Used Filing for sale (439)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Hauzenberg

Hauzenberg

1,386 km

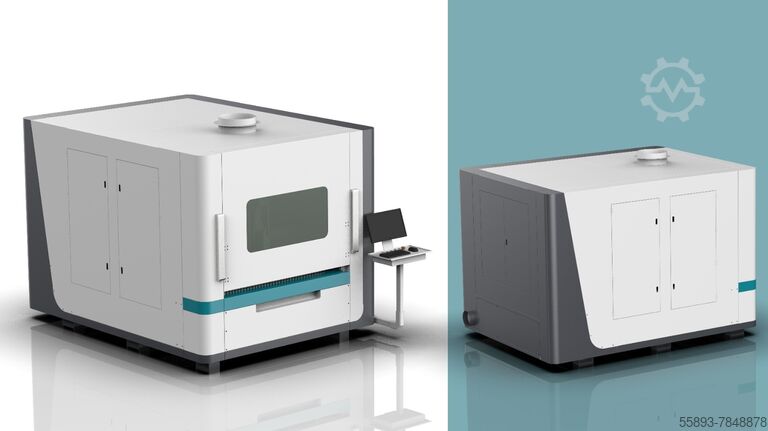

Laser cutting machine

Ledi LaserLG-1530 3kW Eco Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 3,000 W, laser wavelength: 1,070 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 10 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 3kW fiber laser

Delivery time approx. 8 weeks

Our commitment is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair shops.

A thoroughly developed cutting parameter library is included as well as exceptional service.

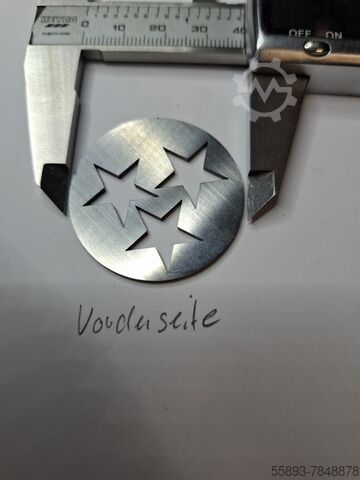

- Includes 2D bevel-cut function for weld seam preparation or production of countersunk holes (see image)

- Machine without automatic shuttle table!

Loading is carried out from the long side of the machine

- Very space-saving

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters floor space

- 3kW laser source by MaxPhotonics (G5/German version)

- Laser generator with socket efficiency better than 30%

- Suitable for aluminum

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel up to 22mm (max.)

- Stainless steel up to 12mm (max.)

- Aluminum up to 10mm (max.)

- Brass up to 8mm (max.)

- Travel range 1500 x 3000mm (for large formats)

- Machine control in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser protection windows for monitoring the cutting process

- Comprehensive cutting parameter file

- Includes nesting module

- Very easy to operate

- Powerful laser chiller

- German language machine control

- German service and spare parts supply

- Powerful laser chiller

- Optional filter extraction system available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase possible through our financing partner

Sale exclusively to commercial customers.

Delivery / consulting / sales only in Germany / Austria / Switzerland

Approx. machine dimensions:

Length: 4.0 m

Height: 2.3 m

Width: 4.5 m

Total weight: approx. 4500 kg

Kjdpfx Aeyacqwjhzowt

Need a different laser power, table type or table size?

No problem.

I'll gladly provide a suitable offer.

E.g. 2kW machine from 29,990 EUR

Not sure which laser power is suitable for your application?

Of course, I will carry out cutting tests according to your requirements.

A lot is possible here.

Listing

Germany

Germany

967 km

Gear Hobbing Machine - Vertical

Gleason-PfauterGP 130

Call

Condition: used, Year of construction: 2002, Technical details:

max. wheel diameter: 130 mm

gear width: 170 mm

max. module: 3

min. module: 0,5

total power requirement: 48 kVA

Kodpowdyx Uefx Ahzewt

weight of the machine ca.: 9 t

dimensions of the machine ca.: 7,64 x 3,14 x 3,25 m

For technical data, see PDF-File enclosed

*

Listing

Germany

Germany

967 km

Coordinate Measuring Machine

KeyenceXM-1000

Call

Condition: used, Scope of delivery see photos

Technical data see PDF file

*

Kedpfxevucgqj Ahzowt

Listing

Germany

Germany

967 km

Bevel Gear Generator - Spiral

OERLIKONC28

Call

Condition: used, Year of construction: 2000, Technical details:

max. wheel diameter: 275 mm

gear width: 55 mm

max. module: 6,5

min. module: 1,5

Face Hobbing-Continious Process

Continuous process: The workpiece and tool (usually Spiron) rotate at the same time, and all teeth are created in one operation at the same time. Knife head has several knife groups (not arranged in a circle) Parallel tooth Conical tooth tip surface

