Used Delem for sale (224)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Trittau

Trittau

913 km

Press brake

TRUMPFTrumabend V170

Call

Condition: good (used), functionality: fully functional, Year of construction: 1999, Hydraulic Press Brake

Make: TRUMPF Model: TrumaBend V170

Year: 1999

Technical Data

Manufacturer: TRUMPF

Model: TrumaBend V170

Year of manufacture: 1999

Operating hours: 45,074 h (read-off)

Press force: 170 t

Ksdpfxox E Tpio Addedg

Usable length: 4000 mm

Stroke: 215 mm

Dimensions: L 4.6 x W 2.70 (without bending aids 2.20 m) x H 2.70 m (transport height 2.5 m)

Weight: approx. 16.5 t

Equipment

• Delem DA 2D graphic CNC controller

• Controlled axes: Y1, Y2, X, R, Z1, Z2

• Pneumatic die shifting

• Hydraulic tool clamping top and bottom (Wila/Trumpf system)

• CNC-controlled crowning

• 2 movable bending aids

• Prepared for ACB angle measurement

• Upper tool, OW210/S 28°/R1, H 140mm, L = 4000mm, segmented

• Lower tool, EV002W8 30°/R1, H 100mm, L = 4000mm, segmented

All details without guarantee.

A demonstration can be arranged at any time in our showroom.

Listing

Kreuztal

Kreuztal

907 km

Hydr. Press brake

TRUMPFTruBend 8300 4100 x 300 to

Call

Condition: excellent (used), Year of construction: 2012, Technical Data:

Working length: 4100 mm

Distance between uprights: 3550 mm

Press force: 300 tons

CNC control: DELEM EPC-3D

Controlled axes: Y1/Y2; X; R; Z1/Z2

Hydraulic tool clamping top and bottom: WILA system

CNC crowning

Stroke: 550 mm

Throat depth: 405 mm

Installation height: 620 mm

2 bending aids

Angle measuring system

Motor power: 30 kW

Laser monitoring

Table height: 980 mm

Dimensions (L x W x H): approx. 5550 x 2950 x 3400 mm

Weight: approx. 24.5 tons

Accessories:

Manual tool changer

Segmented bending with step-by-step support of the bending aids (segment bending)

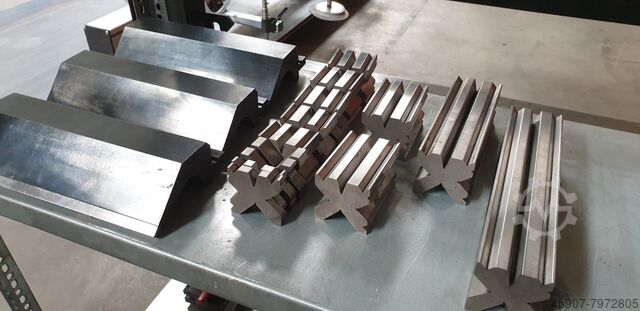

1 set of tools

Condition:

Very good condition

Kedpfx Aexdt Umsddsdg

The seller assumes no liability for typing or data transmission errors. The machine’s appearance, technical condition, and wear are consistent with its age; used machines are sold without any warranty.

Listing

Kreuztal

Kreuztal

907 km

Hydr. Press brake

TRUMPFTrumaBend V130 3000 x 130 to X

Call

Condition: excellent (used), Year of construction: 1999, Technical Data:

Working length: 3050 mm

Distance between uprights: 2690 mm

Pressing force: 130 t

CNC control: DELEM

Adjustable backgauge

Controlled axes: Z1 / Z2; X; R

CNC-controlled crowning

Installation height: 535 mm

Stroke: 365 mm

Kdsdpew Tcncsfx Addeg

Throat depth: 410 mm

Hydraulic tool clamping top and bottom

Ram position measuring system with spring-back compensation via glass scales

Program-controlled lower tool shifting (I-axis) for 2 positions

Motor power: 12.5 kW

Number of backgauge fingers: 2

CE mark

Dimensions (L x W x H): approx. 3800 x 2350 x 3150 mm

Weight: approx. 14 tonnes

Condition:

Good condition

The seller is not liable for typing or data transmission errors. The machine's appearance, technical condition and wear correspond to its age; used machines are sold without any warranty.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Kreuztal

