Used Stone for sale (1,095)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Quarry crusher, Hard stone cone crusherConcrete & stone crusher, mobile crusher

Call

Condition: new, functionality: fully functional, Year of construction: 2025, A compound cone crusher is a type of crusher used in mining and aggregate industries to break down rock into smaller pieces. It combines the advantages of both traditional cone crushers and modern technology to achieve higher efficiency, better product shape, and reliable operation. Here are its key features, working principles, and typical usages:

### Key Features:

Iodpfxotxhybj Addstb

1. Combination of Crushing Technologies:

- Integrates both spring and hydraulic cone crushers to offer improved performance.

2. High Crushing Ratio:

- Capable of crushing materials into fine and uniform sizes with high reduction ratios.

3. Durability:

- Built with robust materials and components for long-lasting operation.

4. Adjustable Settings:

- Allows for easy adjustment of the crusher settings to control the size of the output material.

5. Efficient Crushing Chamber:

- Designed to minimize material clogging and ensure continuous operation.

### Working Principles:

1. Material Feeding:

- Raw material is fed into the crusher through a hopper.

2. Crushing Process:

- The material enters the crushing chamber, where it is crushed between a fixed cone (outer shell) and a moving cone (inner shell).

- The moving cone is supported and driven by an eccentric shaft, which rotates and gyrates to crush the material against the fixed cone.

3. Adjustment Mechanism:

- The gap between the moving cone and the fixed cone can be adjusted to determine the size of the output material.

4. Discharge:

- Once crushed, the material exits the crusher through the bottom discharge opening.

### Typical Usages:

1. Mining Industry:

- Used for crushing various kinds of ores and rocks, particularly in secondary and tertiary crushing stages.

2. Aggregate Production:

- Ideal for producing gravel, sand, and crushed stone for construction and infrastructure projects.

3. Recycling:

- Utilized for crushing construction waste and recycling materials to create reusable aggregate.

4. Construction Industry:

- Applied in producing concrete and asphalt aggregates, road base, and other construction materials.

Types of Cone Crushers

Standard Cone Crusher: Suitable for medium crushing tasks.

Short Head Cone Crusher: Used for fine crushing applications.

Hydraulic Cone Crusher: Equipped with hydraulic systems for improved operation.

Multi-Cylinder Hydraulic Cone Crusher: Provides better control and higher productivity.

Spring Cone Crusher: Uses springs to protect the machine from overloading.

Applications of Cone Crushers

Mining: Crushing of ores for further processing.

Construction: Producing aggregates for roads, bridges, and buildings.

Quarrying: Breaking down rocks for use in gravel or crushed stone products.

Recycling: Processing of demolition debris and concrete.

In summary, a compound cone crusher is a highly efficient, versatile, and durable piece of equipment ideal for various crushing applications in the mining, aggregate, recycling, and construction industries.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mingyuan Stone & rock crusherImpact crusher for sand gravel crushing

Call

Condition: new, power: 75 kW (101.97 HP), Year of construction: 2025, An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material. Impact crushers are versatile and widely used in various industries for the crushing of hard, abrasive materials. They operate by applying force on the material to be crushed, breaking it into smaller pieces. Here is a general introduction to impact crushers:

The impact crusher is a versatile machine used for various applications in construction, mining, and recycling industries. Below are some of the key applications of an impact crusher:

1. Primary and Secondary Crushing

Impact crushers are commonly used in both primary and secondary crushing stages. In primary crushing, they break large rocks into smaller, more manageable sizes, and in secondary crushing, they refine the material further into smaller grades.

2. Production of Aggregates

Impact crushers are widely used in the production of aggregates for construction. They are effective at producing a wide range of materials, including:

Crushed stone for road construction.

Sand for concrete and asphalt production.

Gravel for general construction and drainage.

3. Recycling

One of the most significant applications of impact crushers is in the recycling industry, especially for processing construction and demolition (C&D) waste, which includes materials like concrete, brick, and asphalt. The crushers help convert waste into usable products such as:

Recycled concrete aggregates (RCA).

