = €2,500

Hjdpfx Adjx E U Rhodefb

Our customer, the owner of the complete system, purchased the package at the beginning of 2024.

Listing

Mouvaux

Mouvaux

680 km

Meat processing machine

KoppensEnrobeuse ER 400

Call

Condition: used, Year of construction: 1987, functionality: fully functional, total length: 1,400 mm, total width: 600 mm, total height: 1,800 mm, input voltage: 380 V, input frequency: 50 Hz, The Koppens ER 400 enrober is designed to improve efficiency and precision in food production processes, particularly for enrobing products such as meat, fish and other preparations. Thanks to its robust design, it guarantees uniform and homogeneous coating, delivering a high-quality finished product with every cycle. In fact, this machine adapts easily to different types of production, making coating fast and precise.

What's more, the Koppens ER 400 coater stands out for its ability to offer total control over production speed, enabling parameters to be adjusted to suit specific needs. With an integrated liquid pump, it facilitates even coating application, reducing raw material losses while optimizing results. What's more, its compact design enables seamless integration into existing production lines, while offering flexibility for diverse product types.

Finally, this enrober contributes to increased productivity by reducing manual intervention, thus ensuring greater reliability and efficiency in food processing operations. In short, the Koppens ER 400 coater is an indispensable solution for companies seeking to optimize their coating processes.

Technical specifications:

Hfodpfeu E N Iyjx Addob

Power: 0.61 kW

Frequency: 50 Hz

Voltage: 380 V + 3 Ph

Amperage: 3.2 A

Weight: 135 Kg

Belt width: 400 mm

Mesh width: 5 mm

Adjustable speed

Liquid pump

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Bad Oeynhausen

Bad Oeynhausen

880 km

Vertical machining center

HaitianV8M

Call

Condition: new, Year of construction: 2025, Machine Specification:

Travel distances:

- X axis travel: 850 mm

- Y axis travel: 500 mm

- Z axis travel: 500 mm

- Spindle nose to table: 150–650 mm

Table:

- Table size: 1000 x 500 mm

- Max. load: 600 kg

- T-slots on table: 3 x 18 x 125 mm

Spindle:

- Drive type: Built-in

- Max. speed: 15,000 rpm

- Power: 11/18.5 kW

- Torque: 45/60 Nm

- Tool holder: BBT 40

- Pull stud: MAS403-P-40T-I (45°)

Feed rates:

- Rapid traverse (X/Y/Z): 30/30/30 m/min

- Cutting feed (X/Y/Z): 10/10/10 m/min

- Ball screw diameter (X/Y/Z): 40 mm

Tool magazine:

- Capacity: 24 tool positions

- Type: BBT 40

- Max. tool diameter (with adjacent pockets full/empty): Ø80/Ø150 mm

- Max. tool length: 300 mm

- Max. tool weight: 8 kg

- Tool-to-tool indexing: 2.5 sec

Precision:

- Positioning accuracy (X/Y/Z): 0.006/0.005/0.005 mm

- Repeatability (X/Y/Z): 0.004/0.003/0.003 mm

Other features:

- Machine weight: 6 t

- Dimensions (LxWxH): 2640 x 2870 x 2760 mm

Standard configuration:

- Mitsubishi M80VB CNC

- 15,000 rpm built-in spindle

- Spindle cooling

- Workpiece air cooling

- Machine bed flushing

- External coolant tank

- Full enclosure

- Air gun

- 3-color signal lamp

- Standard accessories

- Documentation

- CE

Options:

- FANUC PLUS 3A

- Mechanical spindle 12,000 rpm (BBT40)

- Kessler spindle 20,000 rpm (HSK-63)

- Control panel air conditioning

- Spindle ring cooling

- Through-spindle coolant 20 bar

- Oil separator

- CNC 4th axis

- Oil mist separator

- Glass scales

- Automatic door

- 24/30-tool magazine

Machine is equipped with:

- Spindle ring spray cooling

- Heidenhain linear scales on three axes

- Through-spindle coolant 20 bar

- Chain-type chip conveyor with chip cart

- Workpiece rinse water gun (automatic switching)

- FANUC PLUS 3A+ 15-inch monitor (CE configuration)

- 30-tool servo magazine

- Oil-water separation device

- HSK-A63 interface for electric spindle tool holder

- ROTOCLEAR

- HPC500II lifting tool

Hfjdpsw Rcxvofx Addob

- Software interfaces for BLUM tool measurement and workpiece probing system (TC60)

- MOV850 lifting tool

- 2-year full machine warranty

- Pre-rinse water system inside the machine

- Control cabinet air conditioning

Listing

Saarbrücken

Saarbrücken

980 km

Zeiss O-Inspect 442 Multisensory CMM

ZeissO-Inspect 442 Zeiss Calypso

Call

Condition: good (used), Year of construction: 2012, functionality: fully functional, measuring range X-axis: 400 mm, measuring range Y-axis: 400 mm, measuring range Z-axis: 200 mm, travel distance X-axis: 400 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 200 mm, input voltage: 230 V, Equipment: lighting, type plate available, Year of manufacture: 2012

Tactile:

Vast XXT

E0 X/Y (1D) in [μm] at 20 ±2 °C 1.7 + L/250

E0 XY (2D) in [μm] at 20 ±2 °C 1.7 + L/250

E0 (3D) in [μm] at 20 ±2 °C 1.9 + L/250

Scanning probing deviation

MPE according to ISO 10360-4:2000 THP at 2.7 [μm]

Hjdpfxouq Nfhe Addjfb

Single probe probing deviation form

MPE according to ISO 10360-5:2010

PFTU 1.9 [μm]

Camera system:

Zeiss Discovery 12

EB X/Y (1D) 5) in [μm] at 20 ±2 °C 1.7 + L/250

EB XY (2D) 5) in [μm] at 20 ±2 °C 1.7 + L/250

Probe deviation MPE according to ISO 10360-7:2011

PF2D 5) 1.7 [μm]

Probe deviation of the image processing system

MPE according to ISO 10360-7:2011

PFV2D 5) 1.2 [μm]

Possible services: delivery, commissioning

Discover more used machines

Listing

Zwevegem

Zwevegem

681 km

Vacuum filler P9 SE Type 595

Karl Schnellvacuümvuller P9 SE Type 595

Call

Condition: used, 250 L. hopper

filling

portioning control

with twister and tube casing holder

PLC control

7,9 kW

3 x 400V, 50 Hz

dimensions (L x W x H): ± 2.100 x 1.300 x 3.100 mm

Hedpfexg Du Aex Addofb

+ built-in loader for eurobins of 200 L

Listing

Riederich

Riederich

1,152 km

Truck mounted crane

MANTGS 18.420 L Pritsche 6,2 m*KRAN HIAB HIDUO 138

Call

Condition: used, mileage: 372,811 km, power: 309 kW (420.12 HP), first registration: 05/2019, fuel type: diesel, overall weight: 18,000 kg, color: white, gearing type: mechanical, loading space volume: 12 m³, loading space length: 6,202 mm, loading space width: 2,472 mm, loading space height: 800 mm, Year of construction: 2019, TGS 18.420 L Flatbed 6.20 m with rear crane