Kreuztal

907 km

Hydr. Press brake

GASPARINI2600 x 45 to

Call

Condition: excellent (used), Year of construction: 2004, Technical specifications:

Working length: 2600 mm

Width between columns: 2150 mm

Pressing force: 45 tons

CNC control: DELEM DA 66 W

Controlled axes: Y1/Y2; X; R; Z1/Z2

Motorized adjustable backgauge with 4 stop fingers

Thrust: 310 mm

Working height: 930 mm

Motor power: 5.5 kW

CE mark

Dimensions (length x width x height): approx. 3000 x 2150 x 2150 mm

Weight: approx. 5 tons

Accessories:

1 set of standard tools

Condition:

Kdedewd Uinepfx Addeg

The machine is in very good condition.

The seller is not liable for typographical or data transmission errors. The machine's appearance, technology, and wear are consistent with its age; used machines are sold without any warranty.

Listing

Kreuztal

Kreuztal

907 km

Hydr. Press brake

TRUMPFTrumaBend V130 3000 x 130 to

Call

Condition: excellent (used), Year of construction: 2000, Technical specifications:

Working length: 3050 mm

Distance between columns: 2690 mm

Press force: 130 t

CNC control: DELEM DA65 2 D graphic

Adjustable backgauge

Controlled axes: Y1 / Y2; X; R; I

CNC table bending compensation: Wila Moducrown

Hydr. Tool clamping at the top and bottom

Pneumatic tool shifting

Number of bending aids: 2

Installation height: 535 mm

Stroke: 220 mm

Thrust: 410 mm

Motor power: 12.5 kW

CE mark

Kjdpfx Aewimvwsddsdg

Dimensions (length x width x height): approx. 3800 x 2350 x 3150 mm

Weight: approx. 14 tons

Accessories:

1 set of standard tools

Condition:

Good condition, tools in mint condition

The seller is not liable for typographical or data transmission errors. The machine's appearance, technology, and wear are consistent with its age; used machines are sold without any warranty.

Listing

Trittau

Trittau

913 km

Press brake

TRUMPFTrumaBend V320

Call

Condition: good (used), functionality: fully functional, Year of construction: 1998, operating hours: 31,792 h, Hydraulic Press Brake

Manufacturer: TRUMPF Model: TrumaBend V320

Year of Manufacture: 1998

Technical Details

Manufacturer: TRUMPF

Model: TrumaBend V320

Kdedpjx Ar T Ejfx Addog

Year: 1998

Operating hours: 31,792 h (read-off value)

Pressing force: 320 t

Bending length: 4,080 mm

Distance between uprights: 3,680 mm

Throat depth: 410 mm

Approach speed: 150 mm/sec

Return speed: 135 mm/sec

Bending speed: 10 mm/sec

Stroke: 365 mm

Installation height: 535 mm

Space requirement: approx. 4.65 x 2.31 x 3.1 m

Weight: 24.5 t

Equipment:

• 2D graphic control Delem DA

• Pneumatic die shifting

• 2 movable support arms

• Hydraulic tool clamping, top and bottom

• CNC-controlled crowning

• Controlled axes: Y1, Y2, X1, X2, R1, R2, Z1, Z2

• Upper tool OW 202/S, 28°/R1, H 220 mm, L = 4,000 mm, segmented

• Lower tool EV006-W20, 30°/R2, H 100 mm, L = 4,000 mm, segmented

All information subject to verification.

A demonstration is possible at any time in our showroom.

Listing

Wijchen

Wijchen

725 km

Sheet shears Colmal HS40-13 2008

ColmalHS40-13

Call

Condition: used, Year of construction: 2008, Cutting bench, cutting shear

Type: Hydraulic

Manufacturer: Colmal

Type: HS 40-13

Year: 2008

Controller: Delem DAC-350

Cutting width: 4050 mm

Max. thickness: 13mm

Incl. documentation and peripherals

Incl. outfeed-conveyor

Kdsdpfx Aowng Rxsddsg

Machine dimensions: 4800x2400x2650mm

Machine weight: 15000kg

- Year: 2008

- Documentation available: No

- CE certificate present: No

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Lukas van Rossum

Listing

Günzburg

Günzburg

1,214 km

Press brake - hydraulic

TRUMPFTrumaBend V 85

Call

Condition: used, Year of construction: 2000, Press force: 85 t

Bending length: 2050 mm

Distance between uprights: 1750 mm

Control: DELEM

Ksdpfx Asxnxwnsddsdg

Stroke: 215 mm

Throat depth: 410 mm

Weight: 7,900 kg

Machine dimensions: 2700x2100x2400 mm

Accessories:

- Two-hand operation

- 2 support arms

- Side safety doors

- Lasersafe Fissler

- Wila tool holder

- Die shifting

- Crowning

- Tool cabinet

Listing

Wasbek

Wasbek

869 km

Press Brake - AHK V 30175 CNC

KnuthAHK V 30175 CNC

Call

Condition: new, The AHK V 30175 CNC is a state-of-the-art press brake that exemplifies precision and performance in the realm of Sheet Metal Processing. Designed with advanced technology and built from certified materials, this powerful machine delivers an impressive pressure force of 175 t and a brake length of 3.100 mm, ensuring superior machining quality even under demanding conditions. The robust frame and high-end CNC machining guarantee exceptional rigidity and accuracy, while the DELEM graphical touchscreen facilitates efficient CNC programming, allowing users to oversee the entire bending process with ease. The motorized crowning feature, standard on this model, ensures consistent bending results across various sheet metal thicknesses. Equipped with premium hydraulic components and a laser optical safety system, the AHK V 30175 CNC prioritizes both safety and productivity in your operations. You can easily adapt it to various requirements with its adjustable back gauge and a wide selection of European type bending tools. For those looking for a reliable Press Brake, the AHK V 30175 CNC is an excellent choice. Order online or request a quote today to take your sheet metal processing to the next level.

Kedpfx Adeww T Suedjdg

Listing

Wijchen

Wijchen

725 km

Press brakes Safan SMK40-2100

SafanSMK40-2100

Call

Condition: used, total length: 2,500 mm, total width: 2,400 mm, total height: 2,400 mm, Weight: 4.000 kg

Kdsdpfx Adoxwmwbsdsg

- Documentation available: No

- CE certificate present: No

- Drive system: CNC

- Control system brand: Delem

- Control system type: DA-53T

- Number of axes [pcs]: 3: Y1+Y2+X

- Press force [ton]: 40

- Max. working width [mm]: 2050

- Column gap [mm]: 2050

- Punch holder: Standard

- Tool holder type: WILA-standard

- Options: Finger safety guard

- Transport dimensions: 2500mm x 2400mm x 2400mm (l x w x h)

- Transport weight [kg]: 4000kg

- Transport packages [pcs.]: 1

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Lukas van Rossum

Listing

Birmingham

Birmingham

339 km

Press Brake

BaykalAphs 3106 x 120

Call

Year of construction: 2006, condition: like new (used), Rushworth Baykal APHS 3106×120 3metre x 120ton hydraulic down stroke cnc pressbrake for sale

Very clean downstroke Baykal 4axis cnc pressbrake for sale – complete with a large amount of tooling

Year 2006

Model Aphs 3106 x 120

Euro tooling

Total 4axis Y1,Y2,X and R axis

Wila crowning system

4 fingers on the backstop, ideal for extra support when folding your full 3metre length and intricate small parts

Large selection of tooling

49cm daylight

Kdsdpfoikfz Dex Addog

Euro tool clamps

Quick release clamps

Modern Delem DA-56 cnc control with usb

Hydraulic down stroking pressbrake

Delivery, installation and training available

Listing

Birmingham

Birmingham

339 km

PressBrake

Trumpf Trubendtrubend 3120

Call

Year of construction: 2010, condition: like new (used), Used Trumpf Trubend Series 3000 CNC pressbrake for sale

VIDEO BELOW:

Used Trumpf Trubend 3120 for sale 3metre x 120ton 6 axis plus pressbrake for sale.

