Used Filing for sale (439)

Burkardroth

Burkardroth MT1212 threading machine

CoastOneMultitapper 1212

Burkardroth

Burkardroth MT1212 threading machine

CoastOneMultitapper 1212

Almelo

Almelo Machining center

CNC-ROUTER DMA-BudgeCraftNesting Professional

+44 20 806 810 84

Nattheim

Nattheim CNC machining center

SCM morbidelliM 400

Waiblingen

Waiblingen Lead/traction spindle lathe

WEILERCONDOR VC plus

Discover more used machines

Waiblingen

Waiblingen Band saw

Erhard+SpiessHK 3C

Almelo

Almelo Multi-spindle drilling machine

Best DEAL Maggi technologyGT800

Neustadt am Rübenberge

Neustadt am Rübenberge Machining center

SCMRecord 110

Schijndel

Schijndel Kolbus case maker DA 260 (2011)

KolbusDA 260

Nattheim

Nattheim CNC machining center

SCMZ1 26A

Borken

Borken Ice cube machine

NordcapSDE 100 l

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000x1800

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000/1800

Wiefelstede

Wiefelstede Stainless steel table

unbekanntTyp 2000/930

Wiefelstede

Wiefelstede Aluminum table

AluminiumTyp 1800/700

Wiefelstede

Wiefelstede Double stainless steel table

unbekanntTyp 2000/1800

Wiefelstede

Wiefelstede Stainless steel table

unbekanntTyp 930/2000

Borken

Borken 3D printers

StratasysDimension

Borken

Borken 3D printer PolyJet

StratasysJ750

Borken

Borken 3D printer

StratasysDimensio elite

Borken

Borken Hardness tester

KB Prüftechnik GmbHKB 750 BVRZ

Borken

Borken 3D printer

German RepRapX1000

Garbsen

Garbsen Machining center

HOMAGBOF311/60/F/FT

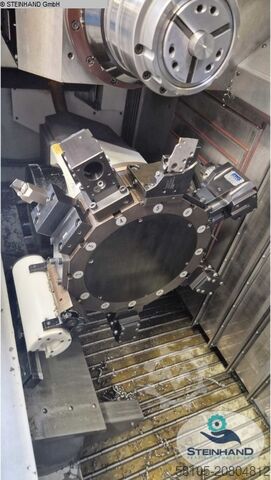

Hattingen

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Falkenberg

Falkenberg Carpentry machine

Randek ABSPL728 Cut Saw

Used Filing (439)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84