* HIAB X-HIDUO 138 ES-3 * Foldable

* Radio remote control * 5th and 6th circuits for grapple control

* Maximum hydraulic capacity 10.20 m with a load capacity of 980 kg

* Vehicle number for customer inquiries: 4244

* Environmental sticker (green)

* Service history maintained

No liability for printing or typographical errors

Sale to commercial customers only

Subject to errors and prior sale* Subject to changes, prior sale, and errors. The description serves to identify the vehicle and does not constitute a warranty under commercial law. The description in the purchase contract is decisive.

* TOP SERVICE + QUALITY

* We are happy to provide you with a LEASING, FINANCING, or HIRE PURCHASE offer.

Warranty insurance available upon request from the insurer.

* TÜV / UVV LBW / tachometer inspection and OBU device installation by our local partners.

* Customs license plate valid for 30 days.

All customs documents for export are available, but must be requested separately.

* Toll Collect can be booked in-house.

* Free transfer from Stuttgart Airport or Metzingen (Württemberg) train station.

* ARRIVAL STATION: 72555 METZINGEN/WÜRTT.

Hfodpfewm Tbhjx Addeb

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

--- Visit us on our website at

* Over 200 vehicles always in stock.

Listing

Poppenhausen

Poppenhausen

1,084 km

ConturoMatic T1 used contour measuring

ConturoMaticTS-X NEU

Call

Condition: new, functionality: fully functional, warranty duration: 24 months, input voltage: 240 V, measuring range X-axis: 280 mm, measuring range Z-axis: 350 mm, overall weight: 100 kg, workpiece weight (max.): 50 kg, Equipment: type plate available, High-end contour and roughness measuring system with air-bearing motion axes, up/down measuring function and X-sensing.

Anytime optionally via software updatable functions:

- Motorized Y-Supporting table

Scope of supply:

- Basic mechanics with integrated Y-adjustment table

- Integrated control system

- integrated gauging force regulation

- software option roughness

- Software option for measurement and evaluation of the following standards:

DIN EN ISO 4287 (10/1998)

DIN EN ISO 4288 (04/1998)

Hodswzlcaspfx Addsfb

DIN EN ISO 11562 (04/1998)

DIN EN ISO 13565-1 (04/1998)

DIN EN ISO 13565-2 (04/1998)

VDA 2006 (07/2002)

Stahl-Eisen-Prüfblatt (SEP 1940)

- PC W11/64Bit; 24"TFT flat screen;

- Compressed air unit consisting:

Particulate filter 25µm/0.1µm, oil filters and water separator

2 precision pressure regulator mounted on base with stand

- ConturoMatic Software; user manual

- Software add-on for roughness calculation

- Cable set

- Protective cover, sturdy and water repellent (material), Commodity-Code 63079098

Description of the up down function:

The scanning of surfaces in two directions is possible by the measuring direction switching function.

This can be assessed without loss of the relationship to other scans from the same measuring process.

Inside and external scans can be calculated to each other. This function is suitable without restrictions in automatic measurement programs.

Additional evaluation possibilities are for example

- Raceway diameters

- Diameter

- Thickness variation

- Parallelism

- Cone angle measurement

- Calculation of pitch deviation

- Thread testing (thread calculation software optionally)

etc.

Technical data contour and roughness measurement:

Aerostatic linear bearings (X and Z)

Measuring range Contour 280mmx350mm (X/Z)

Measuring range Roughness 280mmx350mm (X/Z)

Suitable range Ra Ra from 0.05µm*

Suitable range Rz Rz from 0.5µm*

Resolution 1nm

Sensing system optically incremental

1 point measuring in X direction (static)

Accuracy +/-(0.85µm+L/100)µm* [L=mm]

Measuring speed contour 0.1-3mm/s self-optimizing

Measuring speed roughness 0.1-0,5mm/s self-optimizing

Positioning speed up to 25mm/s

Probing force contour 30mN

Probing force roughness 7.5mN

Table load 25kg

weight: 96kg

* According to our specified terms-

Subject to change without notice

Listing

Bristol

Bristol

440 km

Miyano ABX-64SYY

MiyanoABX-64SYY

Call

Condition: used, Year of construction: 2023, In the market for a Top of the Range Miyano? Then have a look at this one! 18 months old and just over 1000 hours on the clock…it is as new! Still on site where it can be seen under power. The following is from Miyano’s Spec sheet: The Miyano ABX-64SYY – is a Top of the range, twin spindle, twin turrets with Y-axis on each turret. The ability to machine simultaneously at the left and right spindles using the upper and lower turrets, both featuring a Y-axis function, means that complete front and back machining of products with complex shapes can be accomplished simply and in a short time. High rigidity and high torque with 40 Nm driven tools. The use of rigid 40 Nm driven tool drives capable of heavy cutting ensures stable milling. Two turrets with a total of 24 tool positions, all driven, handle complex machining just like a machining centre. This machine also features the optional parts conveyor, Hainbuch collet chucks on both spindles, high pressure coolant, probing and a steady rest that’s mounted on the lower turret. Machining Capacity and Chuck System Maximum Machining Diameter of Bar Work SP1/SP2 ø64/51mm Collet Chuck SP1/SP2 Stationary Power Chuck SP1/SP2 6″/6″ hydraulic drive Standard Turning Length 125mm Spindle Spindle Nose SP1/SP2 A2-8/A2-6 Spindle motor(30min./Cont.) SP1 15/11kW SP2 7.5/5.5kW Spindle Speed Range SP1 50 – 5,000min-1 40 – 4,000min-1 SP2 50 – 5,000min-1 Turrets(Upper L/R Turrets & Lower Turret) Type of Turret 2 x 12 Station Turret Shank Height of Square Turning Tool □20mm Diameter of Drill Shank ø40mm ø20mm ø25mm Slide Stroke X1, X2 axis 190mm Z1/Z2 axis 550mm/721mm Y1, Y2 axis ±40mm Zs axis 756mm Rapid Traverse Rate X1, X2 axis 16m/min Z1/Z2 axis 30/20m/min Y1, Y2 axis 12m/min Zs axis 30m/min Driven Tools Maximum Number of Revolving Tools 24 Rotation speed of Driven Tools 60 – 6,000min-1 Driven Tool Motor AC Servo 4.5kW Machine Dimensions Machine Height 2,222mm Floor Space 3,290×2,204mm Machine Weight 10,900kg