Single Item procedure: The workpiece is stationary and the tool (usually Arcon) rotates and cuts a tooth by immersing the tool. Once a tooth is cut, the tool moves out of the tooth again, the workpiece divides by one tooth width and the next tooth is cut until all teeth are finished. Knife head has arranged all knives in a circular path. Conical tooth height Parallel tooth head surface

Kwedpfx Ahsv N Hilezot

C28 can do both, wheel + pinion. However, a C28 must be “prepared” for the individual part procedure. I.e. direct measuring system + part gear brake, workpiece axis + license file for the production of individual parts.

*

Listing

Martignas-sur-Jalle

Martignas-sur-Jalle

1,189 km

Engraving machine

AcctekAKJ1390H-2

Call

Condition: excellent (used), Year of construction: 2021, functionality: fully functional, laser power: 600 W, type of cooling: water, table length: 1,300 mm, table width: 900 mm, Equipment: CE marking, For cutting and engraving on wood, cardboard, leather, etc.

Purchased new in 2021. In very good condition.

Specially designed with two laser heads, one 600W and one 90W, allowing you to adjust power, detail, and speed according to your project.

- The bed is designed to accommodate a honeycomb structure, ensuring high structural stability if needed

- Ruida control system: USB interface

- Supported graphic formats: CorelDraw, AutoCAD, Photoshop

- Drive system: Stepper motor and Leadshine driver

- Supported graphic file formats: BMP, PLT, DST, DXF, and AI

- Digital control panel

- The transparent viewing window with tinted eye protection allows you to monitor engraving progress at any time and can automatically cut the power when opened.

- An emergency stop button is available for added safety.

- Mobile casters make the machine easy to move

- Front opening allows for processing larger projects

Technical specifications:

• Working area: 1300 x 900 mm

• Laser power: SLW 600W and RECI 90W

• Sealed CO2 laser tube

• Maximum cutting speed: 0-600 mm/s

• Maximum engraving speed: 0-1000 mm/s

• Power supply: 220V±10%, 50/60Hz

Kedpfxjxzruge Ahzswt

Extras included:

Sold with CW6200 chiller, honeycomb bed, and submersible pump for mirror cooling. Spare 2” and 4” lenses included.

Listing

Lahr/Schwarzwald

Lahr/Schwarzwald

1,099 km

Universal grinding machine Haas Multigrind

A.HaasMultigrind CB

Call

Condition: ready for operation (used), Year of construction: 2008, functionality: fully functional, workpiece weight (max.): 500 kg, The HAAS Multigrind CB is a universal multifunctional grinding machine designed for grinding gear cutting tools, involute profiles, and spline shaft profiles. Thanks to its large axis travels of 700 x 410 x 500 millimeters, its robust stability, a spindle power of 30 kW, and a high feed rate of 30 meters per minute, it is optimally equipped for custom grinding applications.

Technical Data

Diameter: 500 mm

Axis travels: X 700, Y 410, Z 500 mm

Dimensions: 3.0 x 2.65 x 3.65 m

Machine weight: approx. 8,500 kg

Kedpjx Uwqpefx Ahzjwt

*All information and data is non-binding, subject to prior sale.

Key Features:

Software:

For grinding straight and helical flute hobbing cutters with dressable and non-dressable grinding wheels, grinding involute profiles and spline shaft profiles by importing .dxf files

Accessories:

Various grinding arbors: Ø 27, Ø 32, Ø 40, Ø 50, Ø 60, Ø 80, grinding wheel adapters and Hainbuch collet chucks.

Listing

Leipzig

Leipzig

1,137 km

Machining Center - Vertical

CINCINNATI-MILACRONSabre 750

Call

Condition: used, Year of construction: 1996, Technical details:

x-travel: 762 mm

y-travel: 510 mm

z-travel: 560 mm

control: Heidenhain TNC 415 OR 360

tool changer with: 21 place

table clamping surface:: 865 x 510 mm

table load: 455 kg

tool taper: SK40

spindle revolutions per minute : 60 - 8000 U/min

feed:: X/Y/Z; 15 000 mm/min

rapid traverse : X/Y/Z: 24 m/min

compressed air: Bedarf: 5,5 bar

Total power requirement: 30 kVA

motor capacity: Spindelmotor: 11,0 kW

max. torque on the spindle: konstant: von 60 - 750 KN

Weight approx.: 4,3 t

dimension machine xH: 2,6 x 2,8 x 2,6 m

dimension coolant device: L: 2,7 x B: 0,8 x H: 0,8 m

Machining center with automatic tool changer

Kwsdpfxou Idmvo Ahzjt

IKZ and coolant supply through nozzles

Chip and coolant tray

Lubrication system through ball screws

Manual control unit

Heidenhain TNC 415 - dialog or according to ISO (machining cycles: deep hole drilling; tapping; slot milling; rectangular pocket and circular pocket milling; SL cycles), up to 100 programs in file management

Machine can be visited with pleasure under power.

i.D.

