Used Digital Production Press for sale (33,665)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wezembeek-Oppem

Wezembeek-Oppem

731 km

Industrial digital printer rigid media

INCAAGFA INCA Onste X2

Call

Condition: excellent (used), Year of construction: 2016, Inca Onset X2, 3/4 automized

Color configuration: 8 channel printer with four colours (CMYK)

1/4 of the new price !!!!!

Perfect printhead status allowing to print at maximum speed with outstanding quality, up to 140 beds per hour/700m² per hour.

The machine is in excellent shape, serviced by manufacturer since day number one. Annual maintennace done in May 2025.

Available: August 2025

As the business expands, Onset X2 provides the capacity to extend the range of jobs companies can handle. The addition of a second set of CMYK delivers even higher productivity - up to 707m²/hr* (equivalent to 138 full-bed sheets/hr) - while an optional six channels can be populated with light cyan (Lc), light magenta (Lm), white (W) and orange (O) to add versatility and superb quality. A choice of uni-directional, bi-directional and super high-quality print modes can be selected depending on the specific job requirements.

* Based on an approximate 6 second material handling time.

Decomissioning, transport, installation, training and warranty are included (in Europe)

For further technical details please refer to enclosed data sheet.

Lhsdpfxsun Swbj Ahzeb

Listing

United Kingdom

United Kingdom

0 km

Veneer Press

ORMAORMA NPC/DIGIT 6/95 30/13 AS-BO

Call

Condition: ready for operation (used), Year of construction: 2023, This ORMA NPC/DIGIT 6/95 30/13 AS-BO was manufactured in 2023. A used hot press, it features a press area of 3000x1300 mm, six cylinders, and a maximum press opening of 400 mm. It delivers a total pressure of 90 tons and includes an 18 kW electro-heater for thermo-oil heating up to 120°C. Consider the opportunity to buy this ORMA NPC/DIGIT 6/95 30/13 AS-BO veneer press. Contact us for more information about this machine.

Application Types

Lsdpfx Ahjx D Nglozshb

Pressing / Laminating

Listing

Deinze

Deinze

675 km

H-frame presses

Fontijne2000 ton heated

Call

Condition: ready for operation (used), 6-kolomspers met 4 hydraulische zuigers opwaartse slag

diameter van de zuiger: 450 mm

slag: 550 mm

Maximale kracht van 2000 ton

max opening zonder verwarmde tafels: 780 mm

max opening met verwarmde tafels: 655 mm

Verwarmde tafels met stoom of olie

Maximale temperatuur: 300° C

Totale oppervlakte: 2000 x 2000 mm

Twee tafels van 2000 x 1000 mm (kunnen samen of apart gebruikt worden)

2x 11 kW hydraulisch vermogen

met invoerroltafel: 4260 x 1550 x 1250 mm

Olietank op platform: 2000 x 2000 x 2500 mm

Totale hoogte van de pers: 3600 mm

De pers zit 920 mm in de grond

Werkhoogte is 750 mm

Lhedpev Rwftofx Ahzob

Toepassingen:

- composietmateriaal

- vulkaniseren

- buigen / strekken

Listing

United Kingdom

United Kingdom

438 km

Punching press

AMADAVIPROS 368 KING BRUSH TABLE

Call

Condition: excellent (used), Year of construction: 2002, Model .Amada. Vipros 368 King

Stock number 01967

Year of manufacture 2002

Lodpfxjvn D Tfo Ahzshb

Frame Construction ... Bridge Type

Press Capacity ... 30 Tonnes (294 kN)

Press Type ... High Speed Hydraulic Servo Ram

Axis Traverse Distance ... 1525 x 2000 mm

Workable Max. Sheet Size ... 1525 x 4000 mm

(with auto repositioning)

Max. Material Thickness ... 3.2 mm mild steel

Max. Hole Dia. Max. Material ... .

