Used Copy Setup for sale (1,346)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Vereinigtes Königreich

Vereinigtes Königreich

0 km

Heavy Duty Lathe

Hoesch MFDD2000 SGK-1

Call

Condition: used, Year of construction: 1973, turning diameter over bed 2235 mm

turning diameter over slide rest 2997 mm

turning length 12200 mm

Control SIEMENS

faceplate diameter 2000 mm

required space ca. 7 x 22 m

weight of the machine ca. 220 t

HOESCH MFD CNC HEAVY DUTY LATHE WITH SIEMENS CONTROL

Type: D2000 SGK-1

Technical documentation is included

Technical Specifications

Space requirement: 7 x 22 metres + control cabinet 4.7 x 0.5 x 2 metres

Faceplate 2006mm

Centre Height 1,499mm

Swing Over Saddle 2235mm

Swing Over Bed 2997mm

Turning Length 12192mm

Min/Max Workpiece Held In Chuck Ø457/1600mm

Maximum Workpiece Weight 110 Ton

Speed Range 0.5- 140rpm (300hp Motor)

Feed Range 0.0118-7.08''/Rev.

Lsdpst Ei Hujfx Ahzorg

Steady Capacity Ø356-902mm

Copying Depth 508mm lnductive

Maximum Cutting Force 30,000Nm

Twin Barrel Steady Capacity Ø356- 902mm, 50 Ton Capacity, Roller Type.

Machine Data

1.1 Total Machine

Max. Swing over bed slide

2,000 mm

Center height over bed

1,500 mm

Distance between centers

12,000 mm

max. weight of workpiece

100,000 kp

height measured from shop floor level up to machine axis 2,200 mm

1.2 Headstock

Diameter of main spindle

670 mm

Diameter of faceplate

2,000 mm

Max. chucking diameter

1,600 mm

Min. chucking diameter

455 mm

Dead Center Angle

80 °

Faceplate Speed:

Constant torque

1st range 0,5 – 2,6

2nd range 1,25 – 7,2

3rd range 3,1 - 18

4th range 7,8 - 45

Constant capacity

1st range 9,0

2nd range 22,6

3rd range 56

4th range 140

Capacity of Main Drive 220 HP

Max. Torque faceplate 30,000 kpm

Key Speed 5,7 rev/min

1.3 Saddle

Max. admissible main cutting force 30,000 kp

Feed Speed longitudinal 0,3 – 120 mm / min

Feed Speed transverse 0,3 – 120 mm / min

Rapid Traverse Speed longitudinal 2,000 mm/ min

Rapid Traverse Speed transverse 1,000 mm/ min

Max. copying depth 500 mm

Max. length of tool carrier measured from front edge cross slide to front edge

tool carrier 700mm

Tool carrier – width 60mm

35 mm

Cutting Edge height of tool units 60 mm

Cutting edge height of shank-type tools beeing located on the clamping table

100 mm

Travel of upper tool post 820 mm

1.4 Tailstock

Tailstock barrel diameter 580 mm

Adjustment of the barrel 150 mm

Dead Center angle 80 °

Speed of rapid traverse 2,000 mm / min

Positioning speed 500 mm / min

1.5 Steady

Clamping range 350 – 900 mm

...

Listing

Wakefield

Wakefield

228 km

Slitter/Stacker - digital printed sheets

HorizonSmartStacker

Call

Condition: excellent (used), Year of construction: 2021, Ref: 11062 . 2021 Horizon SmartStacker

Only 1.1m books on the counter!

The latest, innovative way to process B2 (20” x 29”) digitally printed sheets to finished format size.

Features:

Near-line operation with Sheet Feeder – can be operated as a near-line system.

Newly designed sheet feeder accommodates B2 (20” x 29”) sheets at up to 4,500 sheets per hour.

Finishing Line Controller (FLC) controls all setup and operation of the SmartStacker by use of JDF workflow.

Can serve multiple HP Indigo 10000 Digital Press units and other HP Indigo presses.

Can be connected directly inline to an HP Indigo 10000 Digital Press.

Print submission, print, and sheet processing performed without any manual operation for higher sheet integrity & efficient workflow.

Can be connected with an Horizon signature folder, saddle-stitcher or perfect binder to achieve total finishing automation.

Specification:

Sheet Size (Before Cut)

Max. 762 x 530 mm or 30.000" x 20.865"

Min. 279.4 x 330 mm or 11.000" x 12.995"

Piece Size (After Cut)

Max. 381 x 530 mm or 15.000" x 20.865"

Min. 100 x 105 mm or 3.940" x 4.135"

Sheet Weight Range:

Normal Paper: 81.4 to 370 gsm

Coated Paper (for Merge Stacker): 90 to 360 gsm

Paper Thickness:

4 to 15 pt or 0.1 to 0.381 mm

*1 pt=1/1,000"

Sheet Stacking:

Straight Stack or 10 mm or 0.39" Offset Stack

Maximum Stack Height: 254 mm or 10.00"

Number of Cuts:

1st Process Unit: 1 to 7 columns (14 cutters)

2nd Process Unit: 1 to 4 rows (8 cutters)

Production Speed: Up to 4,600 sheets per hour

* Production speed differs depending on number of cuts in 1st Process Unit and type/condition of sheets.

* HP Press may need to slow down depending on the sheet condition in case of inline configuration.

Lrjdpfeycb Srsx Ahzjg

Listing

Wakefield

Wakefield

228 km

Automatic Variable Three Knife Trimmer

HorizonHT-1000V Variable Trimmer

Call

Condition: excellent (used), Year of construction: 2019, Ref: 10965 . 2019 Horizon HT-1000V Variable Trimmer

ONLY 1.7M books trimmed!