*

Listing

Germany

Germany

1,137 km

Band Saw - Vertical

MÖSSNER-REKORDSM 320

Call

Condition: used, Year of construction: 1983, Technical details:

throat: 315 mm

throat in width: 310 mm

throat in - height: 230 mm

saw band length: 2530 - 2650 mm

Kwodpfxova E E Tj Ahzst

saw band width: 13 mm

band speed: 12 - 750 m/min

Table dimensions: 500 x 500 mm

table height over floor: 950 mm

total power requirement: 1,3 kW

machine weight approx.: 450 kg

dimension machine xH: 0,8 x 0,7 x 1,65 m

Steel and metal band saw

Filing band length 2550 mm

Additional equipment:

Saw band processing Ideal -> saw band cutting device-saw band welding device-saw band grinding device

Cooling via spray feeder

Foot control

Accessories

-div. saw bands

-1x running wheel Ø 320 mm

-Saw band by the meter RRR Roentgen

*

Listing

Wiefelstede

Wiefelstede

785 km

Rubber air drum

KED, Kurt EhemannG 6 x 22,5

Call

Condition: excellent (used), Grinding drum (rubber air drum) Original product from KED, (Kurt Ehemann)

-Condition: unused

-Type: G 6 x 22.5

-consisting of: base body, rubber hose, air valve, 2 clamping caps for rubber hose

-Diameter: 60 mm

-Grinding length: 200 mm

-Length of base body: 225 mm

-Holding bore: 30 mm

-Number: 14 available

Price: per piece

-Available: on request in other sizes:

e.g. diameters 40 mm, 60 mm, 75 mm, 100 mm, 125 mm, 150 mm, 175 mm, 200 mm, 250 mm, 300 mm

e.g. grinding length 100mm, 150mm, 200mm, 250mm, 300mm, 400mm, 500mm

Also available as brush grinding elements.

Furthermore, we also carry general husband spare parts.

Price of grinding drums is shown in the attached PDF file.

Ksdpsb A S Rfsfx Ahzswt

Listing

Aflenz Land

Aflenz Land

1,557 km

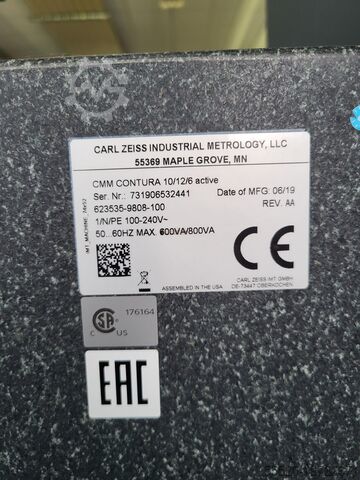

ZEISS coordinate measuring machine

ZeissCMM CONTURA 10126 active

Call

Condition: like new (used), Year of construction: 2019, operating hours: 50 h, functionality: fully functional, measuring range X-axis: 1,000 mm, measuring range Y-axis: 1,200 mm, measuring range Z-axis: 600 mm, Machine description: ZEISS CNC coordinate measuring machine (CMM) in portal design - Measuring volume X = 1000 mm, Y = 1200 mm, Z = 600 mm - Table height TH = 850 mm (standard) - Prepared for tactile active sensors - VAST navigator measuring technology (tactile active scanning) ONLY 50 OPERATING HOURS – THEREFORE AS NEW EQUIPMENT ACCORDING TO ORDER CONFIRMATION – SEE ATTACHED PDF FILE

Kwjdpew H Rfdofx Ahzjt

Listing

Germany

Germany

1,006 km

SAFAN Darley E-Brake Premium

SAFANDarley E-Brake Premium

Call

Condition: ready for operation (used), Year of construction: 2019, number of axes: 3, This 3-axis SAFAN Darley E-Brake Premium press brake was manufactured in 2019. It features a CNC-controlled servo-electronic system with Y1/Y2, X, and R axes, and a stroke of 300 mm. The EC10 control system supports multiple file formats and includes safety equipment compliant with European directives. Ideal for precise bending operations, consider the opportunity to buy this SAFAN Darley E-Brake Premium press brake. Contact us for more information about this machine.