(shearing strength 36 kg/mm2) 82 mm dia

Max. Material Weight ... 75 Kg

Max. Material weight ( Max. Speed) ... 60 Kg

Max. Hole Dia. ... 114.3 mm

Number Of Stations ... 58 stations:24 x 12.7 mm

24 x 31.7 mm

4 x 50.8 mm

2 x 88.9 mm

Auto Index

2 x 31.7 mm

2 x 114.3 mm

Axis Speed ... 113.0 m/min

Hits Per Minute (2mm pitch) ... 860 H.P.M./3 mm stroke

(8mm pitch) ... 560 H.P.M./3 mm stroke

(25mm pitch) ... 460 H.P.M./3 mm stroke

Turret Speed Bi-Directional ... 30 R.P.M.

Punching Accuracy ... ± 0.1 mm

(incl. 1 reposition)

Ram Stoke Length (maximum) ... 40 mm

Tool Lubrication ... Air Blow System

Axis Drive ... AC Servo Motor

Turret Drive ... AC Servo Motor

Electric Power Required ... 28 kVA 400V +/- 10% 50Hz

Air Pressure Required ... 5.0 Kgf/cm2

Air Flow ... 250 1/min

Cooling Water Flow ... Min 40 1/min.

Machine Length ... 5025 mm

Machine Width ... 4120 mm

Machine Height ... 2630 mm (3190 mm to mirror)

Machine Weight ... 18000 Kg

Listing

Rosmalen

Rosmalen

711 km

Window production line

WEINIGConturex Greenline Plus

Call

Condition: good (used), Year of construction: 2019, Weinig Conturex Greenline Plus CNC Window production machine

Description;

Lhedpow N Nixefx Ahzjb

Year of construction: 2019

Processing workpiece length: 4500 mm

Automatic part check on infeed

Clamp adjustment in connection with rebate clamps

Main motor 30 kW indirect driven

Unispindle for mortizing, drilling and special machining

Tool changer 35 and 17 positions

HSK 63F tool holder

Special software for machine data and company data registration

In/output buffer length: 2000/ 2500 mm

Optional tool set/ plan available

Full description on request

(Despite our great care all changes, mistakes in technical data, prices and all information is subject to (typing) errors. No guarantee on printed data!

Availability subject to prior sales).

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen vorbehalten! Keine Garantie auf gedruckte Daten!.

Verfügbarkeit vorbehaltlich Zwischenverkauf).

Prices excl. advertisement cost MachineSeeker / Preise exkl. Inserierungskosten MaschinenSucher

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Listing

Mouscron

Mouscron

684 km

Press brake

LVDPPEB EQ 80/25

Call

Condition: like new (used), functionality: fully functional, Year of construction: 1997, Hydraulic press brake LVD PPEB-EQ 80/25 S630 with retrofit 2023

Year of construction 1997

Serial number 24589

Technical specifications

Force 800kN

Working length 2500mm

Distance between uprights 2050mm

Stroke 200mm

Distance table – ram 400mm

Gap 400mm

Width table 150mm

Approach speed 130mm/s

Working speed 11mm/s

Return speed 115mm/s

weight 6200 kg

motor 7,5 kW

Lhedpfx Aoyag Umjhzjb

NEW 2023 CNC COMMAND CONTROL S-630 4 axes

Y1 - Y2

X - R

Touch screen 10”

2D-Graphic simulation of bending

Automatic sequence bending

Automatic development

Database for tooling and workpieces

...

2 front supports included

.

Listing

Baughurst

Baughurst

472 km

Digital print machine

CanonOce VarioPrint 6330

Call

Condition: used, Year of construction: 2018, functionality: fully functional, FOR SALE:

Canon Océ VarioPrint 6330 TP Titan – High-Speed Monochrome Production Press

Lhjdpfx Asx Hz T Eshzjb

Boost Print Production & Efficiency

A fully functional, high-speed Canon Océ VarioPrint 6330 TP Titan digital production printer is for sale. This machine is known in the commercial print industry for its productivity, offset-like quality, and media versatility.