Inline or offline variable three-knife trimmer capable of zero make-ready on book trim size and thickness changes.

Perfect for short run production, and book of one production which can be achieved through barcode driven set-up.

Features:

Setup automatically on the fly by reading a barcode at the entrance of the trimmer.

Also capable of automatic set-up from the operator panel for same size production runs.

One-to-one book production with variable sizes can be produced.

Both untrimmed and trimmed sizes can be variable, for true variable format production.

Can be used solo or placed in-line with Horizon perfect binders.

Specification:

Untrimmed Book Size:

Max. Spine Length 350 x Fore-edge Length 320 mm/ 13.780” x 12.600”

Limitation: Maximum length from the center to top or bottom is 175 mm/ 6.889”.

Min. Spine Length 148 x Fore-edge Length 105 mm/ 5.825” x 4.130”

Limitation: The minimum length from the center to top or bottom is 74 mm/ 2.91”.

Trim Width:

Fore-edge: Max. 110 mm/ 4.330” Min. 1 mm/ 0.04”

Top and bottom: Max. 80 mm/ 3.150” Min. 1 mm/ 0.04”

Trim Height:

1 to 65 mm/ 0.04” to 2.560”

Ledswu Sptjpfx Ahzerg

Production Speed:

400 to 1,000 cycles per hour (Higher production can be reached with piled books)

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Sunderland

Sunderland

142 km

Folding machine

Multigraf435SM

Call

Condition: excellent (used), Overview

The MultiGraf 435SM is a robust, fully-automatic modular folding system — professionally refurbished and ready for immediate production. Designed for high-accuracy folding across a wide range of applications, this machine features four automatic folding plates and a precision suction feeder, delivering reliable results whether you’re producing high-volume leaflet work, cross-folded mail inserts, or specialist pharmaceutical folds.

Thanks to its modular engineering, the 435SM can be expanded with cross-fold units, high-capacity feeders, miniature fold plates and vertical stackers — allowing the system to evolve as workflow demands increase. Fast setup via the Touchline digital control panel ensures efficient job changes, while the combination steel and rubber roller system provides clean, consistent folds even at high speeds of up to 25,000 sheets per hour.

Ideal for commercial print rooms, mailing departments and finishing operations requiring flexible, high-quality, and upgradeable folding capability without the investment of a brand-new machine.

Key Features

Four fully automatic folding plates — wide range of fold configurations including complex pharmaceutical folds

Precision suction feed system — consistent, mark-free handling across varying paper stocks

Lrjdex Sya Ijpfx Ahzeg

High productivity — speeds up to 25,000 sheets/hour, ideal for short to medium run folding

Touchline touchscreen control — quick setup, easy adjustment, and built-in batch counting

500-sheet feed table — stable, continuous feeding for longer production runs

Combination steel and rubber rollers — accurate, uniform fold quality

Modular upgrade path — compatible with cross-fold units, high-capacity feeders, miniature plates and more

Paper size range A6 to A3+ — versatile handling for both small-format and large-format folding

Optional scoring and perforating unit — for enhanced finishing capabilities

Maximum paper size:

Standard: 375 × 500 mm

With optional extension table: 375 × 650 mm

Specifications

Manufacturer Multigraf

Model 435SM

Min sheet size 90mm x 120mm

Max sheet size 375mm x 500mm or 660mm with extension

Paper weights 40gsm - 250gsm

Feeder system Suction - bottom feed

Speed Variable - up to 25,000 per hour

Control panel Icon based touchscreen

Electrical requirements 230v 50/60Hz

Machine weight 174kg

Machine dimensions (L)1535mm x (D)500mm x (H)1225mm

Listing

Ireland

Ireland

410 km

Custom Strip Processing System

Kinematic Automation Inc.C7100 Reel to Strip Laminator

Call

Year of construction: 2019, condition: like new (used), Automated system to laminate reel of chromotography paper between 2 reels of polyester handle material and on to profile the chromotography paper tip and then cut the web of laminated polyester with chromotography paper into single profiled strips.

The Matrix 7100 Laminator was developed to meet the demanding requirements of the lateral flow test strip industry for a moderately priced system capable of supplying the membrane lamination needs of the moderate to high volume production facility. The unit was designed to allow process flexibility while at the same time optimizing product yields and throughput. Numerous options are available allowing the system to support a wide variety of material types, lamination configurations and process variables.

The Matrix 7100 allows for continuous lamination of membranes onto a plastic backing web and the cutting of the resultant laminate into discrete cards for further processing on other, downstream equipment. Numerous options provide the utmost in process flexibility at a very low overall cost.

The integral touch screen operator interface terminal provides for multiple recipe storage and simple and reliable setup and operation while simplifying process validation.

Lredpfsya H S Sex Ahzjg

Key Features

Touch screen operator interface terminal for simple setup and operation

Simple web guide adjustment

Rapid changeover to support multiple products

Flexible to support changing requirements

Base configuration supports Backing Web with Release Liner plus 4 membranes

Extruded aluminium structural frame

Flying shear for continuous card cutting

Reel to reel lamination option

Discover more used machines

Listing

Neuss

Neuss

817 km

Truck aerial platform

RuthmannT 330

Call

Condition: good (used), Year of construction: 2014, lifting height: 30,500 mm, General information

Mileage: 112.783 km

Weights

Empty weight: 7.240 kg

Functional

Lifting capacity: 320 kg

Working height: 3.250 cm

Condition

Technical condition: good

Visual appearance: good

Other information

Delivery terms: EXW

Max. horizontal reach: 2090 m

Max swing of arm in degrees: 180

Transport dimensions (LxWxH): 8,8x2,55x3,55

Production country: DE

Additional information

Please contact Christian Theißen for more information

Manufacturer: Ruthmann

Type: T 330

Year of manufacture: 2014

Product type: Used

Data:

Lrsdpfx Aoxbqicehzeg

Max. working height: 32.50 m

Max. platform height: 30.50 m

Max. reach: 20.88 m

Overall dimensions LxWxH: 8.80 x 2.55 x 3.55 m

Platform dimensions LxW: 1.71 x 0.86 m

Max. basket load: 320 kg

Swivel range: 180°

Support pressure: 56 kN

Ground clearance: 0.15 m

Vertical support width: 2.53 m

Support width on one side: 3.86 m

Support width on both sides: 5.30 m

Support length: 4.87 m

Unladen weight: 7,240 kg

Driving licence: C1/3

Special features: Rotatable work basket, basket arm, rotation angle, WITHOUT roof protection, advantage: power connection in basket, loading area with tail lifts, box body, enormous lateral reach, automatic setup and retraction, greatest reach on 7.5 t chassis

Note: New TÜV and UVV

Location: 41468 Neuss

immediately available

Listing

Rosmalen

Rosmalen

711 km

Machining center

BIESSERover A 3.40 FT

Call

Condition: used, Year of construction: 2010, Biesse Rover A 3.40 FT K2

Description:

Working fields: X = 3685 mm; Y = 1290 mm; Z = 160 mm

Automatic lubrication system

FT Work Table

4 front stops + 4 back stops equipped with pneumatic system and sensors.

4 side stops equipped with pneumatic system and sensors.

Vacuum tank

300 m3/h rotary claw vacuum pump12 kW (16.1 HP)

Electrospindle with ISO 30 adaptor, air cooled

Blowing unit

Flange for the assembly of aggregates on the electrospindle

Prearrangement for operating device with 360° interpolation and gear transmission.

Boring head BH 21 L

Revolving tool changer with 18 places

Prearrangement for the assembly of the automatic unloading device for nested-based machined panels

Ledpfx Ajxwcb Nohzjrg

Controls on remote keyboard

Numerical Control XP600

BIESSEWORKS - Advanced programming system - machine version

BIESSE NEST Module

Air conditioner for electric cabinet

Inverter

Safety devices with mats

Prearrangement for mechanical copying unit

(Despite our great care all changes, mistakes in technical data, prices and all information is subject to (typing) errors. No guarantee on printed data! Availability subject to prior sales).

(Trotz größter Sorgfalt bleiben Änderungen, Irrtümer bei technischen Daten, Preisen und allen Angaben (Tipp-)Fehler vorbehalten. Keine Gewähr auf gedruckte Daten! Verfügbarkeit vorbehaltlich Zwischenverkauf).

Prices excl. advertisement cost MachineSeeker / Preise exkl. Inserierungskosten MaschinenSucher

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Rosmalen

Rosmalen

711 km

Edgebander

VitapEclipse

Call

Condition: used, Year of construction: 2016, Vitap Eclipse Edgebander for round shaped, curved workpieces

Semi-automatic edge banding machine for large round or curved workpieces with a panel thickness between 10 and 60 mm and a belt thickness between 1 and 3 mm.

The 60 mm height is only possible with an edge banding thickness of 1 mm. If the edge band is thicker, it depends on the quality of the band and must be tested beforehand in connection with the cutting unit.

Description;

Two copy rollers for the shape of the workpiece to be scanned

Gluing station

Glue tray with a capacity of 1 kg

Two 800W heating elements with electronic temperature display via the PLC

Glue application via glue roller

Glue tray made of aluminum for heat distribution

Glue supply can be adjusted by means of a button

Automatic cutting unit for edge banding material on the roll from 3 to 45 mm

Aggregate is activated by a sensor for closed edge tape with a perfect connection or by an encoder if only 1 side is pasted

Laser system for length determination, no pre-measurement necessary

On-off capability for throughput

Height-adjustable table for narrow panels

On-off capability for milling aggregate

Two copy rollers for the shape of the workpiece to be scanned

Lrjdpowgb Hxsfx Ahzog

Milling unit equipped with 2 x 0.5 kW (15000 rpm high frequency) with top, bottom and front copy rollers

Milling unit equipped with blades R=2, Phase 15°, D=69, Z=6

Large panel turntable with vacuum to hold product

(All changes, mistakes in technical data, info and prices reserved. Availability subject to prior sales. No guarantee on printed data!)

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen sowie Zwischenverkauf vorbehalten! Keine Garantie auf gedruckte Daten!)

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Sevenum

Sevenum

767 km

Wheel loadeWheel loader articulated load

Gunter machineGG010

Call

Condition: new, mileage: 1 km, power: 50 kW (67.98 HP), gearing type: automatic, fuel type: diesel, overall weight: 2,850 kg, lifting power: 1,000 kg/m, drive condition: 100 %, chain condition: 100 %, Year of construction: 2024, Equipment: additional headlights, cabin, GG010

The new Günter Grossmann GG010 LOADER The Günter Grossmann GG08 loader (1000 kg payload) is brand new. Günter Grossmann is a high quality machine made for a European company.

The charger is very strong and can work under all conditions. The charger is very nice. The control panel is very nice and clear. The cabin is soundproof, insulated, equipped with heating, very comfortable and beautifully glazed, allowing safe and comfortable work.

The machine has a very durable construction. The machine is equipped with a quick coupler, which makes it possible to change accessories quickly without leaving the cab.

Additional equipment: 4 in 1 bucket, crocodile grab, crocodile grab for trees, straw or silage.