Brand/make: TRUMPF

Model: TRUBEND 3120

Type: CNC hydraulic Press Brakes

New 2010

Location: United kingdom

Low hours – 14,000

Specification

Convert Specs to Imperial

Tonnage 119.749 t / 120ton

Type: hydraulic downstroke

Overall Length 3.1 m /3metre

BH 2.7 m

Stroke 199.9 mm

Number of axis: 7 axis

5 axis back gauge

Weight 18298 (LBS)

Control CNC (T3000)

132 Ton X 10′ Trumpf TruBend 3120 CNC Press Brake

Year: 2010

Specification from new:

Machine

– Stable machine frame as welded all-steel construction

– Ram, highly resistant to torsional forces

– Spherical ram suspension, with ram tilt

– Electro-hydraulic downstroking drive with 4-cylinder technology

– Proportional valve technology

– Modern block hydraulics

– Electronic pressure balance

– Measuring system with glass scale and frame deflection compensation

– Hydraulic oil filled in the machine (lifetime lubrication)

– Oil cooler

Backgauge System

– Backgauge system 2-axes with rack and pinion-drive for X- and R-axis,

– 2 pieces back gauge fingers with safe adjustment in front of the machine

Tool Holder

– TRUMPF Upper tool clamping, manual and hardened

– Lower tool clamping, manual and hardened

Crowning

– Self-regulating crowning system

– Additional hydraulic CNC-crowning

Control

– Machine control: T3000 colour, DELEM based on Real Time for Windows

– USB interfaces for keyboard, mouse, etc.

Kdjdpfxjhtm Ike Addsg

Safety

– Footswitch for Emergency up, down and emergency stop

– Safety equipment: Side doors and manual shutter roller at the rear

Services

– Installation, start-up and instruction

Options for Backgauge System

– Back gauge system 5 axis

Options for Tool Holder

– Amada US Style fast clamping of upper tool holders (segmented, on entire working length)

Options for Safety Device

– BendGuard

Options for Material Handling

– Support bracket (2 pc)

Delivery

– June 2011

Video below:

Used Trumpf V and C series cnc pressbrakes also available in stock for sale.

We are always interested in buying used Trumpf pressbrakes and machines such as:

TruBend 3066 TruBend 3100 TruBend 3170

TruBend Series 5000

TruBend 5085 Trubend 5130

TruBend Series 7000

TruBend 7050 TruBend 7036 TruBend 7050

TruBend Series 8000

TruBend 8230 Trubend 8400

Listing

Austria

Austria

1,578 km

Hydr. pressbrake

HESSE by DURMAAD-S 30220

Call

Condition: new, neu

ca. 10 Wochen ab Auftrags

Türkei

88113 €

1665.34 €

Kdsdowiqudopfx Addjg

220 to

3050 mm

Y1 / Y2 / X Achse

265 mm

2600 mm

450 mm

530 mm

hydraulisch

140 mm/s

10 mm/s

140 mm/s

500 mm/s

350 mm/s

250 mm

900 mm

104 mm

250 l

22 kW

4250 mm

1770 mm

3000 mm

12600 kg

Standard accessories:

3 axes (Y1, Y2,X)

CNC control DT-10

- intuitive touch-screen control (simple drawing of the bending outline with your finger)

- user friendly programming in dialogue form

- automatic calculation of bending sequence

- automatic calculation of the blank sheet size

- graphic product and tool memory

- correction possibility

- USB interfaces for backup and programm transportation

- PC software, generating programms on the PC and transfer to the machine by USB

servo motorized back gauge on linear guides and ball screws

back gauge finger blocks on double linear guides

CNC crowning table

upper tool 1010 / A / 75 °, devidedand cranked

4-V die block 60x60 2009 (V = 16,22,35 and 50 mm)

laser safety device Fiessler AKASmounted on the upper beam

linear guided sheet support arms

according to CE rules

oilfilling

users manual in English or German

ADVANTAGES OF AD-S COMPAIRED TO PDF:

- more stroke, installation height and throat

- higher approach and retraction speed of the top beam

- higher backgauge speed

- backgauge finger on double instead of single linear guide

- more options available such as: additional backgauge axes (e.g. Z1/Z2, Delta X, up to 6 axes), bending aids, laser angle measuring system, tandem design, other CNC controls ...