Name of the machine: Miyano ABX-64SYY

Hedpfew I D Duox Addsfb

Listing

Töltéstava

Töltéstava

1,692 km

Biodecontamination Unit

SterisVHP 1000ED

Call

Condition: ready for operation (used), functionality: fully functional, Steris VHP 1000ED Biodecontamination Unit

APPLICATION

The STERIS VHP® 1000ED Biodecontamination

Unit is designed for mobile biodecontamination1 of

clean, dry, sealed enclosures2 such as isolators,

chambers, and small rooms using STERIS's VHP

process technology, featuring Vaprox® Hydrogen

Peroxide Sterilant

DESCRIPTION

With its mobile design and multi-purpose features,

the VHP® 1000ED is one of the most versatile

pharmaceutical grade Biodecontamination Units on

the market today. The Biodecontamination Unit uses

STERIS patented VHP process technology. The

process uses hydrogen peroxide vapor as a broad

Hfedpjwqz Dlefx Addeb

spectrum antimicrobial without condensation of

active ingredient onto surfaces. This non

condensation feature provides additional benefit of

a wide range of material compatibility.

The VHP® 1000ED Biodecontamination Unit

features easy operation with an easy to use operator

interface and other key built-in design features like

dehumidification, pressure control, Vaprox cartridge

interface and aeration module for an All-In-One unit.

Once the Customer cycle is selected, the control

system automatically completes the desired

biodecontamination cycle.

Additionally, the VHP® 1000ED Biodecontamination

Unit offers an impact printer for hard copy of the cycle

data as well as a USB port for electronic

biodecontamination cycle capture.

The unit includes a connection kit with four (4) Banjo

1.25" couplings and 25 ft. (7.6 m) of tubing for

connecting to enclosures or rooms

Good working condition. Please check out our other listings as well.

Listing

Saarbrücken

Saarbrücken

980 km

Mahr MS662 Complete Package

MahrMS662 KOMPLETTPAKET opt. 0% Finanzierung

Call

Condition: refurbished (used), Year of construction: 2025, operating hours: 12 h, functionality: fully functional, measuring range X-axis: 600 mm, measuring range Y-axis: 600 mm, measuring range Z-axis: 200 mm, type of input current: AC, input voltage: 230 V, year of last overhaul: 2025, Equipment: documentation/manual, lighting, type plate available, Factory-refurbished Mahr Multiscope 662 (factory acceptance before delivery)

Factory-refurbished premium multisensor measuring center with warranty and guarantee, rebuilt in 2025.

Includes the latest software update für windows 10 (Windows 11 and OptiCheck2025 optionally available) free lifetime software hotline, and user support.

Optional delivery with factory service or shipping, worldwide.

Online or on-site demonstrations available with customer parts, and application consulting by accredited Profitech measuring laboratories during project planning.

Complete service:

Optional complete service: – Delivery, setup, commissioning, accuracy acceptance according to standards, certification, and extensive acceptance documentation. Individual training and educational programs also available as online courses.

Rental, hire purchase, or financing directly through Profitech without a financial institution. Measuring device customizable to customer needs.

Multisensor measuring device equipped with a camera, laser, and Renishaw probing system.

Measuring range for all sensors: 600x600x200mm (l x w x h)

Dimensions: 1540x1120x2300mm (l x w x h)

Space requirement: 1940x1520x2500mm (l x w x h)

Weight: approx. 1300kg (including control cabinet and base)

Max. load capacity: Glass plate 40kg

Accuracy: U1=2.4 + L/150; U2=3.2 + L/125; U3=3.9 + L/100 (L= measuring length in mm)

Max. travel speed: 250mm/s

Hfedpfju Dw T Usx Addsb

Including 2-step zoom camera

Including laser

Including LED ring light

Including Renishaw TP200 probing system

Including frame grabber (Eagle)

Including Windows 10

Including new Optichek 3D 5.0 evaluation software

Including Renishaw TP200 probing system

During optional commissioning and calibration, the measuring device can be programmed for customer-specific parts so that you can immediately run your measurement programs even before any required training.

Listing

Frankfurt am Main

Frankfurt am Main

1,003 km

Vertical machining center

MTRent MTEvoUDS41-5A

Call

Condition: used, Year of construction: 2018, operating hours: 13,276 h, functionality: fully functional, travel distance X-axis: 710 mm, travel distance Y-axis: 700 mm, travel distance Z-axis: 610 mm, rapid traverse X-axis: 32 m/min, rapid traverse Y-axis: 32 m/min, rapid traverse Z-axis: 32 m/min, nominal power (apparent): 35 kVA, torque: 120 Nm, controller manufacturer: Heidenhain, controller model: TNC 640, table load: 300 kg, rotary table diameter: 410 mm, overall weight: 9,000 kg, spindle speed (max.): 12,000 rpm, coolant supply: 22 bar, Equipment: chip conveyor, rotational speed infinitely variable, Offered for sale due to upgrade to a larger MT EVO, located near Frankfurt. The machine offers top-tier accuracy.

The worst part about this listing are the photos, which do not accurately reflect the machine's real condition. The machine is in excellent working order and produces highly precise components!

Internal coolant supply 22 bar, including centrifuge.

Heidenhain TS460 for SK40,

workpiece probing system with infrared transmission.

Heidenhain TT460,

tool probing system with infrared transmission for tool measurement.

Technical data:

- 12,000 rpm

- Torque: 120 Nm (S3 25% duty cycle)

- Drive power: 23 kW (S3 25% duty cycle)

- Separate spindle cooling for consistent temperature

- Tool holder DIN SK40 with air blast function

Rotary table:

- Ø 410 mm

General features:

- Travel range X/Y/Z: 710/700/610 mm

- 48-position tool changer with double-arm gripper

- Chip conveyor

Hfodpoxyhg Njfx Addjb

- Coolant and compressed air gun

- Coolant system

- Electronic handwheel

- Work area lighting

- Cast iron machine bed, 9,000 kg

Listing

Riederich

Riederich

1,152 km

Flatbed truck

MANTGS 18.420 L Pritsche 6,2 m*KRAN HIAB HIDUO 138

Call

Condition: used, mileage: 372,811 km, power: 309 kW (420.12 HP), first registration: 05/2019, fuel type: diesel, overall weight: 18,000 kg, color: white, gearing type: mechanical, loading space volume: 12 m³, loading space length: 6,202 mm, loading space width: 2,472 mm, loading space height: 800 mm, Year of construction: 2019, TGS 18.420 L Flatbed 6.20 m with rear crane

* HIAB X-HIDUO 138 ES-3 * Foldable

* Radio remote control * 5th and 6th circuits for grapple control

* Maximum hydraulic capacity 10.20 m with a load capacity of 980 kg

* Vehicle number for customer inquiries: 4244

* Environmental sticker (green)

* Service history maintained

No liability for printing or typographical errors

Sale to commercial customers only

Subject to errors and prior sale* Subject to changes, prior sale, and errors. The description serves to identify the vehicle and does not constitute a warranty under commercial law. The description in the purchase contract is decisive.