Asphalt.

Recycled sand and gravel.

4. Mining Industry

Itodpfov E Ddlsx Addjb

Impact crushers are used in the mining industry to process ore materials. These crushers help break down large rocks and ores into smaller pieces, making them easier to process for extraction of valuable minerals like gold, copper, and other metals.

5. Production of Manufactured Sand

In the production of manufactured sand for concrete, impact crushers are used to break down larger rocks into fine particles, which are then used as an alternative to natural sand. This is especially useful in areas where natural sand is scarce or environmentally protected.

6. Construction and Road Building

Impact crushers are integral in the production of materials for road construction, such as base and sub-base materials. These materials are crucial for the stability and durability of roads, highways, and foundations.

7. Industrial Applications

Impact crushers are also used in various other industrial applications, such as:

Cement production: Crushing limestone and other materials for cement manufacturing.

Glass recycling: Breaking glass waste into smaller pieces for recycling.

8. Demolition and Dismantling

Impact crushers are used in demolition projects where buildings or structures need to be demolished and the materials crushed for reuse or disposal. They help reduce the size of debris like concrete, asphalt, and bricks into smaller, manageable pieces.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Stone crusher /rock crushing equipmentFixed & Mobile stone crushing plant

Call

Condition: new, Year of construction: 2025, Introduction Of Jaw Crusher Plant

The capacity vary according customer request. And in order to meet the different demands of customers, the production line can equip with cone crusher, dust removal equipment and other equipment. It is suitable for the materials like hard limestone, granite,basalt, pebble, metallurgy slag and artificial sand making work. It is widely used in the industries of hydroelectric, building materials, highway, and urban construction. And according to different technological requirement, various types of equipment can be combined to meet the demands of different customers.

Product Advantages of Stone Crusher Machine Plant

1.High reliability, good stability

2.Convenient maintenance, easy operation

3.Low operation costs, wide application range

4.Laminating crushing makes good discharging grain shape

We also provide other stone crushing solutions like

1. Vibrating feeder + Jaw crusher + Fine jaw crusher + Vibrating screen

2. Vibrating feeder + Jaw crusher + Impact crusher + Vibrating screen

3. Vibrating feeder + Heavy hammer crusher + Vibrating screen

4. Sand Production Line

5. Gravel / Aggregate production line

A stone crushing plant for sand and aggregate production involves several stages and equipment. Here's an overview of the process and the main components involved:

Process Overview

Isdpfjq Nyy Esx Addotb

1. Primary Crushing: Large stones from the quarry are fed into a primary crusher, typically a jaw crusher, which reduces them to smaller, manageable sizes.

2. Secondary Crushing: The output from the primary crusher is further reduced in size by a secondary crusher, usually a cone crusher or impact crusher.

3. Screening: The crushed material is separated into different size fractions using vibrating screens. Oversized material is returned to the crushers for further reduction.

4. Sand Making: For producing sand, the material might be passed through a sand making machine, like a vertical shaft impact crusher, to achieve the desired shape and size.

5. Washing: The final product is often washed to remove impurities and improve the quality of the aggregate.

6. Stockpiling: The finished product is stored in stockpiles before being transported to customers.

Main Components of stone crushing plant

1. Jaw Crusher: Used for primary crushing of large stones.

2. Cone Crusher or Impact Crusher: Used for secondary crushing to produce finer aggregates.

3. Vibrating Screen: Separates the crushed material into different size fractions.

4. Sand Making Machine: Special equipment for producing sand.

5. Belt Conveyors: Transport materials between different stages of the process.

6. Vibrating Feeder: Feeds raw material into the crushers evenly and continuously.

7. Sand Washer: Cleans the sand by removing impurities.

8. Control System: Manages the entire process, ensuring efficient and safe operation.

Implementing a well-designed stone crushing plant can significantly increase production efficiency and produce high-quality sand and aggregate.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mobile stone crusher /Portable crusher50-350 t/h mobile stone crushing station

Call

Condition: new, power: 75 kW (101.97 HP), Year of construction: 2025, A mobile jaw crusher is a type of crushing machine that is equipped with a jaw crusher and is mobile in nature. This crusher is designed to be moved around and taken to various locations, especially those where processing materials are needed on-site. Mobile jaw crushers are widely used in industries such as mining, construction, and recycling for processing a variety of materials.