OPTIONAL EQUIPMENT:

R-Axis

R/Z1/Z2-Axis

DBend, 3D CAD/CAM importing- and simulation program (step, iges and dxf file import)

CNC Control Delem DA66 S

CNC Control DELEM DA-69S 3D incl. PC software Profile-S with 3D file import option

Hydraulic or pneumatic tool clamping for Euro or Wila tools

Listing

Bydgoszcz

Bydgoszcz

1,414 km

IN STOCK Press brake 160x3100 PRO

OtinusPBO-3116-PRO

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

Kodju T H Iqjpfx Addedg

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-3116-PRO DA-66T

Specifications

- Nominal bending force: 1600 kN

- Motor power output: 15.0 kW

- Approach speed: 160 mm/s

- Bending speed: 10 mm/s

- Return speed: 130 mm/s

- Weight: 9700.0 kg

- Oil tank: 210 l

- Maximum bending length: 3100 mm

- Distance between side frames: 2550 mm

- Ram width: 1600 mm

- Table height: 880 mm

- Daylight: 540 mm

- Maximum stroke: 260 mm

- Table width: 60 mm

- Throat depth: 410 mm

Tools

- Servo-driven automatic backgauge on linear guides. 2 pcs.

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram control (Y axis): Y1/Y2 independently controlled with servo drives.

- Punch quick change tooling system form AMADA

DA-66T control

- Capable of programming in 2D and 3D

- 3D visualization for preview and operation

- 17-inch color TFT screen of high resolution

- Full Windows operating software

- Compatibility with Modusys Delem system (modular scaling and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Sensor bending with parameter correction menu

- Profile-T3D software that works offline

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Assistance by a specialist

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Financing

We assist Customers interested in financing Otinus machines in obtaining the necessary funds. We also encourage you to take advantage of our advisory services. We work with various banks to select a lease or loan offer that best suits your needs.

Included in the price

2-day training including machine installation

1 day to 8 hours—machine installation and training

2 day up to 8 hours—independent work on the machine with the assistance of an Otinus technician with possibility of making specific parts used by the Customer—1 day to 8 hours

Telephone consultation with an Otinus specialist—8-hour package

from 7:30 a.m. to 9:00 p.m.—8-hour support package valid for 12 months.

Terms of cooperation

24-month warranty

Lead time: 6-8 weeks Not applicable if a machine is immediately available.

The machine is brand new.

Warranty and post-warranty service provided by the seller.

The Customer is responsible for the machine during unloading and transport within their facility.

Listing

Bydgoszcz

Bydgoszcz

1,414 km

IN STOCK PRESS BRAKE 60X2100 DA-66T

OtinusPBO-2106-PRO DA-66T

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-2106-PRO DA-66T

Specifications

- Nominal bending force: 600 kN

- Motor power output: 5.5 kW

- Approach speed: 150 mm/s

- Bending speed: 10 mm/s

- Return speed: 130 mm/s

- Weight: 5400.0 kg

- Oil tank: 140 l

- Maximum bending length: 2100 mm

- Distance between side frames: 1600 mm

- Ram width: 1580 mm

- Table height: 880 mm

- Daylight: 475 mm

- Maximum stroke: 210 mm

- Table width: 60 mm

- Throat depth: 410 mm

Tools

- Servo-driven automatic backgauge on linear guides. 2 pcs.

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram control (Y axis): Y1/Y2 independently controlled with servo drives.

- Punch quick change tooling system form AMADA

DA-66T control

- Capable of programming in 2D and 3D

- 3D visualization for preview and operation

- 17-inch color TFT screen of high resolution

- Full Windows operating software

- Compatibility with Modusys Delem system (modular scaling and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Sensor bending with parameter correction menu

- Profile-T3D software that works offline

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Assistance by a specialist

Kdedpevwmf Nsfx Addjg

We strive to maintain constant communication with our Customers. To support this, every machine purchase includes a specialist support package with hours of expert guidance.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Financing

We assist Customers interested in financing Otinus machines in obtaining the necessary funds. We also encourage you to take advantage of our advisory services. We work with various banks to select a lease or loan offer that best suits your needs.

Manufactured in Turkey

Included in the price

2-day training including machine installation

- 1 day to 8 hours—machine installation and training

- 2 day up to 8 hours—independent work on the machine with the assistance of an Otinus technician with possibility of making specific parts used by the Customer—1 day to 8 hours

- Telephone consultation with an Otinus specialist—8-hour package from 7:30 a.m. to 9:00 p.m.—8-hour support package valid for 12 months.