* TOP SERVICE + QUALITY

* We are happy to provide you with a LEASING, FINANCING, or HIRE PURCHASE offer.

Hjdpfxjwa Evdo Addjfb

Warranty insurance available upon request from the insurer.

* TÜV / UVV LBW / tachometer inspection and OBU device installation by our local partners.

* Customs license plate valid for 30 days.

All customs documents for export are available, but must be requested separately.

* Toll Collect can be booked in-house.

* Free transfer from Stuttgart Airport or Metzingen (Württemberg) train station.

* ARRIVAL STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

--- Visit us on our website at

* Over 200 vehicles always in stock.

Listing

Slovakia

Slovakia

1,741 km

Universal Machining Centre

HAASUMC-750

Call

Condition: ready for operation (used), Year of construction: 2020, operating hours: 5,717 h, General Data

Measurements width 2387 mm

Measurements depth 3978 mm

Measurements height 2565 mm

Machine weight 8200 kg

Control Unit

Brand HAAS

Main Drive

Number of axis 5

Movement

X-Axis Movement 762 mm

Y-Axis Movement 508 mm

Z-Axis Movement 508 mm

Table

Table load 300 kg

Media

Chip conveyor Yes

Hfsdpfsx Hbmrsx Addeb

Additional Equipment

Wireless Intuitive Probing System

Through-Spindle Coolant

This 5-axis HAAS UMC-750 was manufactured in 2020, featuring a 762 mm X-axis, 508 mm Y-axis, and 508 mm Z-axis. It includes a spindle speed up to 12,000 rpm, ISO 40 taper, and a robust 40-position tool changer. The machine supports a maximum table load of 300 kg and offers advanced features like a wireless probing system, chip conveyor, and through-spindle coolant. Consider the opportunity to buy this HAAS UMC-750 universal machining centre. Contact us for more information.

Application Types

Milling

Listing

Bristol

Bristol

440 km

Quaser UX 300 - 15C

QuaserUX 300 - 15C

Call

Condition: used, Year of construction: 2014, Now here's a combo you don't come across every day...and we'll sell it as a full package, or split it into two lots:

2014 Quaser UX 300- 5-Axis VMC with a Halter 12 station stackable pallet pool system (this one is currently configured for Shunk Zero point pallets, but that can changed to suit) all served by a Fanuc M20i A Robot.

Quasar machines (see also Hardinge Bridgeport XR series, bult by Quaser) feature a robust construction with a rigid cast iron bed and high-quality linear guides, ensuring exceptional stability and reduced vibrations during machining operations. This structural integrity is vital for maintaining tight tolerances and high surface finishes

Note: Happy to separate the Halter Pallet Pool & Robot if required.

Quaser Spec:

Full 5-axis simultaneously machining centre with trunnion style table full C-axis 360°, B-axis +30/-120°, 15,000 RPM BBT 40 spindle, 60 tool ATC, Auto door, Blum Laser probing and touch probe system, through coolant, chilled spindle, swarf conveyor, fire suppression system, and robot integration (if required)

Photographed as arrived today, more pictures to follow once set up.

Specification:

X-travel 410 mm

Y-travel 610 mm

Z-travel 500 mm

15,000 RPM face & taper mounted BBT 40 spindle with chiller and through coolant

Heidenhain iTNC 530 HEIDENHAIN smart NC

Table dia: 320 mm

Table load: 100 kg

tool change unit 60 Pos.

total power requirement 35 kVA

weight of the machine ca. 7,4 t

dimensions of the machine ca. 4,15 x 3,8 x 3,28 m

Halter LoadAssitant 12 (Offer with the Quaser UX 300 or sold separately if required.)

Hfjdpfswzyxcex Addob

Halter's "by Fastems" LoadAssitant-2 Mill Stacker, is a stand alone unit and is supplied with a 12 station rotary stacker table, a full enclosure, light curtains and a Fanuc M20i A robot. Currently configured for Shunk Zero Point Vices, but is easily changed to suit you. for This stand alone system is the perfect solution for batch type milling work and or lights out production and can be disconnected if not required.

Speciation:

Minimum workpiece (L x W) 40 mm x 40 mm

Maximum square workpiece (L x W)145 mm x 145 mm

Maximum rectangle workpiece (L x W)40 mm x 200 mm

Height of workpiece (min - max)10 mm - 175 mm

Maximum load capacity robot arm 20 kg

Maximum total weight on rotating table 660 kg

Maximum stacking height 375 mm

Number of stacking stations (1 empty) 12

Maximum weight per station 60 kg

Max. number of workpieces at workpiece height of 10 mm 407

Max. number of workpieces at workpiece height of 20 mm198

Max. number of workpieces at workpiece height of 50 mm 77

Max. number of workpieces at workpiece height of 70 mm 55

Max. number of workpieces at workpiece height of 85 mm 44

Max. number of workpieces at workpiece height of 110 mm 33

Max. number of workpieces at workpiece height of 150 mm22

Listing

Freising

Freising

1,296 km

Pub brewery plant

Johann Albrecht (JBT)

Call

Condition: used, Complete brewery system, consisting of: - Grist mill (ROBIX) with plate weigher - 2-device brewhouse with a wort capacity of 10 hl. One vessel as mash/wort kettle with bottom heating and internal boiler. One vessel as lauter tun/whirlpool. Made by Joh. Albrecht Brautechnik. - Plate heat exchanger (SONDEX) as wort cooler - Wort aeration (Donaldson) with sterile filter - 17.75 hl hot water tank, steam-heated, with pump. Made by Joh. Albrecht Brautechnik. - 5 cylindroconical storage tanks, each with a volume of 27 hl. Made by Joh. Albrecht Brautechnik. - Various beer hoses - Diaphragm pumps (FLOJET) as booster pumps, driven by compressed air - Beer pump (SAWA) for conveying 5 m³/h - Cleaning lance for dispensing tanks - CO2 warning device (Beviclean) - Further accessories with pressure reducers, tap heads etc. - Electric steam generator (VEIT) with an output of 60 kW - Compressed air system (KAESER), air compressor with refrigeration dryer - Water treatment (PENTAIR) - Refrigeration system with compressor, buffer tank, equalising tank, refrigerant pump - Pipework