Here are the key features and components of a typical mobile jaw crusher:

1. Jaw Crusher:

- The primary crushing unit of the mobile jaw crusher is the jaw crusher itself. It consists of a fixed jaw and a movable jaw, with the material being crushed between them.

2. Mobile Chassis:

- The crusher is mounted on a mobile chassis, which may have tracks for mobility or be wheeled for easy transport. The mobility of the chassis allows the crusher to be easily moved between different work sites.

3. Feeder:

- A vibrating feeder is typically included to feed the material into the jaw crusher. It ensures a consistent and controlled feed of the material to the crushing chamber.

4. Engine or Power Source:

- Mobile jaw crushers are powered by diesel engines or electric motors. The choice of power source depends on factors such as the availability of electricity and the need for mobility.

Itodpfx Adeq I N Atedob

5. Control Panel:

- A control panel is provided for operators to manage and monitor the crusher's operation. It may include controls for starting and stopping the crusher, adjusting the discharge setting, and monitoring various parameters.

6. Hydraulic System:

- Mobile jaw crushers often feature a hydraulic system to adjust the crusher's settings. This includes the adjustment of the jaw crusher's CSS (Closed Side Setting), which influences the product size.

7. Conveyor Systems:

- Conveyors are used to transport crushed material from the jaw crusher to the next stages of the processing plant or for stockpiling. Some mobile jaw crushers have integrated conveyor systems.

8. Magnetic Separator (Optional):

- Some mobile jaw crushers come equipped with a magnetic separator to remove metal contaminants from the crushed material, preventing damage to downstream equipment.

9. Dust Suppression System (Optional):

- To control dust generated during the crushing process, some mobile jaw crushers may be equipped with dust suppression systems.

10. Remote Control (Optional):

- Remote control capabilities allow operators to control the crusher from a distance, enhancing safety and convenience.

11. Application:

- Mobile jaw crushers are used for primary crushing of various materials, including hard rock, construction and demolition waste, concrete, asphalt, and natural aggregates.

12. Versatility:

- Mobile jaw crushers are versatile and can be used in various applications. They are suitable for both recycling and quarrying operations, offering flexibility in processing different types of materials.

Mobile jaw crushers are beneficial for operations that require frequent relocation or for processing materials in remote locations. They provide a cost-effective solution for on-site crushing and are widely used in the construction and mining industries. Operators should follow safety guidelines and manufacturer recommendations for proper operation and maintenance.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Bauxite Granite Bentonite Barite Crusher

Mingyuan hard stone jaw crusher machineBauxite Granite Bentonite Barite Crusher

Call

Condition: new, power: 110 kW (149.56 HP), Year of construction: 2025, Bauxite Crusher:

Bauxite is an aluminum ore, and crushers or mills are used to break down the bauxite into smaller pieces for further processing. Jaw crushers, impact crushers, or cone crushers may be used for this purpose.

Itsdpfjq Nx Apsx Addeb

Granite Crusher:

Granite is a hard and durable natural stone. Crushers used for granite crushing typically include jaw crushers, impact crushers, and cone crushers. These crushers can handle the varying hardness of granite and produce different sizes of crushed products.

Bentonite Crusher:

Bentonite is a type of clay with excellent water-absorbing and plasticity properties. Crushers such as jaw crushers or cone crushers are used to break down the bentonite into a manageable size for further processing.

Barite Crusher:

Barite, also known as baryte, is a mineral consisting of barium sulfate. Crushers like jaw crushers and cone crushers are commonly used in the crushing process of barite. Impact crushers may also be used for shaping and processing finer particles.

For each of these minerals, the selection of the appropriate crusher depends on factors such as the hardness of the material, the required final product size, and the specific characteristics of the deposit. It's also important to consider whether a primary crusher, secondary crusher, or even tertiary crusher is needed in the processing flow.