• Control and software:

• EC10 control with split-screen on a height-adjustable swivel arm

• SafanDarley EC Control with center-mounted swivel arm (operation from either side)

• Displays DWG, DXF, PDF, JPG, PNG, BMP, WMV

• German language instructions and HMI

• EC20 software package for EC10 split-screen incl. EC Profiler with 2D bending simulation

• Automatic bend sequence calculation and graphical representation for AutoPol and Radan files

• Axes and travels:

• CNC-controlled Y1/Y2 (stroke 300 mm)

• CNC-controlled X-axis

• CNC-controlled R-axis

• CNC-controlled Z1+Z2 (Type G) with programmable independent lateral adjustment of backgauge fingers

• CNC-controlled dX-axis on Z2 finger, 100 mm stroke (+/- 50 mm), with hardened 3D backgauge cams

• Enlarged installation dimension Q = 650 mm, stroke 300 mm

Kwedpfox Np Ehjx Ahzjt

• Tooling and clamping:

• NSCL-II HC Premium upper tool adapter with hydraulic clamping, hardened surface, incl. hydraulic unit

• Upper tool working height 80 mm; clamping length 1275 mm

• OB II HC Premium mounting table with adjustment wedge, hydraulic clamping, hardened surface

• Mounting table size 110 x 87 x 1275 mm, incl. hydraulic unit

• Measurement:

• E-Bend S sheet thickness measurement at the Z1 backgauge finger

• Safety and lighting:

• CNC-programmable safety light curtain

• Safety equipment compliant with EU Machine Directive MRL/2006/42/EG

• Front-side work area lighting and rear-side tool lighting

• Ergonomics (machine-integrated):

• Ergonomic package: lower beam with legroom recess and tilted footrest

• Foot pedal usable on the footrest or on the floor

• Identification and logistics:

• Customs tariff number: 8462 2110

• Main machine weight: 3250 kg; dimensions: 2330 x 1809 x 2649 mm

• Secondary pallet: 90 kg; 1300 x 800 x 900 mm

Additional equipment

• Ergonomic table system: central segment (height and tilt adjustable) and left/right segments (height adjustable)

• Adjustable chair with seat, footrest, and backrest adjustment on swivel casters

• Left-side material cabinet with five height-adjustable shelves

Listing

Cuggiono

Cuggiono

1,396 km

Puma SMX 2100STB

DN solutions - DOOSANPuma SMX 2100STB

Call

Condition: like new (used), Year of construction: 2023, operating hours: 1,123 h, functionality: fully functional, turning length: 1,040 mm, turning diameter: 600 mm, spindle motor power: 18 W, spindle speed (min.): 20 rpm, spindle speed (max.): 4,000 rpm, spindle bore: 81 mm, travel distance X-axis: 630 mm, travel distance Y-axis: 210 mm, travel distance Z-axis: 1,085 mm, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 36 m/min, rapid traverse Z-axis: 48 m/min, milling spindle length: 300 mm, rotational speed (max.): 12,000 rpm, rotational speed (min.): 60 rpm, spindle nose: Mandrino di fresatura Capto C6, Equipment: documentation/manual, rotational speed infinitely variable, USED 9-axis CNC multitasking Turning Center “DN Solutions model PUMA SMX2100STB” with orientable upper head equipped with tool changer, motorized lower turret, opposing spindles and Fanuc 31i-B Plus CNC, with optical scales on the X1-X2-Y-Z2 axes.

Machine options:

Top X-FILES bar loader, bar processing package, RMP 600 touch probe, bed washing pump, 360-position spindle orientation and total auto shutdown.

Kwjdpfx Ahewc R I Rozst

Fanuc options:

2 GB Data Server, 8 MB program memory and tool life management.

Listing

Schijndel

Schijndel

723 km

Kolbus case maker DA 270 (2010)

KolbusDA 270

Call

Year of construction: 2010, condition: used, Case maker

Kolbus DA 270

Year: 2010

For fully automatic production of book cases, files, display cards, calendar backs or game boards.

Description:

- Automatic setting

- Motorised setting

- Automatic case counter

- Board pre stacking conveyor: 1700 mm

- Board cutter: PS

- Centre strip infeed (flexible)

Ksdox Ary Eopfx Ahzewt

- Waste chopper

- Cloth feeder: Non-Stop

- Glue unit

- Preheated glue tube

- Viscosity control

- Device for inside lining with hotmelt

- Device for producing padded cases

- Pressing station

- Stacking delivery

Max. mechanical speed: up to 65 cycles/min

Size range opened case (max): 670 x 390 mm

Size range opened case (min): 205 x 140 mm

Note!: Specifications are subject to typographical errors and changes in comparable models by the manufacturer!