Additional title: 10 hl brewhouse with storage tanks and supply technology, largely built in 2019

Cast wort capacity: 1000 l

Material: Brewhouse from stainless steel

Features: Mash/wort kettle, lauter tun, whirlpool, wort cooling, wort aeration, hot water tank, 5 x cylindroconical storage tank, booster pump, beer pump, CO2 warning device; cleaning lance, pressure reducer, tap heads, hoses, refrigeration system, compressed air system, electric steam generator, water treatment, pipework

Hfedpfx Aexwyzaoddeb

Listing

Riederich

Riederich

1,152 km

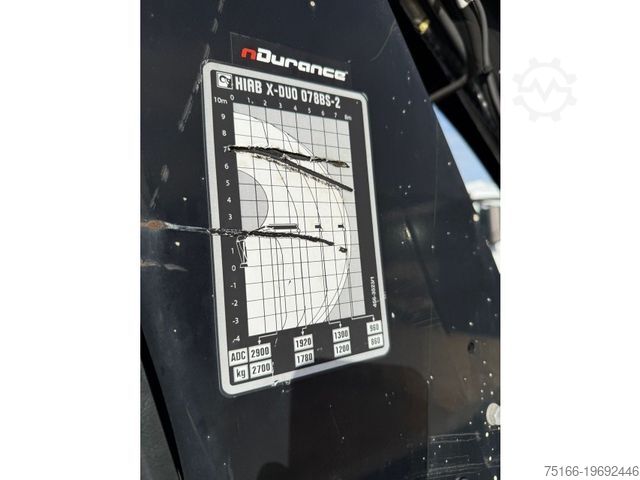

Three-way tipper van

MERCEDES-BENZATEGO 816 Kipper 2-Seiten*KRAN HIAB X 078*2xAHK

Call

Condition: used, mileage: 94,800 km, power: 115 kW (156.36 HP), first registration: 03/2019, fuel type: diesel, overall weight: 7,490 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 4 m³, loading space length: 3,800 mm, loading space width: 2,356 mm, loading space height: 400 mm, Year of construction: 2019, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), soot filter, * ATEGO 816 Tipper, 2-way tipping with ZAA towing hitch + ball head coupling

* HIAB rear crane X-DUO 078 BS-2 * 5th and 6th hydraulic circuits for grab control

* Outreach 7.30 m + lifting capacity 860 kg

CONVERSION to RADIO REMOTE CONTROL possible (additional net cost €6,600 +)

* Vehicle number for customer inquiries: 4

* Crane

* Engine version Euro VI, with OBD-C

* Active Brake Assist

* Air conditioning

* Centre seat, with 3-point seat belt

* Manual transmission

* Lane departure warning system

* Environmental badge (green)

* G 135 towing hitch, for ZAA

* Ringfeder towing coupling

* Electronic Stability Program (ESP)

* Dual-line trailer brake

* Electronic brake system with ABS and ASR

* Driver comfort suspension seat

Hfjdpfxow E T R Te Addjb

* Power windows, both sides

* Transmission G 71-6/9.20-1.0

* NA MB 60-2c, MPA low, N-speed

* Single PTO

* Particulate filter

* Digital tachograph, EC, rpm, ADR

* Cruise control

* AdBlue tank 25 l

* 12 V trailer socket, 13-pin, frame-mounted, LED

* 24 V trailer socket, 15-pin

* Body type: tipper/semi-tipper

* Roof hatch/ventilation flap

* Weight variant 8.6 t (3.8/5.7)

* Main mirror, electric, driver's side

* Heater, electronic air supply unit

* Rear spring, 5.7 t, parabolic

* Plastic tank 120 l, left

* Meiller pump, 7-piston, type 270/45

* Engine OM934, inline-4, 5.1 l, 115 kW (156 hp), 650 Nm

* Wheelbase 3620 mm

* S-Cab ClassicSpace, 2.30 m, tunnel version

* Front spring 4.0 t, parabolic

* Pre-installation for toll detection

* Fully serviced with service booklet

* Three-seater

No liability for printing or typographical errors

Sale only to commercial clients

Errors and prior sale excepted. Changes, prior sale, and errors expressly reserved. Description is for vehicle identification only and does not constitute a warranty in the legal sense. Contract description is binding.

* TOP SERVICE & QUALITY

* We are happy to provide a LEASING-FINANCING-HIRE PURCHASE offer

* Extended warranty available on request via insurance provider

* TÜV / UVV LBW / Tachograph check and installation of OBU device can be arranged with our local partners

* Export registration plates for 30 days

All export documentation possible, but needs to be requested individually

* Toll collection for Toll Collect available in-house

* Free transfer from Stuttgart Airport or Metzingen train station (Württ)

* ARRIVAL TRAIN STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP number * *

---- Visit our website at

* over 200 vehicles always in stock

Listing

Riederich

Riederich

1,152 km

Box semitrailer

SCHMITZ CARGOBULLKRONE 2-Achs ISOLIER-Koffer 13,40 m*29 T zGG

Call

Condition: used, maximum load weight: 7,390 kg, overall weight: 29,000 kg, axle configuration: 2 axles, first registration: 02/2004, next inspection (TÜV): 12/2025, loading space length: 13,410 mm, loading space width: 2,500 mm, loading space height: 2,640 mm, loading space volume: 89 m³, Year of construction: 2004, Equipment: ABS, KRONE 2-axle insulated box trailer, 13.40 m, with portal doors

* Gross vehicle weight 29,000 kg = Payload approx. 21,840 kg

* New TÜV approval available for an additional charge

* Vehicle number for customer inquiries: 3271

* ABS

* Eberspächer cargo space heater

* BPW axles

* 2-axle

* EBS, Wabco

No liability for printing or typographical errors

Sale to commercial customers only

Subject to errors and prior sale* Changes, prior sale, and errors are expressly reserved. The description serves to identify the vehicle and does not constitute a warranty under the terms of the sales contract. The description in the purchase contract is decisive.

* TOP SERVICE + QUALITY

* We are happy to provide you with a LEASING, FINANCING, or HIRE PURCHASE offer.

Warranty insurance available upon request from the insurer.

* TÜV / UVV LBW / tachometer inspection and OBU device installation by our local partners.

* Customs license plate valid for 30 days.

All customs documents for export are available, but must be requested separately.

* Toll Collect can be booked in-house.

* Free transfer from Stuttgart Airport or Metzingen (Württemberg) train station.

* ARRIVAL STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

Hedpfx Adjkf Snqodofb

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

--- Visit us on our website at

* Over 200 vehicles always in stock.