Price

14,550 euros

(excl. VAT) Included as standard GG010 loader + bucket + pallet fork + quick coupler

Model 1000 kg

SPECIFICATIONS

Model: GG10

Brand: Günter Grossmann

Engine: Changchai 390

Engine: In-line setup, water-cooled four-stroke diesel engine

Engine power: 50 hp

Speed: 2200 r/min (rpm)

Steering system: Cycloid full hydraulic steering system: BZZ-80

Ljdpoiit Ersfx Ahzerg

System Pressure: 10MPa

Service brake: Hydraulic four-wheel brake with staggered shoes

Parking brake: manual

Tire: 10-16.5

Wheelbase: 2170mm

Track: 1285 mm

MEASUREMENTS

Total length (bucket at ground position): 41--mm

Ground to top of cab: 2530 mm

Total width: 1600 mm

WORKING RANGE

Bucket capacity: 0.5 m3

Bucket width: 1600 mm

Max. Height Breakout Force: 28KN

Rated load: 1000 kg

Operating weight: 2850 kg

Drive means: four-wheel drive

Min turning radius: 4600 mm

ACCESSORIES

Bucket 4 w 1: 1050 Eur

Pitchfork: 1050 Eur

Pallet fork: 650 Eur

Quick coupler: 600 Eur

Drill: 1400 Eur

Bale clamp: 950 Eur

Grass clip: 950 Eur

Lawnmower: 1450 Eur

Snowplow: 1375 Eur

Listing

Neukamperfehn

Neukamperfehn

747 km

High-bay warehouse pallet racking system

SSI Schäfer PR 600Regallänge: 27,99 lfm.

Call

Condition: good (used), Technical data of the pallet racking system:

Racking system: SSI Schäfer

Type: PR 600

Setup technical data:

Number of rack rows: 01 pcs

Length per rack row: 27,990 mm

Number of compartments per rack row: 10 pcs

Number of levels plus floor level: 03 pcs

Volume technical data:

Ledpfxjyay D Is Ahzerg

Pallet locations per compartment: 12 pcs

Pallet locations per rack row: 120 pcs

Total pallet locations: 120 pcs

Assumed configuration:

Load carrier: Euro pallet EN 13698-1

Dimensions: 1,200 x 800 x 150 mm

Total height incl. pallet: n.d.

Maximum weight per pallet: 1,100 kg

Scope of delivery includes:

11x pallet rack frames, used

Material colour: Sendzimir galvanized

Frame type: P95

Profile dimensions: 90 x 75 x 2.5 mm

Including horizontal and diagonal braces, frame guards, and baseplates

Frames are pre-assembled (bolted truss design)

Height: 4,100 mm

Depth: 1,050 mm

60x pallet rack beams, used

Material colour: RAL 4002 red violet

Box profile: 120 x 50 mm

Beam type: TRV1-270-125-30 CE

Clear span: 2,700 mm

Connector: 5 HK (hooks)

Max. load per pair of beams: 3,300 kg (evenly distributed load)

Note:

The functionality of the beams is not affected by the holes; SSI project with heat-dust plates that were bolted on as per manufacturer’s instructions!

120x safety pins, used

Material colour: Sendzimir galvanized

To secure the crossbeams against unintentional lifting

44x anchor bolts, new

Manufacturer: Hilti

Model designation: HST2 V3 M12x105 5-25

Version: carbon steel, galvanized

Approved for: cracked concrete

44x shims, used

Version: completely galvanized

For leveling the rack frames standing on uneven ground

01x load capacity sign

With specifications for bay and shelf loads, manufacturer and order number

Dimensions: 420 x 297 x 3 mm

Your points of contact in our company:

Mr. Andre Evering

Mr. Mario Klöver

Mr. Falk Deutsch

General information about the item:

This item is offered for collection only. Any additional transport or shipping of this item is subject to extra costs, which can be requested from us separately depending on the delivery location and scope.

Auction

Ends in

d

h

min

s

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

809 km

Sheet metal processing center

SALVAGNINIP4X 2516

Condition: not inspected (used), Year of construction: 2008, operating hours: 32,164 h, functionality: unexamined, machine/vehicle number: 3201250, sheet thickness steel (max.): 2 mm, sheet thickness aluminum (max.): 3 mm, workpiece length (max.): 2,695 mm, workpiece width (max.): 1,524 mm, No reserve price – guaranteed sale to the highest bidder!

Placing a bid commits you to timely collection between 23.03.2026 and 27.03.2026!

TECHNICAL DETAILS

Maximum tensile strength (stainless steel): 600 N/mm²

Sheet thickness (stainless steel): 0.5 mm - 1.25 mm

Typical sheet thickness (stainless steel): 1.0 mm

Maximum tensile strength (steel): 410 N/mm²

Sheet thickness (steel): 0.5 mm - 2.0 mm

Typical sheet thickness (steel): 1.5 mm

Maximum tensile strength (aluminium): 265 N/mm²

Sheet thickness (aluminium): 0.5 mm - 3.0 mm

Typical sheet thickness (aluminium): 1.5 mm

Sheet dimensions

Length: 405 mm – 2,695 mm

Width: 190 mm – 1,524 mm

Max. diagonal: 2,800 mm

Max. centring measurement: 2,500 mm

MACHINE DETAILS

Hydraulic system

Oil capacity (main machine): approx. 500 dm³

Oil capacity (scissor lift table): approx. 20 dm³

Cooling system (closed)