Terms of cooperation

- 24-month warranty

- The machine is brand new.

- Warranty and post-warranty service provided by the seller.

- The Customer is responsible for the machine during unloading and transport within their facility.

Listing

Bydgoszcz

Bydgoszcz

1,414 km

IN STOCK Press brake 200x3100 DA-66T

OtinusPBO-3120-PRO DA-66T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3120-PRO DA-66T

Specifications:

Ksdpfsu T H Rrsx Addodg

- Tonnage: 2000 kN

- Motor Output: 19.0 kW

- Oil Tank Volume: 210 l

- Approx. Weight: 10000.0 kg

- Inside Frames: 2550 mm

- Bending Length: 3100 mm

- Distance between side frames: 2550 mm

- Side Frame Width: 1600 mm

- Bed Height: 880 mm

- Daylight Opening: 530 mm

- Stroke: 260 mm

- Table Width: 90 mm

- Throat Gap: 410 mm

Speed:

- Approach 150 mm/s

- Working 10 mm/s

- Return 130 mm/s

Tools

- Automatic backgauges on linear guides driven by servo: 2 pcs

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): independent control of Y1 and Y2 axes by servo drive

- Type of punch holder: AMADA quick-action clamping

Delem DA-66T controller

- 2D and 3D graphical touch programming module

- 3D visualization for simulation and processing

- 17" colour TFT screen of high resolution

- Full Windows operating system

- Compatibility with the Modusys Delem system (modular scalability and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Bending using the sensors in parameter adjustment menu

- Profile-T3D offline software

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Manufactured in Turkey

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

1,414 km

IN STOCK Press brake 160x3100 DA-66T

OtinusPBO-3116-PRO DA-66T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3116-PRO DA-66T

Specifications:

- Tonnage: 1600 kN

- Motor Output: 15.0 kW

- Oil Tank Volume: 210 l

- Approx. Weight: 9700.0 kg

- Inside Frames: 2550 mm

- Bending Length: 3100 mm

- Distance between side frames: 2550 mm

- Side Frame Width: 1600 mm

- Bed Height: 880 mm

- Daylight Opening: 540 mm

- Stroke: 260 mm

- Table Width: 60 mm

- Throat Gap: 410 mm

Speed:

- Approach: 160 mm/s

- Working: 10 mm/s

- Return: 130 mm/s

Tools

- Automatic backgauges on linear guides driven by servo: 2 pcs

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): independent control of Y1 and Y2 axes by servo drive

- Type of punch holder: AMADA quick-action clamping

Delem DA-66T controller

- 2D and 3D graphical touch programming module

- 3D visualization for simulation and processing

- 17" colour TFT screen of high resolution

- Full Windows operating system

- Compatibility with the Modusys Delem system (modular scalability and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Bending using the sensors in parameter adjustment menu

- Profile-T3D offline software

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Ksdpfju T H Ansx Addjdg

Manufactured in Turkey

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

1,414 km

Press brake 120x3100 DA-66T

OtinusPBO-3112-PRO DA-66T

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-3112-PRO DA-66T

Specifications

- Nominal bending force: 1200 kN

- Motor power output: 11.0 kW

- Approach speed: 160 mm/s

- Bending speed: 10 mm/s

- Return speed: 130 mm/s

- Weight: 8400.0 kg

- Oil tank: 140 l

- Maximum bending length: 3100 mm

- Distance between side frames: 2550 mm

- Ram width: 1590 mm

- Table height: 880 mm

- Daylight: 540 mm

- Maximum stroke: 260 mm

- Table width: 60 mm

- Throat depth: 410 mm

Tools

- Servo-driven automatic backgauge on linear guides. 2 pcs.

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram control (Y axis): Y1/Y2 independently controlled with servo drives.

- Punch quick change tooling system form AMADA

Kdjdpfsvhcgwex Addog

DA-66T control

- Capable of programming in 2D and 3D

- 3D visualization for preview and operation

- 17-inch color TFT screen of high resolution

- Full Windows operating software

- Compatibility with Modusys Delem system (modular scaling and adaptability)

- External USB port

- Detailed user support in a multitasking environment

- Sensor bending with parameter correction menu

- Profile-T3D software that works offline

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Assistance by a specialist

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

Technical Consultation

Our specialists help select the right machine and accessories based on technical drawings of the parts you plan to produce.