Listing

Riederich

Riederich

1,152 km

Truck-mounted crane van

MERCEDES-BENZATEGO 816 Kipper 2-Seiten*KRAN HIAB X 078*2xAHK

Call

Condition: used, mileage: 94,800 km, power: 115 kW (156.36 HP), first registration: 03/2019, fuel type: diesel, overall weight: 7,490 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 4 m³, loading space length: 3,800 mm, loading space width: 2,356 mm, loading space height: 400 mm, Year of construction: 2019, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), soot filter, * ATEGO 816 Two-way tipper with ZAA towing device + ball coupling

* HIAB rear crane X-DUO 078 BS-2 * 5th and 6th hydraulic circuit for grab operation

* Extension 7.30 m + load capacity 860 kg

CONVERSION to RADIO REMOTE CONTROL possible (additional net cost €6,600 +)

* Vehicle number for customer inquiries: 4

* Crane

* Engine specification Euro VI with OBD-C

* Active Brake Assist

* Air conditioning

* Middle seat with 3-point seatbelt

* Manual transmission

* Lane keeping assist

* Emission sticker (green)

* Trailer coupling G 135 for ZAA

* Ringfeder trailer coupling

* Stability control system (ESP)

* Two-line trailer brake

* Electronic brake system with ABS and ASR

* Comfort driver's suspension seat

* Power windows, both sides

* Transmission G 71-6/9.20-1.0

* NA MB 60-2c, MPA low, N speed

* Single PTO (power take-off)

* Particulate filter

* Digital tachograph, EC, rev counter, ADR

* Cruise control

* AdBlue tank 25 l

* 12 V trailer socket, 13-pin, frame mounted, LED

* 24 V trailer socket, 15-pin

* Superstructure type: Tipper/tipping semi-trailer

* Roof hatch/roof ventilator

* Weight variant 8.6 t (3.8/5.7)

* Main mirror, electric, driver's side

* Heater, electronic air supply unit

* Rear springs, 5.7 t, parabolic

* Plastic tank 120 l, left side

* Meiller pump, 7-piston, type 270/45

* Engine OM934, R4, 5.1 l, 115 kW (156 hp), 650 Nm

* Wheelbase 3620 mm

* S-Cab ClassicSpace, 2.30 m, tunnel

* Front springs 4.0 t, parabolic

Hfjdjw E T Sdspfx Addsb

* Pre-equipment for toll recording

* Full service history

* Three-seater

No liability for printing or typographical errors

Sale only to traders

Errors and prior sale reserved. Modifications, prior sale, and errors are expressly reserved. The description serves vehicle identification purposes and does not constitute a warranty as defined by sales law. Only the description in the purchase contract is binding.

* TOP SERVICE & QUALITY

* We are happy to offer you a LEASING-FINANCE-HIRE PURCHASE quote

Guarantee insurance available on request from the insurer

* TÜV / UVV tail-lift inspection / tachograph test and installation of OBU device by our local partners

* Export license plates for 30 days

All export customs documents are possible, but must be requested individually

* TOLL for Toll-Collect can be booked in-house

* Free transfer from Stuttgart Airport or Metzingen train station (Württ)

* TRAIN STATION FOR ARRIVAL: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH: Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

---- Visit us on our website at

* Always over 200 vehicles in stock

Listing

Riederich

Riederich

1,152 km

Reefer semitrailer

SCHMITZ CARGOBULLKRONE 2-Achs ISOLIER-Koffer 13,40 m*29 T zGG

Call

Condition: used, maximum load weight: 7,390 kg, overall weight: 29,000 kg, axle configuration: 2 axles, first registration: 02/2004, next inspection (TÜV): 12/2025, loading space length: 13,410 mm, loading space width: 2,500 mm, loading space height: 2,640 mm, loading space volume: 89 m³, Year of construction: 2004, Equipment: ABS, KRONE 2-axle insulated box trailer, 13.40 m, with portal doors

* Gross vehicle weight 29,000 kg = Payload approx. 21,840 kg

* New TÜV approval available for an additional charge

* Vehicle number for customer inquiries: 3271

* ABS

* Eberspächer cargo space heater

* BPW axles

* 2-axle

* EBS, Wabco

No liability for printing or typographical errors

Sale to commercial customers only

Subject to errors and prior sale* Changes, prior sale, and errors are expressly reserved. The description serves to identify the vehicle and does not constitute a warranty under the terms of the sales contract. The description in the purchase contract is decisive.

* TOP SERVICE + QUALITY

* We are happy to provide you with a LEASING, FINANCING, or HIRE PURCHASE offer.

Warranty insurance available upon request from the insurer.

* TÜV / UVV LBW / tachometer inspection and OBU device installation by our local partners.

* Customs license plate valid for 30 days.

All customs documents for export are available, but must be requested separately.

* Toll Collect can be booked in-house.

* Free transfer from Stuttgart Airport or Metzingen (Württemberg) train station.

Hodpfx Ajkf Snxjddofb

* ARRIVAL STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

--- Visit us on our website at

* Over 200 vehicles always in stock.

Listing

Riederich

Riederich

1,152 km

Tipper van

MERCEDES-BENZATEGO 816 Kipper 2-Seiten*KRAN HIAB X 078*2xAHK

Call

Condition: used, mileage: 94,800 km, power: 115 kW (156.36 HP), first registration: 03/2019, fuel type: diesel, overall weight: 7,490 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 4 m³, loading space length: 3,800 mm, loading space width: 2,356 mm, loading space height: 400 mm, Year of construction: 2019, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), soot filter, * ATEGO 816 Tipper, 2-way, with ZAA towing hitch + ball head coupling

* HIAB rear crane X-DUO 078 BS-2 * 5th + 6th hydraulic circuit for grapple control

* Outreach 7.30 m + Lifting capacity 860 kg

RETROFITTING to radio remote control possible (additional net cost €6,600 +)

* Vehicle No. for customer inquiries: 4

* Crane

* Engine version Euro VI, with OBD-C

* Active Brake Assist

* Air conditioning

* Middle seat with 3-point seatbelt

* Manual transmission

* Lane keeping assist

* Emission sticker (green)

* Trailer coupling G 135, for ZAA

* Ringfeder trailer coupling

* Stability control system (ESP)

* 2-line trailer brake system

* Electronic brake system with ABS and ASR

* Comfort driver's air-suspended seat

* Electric windows, both sides

* Transmission G 71-6/9.20-1.0

* NA MB 60-2c, MPA low, N-speed

* Single PTO

* Particulate filter

* Digital tachograph, EU, RPM, ADR

* Cruise control

Hfedet D Sfkjpfx Addjb

* AdBlue tank 25 l

* Trailer socket 12 V, 13-pin, fixed to frame, LED

* Trailer socket 24 V, 15-pin

* Body type: tipper/tipping semi-trailer

* Roof hatch/roof vent

* Weight variant 8.6 t (3.8/5.7)

* Main mirror, electric, driver's side

* Heating, electronic air supply unit

* Rear suspension, 5.7 t, parabolic

* Plastic fuel tank 120 l, left side

* Meiller pump, 7-piston, type 270/45

* Engine OM934, R4, 5.1 l, 115 kW (156 HP), 650 Nm

* Wheelbase 3620 mm

* S-cab ClassicSpace, 2.30 m, tunnel version

* Front suspension 4.0 t, parabolic

* Preparation for toll collection

* Full service history

* 3-seater

No liability for printing or typing errors

Sale only to business customers

Subject to prior sale and errors* Modifications, prior sale, and errors expressly reserved. The description serves to identify the vehicle and does not constitute a warranty in the sense of sales law. The description as stated in the purchase agreement is binding.