It is ideal for high-volume environments, commercial print shops, and in-house operations. These operations focus on books, manuals, transactional documents, and direct mail.

Key Features & Benefits:

Ultra-High Speed: It can achieve speeds of up to 328 A4 impressions per minute with Océ Gemini Instant Duplex Technology. This technology prints both sides at once in a single pass.

Superior Print Quality: It delivers quality with a 600 x 1200 dpi resolution. It uses advanced Océ Copy Press technology for a matte finish and precise registration.

Wide Media Versatility: It handles media weights from 50 gsm up to 300 gsm (and up to 350 gsm for validated stock). This includes specialty and textured papers, tabs, and carbonless forms.

Robust Paper Handling: It comes with a high-capacity system, expandable to multiple trays. It has a paper input capacity of up to 24,000 sheets.

Eco-Friendly Operation: It features low power consumption, minimal ozone emissions, and low heat output. This makes it efficient and operator-friendly for any print room.

Workflow Integration: It is managed by the PRISMAsync controller. It includes DFD interface support for connection to third-party finishing options (binding, saddle-stitching, punching).

Machine Specifications:

Model: Canon Océ VarioPrint 6330 TP Titan

Condition: Ready for operation (used), fully functional

Year of Manufacture: Year 2018

Resolution: 600 x 1200 dpi (up to 180 lpi)

Max Monthly Volume: Up to 10,000,000 A4 images

Max Paper Size: Up to 350 mm x 500 mm (13.8" x 19.7")

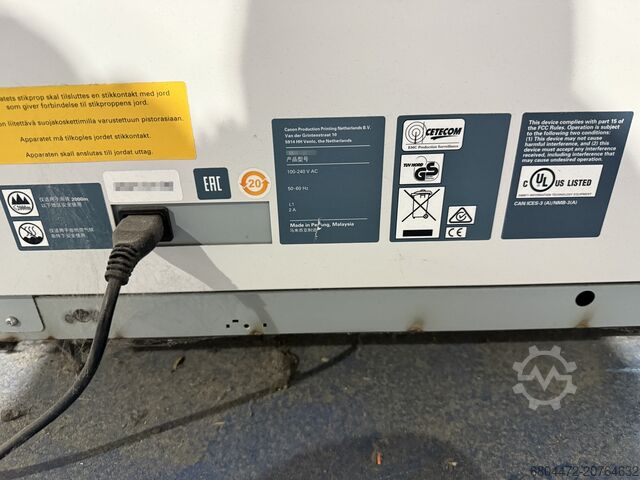

Configuration Includes: (Please check photos to be sure)

Paper Input Modules, 8x Duo Paper Trays]

2x High Capacity Stackers]

PCL, IPDS, PostScript language support]

PRISMAsync Controller]

Current Meter Readings:

See Photo.

Price:

(Negotiable)

The original price for this configuration was over €140,000!

Logistics:

The buyer is responsible for arranging shipping. . The machine is located in [UK].

Listing

Düsseldorf

Düsseldorf

814 km

Upset press with inductive heating

GFUHP 200

Call

Year of construction: 2009, condition: ready for operation (used), Used upsetting press with induction heating, for solid material Ø: 12mm – 60mm

Lhodeycl Idspfx Ahzeb

Listing

Wiefelstede

Wiefelstede

785 km

Eccentric press 35 tons

EdelhoffEP4

Call

Condition: good (used), Year of construction: 1952, Eccentric press, single-column press, stamping press, single-column eccentric press, eccentric press, single-column press

-Safety cage fully enclosed

-pneumatic viewing window with finger protection

-Pressure force: 35 tons

-Protrusion: 190 mm

-Stroke rate: 105 strokes/min

Ledpfx Ahjb A Hwhjzjhb

-Adjustable plunger: 50 mm

-Pulley surface 250 x 200 mm

-Adjustable stroke: 15-70 mm

-Table size: 540 x 310 mm

-Protrusion: 180 mm

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

838 km

Digital print machine

Konica Minoltabooklet finisher SD-513 WY1

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used Konica Minolta SD-513 brochure finisher.

