Used Euromate Mfd for sale (43)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Gdańsk

Gdańsk

1,400 km

Powder coating plant

Powder Coating Production Line100M-9,0/6,1/1,8

Call

Condition: used, Year of construction: 2016, functionality: fully functional, machine/vehicle number: 430/16, Powder Coating Line (Pass-through Polymerization Oven for Powder Paint, complete with Conveyor System and Dual Paint Booth)

Basic technical data of the oven:

- Max. external dimensions (L x W x H): 9.6 m x 6.6 m x 2.5 m

- Weight: approx. 9,000 kg

- Max. operating temperature: 220°C

- Max. burner power / GZ50/: 2 x 160 kW

- Fan motor power: 24 kW

- Power supply: 3 x 400 V +N +PE, 50Hz

Maximum workpiece dimensions:

- L = 2.0 m

- H = 1.0 m

- W = 0.6 m

Included with the machine:

Complete technical documentation + parts lists.

The oven is integrated with an overhead conveyor system by JOKŚ.

The conveyor system includes 42 m of tracks, along with a drive system and lubrication system; control system with speed regulation in the range of 0.5–1.5 m/min. APAR AR200 speed recorder, LG iG5A series inverter, EATON MFD-AC-CP4 manual power/communication module, MFD-CP4, MFD-80.

Manual powder coating booth; pass-through, two-station. Paint access windows on opposite sides, offset.

Max. dimension of painted workpiece:

- L = 2.0 m

- H = 1.0 m

- W = 0.6 m

A linear overhead transport system runs through the center of the booth.

The booth includes 3 tanks adapted for powder recovery/color change, filtration system based on cartridge filters. End tanks equipped with screens.

Ijdpeu Hib Njfx Ah Uobf

Listing

Eilenburg

Eilenburg

1,149 km

Bus

FORDTransit 460 L4H3 HA S&S (17-Si.) Trend

Call

Condition: used, mileage: 166,382 km, power: 114 kW (155.00 HP), first registration: 01/2018, fuel type: diesel, number of seats: 17, gearing type: mechanical, emission class: euro6, color: white, Equipment: ABS, air conditioning, electronic stability program (ESP), parking heater, soot filter, Subject to errors and prior sale!

Internal number: 1108. HK05425

Ibodpfxjr E Tr Us Ah Uof

----EQUIPMENT

* Outside mirrors, electrically adjustable, heated and foldable - with integrated indicators

* Paintwork: Uni

* Climate package 4 - Air conditioning front and rear including dust and pollen filter - including water heating rear - Voltage converter 230 V/150 watts (socket) - Generator 210 A

* Visibility package Premium - Outside mirrors, electrically adjustable and heated - Washer fluid sensor - Outside mirrors, electrically foldable - Instrument lighting adjustable - Windscreen wipers with rain sensor - Headlight assistant with day/night sensor - Rear view camera with image transmission of the rear path in the interior mirror

* Auxiliary heating package 1 - Fuel-water heating, programmable, including remote control

* Parking pilot system front and rear with rear view camera - Rear view camera with image transmission of the rear path in the interior mirror

* Audio system 5: Radio-CD player incl. Ford SYNC with AppLink and DAB/DAB+ - MFD (monochrome/graphics capable) with 8.8cm screen diagonal - Radio-CD player, MP3 capable, double tuner, 4 LSP front and 2 rear - Audio remote control on the steering wheel - Ford SYNC: mobile phone preparation with Bluetooth interface and voice control (wireless hands-free system for operating telephone and audio functions, microphone, access to phone book for various mobile phones and SMS reading function - USB interface and AUX input - Emergency call assistant - Applink

* Seat package 14 - Driver's seat, 4-way adjustable (forward/backward, backrest, inclination, height) - Single passenger seat, 4-way adjustable (forward/backward, backrest, inclination, height) - Headrests, height adjustable - Seat heating for driver - Seat heating for passenger - Inside armrest for driver - Inside armrest for single passenger seat - Lumbar support, manual (driver's seat) -Lumbar support, manual (passenger seat) - Seat cover: fabric

* Gearbox: 6-speed

* Anti-lock braking system with electronic brake force distribution (EBD)