Listing

United Kingdom

United Kingdom

555 km

Vertical machining center

XYZ2-OP

Call

Condition: like new (used), Year of construction: 2020, functionality: fully functional, machine/vehicle number: SOP10107, travel distance X-axis: 355 mm, travel distance Y-axis: 305 mm, travel distance Z-axis: 455 mm, table width: 381 mm, table length: 457 mm, spindle speed (min.): 10,000 rpm, number of slots in tool magazine: 8, XYZ Machine Tools XYZ 2-OP (2020 Model)

Upgrade your workshop with this reliable and high-performance CNC machine from XYZ Machine Tools Ltd, a trusted name in precision engineering.

Machine Specifications:

Feature Spec / Capability

Travel (X × Y × Z) ~ 355 mm × 305 mm × 455 mm

Table size ~ 457 mm × 381 mm

Max work load ~ 250 kg

Spindle BT30 taper, 10,000 rpm, ~ 3 hp (≈ 2.2–2.3 kW) motor

Tool changer 8-station automatic tool changer

Rapid traverse ~ 15 m/min (X/Y/Z)

Control ProtoTRAK TMX conversational CNC (menu-driven, with G-code compatibility), USB file transfer

Accuracy / repeatability Positioning accuracy typically around ±0.005 mm (varies with condition), repeatability ±0.003 mm

Footprint ~ 760 × 1,220 mm, ~ 2.5 m tall

Machine weight ~ 1,100 kg

• Year of Manufacture: 2020

• Rated Voltage: 400V

• Full Load Current: 15A

• Short Circuit Rating: 10kA

• Phase: 3

• Cycle: 50Hz

• Main Motor Power: 2.2 kW

• Max Spindle Speed: 10,000 RPM

• Pneumatics: 6 bar / 100 L/min

• CE Certified

_____

Practical machining use

• High-speed drilling, tapping, and small-tool milling: The 10k rpm spindle makes it much better for smaller cutters (Ø3–10 mm) and aluminium machining compared to the older 6k rpm version.

• Secondary ops & light milling: Great for “clean-up” cuts, bolt holes, chamfers, flat milling, and side ops after turning.

• Batch work with multiple ops: The 8-station tool changer is limiting, but with smart tooling (spot, drill, tap, end mill, chamfer, face) you can cover a lot.

• Compact footprint: It can be placed near lathes or VMCs to absorb “2-op” bottlenecks.

Condition:

Kedpfxsxd Dgyj Ahzewt

• Excellent working order

• Lightly used, well-maintained. Has only been used to make Aluminium and Nylon shop fittings.

• Ready to go straight into production

Why Choose the XYZ 2-OP?

• Precision engineering and durability

• High spindle speed and robust motor for versatile machining

• Compact and efficient design

• Backed by XYZ’s reputation for service and reliability

Don’t miss this opportunity to own a top-quality XYZ 2-OP machine—perfect for workshops, tool rooms, and production facilities looking to boost their machining capabilities.

Listing

Weilheim an der Teck

Weilheim an der Teck

1,162 km

Duramax

Carl ZeissDuramax

Call

Condition: like new (used), Year of construction: 2012, functionality: fully functional, measuring range X-axis: 500 mm, measuring range Y-axis: 500 mm, measuring range Z-axis: 500 mm, Measuring range: X=500mm, Y=500mm, Z=500mm

Length measurement deviation E0 in µm E0/E40 in µm MPE according to ISO 10360-2:2009 2.4 + L/300 at 18°C – 22°C

C99 control unit with BP26_SE operator panel

Equipment:

VAST XXT sensor

6-position probe changer magazine

4-position probe changer rack

Calibration sphere with certificate

Machine file, technical documentation, operating manual

Various probes

HP workstation and monitor

Additional accessories

Software:

Kjdpfsttza Rjx Ahzswt

Calypso Basic CNC

Upgrade to the latest Calypso version and additional options possible

Listing

Unterhaching

Unterhaching

1,315 km

3D Printer

StratasysF370

Call

Condition: like new (used), functionality: fully functional, machine/vehicle number: D31369, Year of construction: 2019, operating hours: 73 h, total length: 864 mm, total height: 1,626 mm, total width: 711 mm, type of input current: AC, overall weight: 227 kg, input voltage: 230 V, input current: 7 A, input frequency: 50 Hz, table width: 355 mm, table length: 254 mm, construction height: 355 mm, --- RARE OPPORTUNITY ---

Stratasys F370 for sale due to business closure. Barely used, with only 70 operating hours—essentially in like-new condition. This printer is ideal as an addition to existing machine parks or as a high-quality all-rounder for newcomers to 3D printing.