Item for sale:

1 x Konica Minolta SD-513:

Condition:

Ledpfx Ajx D Ab Aohzshb

This offer is for a used device, which may show signs of wear

(minor scratches or yellowing).

The device has been tested for functionality.

A test print can be seen in the photo.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Seaworthy packaging and worldwide shipping available on request!

For more information, please feel free to contact us personally.

Listing

Langenfeld (Rheinland)

Langenfeld (Rheinland)

838 km

Brochure production system

Bourg BBF2005 Perfect Binderfor div. Xerox systems

Call

Condition: used, functionality: fully functional, With this offer, you are purchasing a used brochure production system, the ‘C.P. Bourg BBF2005 Perfect Binder’.

Lhodjxzqa Ujpfx Ahzeb

Item for sale:

1 x Bourg BBF2005 suitable for various Xerox model families:

iGen

ColorPress

Nuvera

DocuTech

Condition:

This offer is for a used device, which may show signs of wear

(minor scratches or yellowing).

The device has been tested for functionality.

Packaging and shipping:

You are welcome to view the device during our business hours. Please make an appointment!

Seaworthy packaging and worldwide shipping available on request!

For more information, please feel free to contact us personally.

Listing

Bünde

Bünde

865 km

Hand-Operated Fly Press

Fritz Werner

Call

Condition: used, pressure ca. 5 t

dayligth 110 mm

throat 40 mm

weight of the machine ca. ca. 50 kg

dimensions of the machine ca. 1,2 x 0,5 x 1,3 m

6 t (estimaeted) hand-operated spindle press. The machine is professionally

Lodpjxr Ravefx Ahzshb

and durably lashed.

Machine dealer with own stock of 1600 m².

Listing

Wasbek

Wasbek

869 km

Press Brake - AHK M 1230 NC

KnuthAHK M 1230 NC

Call

Condition: as good as new (ex-display), The AHK M 1230 NC is a robust press brake from the renowned KNUTH brand, designed as a modern, cost-effective alternative to traditional CNC press brakes. This versatile machine is well-suited for operators who prefer working without complex CNC programming, featuring a user-friendly touchscreen interface for direct positioning of the back gauge along the X and R axes. The machine's high-precision steel construction and hydraulic design ensure excellent rigidity and durability, accommodating intricate bending sequences. With a pressure force of 30 tons and a bending length of 1,250 mm, it is ideal for processing various materials and contours. Noteworthy standard equipment includes the Weintek 7'' NC control, motorized back gauge, and light curtains, which enhance both safety and productivity. You can confidently order this reliable press brake online to elevate your sheet metal processing capabilities.

Lhjdpemf Tilefx Ahzjb

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi60 SLS

Call

Condition: good (used), Year of construction: 2016, functionality: fully functional, Baler Dixi 60 SLS, Year of Manufacture 2016

Technical Specifications:

Manufacturer: Maschinenfabrik Bermatingen

Year of Manufacture: 2016

Lhodpoyba Dwofx Ahzob

Pressing Force: 60 t

Drive Power: 11 kW, 32 A

Filling Opening: 990 x 1110 mm (W x L)

Bale Dimensions: 1100 x 800 x 1200 mm

Bale Weight: approx. 370-450 kg

Binding: 3-fold manual

Machine Dimensions: approx. 4870 x 2100 x 2150 mm (L x W x H)

Weight: approx. 5,220 kg

Suitable Materials: Paper, Cardboard, Film

The press is in good condition. It has been inspected and tested by us. A video can be found on our website or YouTube channel. The operating manual and CE declaration are available.

Inspections, including under power, are possible at any time by appointment. Upon request, we can also perform tests with your material for a service fee.

For questions regarding the machine, we will be happy to assist you by phone from Monday to Thursday between 08:00 and 14:00 and on Friday from 08:00 to 13:00.