* Axle load increase - front to 1850 kg

* Airbag (passenger side)

* Airbag driver's side

* Outside mirrors, electrically adjustable and heated - with integrated indicators

* On-board computer with consumption and mileage information and outside temperature display

* Roof, high

* Roof, overhead storage compartment at the front

* Complete roof lining

* Rear roof hatch

* Double-wing rear door with 256° opening angle, (with window) - with heated rear windows

* Tachometer

* Electronic safety and stability program (ESP) with traction control (TSC) - Hill start assist - Curve control - Safety brake assist - Rollover protection

* Lane assistant and fatigue warning

* Windows: hinged windows, 4th row left and right

* Windows: sliding windows 2nd row left

* Electric front window lifter - with quick down/up switch for driver's side

* Ford Easy Fuel - comfort tank cap and misfuelling protection

* Heated windscreen

* Speed limiter 100 km/h - cannot be switched off

* Cruise control including leather steering wheel

* Grab handles to the left and right of the sliding door

* Lockable glove compartment with lid

* Interior lighting with delay switch with reading lights at the front

* Steering column, adjustable in height and reach

* Ventilation nozzles in each row of seats in the footwell

* Fog lights

* Emergency brake light - pulsating brake lights when braking hard

* Parking pilot system front and rear

* Particle filter: diesel particle filt

Listing

Рівне

Рівне

2,041 km

Lamination unit

Windmöller & HölscherVaricoater LF

Call

Condition: ready for operation (used), Year of construction: 1986, functionality: fully functional, working width: 1,420 mm, Year: 1986

Width/mm: 1420

Thickness/µm: 14-400

Material: PO, PE, paper, HDPE, LDPE

Detail: Plant consists of:

2x Fife edge trim control

2x Ahlbrand MFD 2000 pre-treatment units (year 2001)

1x Print Concept UV unit type PC 2w-1600-2x1 (year 2001)

Coating unit with individually temperature-controlled rollers.

Iodpexcy Hyefx Ah Usbf

Sleeve system D: 76mm.

Several spare parts included.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Oak Forest

Oak Forest

6,005 km

Vertical machining center

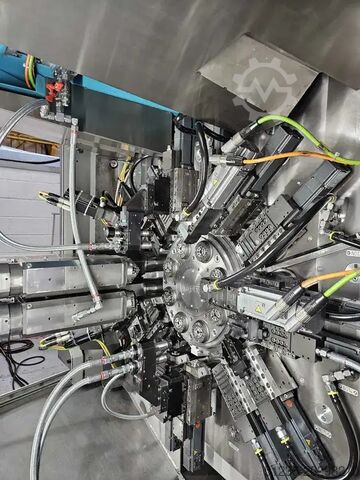

WilleminMacodel 408MT

Call

Condition: excellent (used), Year of construction: 2020, Willemin Macodel 408MT

Machine never in production!

Mfd. 2020

505 Hours

SN: 538

Schema: 408 MT-538

Premium Upgrades Included:

High-Speed Spindle Package

42,000 RPM Motor Spindle (upgraded from standard 30,000 RPM)

Air/oil lubrication system for maximum speed capability

10 kW / 13 hp power

HSK-E40 interface

Control: Fanuc 31i-B5 with advanced software package

Total Axes: 7 (X, Y, Z, A, B, U, W)

Work Envelope: 250mm x 200mm x 300mm (X/Y/Z)

Positioning Accuracy: 0.0001mm resolution via Heidenhain scales

Tool Capacity: 48 tools HSK-E40 with dual-disc magazine

Willemin-Macodel 408MT 7-Axis Mill/Turn Center

Premium Swiss Precision Configuration with Extensive Upgrades

Advanced Machining Systems

Automatic Back-Working Device (U-axis) with hydraulic vice

Bar Feed System for 500mm / 20" bar stock

Collet Chuck System (F35) for bar work up to 27mm diameter

Angular positioning W-axis (± 0.02°) for turning tools

Thermal & Environmental Controls

DTS Dynamic Thermal Stabilization for machine base

DTS Spindle Thermal Management

Elbaron Oil Vapor Extraction System with dual filtration

Complete thermal compensation package

Measurement & Monitoring

Renishaw TS-27R Touch Probe for tool measurement

Renishaw OMP 400 Spindle Probe for in-process measurement

Renishaw AXISET HD-TB for rotary axis calibration

Broken Tool Detection System (0.2mm minimum diameter)