The printer is currently packaged and in storage. It was inspected and serviced by the manufacturer’s authorized distributor prior to proper decommissioning. The most recent exported cfg file can be provided upon request.

The F370 was designed with user-friendliness in mind, offering a powerful and virtually maintenance-free 3D printing system that is quick to learn and easy to operate. It supports a wide selection of materials for various 3D printing applications, typically including prototyping, the production of tools and fixtures, as well as low-volume manufacturing of end-use parts.

Kwsdexgh U Tspfx Ahzst

Its compact footprint and quiet, safe operation—without requiring special arrangements—make the F370 ideal for workshops, offices, or even classroom environments.

With soluble support material, even complex geometries with internal cavities can be created—uncommon in this class of printers. The four easily accessible material spool bays on the front (2x model & 2x support) allow for quick material changes.

The complete package is rounded off by the GrabCAD Print and Insight design-to-print software applications, automatic calibration, an integrated camera for remote print job monitoring from your computer, and an intuitive front-panel interface.

Listing

Dinkelsbühl

Dinkelsbühl

1,170 km

Thread tapping center

CMAFTC 3015

Call

Condition: new, metric thread diameter (min.): 3 mm, metric thread diameter (max.): 16 mm, overall weight: 500 kg, feed length X-axis: 3,000 mm, feed length Y-axis: 1,500 mm, feed length Z-axis: 200 mm, torque: 24 Nm, spindle speed (max.): 3,000 rpm, spindle speed (min.): 50 rpm, power: 0.005 kW (0.01 HP), The CMA 3-axis controlled tapping center is designed for the post-processing of laser-cut sheet metal parts and complete processing of small parts and tubes, for example.

The machine offers the following processing options:

- Thread cutting

- Drilling (standard / with chip breaking / hollow profile cycle)

- countersinking

- Flow drilling (with optimum feed curve)

- reaming

- Simple graphical programming

- Import of 2D DXF or DWG files

- Machine table according to System 28 (similar to Demmeler and Siegmund welding tables, among others)

Kwjdpfx Aorbz T Nohzet

- Radial compensation of the tool by means of patented tool holder (accessory)

- Tool probe for length measurement and as a breakage detector

- Intuitive safety system using light barriers

Standard version:

Automatic tool changer with 10 positions, mounted on the machine portal

Listing

Grâce-Hollogne

Grâce-Hollogne

797 km

Laser cutting machine

EpilogFusion Edge 12 (CO2/60W)

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2023, operating hours: 98 h, machine/vehicle number: 17000-23051522412, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: CO₂ laser, laser source manufacturer: Epilog, laser hours: 97 h, laser power: 60 W, table length: 1,003 mm, table height: 673 mm, working length: 610 mm, working width: 305 mm, workpiece weight (max.): 63 kg, type of cooling: air, overall weight: 63 kg, total length: 1,003 mm, total width: 673 mm, total height: 455 mm, Equipment: cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser engraver in excellent condition, supplied with a professional extraction unit and professional compressor. The system is totally complete and fully functional, virtually like-new (97 hours of operation).

Business closed due to bereavement.

Dimensions & Capabilities

Working area (X × Y × Z): 610 × 305 mm

Machine dimensions (L × W × H): approx. 1003 × 673 × 455 mm (39.5 × 26.5 × 17.9 in)

Weight: approx. 63 kg (138 lbs)

Laser Options

Available type:

CO₂ (metal/ceramic tube, air-cooled, 10.6 µm) with 60 W of power

Speed & Precision

Max. speed: 120 IPS (≈3.05 m/s) with 5 G acceleration

Resolution: adjustable from 75 to 1,200 dpi

Software & Memory

Software interface: Laser Dashboard™ and Epilog Job Manager™

Internal memory: up to 1 GB, allows for jobs of any file size

Control Features & Mechanical Construction

Operation modes: raster, vector, or optimized combined mode

Motors: DC brushless servo motors with rotary encoders for precise positioning

Guide structure:

* X-axis: polished stainless steel bearings with Teflon coating

Ksdpfxjw Hg Nfe Ahzewt

* Belts: double-width Kevlar type B for high accuracy

Camera & Display

IRIS™ system: integrated overhead camera for visual job placement directly onto the laser table

7″ LED touchscreen on the machine for job selection and direct autofocus

Connectivity & Power Supply

Connections: USB, Ethernet and optional wireless (Wi-Fi), compatible with Windows 7/8/10/11

Electrical supply: auto-switching 100–240 V, single-phase 50/60 Hz; max amperage ≈13 A (or ≈6.5 A depending on region)

Ventilation & Safety

Extraction requirements: external venting or internal filtration unit, airflow of 350–400 CFM (≈595–680 m³/h), single 4″ (102 mm) exhaust

*Safety standard: Class 2 laser product (≤1 mW, 600–700 nm)

Listing

Hauzenberg

Hauzenberg

1,386 km

Laser cutting machine

Ledi LaserLG-1530 6kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 12 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 3,000 mm, door opening height: 600 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Delivery time approx. 6-8 weeks

Our goal is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included in the delivery, as well as first-class service.