Please note:

All technical data is based on manufacturer information. We do not accept liability for any errors or inaccuracies in the above details.

This offer is subject to change, prior sale reserved and can be withdrawn at any time. Inspections are possible by appointment.

Sale is ex works, prepayment required, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi80 SLD

Call

Condition: good (used), Year of construction: 2019, functionality: fully functional, Bale Press Dixi 80 SLD, with lifting/tipping device, semi-automatic, year of manufacture 2019

Manufacturer: Dixi

Model: Dixi 80 SLD

Year: 2019

Drive Power: 11 kW, 400 V / 32 A

Feed opening: 1,040 x 1,110 mm (W x L)

Pressing force: 80 t

Press cycle time: approx. 35 s

Throughput: approx. 1,000 kg/h

Bale size: 1,120 x 1,120 x 1,200 mm (W x H x L)

Bale weight: approx. 500-600 kg

Tying: 4-fold, manual

Machine dimensions: approx. 4,320 x 1,830 x 2,620 mm (L x W x H)

Machine weight: approx. 8,000 kg

Materials: Paper, cardboard, film

The press is in good condition. It has been inspected and tested by us. A video is available on our website or YouTube channel. Operating manual and CE declaration are available.

Lsdpoyba A Tofx Ahzjhb

Inspections, including under power, can be arranged by appointment at any time. Upon request, we can also perform test runs with your material for a handling fee.

We are happy to answer any questions you may have about the machine, also by phone from Monday to Thursday between 08:00 and 14:00. On Friday we are available from 08:00 to 13:00.

Please note:

All technical data is based on manufacturer’s information. We accept no liability for the specifications provided or for any potential errors. Offer is subject to change, prior sale reserved, and can be revoked at any time. Inspections are possible by appointment. Sale is ex-works against advance payment, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi60 SLD

Call

Condition: good (used), Year of construction: 2015, functionality: fully functional, Dixi 60 SLD Baler, Year of Manufacture 2015

Manufacturer: Maschinenfabrik Bermatingen

Model: Dixi 60 SLD

Year of Manufacture: 2015

Drive Power: 7.5 kW, 400 V / 32 A

Feed Opening: 990 x 1,110 mm (WxL)

Pressing Force: 60 t

Press Cycle: approx. 47 s

Bale Size: 800 x 1,100 x 1,200 mm (WxHxL)

Bale Weight: approx. 370–410 kg

Tying: 3-fold, manual

Machine Dimensions: approx. 4,150 x 1,725 x 2,035 mm (LxWxH)

Machine Weight: approx. 5,420 kg

Lsdpfx Ahoyba Amjzohb

Materials: Paper, Cardboard, Film

The press is in good condition. It has been checked and tested by us. A video is available on our website or YouTube channel. The operating manual and CE declaration are included.

Inspections, including under power, are possible at any time by arrangement. On request, we also conduct tests with your material for a handling fee.

We are happy to answer any questions about the machine by phone from Monday to Thursday, 08:00 to 14:00, and on Fridays from 08:00 to 13:00.

Please note:

All technical data refer to the manufacturer's information. We accept no liability for the accuracy of the stated information or possible errors.

The offer is non-binding, subject to prior sale, and can be withdrawn at any time.

Viewings are available by appointment.

Sale is on a prepayment basis, ex works, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi60 SLS

Call

Condition: good (used), Year of construction: 2013, functionality: fully functional, Baling Press Dixi 60 SLS, Year of Manufacture 2013

Technical Data:

Manufacturer: Maschinenfabrik Bermatingen

Year of Manufacture: 2013

Pressing Force: 60 t

Drive Power: 11 kW, 32 A

Feed Opening: 990 x 1110 mm (W x L)

Bale Dimensions: 1100 x 800 x 1200 mm

Bale Weight: approx. 370–450 kg

Tying: 3-fold manual

Machine Dimensions: approx. 4870 x 2100 x 2150 mm (L x W x H)

Weight: approx. 5220 kg

Ljdpfxjyba Agj Ahzohb

Materials: Paper, Cardboard, Film

The press is in good condition. It has been checked and tested by us. A video is available on our website or YouTube channel. The operating manual and CE declaration are included.