Additionally, for certain applications, grinding mills may be employed after the initial crushing stage to further reduce the size of the particles. Grinding mills suitable for these minerals might include ball mills, Raymond mills, or vertical roller mills, depending on the specific requirements of the process.

Remember that the choice of crushers and mills is often part of a larger mineral processing plant design, and the selection process should take into account the overall production requirements, mineral characteristics, and economic considerations.

Discover more used machines

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mobile / Stationary stone crusher plantSand & aggregate production plant

Call

Condition: new, Year of construction: 2025, A sand aggregate production plant is a facility where various types of aggregates (such as sand, gravel, crushed stone, or recycled concrete) are produced for use in construction and other applications. These plants typically include various stages of processing, from raw material extraction to the final product.

Here are the key components and processes typically involved in a sand aggregate production plant:

1. Raw Material Extraction:

- Quarrying or Mining: Aggregates are often extracted from quarries, mines, or riverbeds. Depending on the type of aggregate, the extraction process may involve drilling, blasting, or dredging.

2. Primary Crushing:

- Jaw Crusher or Gyratory Crusher: The extracted raw material is usually transported to the plant and fed into a primary crusher, where large rocks are broken down into smaller pieces.

3. Secondary Crushing:

- Cone Crusher or Impact Crusher: The crushed material from the primary crusher may undergo further reduction in size through secondary crushing.

4. Screening:

- Vibrating Screens: After crushing, the material is often screened to separate different sizes of aggregates. This process ensures that the final product meets the required specifications.

5. Washing:

- Sand Washers: In some cases, especially for sand production, washing is done to remove impurities, clay, and fines from the aggregates, ensuring a cleaner and higher-quality product.

Isdpfx Asq Ngb Djddstb

6. Grading and Sorting:

- Classifiers or Graders: After washing and screening, the aggregates may go through additional processes to separate them based on size or quality.

7. Stockpiling:

- Stockpiles: The final aggregates are usually stockpiled for storage before being transported to construction sites or other end-users.

8. Aggregate Storage and Handling:

- Storage Bins or Silos: Larger production plants may have storage facilities, such as bins or silos, to store different types and sizes of aggregates before distribution.

9. Quality Control:

- Laboratory Testing: Regular quality control testing is performed on aggregates to ensure they meet specifications for strength, size, gradation, and other properties.

10. Environmental Considerations:

- Water Management: Some plants incorporate water management systems to recycle and reuse water used in the washing process, minimizing environmental impact.

11. Transportation:

- Conveyors or Trucks: Aggregates are typically transported from the production plant to construction sites by conveyors, trucks, or other means.

Listing

Zheng Zhou Shi

Zheng Zhou Shi

8,333 km

Crushing equipment

Mingyuan stone crusher machinegravel & aggregate production equipment

Call

Condition: new, Year of construction: 2025, Gravel and aggregate production equipment is used to crush, screen, and process stones, rocks, and other materials for the construction industry. This equipment is essential in producing various types of aggregates, including crushed stone, gravel, sand, and recycled concrete, which are used in the construction of roads, buildings, bridges, and other infrastructure projects. Here are some common types of equipment used in gravel and aggregate production:

1. Jaw Crusher:

- Jaw crushers are primary crushers used to break down large rocks into smaller, more manageable pieces. They are essential for the initial stage of aggregate production.

2. Impact Crusher:

- Impact crushers are used to crush rocks and stones with the help of impact force. They are suitable for shaping and producing fine aggregates.

3. Cone Crusher:

- Cone crushers are often used for secondary and tertiary crushing in aggregate production. They produce well-shaped and finely graded aggregates.

4. Vertical Shaft Impact (VSI) Crusher:

- VSI crushers are designed for shaping and producing high-quality artificial sand. They are suitable for processing materials with high abrasiveness.

5. Screens:

- Vibrating screens are used to separate different sizes of aggregates. They classify the material based on particle size and ensure that the final products meet specified gradation requirements.

