DepalletizerFANUC

M-410 iB 160

Depalletizer

FANUC

M-410 iB 160

Year of construction

2003

Condition

Used

Location

Fumane (Verona)

Show images

Show map

Machine data

- Machine type:

- Depalletizer

- Manufacturer:

- FANUC

- Model:

- M-410 iB 160

- Year of construction:

- 2003

- Condition:

- used

- Operating hours:

- 10,000 h

Price & Location

- Seller location:

- Via Incisa 1, 37022 Fumane (Verona), Italy

Call

Details about the offer

- Listing ID:

- A18007671

- Reference number:

- DEPAL31

- Update:

- 16.12.2024

Description

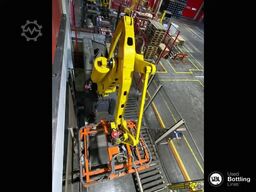

Used Robot Depalletizer Fanuc 2003 – The Ultimate Solution for Depalletizing Operations

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

Iodovgvx Dopfx Aadsan

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

The classic push system has this limitation, it cannot process bottles other than round ones.

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

Are you looking for a reliable and efficient robot depalletizer for your business operations? Look no further than the 2003 Fanuc Robot Depalletizer model M-410 iB 160. Equipped with a pick-up head for cardboard and an available base, this depalletizer is designed specifically for depalletizing tasks.

With its intelligent cable routing inside the hollow wrist, high operating speeds, and high inertia and wrist moments, this machine can handle large grippers and heavy payloads with ease. Its 6-axis control servo gripper provides better adaptability in handling products of different sizes.

Operating within an optimized workspace and with high vertical travel, this robot can depalletize products up to a height of almost 2.7 meters. The integrated base and controller in the pedestal (or the available non-pedestal version) save floor space and simplifies transportation and installation.

Upgrade your depalletizing operations with the 2003 Fanuc Robot Depalletizer – the ultimate solution for efficient and effective depalletizing. With a gripper head for depalletizing one layer of bottles at a time (inflatable)

Botte holding system:

This Fanuc robot depalletizer has a particular bottle gripper:

Use the neck bottle gripping system using inflatable bars.

Iodovgvx Dopfx Aadsan

This system helps to process shaped bottles and therefore allows them to be deposited on the loading table with irregular bottles.

The classic push system has this limitation, it cannot process bottles other than round ones.

But the Fanuc robot depalletizer has a speed of 200 layers per hour to a maximum of 12,000 BPH.

Another important feature is the space required to work with that equipment, compared to traditional systems at least 50% of the usable surface is saved; for the same performance, a robot is always preferable, also because being able to change the bottle gripper, all types of bottles can be processed with very high peak loads.

Seller

Note: Register for free or log in, to access all information.

Registered since: 2021

Send inquiry

Telephone & Fax

+39 344 0... show

These listings may also fit your interest.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Palletizer

FANUCM-410 iB 160

FANUCM-410 iB 160

Listing

Urk

Urk

665 km

Thermoformer

WebomaticAPS ML 7100

WebomaticAPS ML 7100

Listing

Romano di Lombardia

Romano di Lombardia

1,436 km

Embroiderer

BAITHE VISION 2

BAITHE VISION 2

Listing

Krotoszyn

Krotoszyn

1,434 km

Packer/Packaging machine

MultivacR230

MultivacR230

Listing

Ukmergė

Ukmergė

1,773 km

Automated pallet dispenser, stacker

UMP TechnikaPD-10

UMP TechnikaPD-10

Listing

Misterton

Misterton

274 km

Vacuum stuffer

RiscoRS1040 MAS

RiscoRS1040 MAS

Listing

Menslage

Menslage

797 km

GM Gera ARCADE GEL 6 RV1-VL 362/110-30 Bottle Washer (2010)

GM GeraFlaschenreinigungsmaschine

GM GeraFlaschenreinigungsmaschine

Listing

Ystad

Ystad

1,087 km

Thermoformer

COLIMATICTHERA

COLIMATICTHERA

Listing

Milan

Milan

1,417 km

Sheet & Tube Fiber Laser Cutting Machine

Bodor C-T

Bodor C-T

Listing

Strenči

Strenči

1,792 km

Pellet production line

Your listing has been deleted successfully

An error has occurred