Cooling unit R81: approx. 175 litres

Cooling unit R101: approx. 260 litres

Power supply connections

Mains voltage: 400 V

Lsdoycqucopfx Ahzerg

Frequency: 50/60 Hz

Cable cross-section: 4 × 25 mm²

Main fuse: 80 A

Average current: 42 A

Power consumption: 24 kW

Control voltage: 24 V AC/DC

Industrial PC / monitor / power supply units: 220 V AC

Open cooling system

Cooling water requirement: approx. 2.0 m³/h

Max. inlet temperature: 20 °C

Compressed air

Required pressure: 6 – 12 bar

Max. air consumption at 6 bar: approx. 2,275 Nl/min

Machine tolerances

Angular accuracy: ±1°

Dimension tolerance of bent parts: ±0.2 mm

Repeatability: ±0.1 mm

Centring positioning accuracy: ±0.1 mm

Straightness of bent parts: ±0.1 mm/m

Tool setup time: Automatic during loading/unloading

Length setting: Via bending program and in increments of 4 (5) mm

Dimensions & weight

Footprint (L × W × H): approx. 18,000 × 11,500 × 3,500 mm

Transport width: Presumably up to 3,000 mm

Total weight (without oil): approx. 27,760 kg

Heaviest component (bending machine): approx. 20,040 kg

Operating hours: 32,164 h

Robot

Manufacturer: KUKA

Type: KR 150 L110-2 2000

Year of manufacture: 2008

Weight: 1,285 kg

Note: Robot converted to magnetic lifter

EQUIPMENT

Various spare parts in wooden crates

Listing

Baughurst

Baughurst

472 km

Digital print machine

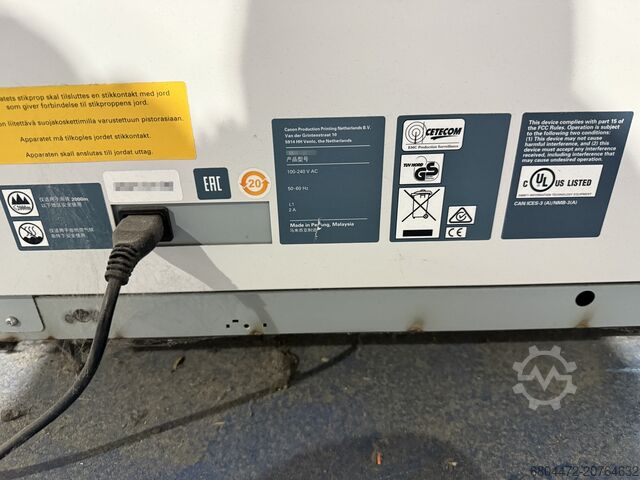

CanonOce VarioPrint 6330

Call

Condition: used, Year of construction: 2018, functionality: fully functional, FOR SALE:

Canon Océ VarioPrint 6330 TP Titan – High-Speed Monochrome Production Press

Boost Print Production & Efficiency

A fully functional, high-speed Canon Océ VarioPrint 6330 TP Titan digital production printer is for sale. This machine is known in the commercial print industry for its productivity, offset-like quality, and media versatility.

It is ideal for high-volume environments, commercial print shops, and in-house operations. These operations focus on books, manuals, transactional documents, and direct mail.

Key Features & Benefits:

Ultra-High Speed: It can achieve speeds of up to 328 A4 impressions per minute with Océ Gemini Instant Duplex Technology. This technology prints both sides at once in a single pass.

Superior Print Quality: It delivers quality with a 600 x 1200 dpi resolution. It uses advanced Océ Copy Press technology for a matte finish and precise registration.

Wide Media Versatility: It handles media weights from 50 gsm up to 300 gsm (and up to 350 gsm for validated stock). This includes specialty and textured papers, tabs, and carbonless forms.

Robust Paper Handling: It comes with a high-capacity system, expandable to multiple trays. It has a paper input capacity of up to 24,000 sheets.

Eco-Friendly Operation: It features low power consumption, minimal ozone emissions, and low heat output. This makes it efficient and operator-friendly for any print room.

Workflow Integration: It is managed by the PRISMAsync controller. It includes DFD interface support for connection to third-party finishing options (binding, saddle-stitching, punching).

Machine Specifications:

Model: Canon Océ VarioPrint 6330 TP Titan

Condition: Ready for operation (used), fully functional

Year of Manufacture: Year 2018

Resolution: 600 x 1200 dpi (up to 180 lpi)

Max Monthly Volume: Up to 10,000,000 A4 images

Max Paper Size: Up to 350 mm x 500 mm (13.8" x 19.7")

Configuration Includes: (Please check photos to be sure)

Paper Input Modules, 8x Duo Paper Trays]

2x High Capacity Stackers]

Lrjdpfx Aox Hz T Eohzeg

PCL, IPDS, PostScript language support]

PRISMAsync Controller]

Current Meter Readings:

See Photo.

Price:

(Negotiable)

The original price for this configuration was over €140,000!

Logistics:

The buyer is responsible for arranging shipping. . The machine is located in [UK].

Listing

Neukamperfehn

Neukamperfehn

747 km

High-bay warehouse pallet racking system

SSI Schäfer PR 600Regallänge: 14,04 lfm.

Call

Condition: good (used), Technical data for the pallet racking system:

Racking system: SSI Schäfer

Type: PR 600

Technical data for the setup:

Number of racking rows: 01 unit

Length per racking row: 14,040 mm

Number of bays per row: 05 units

Number of levels plus ground level: 02 units

Volume data:

Pallet locations per bay: 09 units

Pallet locations per row: 45 units

Total pallet locations: 45 units

Assumptions:

Load carrier: Euro pallet EN 13698-1

Dimensions: 1,200 x 800 x 150 mm

Total height incl. pallet: n.d.