Viewings, including under power, are possible at any time by appointment. Upon request, we can also perform test runs with your material for a handling fee.

We are happy to answer any questions about the machine by phone from Monday to Thursday, 8:00 am to 2:00 pm. On Friday, we are available from 8:00 am to 1:00 pm.

Please note:

All technical data is based on the manufacturer's information. We accept no liability for any errors in the information provided. This offer is non-binding, subject to prior sale, and can be withdrawn at any time.

Viewings are possible by prior arrangement. Sale is ex works, prepayment required, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi80 SLD

Call

Condition: excellent (used), Year of construction: 2016, operating hours: 1,030 h, functionality: fully functional, Baler Dixi 80 SLD, with lift/tilt device, semi-automatic, year of manufacture 2016

Manufacturer: Dixi

Model: Dixi 80 SLD

Year of manufacture: 2016

Operating hours: 1,030

Drive power: 11 kW, 400 V / 32 A

Feed opening: 1,040 x 1,110 mm (W x L)

Pressing force: 80 t

Pressing cycle: approx. 35 s

Capacity: approx. 1,000 kg/h

Bale size: 1,120 x 1,120 x 1,200 mm (W x H x L)

Bale weight: approx. 500-600 kg

Ljdpfxjybaz As Ahzjhb

Tying: triple, manual

Machine dimensions: approx. 4,320 x 1,830 x 2,620 mm (L x W x H)

Machine weight: approx. 8,000 kg

Materials: Paper, cardboard, film

Note: The press is in very good condition. It has been inspected and tested at our location in 28816 Stuhr. You will find the video on our website or YouTube channel. The hydraulic hoses should be renewed.

Inspections with power connection are possible at any time by appointment. On request, we can also carry out tests with your material for a handling fee.

We are happy to answer any questions about the machine by phone from Monday to Thursday from 08:00 to 14:00. On Fridays, we are available from 08:00 to 13:00.

Please note:

All technical data are based on information provided by the manufacturer. We assume no liability for the information provided or for any errors. This offer is subject to change and prior sale, and can be revoked at any time.

Inspections are possible by appointment.

Sale is conducted on a prepayment basis, ex works, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi60 SLD

Call

Condition: good (used), Year of construction: 2012, functionality: fully functional, Baler Dixi 60 SLD, year of manufacture 2012

Manufacturer: Maschinenfabrik Bermatingen

Model: Dixi 60 SLD

Year of manufacture: 2012

Drive power: 7.5 kW, 400 V / 32 A

Feed opening: 990 x 1,110 mm (W x L)

Pressing force: 60 t

Lhodpfxjybazio Ahzsb

Press cycle: approx. 47 s

Bale size: 800 x 1,100 x 1,200 mm (W x H x L)

Bale weight: approx. 370-410 kg

Tying: 3-fold, manual

Machine dimensions: approx. 4,150 x 1,725 x 2,035 mm (L x W x H)

Machine weight: approx. 5,420 kg

Materials: Paper, cardboard, film

Please note:

All technical data are based on the manufacturer's specifications. We assume no liability for the information provided or for possible errors.

This offer is subject to change without notice, prior sale reserved, and may be withdrawn at any time.

Viewings are possible by appointment.

Sale is ex works, prepayment required, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi50 S

Call

Condition: excellent (used), Year of construction: 2019, functionality: fully functional, Vertical baler Dixi 50 S, year of manufacture 2019, in very good condition

Technical Data

Manufacturer: Maschinenfabrik Bermatingen

Model: Dixi 50 S

Year of manufacture: 2019

Drive power: 7.5 kW

Pressing force: 50 t

Pressing cycle time: 23 s

Lhsdpfx Ajybapaehzeb

Filling opening: 1200 x 620 mm

Filling height: 1000 mm

Bale size: 1200 x 800 x 830 mm

Bale weight: 300–350 kg

Tying: manual

Transport dimensions: 1600 x 1300 x 2200 mm

Weight: 2300 kg

Materials: PET bottles, HDPE/LDPE/PP, hollow bodies, big bags, textiles, film, Styrofoam, fleece, glass wool, etc.