Financing

We assist Customers interested in financing Otinus machines in obtaining the necessary funds. We also encourage you to take advantage of our advisory services. We work with various banks to select a lease or loan offer that best suits your needs.

Transport

We provide free loading of purchased machines and assistance in organizing transport.

Included in the price

2-day training including machine installation

1 day to 8 hours—machine installation and training

2 day up to 8 hours—independent work on the machine with the assistance of an Otinus technician with possibility of making specific parts used by the Customer—1 day to 8 hours

Telephone consultation with an Otinus specialist—8-hour package

from 7:30 a.m. to 9:00 p.m.—8-hour support package valid for 12 months.

Terms of cooperation

24-month warranty

Lead time: 6-8 weeks Not applicable if a machine is immediately available.

The machine is brand new.

Warranty and post-warranty service provided by the seller.

The Customer is responsible for the machine during unloading and transport within their facility.

Listing

Bydgoszcz

Bydgoszcz

1,414 km

Hydraulic press brake

OtinusPBO-3120-PRO

Call

Condition: new, Year of construction: 2024, Many of our machines are available from stock. Call and ask to find out more.

Hydraulic press brake PBO-3120-PRO

Specifications

- Max working thickness (S235): up to 8.0 mm

- Nominal pressure: 2000 kN

- Max working length 3100 mm

- Throat depth: 410 mm

- Max stroke: 260 mm

- Daylight: 540 mm

Kdedpfxsvhcnbj Addsg

- Distance between side frames: 2550 mm

- Max backgauge distance: 1000 mm

- Nominal motor power: 19.0 kW

- Length: 3300 mm

- Width: 1650 mm

- Height: 2975 mm

- Weight: 10000.0 kg

Tools

- Automatic backgauges on linear guides driven by servo: 2 pcs

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): independent control of Y1 and Y2 axes by servo drive

- Type of punch holder: AMADA quick-action clamping

Delem DA-66T controller

- by automatically controlling 8 axes, bending is more efficient

- can store 500 programmes consisting of 25 steps and 99 repetitions each

- up to 30 lower and upper dies can be stored in the memory

- controller with 2D/3D programming mode

- 17″ TFT touch screen

- Windows with driver software (possibility to create programmes using the external computer)

- control of bending compensation from the controller

- comprehensive design of the Delem controller

- USB with possibility to connect devices

- space for connecting a bending angle sensor

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Germany

Germany

1,148 km

CNC press brake

TrumpfTruma Bend V170

Call

Condition: used, Year of construction: 2000, CNC press brake

Manufacturer: Trumpf

Model: Truma Bend V170

Year of manufacture: 2000

Kdedex Di Hxspfx Addog

CNC control: Delem

Press force: 170 t

Working width: 4 m

Crowning

Backgauge

6 axes

Hydraulic tool clamping

Height: 2.9 m

Without tools

161225

Listing

Topole

Topole

1,361 km

ACTION Bending machines Hauxia WD67K

HauxiaWD67K

Call

Condition: excellent (used), We are offering a Hauxia bending machine for sale. It is a demonstration machine that was used for prototypes in our production hall. Therefore, it has only been in operation for a few hours. The bending machine is being sold with tools. See photos.

technical data:

Bending force: 40T

Bending length: 1600mm

Distance between columns: 1200mm

Stroke (Y-axis): 150mm

Open height: 390mm

Table width: 120mm

Working speed: 15mm/s

Fast speed: 150mm/s

Return speed (upwards): 100mm/s

Control axis (8 + 1 axis): Z1,Z2, Z1, Z2, R1, R2+V

Power: 5.5 kW

Control - Delem-DA-66T (multilingual)

Kdsdpfx Adjixl Tgjdeg

Operating instructions: English

Special price net: 19,000€

Viewing possible by prior arrangement. Location 89-600 Chojnice

If you are interested, please contact us

Trust Seal

Dealers certified through Machineseeker

Listing

Rödermark

Rödermark

1,021 km

Hydr. CNC press brake

TRUMPFTrumabend V 85 x 2000

Call

Condition: good (used), Year of construction: 1999, machine/vehicle number: 883345, Offer 25513