Lrjdpfx Ahjyapf Iszsg

Maximum pallet weight: 1,100 kg

Scope of delivery includes:

06x pallet racking frames, used

Material finish: Sendzimir galvanized

Frame type: P73

Profile dimensions: 90 x 75 x 2.5 mm

Incl. horizontal and diagonal bracing, frame protectors, and base plates

Frames are pre-assembled (bolted truss design)

Height: 3,600 mm

Depth: 1,050 mm

20x pallet racking beams, used

Material color: RAL 4002 red violet

Box profile: 120 x 50 mm

Beam type: TRV1-270-125-30 CE

Clear span: 2,700 mm

Connector: 5 HK (hooks)

Maximum load per pair of beams: 3,300 kg, with evenly distributed load

Note:

Functionality of the beams is ensured despite holes (SSI project with heat protection plates bolted as per manufacturer’s specifications)

40x safety pins, used

Material finish: Sendzimir galvanized

For securing the longitudinal beams against unintended lifting

24x wedge anchors, new

Manufacturer: Hilti

Type: HST2 V3 M12x105 5-25

Material: Carbon steel, galvanized

Approved for: Cracked concrete

12x shims, used

Material: fully galvanized

For leveling racking frames placed on uneven floors

01x load sign

With specification of bay and shelf loads, manufacturer, and order number

Dimensions: 420 x 297 x 3 mm

Your contacts at our company:

Mr. Andre Evering

Mr. Mario Klöver

Mr. Falk Deutsch

General information about the item:

This item is only offered for collection. Additional transport or shipping of this item is subject to extra costs, which can be quoted separately depending on delivery location and scope of delivery.

Listing

Neuss

Neuss

824 km

Truck aerial platform

RuthmannT 330 (TÜV und UVV neu!)

Call

Condition: good (used), Year of construction: 2012, lifting height: 30,500 mm, fuel type: diesel, Weights

Empty weight: 7.240 kg

Functional

Lifting capacity: 320 kg

Working height: 3.250 cm

Working width: 255 cm

Condition

Technical condition: good

Visual appearance: good

Other information

TÜV Marked: yes

Delivery terms: EXW

Lsdpfxeyccpxo Ahzjrg

Max. horizontal reach: 2088 m

Max swing of platform in degrees: 180

Transport dimensions (LxWxH): 8,8x2,55x3,55

Production country: DE

Additional information

Please contact Christian Theißen for more information

Manufacturer: Ruthmann

Model: T 330

Year of build: 2012

Condition: Used

Data:

Max. working height: 32,50 m

Max. platform height: 30,50 m

Max. reach: 20,88 m

Total dimensions LxWxH: 8,80 x 2,55 x 3,55 m

Platform dimensions LxW: 1,71 x 0,86 m

Max. basket load: 320 kg

Swivel range: 180°

Ground pressure: 56 kN

Ground clearance: 0,15 m

Support width vertical: 2,53 m

Support width one side: 3,86 m

Support width both sides: 5,30 m

Support length: 4,87 m

Empty weight: 7.240 kg

Driving license category: C1/3

Special features: Rotating work basket, basket arm, swivel angle, WITHOUT roof protection, advantage: power connection in the basket, loading area with tailgates, van body, enormous lateral reach, setup and driving-in automation, greatest reach on a 7.5t chassis.

Information: TÜV und UVV new

Listing

Wasbek

Wasbek

869 km

Column Drilling Machine - SSB 40 F Super VT

KnuthSSB 40 F Super VT

Call

Condition: new, The SSB 40 F Super VT, a robust Column Drilling Machine from KNUTH, is expertly designed for precision drilling, countersinking, reaming, and tapping in various settings, from maintenance tasks to finishing operations. This drill press features a sturdy construction with a thick-walled column and a large throat, ensuring stability and reliability during operation. With its advanced touchscreen control panel, users can easily select the necessary operating parameters, while the infinitely variable spindle speed allows for flexibility in machining. The motorized vertical movement of the setup table simplifies the handling of heavy parts, making it ideal for custom and small-series machining. Standard equipment includes a powerful LED work lamp, a coolant device, and an automatic quill feed with an intuitive manual transmission. You can expect exceptional performance for your drilling needs. For more information or to request a quote, consider the SSB 40 F Super VT, a top choice in the Column Drilling Machines category.

Lrodpfsnp Hymox Ahzjg

Listing

Wasbek

Wasbek

869 km

Tool Grinder - FSM 14 S

KnuthFSM 14S

Call

Condition: new, The FSM 14 S Tool Grinder by KNUTH is a robust machine designed specifically for the precise and cost-effective grinding of HSS and carbide milling cutters, ranging from 4 to 14 mm in diameter. This handy milling cutter grinder series stands out for its user-friendly operation, making it an ideal choice for any tool crib, where efficient tool maintenance is essential. The FSM 14 S features the capability to grind 2, 3, and even 4-blade cutters, with an additional station available for outer spiral cutting edge grinding. Included in the package are collets tailored for common cutter diameters—4, 6, 8, 10, 12, and 14 mm—along with high-quality grinding wheels that enhance your workflow. This machine ensures rapid tooling and quick setup, enabling you to maintain your tools effectively. Invest in the FSM 14 S Tool Grinder today and elevate your tool sharpening capabilities. Request a quote for this reliable Tool Grinder and ensure your cutting tools are always ready for use.

Lsdjp Dtx Uspfx Ahzorg

Listing

Wasbek

Wasbek

869 km

Workshop Press - KNWP H 100

KnuthKNWP H 100

Call

Condition: new, The KNWP H 100 is a robust Motorized Workshop Press, part of the Workshop Presses category by KNUTH. This hydraulic workshop press features a torsionally rigid welded gantry-style frame, making it ideally suited for professional use in technical workshops and maintenance departments. Its stable portal design includes an adjustable open support table that allows for versatile applications, such as pressing in and out bearings, assembly work, and testing workpieces. The press boasts a finely adjustable press force of up to 100 tons and a long piston stroke of 400 mm, ensuring efficiency and adaptability for various tasks. Operators can monitor the current working pressure via the built-in gauge, while the horizontal adjustment of the working cylinder simplifies setup without needing to reposition the workpiece. To enhance reliability, the KNWP H 100 is equipped with premium components and includes a motorized hydraulic drive, movable working cylinder, and height-adjustable work table. For anyone seeking a dependable Motorized Workshop Press, the KNWP H 100 is an excellent choice—request a quote today to add this essential tool to your lineup.