Advanced CNC Features

High-Speed Machining Package (HPCC with 1,000 block look-ahead)

Timer Start Function for automated warm-up

Integrated Data Server with Ethernet and 1GB flash storage

Extended Program Memory (3,900 KB)

TCPC/TRC for advanced tool compensation

Medical device manufacturing

Aerospace components

High-precision contract manufacturing

Complex parts requiring minimal setups

Configuration Highlights:

Complete 7-axis simultaneous capability

Iodpfox H Tl Tex Ah Uobf

Mill/turn operations up to 6,000 RPM

Bar feeding with automatic back-working

Ultra-high speed finishing (42,000 RPM)

Comprehensive thermal management

Full probing and tool monitoring

Network-ready with data server

Listing

Oak Forest

Oak Forest

6,005 km

Turning automatic lathe

IndexMS22-8

Call

Condition: excellent (used), Year of construction: 2019, operating hours: 13,000 h, functionality: fully functional, bar diameter (max.): 22 mm, INDEX MS22-8

Mfd. 2019

2 NCU

2 Syncrons

2 Y-Axis

Control: Siemens Solution Line

Knoll System

Bar Feed: IEMCA SIR rack loader (12-ft)

22,000 on-hours

10,000-15,000 Hours

Ijdpfx Ahjx H H Nrs Usbf

Discover more used machines

Listing

Oak Forest

Oak Forest

6,005 km

Vacuum Parts Washer

IFPKP 50 HMA

Call

Condition: good (used), Year of construction: 2013, IFP Europe KP 50 HMA Basic Vacuum Parts Washer

Mfd. 2013

S/N: 201305-00974

Specifications:

Number of Baskets per Wash Cycle 1

Basket Size 11.9″ x 7.9″ x 17.7″

Machine Dimensions 70″ x 103″ x 70″

Chiller Size 5 ton

Iedpfxox Ddc Ie Ah Uobf

Solvent Capacity 106 Gallon

Wash Cycles Per Hour 4 to 8

Chamber “Max. Load Weight” 110 lbs

Machine Weight 4,000 lbs

Equipped With:

Rotos & Vane Pumps,

Liquid Ring Tank,

Rust Inhibitor Tank Filter,

Waste Oil Separator,

Siemens Touch Screen Control,

Budzar BWA-AC-05-FCB-12-0-000 5-HP Chiller,

Safety Guarding,

Light Curtains,

Automatic Door,

(3) Wash Settings,

Rust/Vap/Mist/Vac/Oscillation Settings,

100-Lb. Batch Weight

Repairs necessary:

Pumps

C301.00020 DVP LC106 Vane Pump — $5,500.00

C301.00078 Liquid Ring Pump — $3,561.55

C301.00081 RBS 45 Rotary Lobe Pump — $13,500.00

Pump Subtotal: $22,561.55

Accessories / Pipes for Conversion

A508.00031 — $287.50

A508.00012 — $287.50

A508.00013 — $345.00

Accessories Subtotal: $920.00

Grand Total

$23,481.55

Listing

Oak Forest

Oak Forest

6,005 km

Multi-spindle machine

INDEXMS22-8

Call

Condition: excellent (used), Year of construction: 2024, INDEX MS22-8

Mfd. 2024

2 NCU

(4) Y-Axis

SL Control

Cutting hours: 1,000

Turnkey Available

Located in Europe

4-Meter IEMCA SIR MS22-8/43/P

Rack loader 50 Hz D9-13-19-25

Bar length 4300 mm

with drilling unit and minimum quantity lubrication unit

additional end-of-bar sensor

Bar stock 500mm (D12-D24)

Bar stock 340 mm (D5-D11).

Additional storage chain for 22 bars

with Profinet interface.