6. Scalping Screens:

- Scalping screens are used to remove oversized materials before they reach the primary crusher. This helps to optimize the crushing process and prevent damage to the equipment.

7. Washing Equipment:

- Washing equipment, such as sand screws or log washers, is used to remove impurities and fine particles from aggregates. This is particularly important for producing high-quality concrete sand.

8. Conveyors:

- Conveyors are used to transport materials between different stages of the crushing and screening process. They play a crucial role in enhancing efficiency in material handling.

9. Stackers and Reclaimers:

- Stackers are used to create stockpiles of processed aggregates, while reclaimers are used to retrieve the material from the stockpile. Both are essential for efficient material storage and handling.

10. Crushing Plants:

Iodoq Nxz Dspfx Addstb

- Complete crushing plants include various types of crushers, screens, and conveyors integrated into a single system. These plants are designed to handle large volumes of material efficiently.

Listing

Norway

Norway

762 km

Construction equipment

HinowaTP2000 Vacuum lifter for stone slabs

Call

Year of construction: 2011, condition: used, Serial number: 2xxxx

Please contact ATS Norway for more information

Please provide reference number upon request: 20426

Specifications:

- 2011 model

- 845 kg

- 9.6kW

- Max lifting capacity of 140 kg

Itsdpfjwi Rxisx Addsb

- Ready to ship

Description:

We have a 2011 Hinowa TP2000 Vacuum lifter for stone slabs for sale.

Everything works as it should according to the owner.

Efficient vacuum lifter that makes the job much easier for the gardener who will carry out the job.

Ready to ship

Own weight: 845

Total Weight: 845

Kw: 9.6

Model: TP2000 Vakumløfter til steinheller

Listing

Norway

Norway

768 km

AMW Stone Spider

AMW Stone Spider

Call

Condition: used, Year of construction: 2019, New: No

Field of application: Construction

Serial number: 03xxxx

Please contact ATS Norway for more information

Please provide reference number upon request: 16463

Itedpovg Hvajfx Addeb

Specifications:

-2019 model

- 2050 engine hours

- 347 operating hours

- Hc 95 Montabert hammer

- 390 compressor hours

- L5 Gps

- Straight grinder

- Rotabom

- Winch

- Central grease

- 249cm machine width

- 30 cm belt width

- Range of 4.90m

- 40cm2 drilling circle

- Overcarriage can turn 360 degrees

- Service history

- Commuting on belts

- Delivery by agreement

Description:

Great Stone Scout sold with few hours.

Just had 1000 hours of service.

Has a reach of 4.90 m and can drill approx. 40 cm2 in one space.

Comes with L5 Gps and straight grinder.

Delivery by agreement.

Hours: 968

Width: 249

Listing

Schermbeck

Schermbeck

795 km

Stone cutting saw

HusqvarnaHusqvarna TS 400 F Steintrennsäge NEU

Call

Year of construction: 2025, condition: new, functionality: fully functional, Husqvarna TS 400 F Masonry Saw NEW

Husqvarna TS 400 F Masonry Saw – NEW | 125 mm Cutting Depth | 400 mm Blade | 230 V Electric Motor

Item No.: 965 14 81 01

Technical Specifications:

Manufacturer: Husqvarna

Model: TS 400 F

Condition: NEW

Operating Weight: 100 kg

Blade Diameter: 400 mm

Bore Diameter: 25.4 mm

Max. Cutting Depth: 125 mm

Motor: Electric

Voltage: 230 V

Water Tank: 40 litres

Starting System: Direct start

Highlights & Features:

- Includes 400 mm cutting blade – ready for immediate use

- Robust slurry collection tray for clean operation

- High-performance water pump for effective cooling

- Adjustable cutting table with angle stop

- Precise cuts in concrete, stone, and tiles

- Ergonomic design for comfortable operation

- Stable construction – ideally suited for tough job site conditions

- Made by Husqvarna – proven professional quality

Fields of Application:

✓ Structural and interior construction

✓ Paving and natural stone processing

✓ Tiling and stonemasonry businesses

✓ Landscaping and garden construction

✓ Refurbishment and renovation works

✓ Construction companies and municipalities

Location: Warehouse D-46514 Schermbeck (NRW) – Inspection & collection possible

Delivery: Nationwide & international delivery upon request

Other sizes & models available!