Lredpfx Ahouyh A Eezjg

Listing

Wasbek

Wasbek

869 km

Column Drilling Machine - SSB 50 F Super VT

KnuthSSB 50 F Super VT

Call

Condition: new, The SSB 50 F Super VT, a robust Column Drilling Machine from KNUTH, is expertly designed for precision drilling, countersinking, reaming, and tapping in various settings, from maintenance tasks to industrial construction. This drill press features a sturdy construction with a thick-walled column and a large throat, ensuring stability and reliability during operation. With its advanced touchscreen control panel, users can easily select the necessary operating parameters, while the infinitely variable spindle speed allows for flexibility in machining. The motorized vertical movement of the setup table simplifies the handling of heavy parts, making it ideal for custom and small-series machining. Standard equipment includes a powerful LED work lamp, a coolant device, and an automatic quill feed. For those looking for a high-quality Column Drilling Machine, the SSB 50 F Super VT is an excellent choice. Request a quote today to learn more about this exceptional machine!

Lredpfx Asnp Hp Iehzeg

Listing

Neukamperfehn

Neukamperfehn

747 km

2,500 x 1,050 mm | 11.72 linear meters | 2 levels

Alser NSPalettenregal Hochregal Schwerlastregal

Call

Condition: used, clear span: 1,860 mm, total width: 11,720 mm, total height: 2,500 mm, Technical Data for Pallet Racking System:

Racking System: Alser

Type: NS

Setup Specifications:

Number of rack rows: 01 pcs

Length per rack row: approx. 11,720 mm

Number of bays per rack row: 06 pcs of 1,860 mm each

Number of levels plus ground level: 02 pcs

Volume Specifications:

Pallet locations per bay: 06 pcs

Pallet locations per row: 36 pcs

Total pallet locations: 36 pcs

Based on:

Load carrier: Euro pallet EN 13698-1

Dimensions: 1,200 x 800 x 150 mm

Total height incl. pallet: n.d.

Max. pallet weight: approx. 1,000 kg

Scope of delivery includes:

07x pallet racking uprights, used

Material color: brown

Profile dimension: C80 x 40 x 15 x 2.00 mm

Lsdpex Upqbjfx Ahzorg

Including horizontal and diagonal braces, base plates

Uprights are pre-assembled

Max. bay load: 4,000 kg

At buckle height: 1,250 mm

(min. 5 bays per row)

(welded truss)

2,500 mm high

1,050 mm deep

24x pallet racking beams, used

Material color: orange

Profile dimension: S 110 x 55 mm

Beam type: B113

Connector: 2 HK

Clear width: 1,860 mm

Max. load per pair of beams: 2,000 kg, with evenly distributed load

48x safety pins, used

Material finish: sendzimir galvanized

For securing longitudinal beams against unintentional lifting

28x anchor bolts, new

Manufacturer: Hilti

Model: HST2 V3 M12x105 5-25

Design: Carbon steel, galvanized

Approved for: cracked concrete

14x leveling plates, used

Material: sendzimir galvanized

To level uprights set up on uneven ground

01x load plate

with information on bay and shelf loads, manufacturer, and commission number

Dimensions: 420 x 297 x 3 mm

General Information about the Item:

This item is offered for collection only. Any transportation or shipping of this item is subject to additional costs, which can be provided upon request depending on the delivery location and order volume.

Listing

Lüneburg

Lüneburg

928 km

ATC measuring microscope

TraubTNA400

Call

Condition: excellent (used), manufacturer: GRÜN SYSTEMTECHNIK WETZLER

including case

We offer an original ATC measuring microscope, originally taken from a TRAUB TNA turning center. The unit is designed for installation in the automatic tool changer and can be used on various CNC machines with a suitable toolholder interface (size comparable to TRAUB TNA400

Key Features & Benefits:

• Universal application: Suitable for any CNC machine with compatible toolholder interface.

• Fast tool setup: Enables direct measurement of cutting edges, tool lengths, and radii inside the machine.

• Process reliability: Tool wear can be identified immediately and corrected without removing the tool.

Lredpfx Aeycuhtshzog

• Precise referencing: Useful for checking zero points, bores, and fixtures directly in the setup.

• Time savings: Eliminates the need for external presetting devices and reduces downtime.

• Compact & robust design: Easy to integrate and operate within the tool changer system.

This ATC measuring microscope turns your CNC machine into a precise measuring station, helping you achieve higher accuracy, shorter setup times, and improved process reliability.

Listing

Lüneburg

Lüneburg

928 km

CNC Lathe

DMT KERNCD650

Call

Condition: used, Year of construction: 2006, functionality: fully functional, Turning diameter: 650 mm Turning length: 1,500 mm Total power requirement: 33 kW Center distance: 1,500 mm Swing diameter over bed: 650 mm Swing diameter in recess: 670 Turning diameter: 650 mm