- Machine without automatic shuttle table!

Loading is performed on the long side of the machine

- Very space-saving design

- Extremely energy-efficient cutting system

- Requires only approx. 4 x 4.5 meters of floor space

- 6kW laser source from MaxPhotonics (G5/German specification)

- Laser generator with socket efficiency better than 30%

- Suitable for aluminum

- Top quality, book a viewing now!

Maximum cutting capacities:

- Steel sheet up to 30mm

- Stainless steel up to 15mm

- Aluminum sheet up to 12mm

- Brass sheet up to 8mm

- Travel range: 1500 x 3000mm (for large formats)

- Machine control system in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser safety windows to monitor the cutting process

- Comprehensive cutting parameter files included

- Including nesting module

- Very easy to operate

- High-performance laser chiller

- German service and spare parts supply

- Filter extraction system is optionally available (5.5kW with frequency converter for pleasantly quiet operation)

Leasing or hire purchase is possible through our financing partner

Sale only to commercial customers.

Shipping / advice / sales only in Germany / Austria / Switzerland

Kwodpjxw T Nkjfx Ahzot

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.5m

Total weight: approx. 4500kg

Need a different laser power, table design, or table size?

No problem. I am happy to prepare a suitable offer.

E.g. 2kW machine from 29,990 Euro

Not sure which laser power is suitable for your application?

I will of course perform cutting tests according to your requirements.

There are many possibilities.

Listing

Hauzenberg

Hauzenberg

1,386 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser ecoline

Our goal is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses.

A perfectly developed library of cutting parameters is included in delivery, as is first-class service.

The cost-effective entry into laser cutting technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approx. 3.0 x 3.0 meters of installation space

- Top quality, schedule a viewing now!

Cutting capacity:

- Steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel distance approx. 1300 x 1300mm

- Table size: approx. 1300 x 2500mm

(suitable for a full mid-format sheet)

- Machine control system in German

- Manual front door

- Extensive collision protection measures

- Large front window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Comprehensive cutting parameter files

- Including nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy operation

- High-performance laser chiller

Sales exclusively to commercial customers.

Delivery / consultation / sales only in Germany / Austria / Switzerland

Machine dimensions approx.:

Width: 3.2m

Height: 2.3m

Length: 3.3m

Total weight: approx. 2800kg

Leasing or hire-purchase available through our financing partner.

Kwodpfeitu Srox Ahzjt

Need different laser power, table type or table size?

No problem.

I will be happy to prepare a customized offer.

Not sure which laser power is suitable for your application?

Of course, I can carry out cutting trials tailored to your requirements.

A wide range is possible. From 0.5 kW up to 20 kW laser power.

Listing

Borgo San Dalmazzo

Borgo San Dalmazzo

1,454 km

Vertical machining center

DMG MORIDMC 1450 V

Call

Condition: used, Year of construction: 2017, operating hours: 1,400 h, functionality: fully functional, travel distance X-axis: 1,450 mm, travel distance Y-axis: 700 mm, travel distance Z-axis: 550 mm, rapid traverse X-axis: 42 m/min, rapid traverse Y-axis: 42 m/min, rapid traverse Z-axis: 42 m/min, spindle speed (max.): 14,000 rpm, CNC Heidenhain 640

WORKING AREA:

X-axis: mm 1.450

Y-axis: mm 700

Z-axis: mm 550

Kwjdpoya Imqjfx Ahzot

Rapid traverse (X/Y/Z): m/min 42

Max. spindle speed: Rpm 14.000

Tool holder: SK 40

Tool magazine capacity: 30

Table size: mm 1.760 × 750

Max. table load: kg 2.000

Equipped with:

• HEIDENHAIN 640 CNC

• DXF file reader

• Preparation for the fourth axis

• Tool setter

• Heidenhain workpiece measuring probe

• 40 bar through-spindle high-pressure coolant system with paper filtration tank, 600-liter capacity