➡️ Masonry saws with various cutting depths & blade diameters – also available with 400 V or diesel drive

Buy Husqvarna Masonry Saw | TS 400 F NEW | Masonry Saw with Blade | Cutting Table with Angle Stop | 400 mm Masonry Saw | 125 mm Cutting Depth | Husqvarna TS Series | Electric Masonry Saw | Professional Stone Cutting Technology

Itjdpfx Aeya Huysddsb

Your reliable partner for cutting and separation technology:

Claudio Macagnino Construction Machinery & Commercial Vehicle Trading GmbH

➡️ Contact us now & secure immediately available new equipment!

We are happy to offer a virtual viewing of the machine via video call upon request.

Listing

Wiefelstede

Wiefelstede

785 km

Stone cutter

Stahlmax 6 cm Steine

Call

Condition: excellent (used), Slab cutter, paving stone cutter, stone cutter, paving stone cutter

-for effortless cutting of slabs and paving stones to length through the translation of the eccentric lever

-High stability with low weight

-precise guidance of the cutting blades

-Pendulum-mounted upper blade for cutting materials with a conical cross-section (curbstones)

Itsdpfx Adeb A Rz Asdob

-max. for 6 cm stones

-Weight: 10 kg

Listing

Oberleichtersbach

Oberleichtersbach

1,053 km

Stone gripper

STC B.V.Steinzange Steingreifer

Call

Condition: excellent (used), functionality: fully functional, overall weight: 3,300 kg, Year of construction: 2010, Model: GVZ 3000-D-S

Opening width: approx. 2.60 m

incl. CW55 adapter plate (e.g. for CAT 345)

Itsdpjtgpg Isfx Addsb

Listing

Bitburg

Bitburg

902 km

Stone and tile bridge saw

ACHILLITAG80 - WS

Call

Year of construction: 2013, condition: excellent (used), Robust and compact bridge saw with fixed bridge for cutting stone tiles and slabs up to 800 mm long:

Special design of the beam for maximum cutting precision;

Water collection tray with built-in water circulation system for cooling the blade;

Itodpfxsi Akvvo Addob

Robust and compact design.

Roller conveyor front

Roller conveyor rear

Saw blade size: 350 mm

Motor power: 2 KW

Voltage: 230 Volt

Weight: 173 kg

Mobile

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Wiefelstede

Wiefelstede

785 km

Stone cutter

StahlAL 50

Call

Condition: excellent (used), Slab cutter, paving stone cutter, stone cutter, paving stone cutter

-for effortless cutting of slabs and paving stones to length through the translation of the eccentric lever

-High stability with low weight

- precise guidance of the cutting blades

-Pendulum-mounted upper blade for cutting materials with a conical cross-section (curbstones)

Itedpfob A I Sfjx Addeb

-Working length: 500 mm

-Weight: 100 kg

Listing

Wiefelstede

Wiefelstede

785 km

74 grinding stones

unbekanntRund 50 x 65 mm

Call

Condition: good (used), grinding stone, grinding pin

Iodpfx Ajb A Nc Rjddjtb

-Recording: M12

-Outer diameter: 50 mm

-Length: 65 mm

-Quantity: 74 pieces

-Sale: only complete set

-Weight: 28 kg

Listing

Germany

Germany

1,034 km

Attachment - Other

Wheel Wash SystemOktopus Stone 2 RU

Call

Year of construction: 2023, condition: used, 2023 | Wheel Wash System Oktopus Stone 2 RU | Used Attachment - Other

📍Location: Germany, Offenbach am Main

🚛 Delivery available to your destination – Use our shipping calculator to estimate transport costs!

Itsdpfjx Nz A Eex Addob

💰 Buy Now for EUR 25900 or Make an Offer.