1 11007253

(21711)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D7-D10 mm,

internal clamping for bar stock diameters D13-D18 mm, consisting of:

8 bar stock pushers D12

8 rotating sleeves D12

1 10287026

(21712)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D11-D16 mm,

internal clamping for bar stock diameters D19-D24 mm, consisting of:

8 bar stock pushers D18

8 rotating sleeves D18

1 10536056

(21713)

1 set (8 pieces) bar stock pushers for bar diameters D17 mm-D22 mm,

consisting of:

8 bar stock pushers D23

8 rotating sleeves D23

1 10414481

(21702)

1 set (8 pcs.) of internal clamping sleeves D12mm

for bar diameters D13 mm - D18 mm

Drill diameter D8 mm.

1 10472413

(21704)

1 set (8 pcs.) of external stops D12 mm

for bar diameters D13 mm - D18 mm

pre-machined.

1 10264327

(21703)

1 set (8 pcs.) of internal clamping sleeves D18mm

for bar diameters D19 mm - D24 mm

Drill diameter D15mm.

1 10058206

(21705)

1 set (8 pcs.) of external stops D18 mm

for bar diameter D19 mm - D24 mm

pre-machined.

1 12123486

Iodpfx Ahjx Ddcus Ujbf

Drill for drilling unit consisting of:

1 indexable insert drill D 15 mm

10 indexable inserts for steel

2 solid carbide drills D 8 mm

Listing

Oak Forest

Oak Forest

6,005 km

Vertical turning lathe

EMAGVL 3 DUO

Call

Condition: excellent (used), Year of construction: 2018, EMAG VL 3 DUO

CNC Twin Spindle, Vertical Turret Lathe

Mfd. 2018

S/N 1100619,

EMAG CNC control,

(2) 12-station turrets,

Chip conveyor,

Full automation system

Hennig system

Hours: 4,684

2 Machines Available

Ibsdpsu T Shvjfx Ah Ujf

110612, (2)

w/Hennig Mdl. 102783 chip conveyor, full automation system, 4,684 and

7,401 hours.

Listing

Oak Forest

Oak Forest

6,005 km

CNC turning and milling center

DMG MORISprint 32/8

Call

Condition: used, Year of construction: 2018, DMG Mori Sprint 32/8

CNC Swiss Lathe

Mfd. 2018

Control: Fanuc 32-B Plus

8-Axis

Power: 75 HP

RPM 8,500

Diameter: 32mm

With 12-ft Patriot 338 Bar Feed

Equipped as pictured

Machine concept

Number of linear axes + C-axes 6 + 2

Number of spindles 2

Number of channels 2

Main spindle

Isdpfx Aexxm A Tsh Usbf

Maximum bar capacity mm | in 32 | 1.26

Speed rpm 8,500

Power (S2 30 min/S1) kW | hp 7.5/5.5 | 10.1/7.4 S2 15 min/S1

Torque (S2 30 min/S1) Nm | ft lbs 51.9/40.4 | 38.3/29.8 S2 15 min/S1

Counter spindle

Maximum bar capacity mm | in 32 | 1.26

C-axis (0.001°)

Speed rpm 8,500

Power (S2 30 min/S1) kW | hp 3.7/2.2 | 5.0/3.0

Torque (S2 30 min/S1) Nm | ft lbs 23.6/14 | 17.4/10.3

Working area/ travels

Z1 travel (spindle travel) mm | in 100 | 3.94

Rapid traverse speed on linear axes

X1, Z1, X2, Z2/Y1, Y2 m / min | in/ min 40/30 | 131/98

Acceleration in linear axes m /s² | ft 5 | 0.02

Tool holder on slide 1

Fixed turning tools 6

Tools for front machining/back-working 4/4

Driven tools 2 + 2

Maximum speed rpm 6,000

Power (S3 40 % /S1) kW | hp 1.9/1 | 2.5/1.3

Maximum torque (S3 40 % /S1) Nm | ft lbs 3.