• Air conditioning unit

• 30 position tool magazine

• Instruction manuals and CE declaration

Trust Seal

Dealers certified through Machineseeker

Listing

Jonschwil

Jonschwil

1,235 km

Vertical Bandsawing-Machine

JAESPAAS 6

Call

Condition: good (used), Year of construction: 1997, functionality: fully functional, saw band length: 4,500 mm, saw band width: 20 mm, total height: 2,380 mm, total length: 1,250 mm, total width: 1,500 mm, overall weight: 900 kg, table width: 660 mm, table length: 660 mm, working height: 950 mm, workpiece weight (max.): 350 kg, throat depth: 610 mm, power: 3 kW (4.08 HP), Vertical Bandsawing-, Filing-, Grinding- and Polishing Machine, band speed 15-1600 m/min, motor 3 KW, band dimension 4500x20 mm, table size 660x660 mm, table high 950 mm, throat 610 mm, dimension 1250x1500x2350 mm, weight ca. 900 kgs

Kwjdpfxeu Rghzj Ahzot

Listing

Bydgoszcz

Bydgoszcz

1,404 km

Universal lathe machine

PorebaTPK 90A1/10M - 10.000 mm

Call

Year of construction: 2024, condition: reconditioned (used), functionality: fully functional, This universal lathe machine can be generally overhauled and modernized and will be available within 3 to 3,5 months, starting from the customer´s order.

We give a full 12 months warranty for this machine (spare parts, material, electronic cabinet).

Kwjdpfx Aokh D Txehzjt

Details of the overhaul and detailed specs see attached PDF-files.

Listing

Soerendonk

Soerendonk

751 km

Eddy Current Separator

SGM MagneticsT-VIS 100

Call

Condition: good (used), Year of construction: 2014, Manufacturer: SGM Magnetics

Type: T-VIS 100

Year of manufacture: 2014

With New Control-unit.

See PDF-file below for more detailed information.

Kwsdpfx Asma Tt Aehzet

Eddy Current Separator can be sandblasted and painted.

Listing

Schijndel

Schijndel

723 km

Kolbus case maker DA 370 (2023)

KolbusDA 370

Call

Year of construction: 2023, condition: used, Case maker

Kolbus DA 370

Year: 2023

New generation of casemaker for faster production and shorter make-ready times.

Automatic production of book cases, files, display cards, calendar backs or game boards, at rates of up to 65 cycles/min.

Maximum production and process reliability in the manufacture of book cases. The DA 370 casemaker is a versatile machine for a wide range of applications. The machine with its non-stop case feeder is engineered to be ergonomic and extremely operator-friendly so that it can be easily operated by one person.

Configuration:

- Copilot system with touchscreen

- sectional touch panel for direct operation

- large display for showing the speed and malfunction messages

- board prestacking conveyor to automatically reload the magazines (stream cover and stack feeder)

- counter-stacker delivery with roller conveyor delivery incl. table

- cloth feeder for non-stop operation with stack magazine

- missing product check during separation of cloth and cardboard

- cloth cylinder with grippers and interchangeable plates for rubber pads (5 plates 500 mm wide and 5 plates 720 mm wide, incl. 10 rubber pads)

- cardboard centre strip magazine

- device used to prepare centre strip roll

- centre strip waste chopper

- centre strip rub-down unit (head and foot)

- rub-down unit used to bond the covering material to cardboards and spine strip without creases

- extendable gluing station for processing hot glue with glue preparation in the premelter, heated glue roller and scraper roller

- viscosity control unit for an automatic supply of water via a water container with a pump

- device for padded cases

- function used to request individual cases for monitoring purposes on the operating side

Kwodpsv N Ep Djfx Ahzst

- servo-controlled drive technology based on Siemens technology

Special equipment:

- device for producing quarter-bound cases in two operating steps

- device for small format

- device for large format

- Remote Service Gateway

Technical specifications:

- Mechanical speed: up to 65 cycles/min

- Open cover size max.: 205 x 670 mm

- Joint width: 4 - 15 mm

- Spine width: 14 - 120 mm

- Turn in width open: up to 19 mm

- Cloth width: 223 - 708 mm

- Cloth height: 158 - 428 mm

- Board thickness: 1 - 4 mm

- Board width: 95 - 328 mm

- Board height: 140 - 390 mm

- Board centre strip thickness: 1 - 4 mm

- Board centre strip width: 6 - 90 mm

- Centre strip roll thickness: 0,3 - 0,6 mm

- Centre strip roll width: 6 - 90 mm

- Lining width: 195 - 670 mm

- Lining height: 130 - 390 mm

We make it easier for you to find: "filing"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Filing (439)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you