Turning length: 1,500 mm

Total power requirement: 33 kW

Center distance: 1,500 mm

Swing diameter over bed: 650 mm

Swing diameter in recess: 670 mm

Swing diameter over face slide: 260 mm

Face slide travel: 380 mm

Main drive

Drive power AC motor - 40/60/100% duty cycle: 33/27/22 kW

Spindle box

Spindle bore diameter: 106 mm

Spindle diameter in front bearing: 140 mm

Speed range (V constant): 1 - 2,000 rpm

Cross slide

Feed range, face: 0.001 - 1,000 mm/rev

Feed range, face, optional up to: 5,000 mm/rev

Feed range, longitudinal and thread pitch: 0.001 - 2,000 mm/rev

Feed range longitudinal and thread pitch, optional up to: 13,000 mm/rev

Feed force flat: 9,000 N

Feed force longitudinal: 12,000 N

Automatic tool turret

Number of tool stations: 12

With tool drive for 6 stations

Tool holder system (DIN69880) VDI40

Lrjdpfjycuflsx Ahzog

Equipment

SIMENS SINUMERIK 840D sl (Shop Turn with manual functions)

COMBI control station

C-axis with drilling, milling, and engraving cycles

Residual material detection and machining – during roughing and contour pockets

MULTIFIX C forne setup

Three-jaw chuck SMW AUTOBLOK: HI-GRIP HGF260-81-3

Oil emulsion mist filter for work area extraction: MAHLE LTA600

4 driven axial tool holders

2 driven radial tool holders

Trust Seal

Dealers certified through Machineseeker

Listing

Achim

Achim

853 km

Band saw

BEHRINGERHBE 411 A Dynamic

Call

Condition: new, Year of construction: 2025, functionality: fully functional, BEHRINGER HBE 411 A Dynamic, BRAND NEW MACHINE!

Cut monitoring 22

AFC-Pro 33

Saw drive 5.2kW 50-2

Chip conveyor 100

Bar start detection 535

Lighting

Behringer new machines: Come-See-Buy

Immediately available from stock

Lrsdpfx Ahsyam Srezeg

Warranty from date of purchase

Machine breakdown? Replacement in the shortest possible time

Delivery and setup available on request

Immediately available from stock

Listing

Ennepetal

Ennepetal

848 km

Welding Table

GERD WOLFFKugelspannbolzen D28 x 50 mm

Call

Condition: new, Year of construction: 2025, diameter 28 mm

length 50 mm

clamping range 45-50 mm

The price is exclusive of statutory VAT.

Also available in D28 x 75 mm (clamping range 70–75 mm).

Clamping range: 45–50 mm

Type: Ball Lock Pin 50 mm

Diameter: 28 ± 0.02 mm

Material: 45# steel

Hardness: HRC28–32

Surface roughness: Ra 0.8 µm

GERD WOLFF ball lock pins are specialized fastening components designed for

integration into a wide range of welding table systems and setups.

Their main function is the efficient and precise positioning and securing of

workpieces. These pins are compatible with welding tables from all

manufacturers that feature 28 mm bore holes.

The unique ball-lock design enables flexible alignment of workpieces at various

Lodpsw Td Auofx Ahzjrg

angles and positions.

Thanks to their high-quality manufacturing and robust construction, GERD WOLFF

ball lock pins provide reliable holding force throughout the entire welding

process.

These pins allow for easy handling, fast clamping, and release of workpieces —

without the need for additional tools.

GERD WOLFF stands for quality and precision in welding technology. These ball

lock pins are engineered to meet the high demands of professional welding

applications.

Quick release locking pins, quick lock pins, quick releases, quick installation

pin, metal horizontal quick release, working pin, quick release locking pin,

quick latch pin, locking quick release pins.

Listing

Ennepetal

Ennepetal

848 km

Center Lathe

PADOVANILABOR 180S

Call

Condition: used, turning diameter over bed / mm

turning diameter over slide rest / mm

turning length / mm

total power requirement / kW

weight of the machine ca. / t

required space / m

Conventional lathe with copying attachment and extensive accessories

Turning diameter over cross slide:

240 mm

Spindle bore:

52 mm

Turning diameter:

360 mm

Center height:

180 mm

Turning length:

1,000 mm

Overall length:

2,200 mm

Overall width:

750 mm

Overall height:

1,400 mm

Maximum spindle speed:

Ljdpfxsv Rgzws Ahzsrg

1,750 rpm

Min. spindle speed:

60 rpm

Total weight:

1,800 kg

All technical specifications are subject to change without notice. Deviations may occur depending on the year of manufacture, model, or condition of the machine. We assume no liability for the accuracy or completeness of this information.

Listing

Ennepetal

Ennepetal

848 km

Welding Table

GERD WOLFFKugelspannbolzen D28 x 75 mm

Call

Condition: new, Year of construction: 2025, diameter 28 mm

length 75 mm

clamping range 70-75 mm

The price is exclusive of statutory VAT.

Also available in D28 x 50 mm (clamping range 45–50 mm).

Clamping range: 70–75 mm

Type: Ball Lock Pin 75 mm

Diameter: 28 ± 0.02 mm

Material: 45# steel

Hardness: HRC28–32

Surface roughness: Ra 0.8 µm

GERD WOLFF's ball lock pins are specialized fastening elements designed for

integration into various welding table systems and setups.

Their primary function is the efficient and precise positioning and securing of

workpieces. These pins are compatible with welding tables from all

manufacturers featuring 28 mm bore holes.

The unique ball-lock design enables flexible alignment of workpieces at

different angles and positions.

Thanks to high-quality craftsmanship and robust construction, GERD WOLFF's ball

lock pins provide reliable holding force throughout the entire welding process.

These pins ensure easy handling, quick clamping, and release of workpieces — no

additional tools required.

Lrsdeuia Ngepfx Ahzsg

GERD WOLFF stands for quality and precision in welding technology. These ball

lock pins are engineered to meet the demanding requirements of professional

welding applications.

Quick release locking pins, quick lock pins, quick releases, quick installation

pin, metal horizontal quick release, working pin, quick release locking pin,

quick latch pin, locking quick release pins.

We make it easier for you to find: "copy setup"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Copy Setup (1,346)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month