The 2018 DMG Mori Sprint 32/8 is a high-performance CNC screw machine built for precision, speed, and versatility in complex small-part production. Featuring an 8-axis configuration with 6 linear axes and 2 C-axes, the machine is powered by the FANUC 32i-B Plus control system with a 10.4” color display. The Sprint 32/8 is designed with dual spindles capable of 8,500 RPM, with the main spindle delivering 7.4 hp and 29.8 ft-lbs of torque, and the counter spindle generating 3 hp and 10.3 ft-lbs. Both spindles handle bar stock up to 32mm (1.26"), making it ideal for precise machining in medical, aerospace, and automotive industries.

The machine supports simultaneous machining with up to 2 tools and offers advanced back-working capabilities. The working area includes Z1, X1/Y1, and X2/Z2/Y2 travels, allowing for intricate multi-sided operations. Tooling includes 8 driven tool stations and multiple configurations for both front and back machining, with speeds up to 6,000 RPM and torque of 2.2 ft-lbs. The Tool Monitoring System offers graphical tool load display, aiding in predictive maintenance and minimizing downtime.

Additional features include high-pressure coolant and an integrated air handler, contributing to stable thermal conditions and chip evacuation. Its compact footprint of 30.1 ft² and total weight of 7,826 lbs make the Sprint 32/8 a space-efficient and powerful addition to any high-volume CNC shop. This machine is engineered to streamline part production while ensuring repeatable accuracy, robust power, and operational efficiency.

Listing

Oak Forest

Oak Forest

6,005 km

Multi-spindle machine

INDEXMS-22-8

Call

Condition: used, Year of construction: 2024, INDEX MS22-8

Mfd. 2024

2 NCU

(4) Y-Axis

Ibodpfxsxnrtcs Ah Uof

SL Control

Cutting hours: 1,000

Turnkey Available

Located in Europe

4-Meter IEMCA SIR MS22-8/43/P

Rack loader 50 Hz D9-13-19-25

Bar length 4300 mm

with drilling unit and minimum quantity lubrication unit

additional end-of-bar sensor

Bar stock 500mm (D12-D24)

Bar stock 340 mm (D5-D11).

Additional storage chain for 22 bars

with Profinet interface.

1 11007253

(21711)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D7-D10 mm,

internal clamping for bar stock diameters D13-D18 mm, consisting of:

8 bar stock pushers D12

8 rotating sleeves D12

1 10287026

(21712)

1 set (8 pieces) bar stock pushers,

external clamping for bar stock diameters D11-D16 mm,

internal clamping for bar stock diameters D19-D24 mm, consisting of:

8 bar stock pushers D18

8 rotating sleeves D18

1 10536056

(21713)

1 set (8 pieces) bar stock pushers for bar diameters D17 mm-D22 mm,

consisting of:

8 bar stock pushers D23

8 rotating sleeves D23

1 10414481

(21702)

1 set (8 pcs.) of internal clamping sleeves D12mm

for bar diameters D13 mm - D18 mm

Drill diameter D8 mm.

1 10472413

(21704)

1 set (8 pcs.) of external stops D12 mm

for bar diameters D13 mm - D18 mm

pre-machined.

1 10264327

(21703)

1 set (8 pcs.) of internal clamping sleeves D18mm

for bar diameters D19 mm - D24 mm

Drill diameter D15mm.

1 10058206

(21705)

1 set (8 pcs.) of external stops D18 mm

for bar diameter D19 mm - D24 mm

pre-machined.

1 12123486

Drill for drilling unit consisting of:

1 indexable insert drill D 15 mm

10 indexable inserts for steel

2 solid carbide drills D 8 mm

Listing

Oak Forest

Oak Forest

6,005 km

Cnc lathe

INDEXABC

Call

Condition: excellent (used), Year of construction: 2000, INDEX ABC CNC Lathe.

