Used Forester Group for sale (3,349)

Odesa

Odesa Driveshaft balancing machine

VTM GroupBVI-03-88

Odesa

Odesa Dynamic Balancing Machines

VTM Group9D716

Odesa

Odesa Turbo balancing machine

VTM GroupSBR-10

+44 20 806 810 84

Susuz

Susuz Clamshell

Galen GroupLog Grapple Manufacturing

Susuz

Susuz CAT988 Marble Fork and Marble Attachment

Galen GroupMarble Attachments

Discover more used machines

Susuz

Susuz Sany SY35 V-Ditch&Ditch Cleaning Bucket

Galen GroupMini Excavator Bucket

Grand Rapids

Grand Rapids CNC machining center

SMC Group Routech Accord30FX CNC machining center

Kindberg

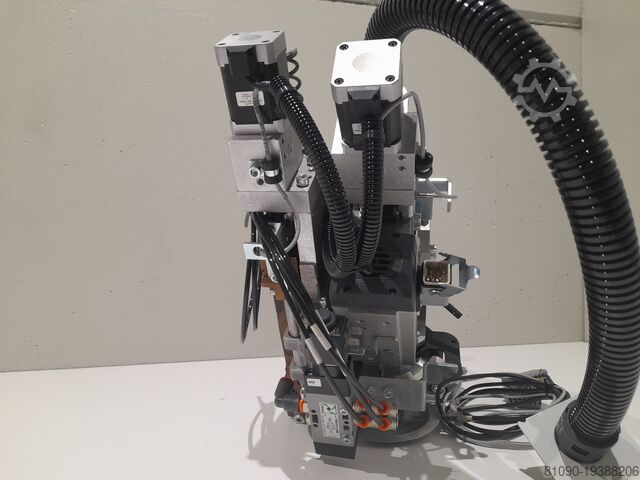

Kindberg Linck recutting group

LinckEV 40 - V40 - MKV - Abscheider

Wald

Wald Multiple group workbench

Garant6-Eck

Wald

Wald Multiple group workbench

Garant6-Eck

Pollenzo

Pollenzo VERTICAL MOULDING GROUP

HOMAG

Pollenzo

Pollenzo Upper stripping group

BIESSE

Pollenzo

Pollenzo Ear-gathering group

HOMAG

Pollenzo

Pollenzo Ear-gathering group

HOMAG

Pollenzo

Pollenzo Double chipper + anti-chipping group SCM

SCM

Lorquí

Lorquí FMC 452 SEAMING GROUP WITH VACUUM FILLER

FMC

Lorquí

Lorquí S/S MADOMUR FILLER WITH SEAMER GROUP FOR

EFABIND

Scerne

Scerne Door tool group

Diatech

Pontirolo Nuovo

Pontirolo Nuovo RANKING GROUP SANDS

COMEC S.p.A.65/10000 W

Vincennes

Vincennes Automatic coffee machine with 2 groups

FUTURMATMFH092G

Åsby

Åsby Log bandsaw groups

AKE245

Minareliçavuş

Minareliçavuş PVC SINGLE HEAD PRODUCTION GROUP

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNELERİPVC TEK KAFALI ÜRETİM MAKİNE SETİ

Krotoszyn

Krotoszyn Device for grouping sausages

VemagSK5909, 712

San Giovanni Al Natisone

San Giovanni Al Natisone Wigo Double squaring machine with 3 groups per side, complete with inverters.

Wigo

Kindberg

Kindberg Pre-cutting group EWD

EWDFZ3-EVW-FR14R

Used Forester Group (3,349)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84