Payment at delivery available for an affordable fee (subject to approval)*

👷♂️ Inspected by an independent expert

0 inspection points 0 approved ✅ 0 imperfect ℹ️ 0 issues ⚠️

📌 Inspector's Comment:

Disassembled system. One bay, one tank with electrics, 4 pcs of concrete ramps and some grills. Bay dimension: W:3m x L: 5,8m x H:2,07m (sides can be dismounted, rolling plane is at c.a 0,45m) Tank dimension (28m3): W: 2,05 x L:4,27 =3,07 withouth control box) x H:2,16m Conrete ramps: W:1m L:3,55

📄 Want to see the full inspection, extra photos, or a video?

Tip: The reference "39762 Equippo" is commonly used when looking up more details online.

💡 Why this machine and our service stands out:

✔ Thorough inspection by professionals

✔ Jobsite delivery available

✔ Money-Back Guaranteed

✔ Secure and flexible payment options

🔄 Considering other equipment options?

We offer helpful tools and resources for all equipment owners and operators – easily accessible on our platform.

Listing

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

1,192 km

Stone cutting saw

Fuhrer und BachmannT

Call

Condition: excellent (used), Stone cutting saw with diamond blade

Itjdew Evznopfx Addob

Listing

Germany

Germany

1,034 km

Stone Production Plant

OmagTronic S22 140-90

Call

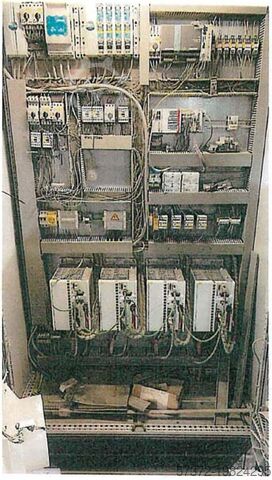

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Iodjw R Uziepfx Addjtb

Listing

Gräfenberg

Gräfenberg

1,179 km

Natural stone bridge saw

SpielvogelMultifräser M325MX

Call

Operating hours: 13,373 h, condition: used, functionality: limited functionality, main saw diameter: 500 mm, table length: 1,500 mm, table width: 3,200 mm, machine/vehicle number: 2964, Spielvogel bridge saw with fully rotatable table.

Saw:

- Cutting length: 3300 mm

- Rail length: 3500 mm

- Max. saw blade diameter: up to 600 mm

- Height adjustment: 500 mm

Ijdpfx Asx Thr Ueddotb

Table:

- 360° rotatable and lockable (hydraulically with hand pump), stops adjustable every 90°.

- Table equipped with pneumatic rollers or omnidirectional rollers (see photos).

- Table dimensions with boards: 3000 x 2000 mm.

All documents are still available.

Listing

Wadersloh

Wadersloh

872 km

Stone band

SieboTecSteinband

Call

Year of construction: 2025, operating hours: 7 h, condition: new, functionality: fully functional, Our semi-mobile electric stone conveyor for sorting rollable materials such as stones. To be placed directly behind a drum screen for the separation of stones from green waste, compost, or soil. Easily powered via a 16-amp electrical connection. The conveyor angle and belt speed are adjustable. Demonstration unit from 2025 with

Iedpjrhkpzjfx Addetb

Listing

Köln

Köln

842 km

Deck oven stone oven 8/6

FriedrichEtagenofen Steinbackofen premium

Call

Condition: excellent (used), Year of construction: 2023, functionality: fully functional, For sale is a stone deck oven / deck oven from Friedrich in Solingen. The oven is the 800/600 model. It was purchased at the end of 2023 and has been in use for less than 1.5 years. The condition is very good. Viewing by appointment. Further information about the oven can be found on the manufacturer's website. VAT can be shown separately!

Iodpfew S T Htox Addstb

Trust Seal

Dealers certified through Machineseeker

Listing

Herstal

Herstal

798 km

Small cutting machine - Stone/Marble/Granite

ZambonScie

Call

Year of construction: 1995, condition: used, functionality: fully functional, Compact bridge saw, perfect for cutting stone, marble, and granite. The machine is fully functional.