Technical Data:

- Max. working length: 2050 mm

- Distance between uprights: 1750 mm

- Max. pressing force: 850 kN

- Distance table/ram: 535 mm

- Throat depth: 410 mm

- Ram stroke: 365 mm

- Stroke speeds:

- Rapid downstroke speed: 200 mm/sec

- Return speed: 135 mm/sec

- Pressing downstroke speed: 1 - 11 mm/sec

Ksdpfex Exzkjx Addedg

- Total drive power: 13 kVA

- Space requirement approx.: W 2700 x H 2900 x D 2100 mm

- Weight approx.: 9100 kg

Equipped with:

- 5-axis CNC control DELEM, DA

- Y1 + 2; X; R; Z

- Two-hand control panel with foot switch

- CNC-controlled crowning system

- CNC-controlled backgauge with height adjustment 5 - 860 mm

- Hydraulic tool clamping

- Pneumatically assisted die table displacement

Listing

Rödermark

Rödermark

1,021 km

Hydr. CNC press brake

TRUMPFTrumabend V 130 x 3000

Call

Condition: good (used), Year of construction: 1997, machine/vehicle number: 885258, Offer 25514

Technical Data:

- Max. working length: 3060 mm

- Frame opening: 2690 mm

- Max. pressing force: 1300 kN

- Max. distance table/ram: 535 mm

Kdodpfxox Ew Dqs Addog

- Throat depth: 410 mm

- Ram stroke: 215 mm

- Stroke speeds:

- Downward idle speed: max. 200 mm/sec

- Upward speed: 135 mm/sec

- Pressing speed (downward): 1 to 11 mm/sec

- Total drive power: 18 kW

- Pneumatic connection: 6 bar

- Required space: approx. W 3800 x H 2700 x D 2400 mm

- Weight: approx. 11,500 kg

Features:

- 6-axis CNC control system DELEM

- Two-hand control panel with foot pedal

- Crowning system

- CNC-controlled backgauge with height adjustment 5 - 860 mm

- Hydraulic upper and lower tool clamping

- Pneumatically assisted die table shifting

Listing

Kruszyn Krajeński

Kruszyn Krajeński

1,403 km

Run press

TRUMPFTrumaBend V50

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 1997, control type: CNC control, actuation type: hydraulic, controller manufacturer: DELEM, controller model: DA65, bending force (max.): 50 t, working width: 1,200 mm, number of axes: 4, overall weight: 4,750 kg, total length: 2,500 mm, total width: 2,000 mm, total height: 2,100 mm, power: 8 kW (10.88 HP), input voltage: 400 V, Equipment: CE marking, angle measuring system, documentation/manual, emergency stop, foot remote control, For sale: Used TRUMPF TrumaBend V50 press brake, year of manufacture 1997.

The machine is in excellent technical condition and is highly reliable.

Very precise and repeatable.

In February 2024, all valve seals, safety valves, and hydraulic oil with filters were replaced by authorized service.

The machine has a very low number of operating hours.

Equipped with wiring for ACB sensors.

Hydraulics: Hoerbiger

Tool type: hydraulic Wila / Trumpf

Control unit: DELEM DA65

Number of axes: 4 - Y1, Y2, X, R

Number of back gauge fingers: 4

Machine number: 881125

Model: TrumaBend V50

Year of manufacture: 1997

Maximum pressing force: 500 kN

Working length: 1200 mm

Power: 8 kW

Voltage: 400 V

Kdsdpfx Adjx Rcf Dedjg

Hydraulic system pressure: 290 bar

Weight: 4750 kg

Overall length: 2500 mm

Overall width: 2000 mm

Overall height: 2100 mm

If you have any questions or need additional information, please send a message or contact us by phone.

Listing

Drachten

Drachten

667 km

Press brake

ErmakCNCAP 3100x120

Call

Condition: used, Used CNC press brake from Ermaksan

Type: CNC AP 3100 120

Capacity: 3100 x 120 tons

Delem DA66w graphical control

CNC controlled axes: Y1, Y2, X, R, Z1 and Z2

Crowning system

Euro tool clamping with 1 set of tools

Kdjdpfx Adsxnp S Nodsg

Year of manufacture: 2006

We make it easier for you to find: "delem"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Delem (224)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month