* TOP SERVICE + QUALITY

* We will be happy to provide a LEASING–FINANCING–HIRE PURCHASE offer

Guarantee insurance available upon request with insurer

* TÜV / UVV LBW / tachograph inspection and OBU device installation by our local partners

* Export license plates for 30 days

All export customs documents possible, but must be requested individually

* TOLL for Toll Collect can be booked in-house

* Free transfer from Stuttgart Airport or Metzingen (Württ) train station

* TRAIN STATION FOR ARRIVAL: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP Number * *

---- Visit us on our website at

* More than 200 vehicles in stock at all times

Trust Seal

Dealers certified through Machineseeker

Listing

Riederich

Riederich

1,152 km

Box van

MANTGL 8.190 Koffer 6,50 m LBW 1,5 T*Diff-Sperre HA

Call

Condition: used, mileage: 218,811 km, power: 140 kW (190.35 HP), first registration: 09/2019, fuel type: diesel, overall weight: 7,490 kg, next inspection (TÜV): 10/2026, color: white, gearing type: automatic, emission class: euro6, number of seats: 2, loading space volume: 38 m³, loading space length: 6,480 mm, loading space width: 2,460 mm, loading space height: 2,410 mm, Year of construction: 2019, Equipment: ABS, electronic stability program (ESP), navigation system, soot filter, tail-lift, TGL 8.190 box truck, 6.50 m body with 1.5 t tail lift.

* Rear axle differential lock

* Vehicle number for customer inquiries: 4527

* Engine version: Euro VI

* Truck navigation system

* Telligent lane departure warning system

* Rear axle differential lock

* Automatic transmission

* Green environmental badge

* Tail lift

* Electronic Stability Program (ESP)

* Reversing camera

* Cruise control

* Particulate filter

* Electric windows

* Anti-lock braking system (ABS)

* Two-seater

* Full service history

* Air-operated engine brake

* Roof hatch/ventilation flap

* Air-sprung driver's seat

* Collision avoidance assist

* AdBlue tank, plastic

* 2/3 doors

Hfodpsx Alwkofx Addeb

No liability for typographical or printing errors.

Sale exclusively to commercial buyers.

Subject to errors and prior sale. Changes, prior sale and errors expressly reserved. The description is for vehicle identification purposes only and does not constitute a warranty under sales law. The specification according to the purchase contract is binding.

* TOP SERVICE + QUALITY

* We are happy to offer you a LEASING-FINANCING-HIRE PURCHASE proposal

* Warranty insurance available upon request with the insurer

* TÜV / UVV tail lift inspection / tachograph test and installation of OBU unit by our local partners

* Export license plates valid for 30 days

* All export customs documents can be arranged, but must be requested individually

* Toll Collect toll registration available in-house

* Free transfer from Stuttgart Airport or Metzingen train station (Württ)

* ARRIVAL TRAIN STATION: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas * Alexander Pittas * Robin Pittas

WHATSAPP number *

---- Visit our website at

* over 200 vehicles permanently in stock

Listing

Riederich

Riederich

1,152 km

Three-way tipper van

MERCEDES-BENZATEGO 816 Kipper 2-Seiten*KRAN HIAB X 078*2xAHK

Call

Condition: used, mileage: 114,811 km, power: 115 kW (156.36 HP), first registration: 03/2019, fuel type: diesel, overall weight: 7,490 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 4 m³, loading space length: 3,800 mm, loading space width: 2,356 mm, loading space height: 400 mm, Year of construction: 2019, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), soot filter, ATEGO 816 Tipper, 2-way with ZAA trailer hitch + ball-type coupling

* HIAB rear-mounted crane X-DUO 078 BS-2 * 5th and 6th hydraulic circuits for grab control

* Outreach: 7.30 m, lifting capacity: 860 kg

* RETROFIT to RADIO REMOTE CONTROL possible (additional net cost: €6,600 +)

SPECIAL CLEARANCE PRICE!

* Vehicle number for customer inquiries: 4209

* Crane

* Engine specification Euro VI, with OBD-C

* Active Brake Assist

* Air conditioning

* Centre seat with 3-point safety belt

* Manual transmission

* Lane Keeping Assist

* Emissions sticker (green)

* Trailer coupling G135, for ZAA

* Ringfeder trailer coupling

* Full service history

* Electronic Stability Program (ESP)

* Two-line trailer brake

* Three-seater

* Electronic braking system with ABS and ASR

* Driver’s comfort suspension seat

* Power windows, left and right

* Gearbox G71-6/9.20-1.0

* NA MB 60-2c, MPA low, nominal speed

* Single PTO

* Particulate filter

* Digital tachograph, EU, speed sensor, ADR

* Cruise control

* Pre-installed for toll collection system

* AdBlue tank 25 l

* 13-pin 12V trailer socket, frame mounted, LED

* 15-pin 24V trailer socket

* Roof hatch/roof ventilation flap

* Weight variant 8.6 t (3.8/5.7)

* Main mirror, electric, driver’s side

* Heater, electronic compressed air supply unit

* Rear parabolic suspension, 5.7 t

* Plastic fuel tank, 120 l, left-hand side

* Meiller pump, 7-piston, type 270/45

* Engine OM934, inline-4, 5.1 l, 115 kW (156 HP), 650 Nm

* Wheelbase: 3620 mm

* S-Cab ClassicSpace, 2.30 m, tunnel

* Front parabolic spring, 4.0 t

* Preparation for later installation of loading crane

No liability for printing or writing errors.

Sales to business customers only.

Subject to error and prior sale. Changes, prior sale, and errors reserved. The description serves to identify the vehicle and does not constitute a warranty in the legal sense. The contract description is decisive.