Features:

Hydraulic table, very convenient to use

Electric head movement

Iedpfx Asx A Dc Seddjtb

Blade: Ø 600 mm

Z-axis stroke: 500 mm

Listing

Pressbaum

Pressbaum

1,558 km

EURO stone removal and washing machine

JabelmannTWM 2000 D-DR

Call

Condition: new, functionality: fully functional, total length: 2,200 mm, total width: 2,200 mm, total height: 2,100 mm, overall weight: 680 kg, EURO Destoner and Washing Machine TWM 2000 D-DR

With automatic stone discharge and counterflow washing

Long feed chute and stone chute

Two double-bearing, driven support shafts

Heavy-duty drive chains

Four discharge paddles

Large discharge ring, water consumption approx. 1.0 – 4.8 m³/h depending on contamination and washing capacity

Drive motor 2.2 kW/400 Volt

Itedjx Swptjpfx Addsb

Drum length approx. 1100 mm

Drum diameter approx. 1800 mm

Machine length approx. 2200 mm

Machine width approx. 2200 mm

Machine height approx. 2100 mm

Weight approx. 680 kg

Capacity max. 20 t/h.

Listing

Siegen

Siegen

910 km

Machining center

Eckert Cutting Technology GmbHOpal Waterjet Stone Version

Call

Condition: new, Year of construction: 2026, For sale: versatile Eckert Opal Waterjet cutting system, ideal for processing stone (natural stone, marble, granite), but also suitable for a variety of other materials. Waterjet cutting is performed without thermal impact, enabling precise and clean cutting edges. Perfect for complex contours, inlays, cutouts, or demanding shapes in stone.

🛠 Technical Specifications & Equipment (Manufacturer Data)

Working width: 1,000 – 6,000 mm

Working length: 1,000 – 12,000 mm

Cuttable material thickness (waterjet 2D): 0.5 – 250 mm

Cuttable material thickness (waterjet 3D, optional): 0.5 – 150 mm

Positioning speed: up to 25,000 mm/min

Positioning accuracy: ± 0.025 mm

Design: Gantry construction with closed steel profiles for maximum stability and durability. The cutting tank is statically decoupled and corrosion-protected.

Iedpfx Adex A Tr Njdetb

Control system: Modern CNC control with touch display (Corning® Gorilla® Glass) – intuitive to operate for efficient workflow.

Cutting process: Pure water or abrasive waterjet cutting; optional 5-axis cutting head available for 3D/bevel cutting.

Optional additional equipment (if available / to be specified):

[e.g. “Pro-X 3D Cutting Head”, “Abrasive Cutting”, “Multiple Cutting Heads (e.g. 2-Head / 4-Head)”, “CAD/CAM Software”, “Water Softening System”, “Scraper Chain Conveyor”, “Wastewater / Filtration Unit”, etc.]

🎯 Ideal for:

Stone and natural stone processing businesses, marble or natural stone design workshops.

Companies requiring precise, heat-free cuts for contours, inlays, cutouts, or shaped stones.

Operations that value clean cutting quality, minimal reworking, and high flexibility in terms of materials.

Projects with complex shapes, bevel cuts, or 3D processing – especially with the optional 3D cutting head.

Listing

Castello di Godego

Castello di Godego

1,523 km

Cutting Machine for Squaring Stone Block

BretonEASY2WIRE

Call

Condition: new, Year of construction: 2021, functionality: fully functional, total height: 5,400 mm, total length: 8,300 mm, total width: 2,300 mm, warranty duration: 12 months, input voltage: 380 V, input frequency: 50 Hz, Machine for squaring blocks and cutting slabs and thick slabs, featuring a heavy-duty, arc-welded steel structure, which is heat treated to ensure the required stiffness of the system and a top cutting precision.

Extremely user-friendly, the machine is provided with a control console with touch-screen housed in the electric cabinet and a mobile button panel to actuate the main working axes.

The machine needs to be adapted for different voltages and frequency.

The machine is not available for North America.

Itjdpfx Ajtwww Hsddob

We make it easier for you to find: "stone"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Stone (1,095)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you