The operating manual and EC Declaration of Conformity are available in German.

Remarks:

The machine is in very good condition. It has been inspected and tested at our facility in 28816 Stuhr. The video can be found on our website or our YouTube channel.

Viewings, including under power, are possible at any time by appointment. Upon request, we can also conduct tests with your material for a handling fee.

If you have questions about the machine, we are happy to answer them by phone from Monday to Thursday from 08:00 to 14:00, and on Friday from 08:00 to 13:00.

Please note:

All technical data is based on the manufacturer's information. We assume no liability for the details provided or for any errors. Offers are non-binding, subject to prior sale and may be withdrawn at any time. Inspections are possible by prior arrangement. Sale is ex location, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

PresonaLP 85 VH2

Call

Condition: good (used), Year of construction: 2018, operating hours: 40,350 h, functionality: fully functional, Baling Press Presona LP 85 VH2 with Cross Tying, Year of Manufacture 2018

Technical Specifications:

Manufacturer: Presona Sweden

Model: LP 85 VH2

Year: 2018

Drive Power: 2 x 45 kW

Operating Hours: 40,350

Effective Operating Hours: Approx. 22,000

Pre-press Force: 28 t

Main Press Force: 85 t

Feed Opening: 1500 x 1100 mm

Bale Dimensions: 750 x 1100 mm

Bale Weight: 450–650 kg

Theoretical Throughput Volume: 1,200 m³/h

Throughput Capacity at 30–100 kg/m³: 13–30 t/h

Tying: 5-fold vertical, 3-fold horizontal

Oil Tank Capacity: 2,000 L

Press Transport Dimensions: 10,400 x 2,400 x 2,800 mm (LxWxH)

Weight: Approx. 27,000 kg

The press was removed from ongoing operation. A spare parts package is included in the scope of delivery.

Technical documentation is available.

Please note:

Lhsdjybaniepfx Ahzob

All technical data refer to the manufacturer’s information. We do not assume liability for the specifications provided or for any errors. The offer is non-binding, subject to prior sale, and may be revoked at any time. Viewings are possible by appointment. Sale only by advance payment, ex works, without warranty or guarantee.

Trust Seal

Dealers certified through Machineseeker

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi50 S

Call

Condition: excellent (used), Year of construction: 2019, functionality: fully functional, Vertical baler Dixi 50 S, year of manufacture 2019, in very good condition

Technical Data

Manufacturer: Maschinenfabrik Bermatingen

Model: Dixi 50 S

Year of manufacture: 2019

Drive power: 7.5 kW

Pressing force: 50 t

Pressing cycle time: 23 s

Filling opening: 1200 x 620 mm

Filling height: 1000 mm

Bale size: 1200 x 800 x 830 mm

Bale weight: 300–350 kg

Tying: manual

Transport dimensions: 1600 x 1300 x 2200 mm

Weight: 2300 kg

Materials: PET bottles, HDPE/LDPE/PP, hollow bodies, big bags, textiles, film, Styrofoam, fleece, glass wool, etc.

The operating manual and EC Declaration of Conformity are available in German.

Remarks:

The machine is in very good condition. It has been inspected and tested at our facility in 28816 Stuhr. The video can be found on our website or our YouTube channel.

Viewings, including under power, are possible at any time by appointment. Upon request, we can also conduct tests with your material for a handling fee.

If you have questions about the machine, we are happy to answer them by phone from Monday to Thursday from 08:00 to 14:00, and on Friday from 08:00 to 13:00.