Mfd. 2000

Control: Siemens 840C

Capacity 65mm

Ran oil

Still in production, running nylon

With 12-ft Bar Feed (pictured)

Chip Conveyor

Comes the a good amount of tooling

Control Type: Siemens SINUMERIK 840C

Spindle Speed (max.): 6,000 RPM

Power Requirements (V/Hz/PH): 400/60/3

Main Spindle

Speed (max.): 6,000 RPM

Bar Capacity: 65 mm

Power: 20 kW (at 100%)

Power: 27 kW (at 40%)

Synchronous Spindle

Speed (max.): 4,500 RPM

Power (max.): 4.2 kW

Capacity

Tool Carrier 1: 8 (7 + synchronous spindle)

Tool Carrier 2: 6

Dimensions

Bar Feeder: L 150" x W 27" x H 52"

Ibjdpfx Aow Td U Reh Ujf

Turning Center: L 80" x W 48" x H 65"

Power Enclosure: L 52" x W 18" x H 70"

Chip Conveyor: L 88" x W 48" x H 35"

Listing

Oak Forest

Oak Forest

6,005 km

CNC turning and milling center

DOOSANPuma TT2100SYY

Call

Condition: excellent (used), Year of construction: 2019, Doosan Puma TT2100SYY

Mfd. 2019

Tooled as pictured

Specifications

SWING OVER BED 9.05"

MAX CUTTING DIAMETER 9.05"

DISTANCE BETWEEN CENTERS 38.5"

X-AXIS TRAVEL 6.5"

Y-AXIS Yes

Y-AXIS TRAVEL 3.93"

Z-AXIS TRAVEL 27.5"

C-AXIS INDEXING FULL CONTOURING C-AXIS

CHUCK SIZE 8"

Ibedpfxsw Dvnxo Ah Uef

BAR CAPACITY 2.625"

SPINDLE NOSE A2-6

SPINDLE MOTOR 35 hp

SPINDLE SPEED 5,000 RPM

RAPID TRAVERSE RATE - X-AXIS 1,181 in/min.

RAPID TRAVERSE RATE - Z-AXIS 1,575 in/min.

SUB SPINDLE Yes

SUB SPINDLE - CHUCK SIZE 8"

SUB SPINDLE - BAR CAPACITY 2.56"

SUB SPINDLE - SPINDLE NOSE A2-6

SUB SPINDLE - SPINDLE MOTOR 25 hp

SUB SPINDLE - SPINDLE SPEED 5,000 RPM

SUB SPINDLE / W-AXIS TRAVEL 28.7"

TURRET CAPACITY 12

TURRET TYPE BMT55

LIVE MILLING Yes

LIVE MILLING SPEED 5,000 RPM

LIVE MILLING MOTOR 10 hp

TURRET 2 CAPACITY 12

TURRET 2 - X-AXIS TRAVEL 6.5"

TURRET 2 - Z-AXIS TRAVEL 27.56"

Dimensions 93" X 153" (W/CONVEYOR - 186") X 88.6"H

Weight 20,940 LBS

Equipped With

FANUC OiTF CNC CONTROL

DOOSAN EZ GUIDE i PROGRAMMING

TWIN 12 POSITION TURRETS UPPER AND LOWER, W/24 POSITION INDEXING ON EACH TURRET WITH BASE MOUNT TOOLING SYSTEM

Y-AXIS ON BOTH TURRETS

(2) INTEGRAL SPINDLES

FULL CONTOURING C-AXES ON BOTH SPINDLE

MILL/DRILL ON UPPER AND LOWER TURRETS

PARTS CATCHER LEFT AND RIGHT

PROGRAMMABLE PARTS UNLOADER

PARTS CONVEYOR

BAR FEED INTERFACE

8" 3-JAW KITAGAWA CHUCK FOR LEFT AND RIGHT SPINDLES (COLLET SYSTEMS IN ON MACHINE NOT INCLUDED IN SALE)

(2) X-AXIS LIVE HOLDERS

(2) Z-AXIS LIVE HOLDERS

STANDARD FACTORY STATIC TOOLING

DOOSAN TOOL LOAD MONITORING SYSTEM

AIR BLAST SYSTEM FOR CHUCK CLEANING

2 machines available

Listing

Oak Forest

Oak Forest

6,005 km

CNC Swiss Lathe

KSITCM20S

Call

Condition: good (used), Year of construction: 2018, Mfd. 2018

Equipped with:

BWG Bar Loader (20mm),

LNS MH250 Chip Conveyor,

Ibjdpfx Ahowrty Ue Uof

MP Systems High Pressure Coolant System,

Tri-Dim Tri-Mist 850 Mist Collector

Power on time: 30513 hours

Cutting time hours: 6275 hours

Listing

Oak Forest

Oak Forest

6,005 km

Turning automatic lathe

TORNOSMultiSwiss 6x16

Call

Condition: excellent (used), Year of construction: 2016, Tornos MultiSwiss 6x16

CNC Multi-Spindle Screw Machine

Mfd. 2016

6 Spindles

Diameter:16mm

Fanuc Control

Equipped as pictured

Run time: 42,689 hrs

Power on: 64,668 hrs

Standard tornos bar feed (5ft)

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 14 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Counter spindle with integrated motor 6 kW

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Integrated PC with screen 17”

Iedowa D Tujpfx Ah Uobf

Programming system TB DECO

(DCS version)

(requires 3001)

contact us for more details

Listing

Oak Forest

Oak Forest

6,005 km

Turning automatic lathe

TORNOSMultiSwiss 6x16

Call

Condition: excellent (used), Year of construction: 2019, machine/vehicle number: 14974, Tornos MultiSwiss 6x16

CNC Multi-Spindle Screw Machine

Mfd. 2019

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 16 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Counter spindle with integrated motor 6 kW

Ibedpfsv S H Uyjx Ah Ujf

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Integrated PC with screen 17”

Programming system TB DECO

(DCS version)

(requires 3003)

contact us for more details

Listing

Oak Forest

Oak Forest

6,005 km

Cnc swiss lathe

TSUGAMISS-327-5AXIII

Call

Condition: excellent (used), Year of construction: 2020, machine/vehicle number: 300565, Tsugami SS327-5AXIII

Mfd. Nov. 2020

Fanuc Series 31i-Model B5

IEMCA Boss 338 HD

Ibsdpfx Ahevnf Rfs Uof

Run less than one shift

Cut Steel

Standard tooling included

Listing

Oak Forest

Oak Forest

6,005 km

Cnc lathe

TraubTNX 65/42

Call

Condition: good (used), Year of construction: 2007, Traub TNX 65/42 Milling and Turning Center

Mfd. 2007

Serial #7060107

Commissioned in 2010

TX 8i-S control (Mitsubishi/Traub based control with Mitsubishi drives and motors)

15 CNC axis’s

(4) X-Y-Z turrets with 10 positions each. Up to 20 tools per turret

65 mm thru hole main and sub spindle (sub spindle has coolant flush)

Foot pedal control for clamp/unclamp of spindle chucks

Servo driven gantry receiver

Hydraulic swivel w/ pneumatic finished part and bar remnant gripper

Finished part conveyor belt

RESY paper band coolant filter

Knoll Coolant tank with BKW refrigerated coolant temperature control

20 Bar High pressure and 8 Bar Low pressure coolant pumps

Knoll chip conveyor

FMB Turbo 5-55 magazine bar feeder (new in 2010)

2) Single stick turning tool holders

Iodpsq Npqmofx Ah Uobf

2) Double stick turning tool holders

1) Cut-off tool holder

1) Overdriven double radial live ER Collet tool holder

1) Overdriven radial live ER Collet tool holder

4) Radial live ER Collet tool holders

1) Radial live End Mill tool holder

1) Angle adjustable live ER Collet tool holder

2) Radial live Shell Mill tool holders

2) Axial live End Mill tool holders

6) Axial live ER Collet tool holders

43) Additional tool holders on separate list (see supplemental attachment)

Hainbuch main spindle collet chuck

Rohm sub spindle 2 jaw chuck

2 Spare sets of spare Z-axis ball screws and bearing packs.

Listing

United States

United States

6,838 km

Multi-spindle machine

INDEXMS52C

Call

Condition: good (used), Year of construction: 2006, INDEX MS52C

CNC Multi-Spindle

Mfd. 2006

Control: Siemens 840D

6 Spindles

52mm Capacity

Equipped as pictured

Under power

Knoll System

Chip Conveyor

Riedel Chiller

Ibsdpfx Ahjt Rkzwe Usf

3.6 meter (12ft) IEMCA SIR Bar Feed

SIR MS52/F

Type 38 XL

Mfd. 2005

We make it easier for you to find: "euromate mfd"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Euromate Mfd (43)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month