* TOP SERVICE & QUALITY

* We can provide a LEASING, FINANCING, or HIRE PURCHASE offer

Guarantee insurance available on request via insurer

Hfodpfsvzdb Nox Addob

* TÜV / UVV tail lift / Tachograph inspection and installation of OBU device by our local partners

* 30-day export license plates

All customs documents for export available upon request

* Toll-Collect toll system can be booked in-house

* Free transfer from Stuttgart Airport or Metzingen (Württ) station

* ARRIVAL BY TRAIN: 72555 METZINGEN/WÜRTT.

* FOR ENGLISH: Andreas Pittas * Thomas Pittas * Alexander Pittas * Robin Pittas

WHATSAPP NUMBER *

Visit our website

* Over 200 vehicles always in stock

Listing

Riederich

Riederich

1,152 km

Truck-mounted crane van

MERCEDES-BENZATEGO 816 Kipper 2-Seiten*KRAN HIAB X 078*2xAHK

Call

Condition: used, mileage: 114,811 km, power: 115 kW (156.36 HP), first registration: 03/2019, fuel type: diesel, overall weight: 7,490 kg, color: white, gearing type: mechanical, emission class: euro6, number of seats: 3, loading space volume: 4 m³, loading space length: 3,800 mm, loading space width: 2,356 mm, loading space height: 400 mm, Year of construction: 2019, Equipment: ABS, air conditioning, crane, electronic stability program (ESP), soot filter, ATEGO 816 Tipper, 2-way with ZAA towbar + ball head coupling

* HIAB Rear Crane X-DUO 078 BS-2 * 5th & 6th hydraulic circuits for grab operation

* Reach: 7.30 m + Lifting capacity: 860 kg

* Conversion to remote control possible (additional net cost: €6,600+)

SPECIAL CLEARANCE PRICE!!!

* Vehicle No. for customer inquiries: 4209

* Crane

* Engine version Euro VI, with OBD-C

* Active Brake Assist

* Air conditioning

* Middle seat with 3-point safety belt

* Manual transmission

* Lane assist

* Environmental sticker (green)

* Trailer hitch G 135, for ZAA

* Ringfeder trailer coupling

* Full service history

* Stability Control Assist (ESP)

* Dual-line trailer brake

* Three-seater cab

* Electronic braking system with ABS and ASR

* Comfort driver's suspension seat

* Electric windows, both sides

* Gearbox G 71-6/9.20-1.0

* NA MB 60-2c, deep MPA, N-speed

* Single PTO

* Particle filter

* Digital tachograph, EU, RPM, ADR

* Cruise control

* Preparation for toll collection

* AdBlue tank 25 l

* Trailer socket 12 V, 13-pin, chassis mounted, LED

* Trailer socket 24 V, 15-pin

* Roof hatch/roof ventilation flap

* Weight variant 8.6 t (3.8/5.7)

* Main mirror, electric, driver's side

Hfodpfx Adew E T R Hjdsb

* Heating, electronic air supply unit

* Rear spring, 5.7 t, parabolic

* Plastics fuel tank 120 l, left

* Meiller pump, 7-piston, type 270/45

* Engine OM934, R4, 5.1 l, 115 kW (156 hp), 650 Nm

* Wheelbase 3,620 mm

* S-Cab ClassicSpace, 2.30 m, tunnel

* Front spring 4.0 t, parabolic

* Preparation for later installation of loader crane

No liability for printing or typographical errors

Sale to trade customers only

Subject to prior sale and errors. Changes and errors expressly reserved. This description serves for vehicle identification only and does not constitute a guarantee in the sense of consumer law. The purchase contract description is binding.

* TOP SERVICE & QUALITY

* We can offer leasing, financing, and hire-purchase upon request

* Warranty insurance available on request from insurer

* TÜV / UVV LBW / Tachograph testing & OBU device installation through local partners

* 30-day export license plates available

* All necessary customs documents for export can be arranged, must be requested individually

* Toll-Collect toll booking available in-house

* Complimentary transfer from Stuttgart Airport or Metzingen railway station (Württ)

* ARRIVAL BY TRAIN: 72555 METZINGEN/WÜRTT

* FOR ENGLISH * Andreas Pittas * Thomas Pittas * Alexander Pittas * Robin Pittas

WHATSAPP number *

---- Visit our website at

* Over 200 vehicles in stock at all times

Listing

Riederich

Riederich

1,152 km

Box van

MANTGL 8.190 Koffer 6,50 m LBW 1,5 T*Diff-Sperre HA

Call

Condition: used, mileage: 218,811 km, power: 140 kW (190.35 HP), first registration: 09/2019, fuel type: diesel, overall weight: 7,490 kg, axle configuration: 2 axles, next inspection (TÜV): 10/2026, color: white, gearing type: automatic, emission class: euro6, loading space volume: 38 m³, loading space length: 6,480 mm, loading space width: 2,460 mm, loading space height: 2,410 mm, Year of construction: 2019, Equipment: ABS, electronic stability program (ESP), navigation system, soot filter, tail-lift, TGL 8.190 box body, 6.50 m, with tail lift 1.5 t

* Rear axle differential lock

* Vehicle number for customer inquiries: 4527

* Engine specification Euro VI

* Truck navigation system

* Telligent lane assist

* Rear axle differential lock

* Automatic transmission

* Environmental badge (green)

* Tail lift

* Electronic Stability Program (ESP)

* Reversing camera

* Cruise control

* Particulate filter

* Electric windows

* Anti-lock braking system (ABS)

* Two-seater

Hfodpfxjx Alwqe Addeb

* Full service history

* Engine brake, air operated

* Roof hatch/roof ventilation flap

* Air-suspended driver's seat

* Collision warning assist

* AdBlue tank, plastic

* 2/3 door configuration

No liability for typographical or printing errors

Sale to traders only

Subject to prior sale and changes; errors excepted. The description is for vehicle identification and does not constitute a legal warranty. The contractual purchase description prevails.

* TOP SERVICE & QUALITY

* We are happy to offer you leasing, financing or hire purchase options

Warranty insurance available upon request from the insurer

* TÜV / UVV tail lift / tachograph inspection and OBU unit installation available through our local partners

* Customs plates for 30 days

All export customs documents can be provided on request, but must be arranged individually

* Toll registration for Toll Collect can be handled in-house

* Free transfer from Stuttgart Airport or Metzingen (Württ.) train station

* TRAIN STATION FOR ARRIVAL: 72555 METZINGEN/ WÜRTT.

* FOR ENGLISH * Andreas Pittas * Thomas Pittas

* Alexander Pittas * Robin Pittas

WHATSAPP number * *

---- Visit us on our website

* Over 200 vehicles in stock at all times

We make it easier for you to find: "robi"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Robi (384)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month