Please note:

Lhodpsybal Uefx Ahzeb

All technical data is based on the manufacturer's information. We assume no liability for the details provided or for any errors. Offers are non-binding, subject to prior sale and may be withdrawn at any time. Inspections are possible by prior arrangement. Sale is ex location, without warranty or guarantee.

Listing

Stuhr

Stuhr

835 km

Bale press

Dixi50 S

Call

Condition: excellent (used), Year of construction: 2020, functionality: fully functional, Vertical baler Dixi 50 S, year of manufacture 2020, in very good condition

Technical data

Manufacturer: Maschinenfabrik Bermatingen

Model: Dixi 50 S

Year of manufacture: 2020

Drive power: 7.5 kW

Pressing force: 50 t

Press cycle time: 23 s

Filling opening: 1200 x 620 mm

Filling height: 1000 mm

Bale size: 1200 x 800 x 830 mm

Bale weight: 300–350 kg

Binding: manual

Transport dimensions: 1600 x 1300 x 2200 mm

Weight: 2300 kg

Materials: PET bottles, HDPE/LDPE/PP, hollow bodies, big bags, textiles, film, polystyrene, fleece, glass wool, etc.

The operating manual and EC Declaration of Conformity are available in German.

Lhodpfeybak Rex Ahzeb

Note:

The machine is in very good, as-new condition. The seals on both cylinders for the retaining clamps have been replaced. The machine has been inspected and tested at our facility in 28816 Stuhr. You can find the video on our website or our YouTube channel.

Inspections, including under power, are possible at any time by prior arrangement. Upon request, we also conduct tests with your material for a processing fee.

If you have any questions about the machine, we will be happy to assist you by phone from Monday to Thursday between 8:00 am and 2:00 pm. On Fridays, we are available from 8:00 am to 1:00 pm.

Please note:

All technical data refer to the manufacturer's specifications. We accept no liability for the information provided or for possible errors.

Offers are subject to change, prior sale reserved, and can be revoked at any time.

Inspections are possible by appointment.

Sale is ex works, without warranty or guarantee.

Listing

Birmingham

Birmingham

339 km

Press brake

BystronicPR 250x5100

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2005, control type: CNC control, controller manufacturer: Cybelec, bending force (max.): 250 t, stroke length: 265 mm, number of axes: 6, type of crowning: CNC-controlled, Equipment: CE marking, emergency stop, safety light barrier, Used Bystronic 250ton x 5metre multi axis hydraulic downstroke cnc pressbrake for sale

PR250 x 5100

Make: Bystronic

Model: PR 250 Pressure Reference

Year / new: 2005

Total axis:6 – 4axis back gauge X R Z1 Z2

Free standing no pit required

Lodpjx R Ut Hjfx Ahzehb

Capacity / bed size / tonnage: 5metre x 5100mm x 250ton

Cnc control: Cybelec

Delivery to your factory and installation complete with tuition with your operators can be arranged (mainland UK only) shipping worldwide can be arranged

Listing

Birmingham

Birmingham

339 km

Press brake

TrumpfTrumabend V170

Call

Condition: excellent (used), functionality: fully functional, control type: CNC control, controller manufacturer: Delem, bending force (max.): 170 t, number of axes: 4, type of crowning: CNC-controlled, Equipment: CE marking, foot remote control, lower tooling, safety light barrier, upper tooling, Used Trumpf Trumabend V170 CNC Hydraulic Press Brake For Sale

Subcategory: Press Brakes

Tonnage: 170Ton

Manufacturer: Trumpf

Model: V170 Trumabend

Condition: Used

Trumabend DA65 2D CNC Controls

Lodsx R Ul Aepfx Ahzjhb

4 Axis machine, complete with i axis

2 Axis CNC Back Gauges R and X Axis complete with 4 fingers on the back stop

CNC Ram Control Y1, Y2

CNC Bed Crowning

Die Shift (iaxis)

Pedestal Controls

Electric Foot Switch

Safety Light Guards

We make it easier for you to find: "digital production press"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Digital Production Press (33,665)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you