Used Wobble for sale (19)

Eislingen/Fils

Eislingen/Fils Wobbling and Riveting Machine

EDELStanzall 403

Kaufungen

Kaufungen Wobble riveting machine

SteinelNR 10

Schlitz

Schlitz Wobble riveting machine

DUNKESDNX 05

+44 20 806 810 84

Germany

Germany Crushing equipment

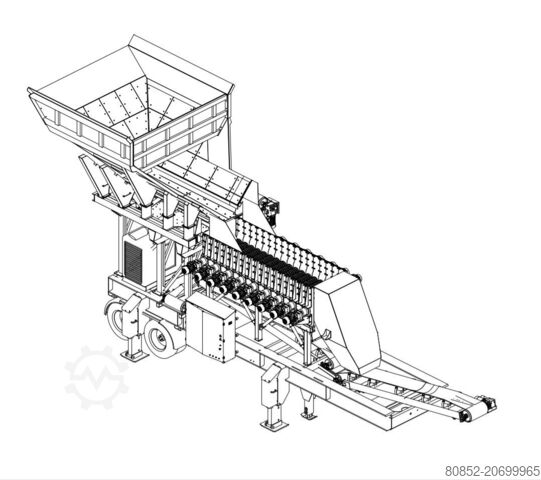

Constmach Wobbler FeederWobbler Feeder / Feeding for Crusher

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crusher

PolygonmachWF wobbler feeder

Discover more used machines

Turkey

Turkey Impact crusher

PRO-150 MOBILE IMPACT CRUSHERPRO-150 MOBILE CRUSHER | WOBBLER FEEDER

Turkey

Turkey Wobbler feeder

FABO FEEDERWOBBLER FEEDER

Turkey

Turkey Wobbler Feeder/ Feeding

ConstmachWobbler Feeder / Feeding for Crusher

Maastricht

Maastricht Wobbler screen Kleemann

Kiel

Kiel LEVIBRETON ONE surface sanding machine

BretonLEVIBRETON ONE

Hauzenberg

Hauzenberg Engraving laser, engraving machine, 4th axis

LD-LaserLG50Q 60Watt Faserlaser

Hauzenberg

Hauzenberg CO2 Laser Engraving Machine 30Watt

LD-LaserLD-RF-30

Hauzenberg

Hauzenberg Engraving laser engraving machine

LD-LaserlQ30G 30Watt Faserlaser

Siedlce

Siedlce Circular saw sharpener

CORMAKJMY-870

Siedlce

Siedlce Laser welding machine 2000W

CORMAKWL2000

Hessisch Lichtenau

Hessisch Lichtenau Oscillating rivet head, oscillating riveting machine, rivet head

BODMER KÜSNACHTFMK 3

Wissen

Wissen Programmable focusing optics

TRUMPFPFO 3D

Celle

Celle Measuring system

ZollersmarTcheck/CNC

Germany

Germany Remaining Stock

Thielicke/Schlenker & Cie/Müller/Berg & SchmidWN6/ATLAS W4/OMP67F/Mini Compact

Used Wobble (19)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84