Used Innovation Splicing for sale (1,189)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Mönchengladbach

Mönchengladbach

810 km

Coordinate measuring machine

AberlinkAzimuth

Call

Condition: new, Year of construction: 2025, functionality: fully functional, The Aberlink Azimuth CNC Coordinate Measuring Machine (CMM) is the largest model in our range and reflects over twenty years of experience and excellence in developing innovative metrology.

It has been specifically designed for the precise measurement of large and heavy workpieces weighing up to 6000kg. The revolutionary bridge design incorporates aluminium honeycomb core panels originally developed for Formula 1 and aerospace.

This design offers a remarkable stiffness to weight ratio that improves both the performance and speed of the Azimuth. With travels of X 1200mm, Y 2000 or 3000mm and Z 1000mm and volumetric accuracy of up to (2.6 + L/250)µm, the Azimuth ensures the highest precision.

Lodsvwbabopfx Ahzehb

The scale resolution is 0.1µm. A specially designed load plate system allows heavy components to be placed directly on the granite base, transferring the load directly to the floor without affecting metrological performance.

The user-friendly Aberlink 3D measurement software enables a short training period, so that even without prior knowledge, precise measurements can be taken. Free software updates ensure that the system is always kept up to date.

Listing

Mönchengladbach

Mönchengladbach

810 km

Coordinate measuring machine

AberlinkFulcrum

Call

Condition: new, Year of construction: 2025, functionality: fully functional, measuring range X-axis: 280 mm, measuring range Y-axis: 280 mm, measuring range Z-axis: 150 mm, Discover the Fulcrum, an intuitive coordinate measuring machine that sets new standards in industrial measurement technology. This innovative measuring system impresses with its accuracy, intuitive operation and robust design - ideal for demanding applications in production and quality control.

Your advantages at a glance:

Robust & reliable:

The Fulcrum was designed for industrial use and can withstand even the toughest production conditions - for continuous, reliable performance.

Easy integration & intuitive operation:

Thanks to a user-friendly interface, the Fulcrum can be easily integrated into existing production processes.

Increased efficiency & time savings:

With fast measuring cycles and automated data evaluation, you can optimize your production processes and increase your competitiveness.

Future-proof & innovative:

With regular software updates and the latest hardware, you are investing in a solution that always adapts to technical progress and sustainably improves your processes.

Rely on the Fulcrum to take your quality assurance to the next level and optimize your production processes. Whether individual components or series production - this coordinate measuring machine is your key to more precision and efficiency in production.

See for yourself:

Find out how the Fulcrum can revolutionize your production processes. Contact us today for personal advice and start a future full of innovation and quality!

Lhsdpfx Ahjvwa Rljzeb

Listing

Buseck

Buseck

976 km

Planetary mixer

Robot CoupeBlixer 23A

Call

Condition: used, functionality: fully functional, We are offering for sale a Robot Coupe Blixer 23 A, 23 L, as pictured, complete with necessary tools and in excellent condition. This machine combines two functions in one: The Blixer unites the features of two well-known machines—a cutter and an emulsifier-mixer. It enables the processing of all kinds of raw and cooked foods into liquid, semi-liquid, or pureed end products.

Efficient: Thanks to its large liquid capacity and a lid with scraper and sealing ring, this appliance allows for the preparation of a wide variety of blended foods, including enteral nutrition.

Reliable: Blade with patented, innovative cutting profile for optimum cutting quality. Consistent cuts and fully uniform processing, even with the smallest quantities.

With its high portion capacity (20–75), the Blixer 23 is ideally suited for use in hospitals, nursing homes, childcare centers, and, of course, restaurants. Maximum processing quantities: 4–15 kg.

The control panel is equipped with a digital timer adjustable from 0 to 15 minutes and features a removable 23-liter tilting stainless steel bowl. An extra-low stainless steel blade with two removable, height-adjustable serrated blades is included.

The unit has undergone a comprehensive inspection in our workshop and is fully operational.

You will receive an invoice with VAT shown separately.

Lhedpox Uw R Nefx Ahzjb

Control panel:

• Timer, adjustable from 0 to 15 minutes. The previously set processing time repeats automatically after the machine is stopped.

• Flush stainless steel buttons for easy cleaning and long service life.

• Indicator lights for maximum safety.

• Pulse function for even higher cutting precision.

Lid:

• Transparent polycarbonate lid for continuous monitoring during processing.

• Absolutely tight-fitting lid that closes with a simple hand movement.

• Swing mechanism on the lid ensures that no liquids reach the motor block.

• Central opening in the lid for adding liquids or ingredients during processing.

• Lid and sealing ring are easily removable for thorough cleaning.

Our used equipment service for you:

• 6-month warranty on all electrical parts, limited to replacement of defective parts (does not include labor costs for removal and installation).

• High-quality branded machines at fair prices.

• Professional refurbishment/inspection & expert cleaning.

• Tested & fully functional—or your money back.

• Flexible shipping or local pickup options.

• Competent advice—before and after purchase.

• Provision of user manuals, wiring diagrams & spare parts.

• DGUV V3-tested.

Technical data:

• Two speeds: 4400/5400 Watts

• Speeds: 1,500 and 3,000 rpm

• 400 V/50 Hz, three-phase

• A: 8.5/10.5 W: 4,500

• Serial number: N6140112811

• Weight: 140.7 kg

Condition: used, fully inspected, fully operational

Specifications and errors subject to change.

If you have any questions, require advice, or would like to view something on-site, please feel free to contact us during our business hours:

Monday–Friday 09:00–13:00 and 14:00–17:00.

Sale is subject exclusively to our general terms and conditions (GTC).

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Wiefelstede

Wiefelstede

785 km

CNC control

Power Automation / Innovance Technology181998

Call

Condition: good (used), CNC control, control rack, electronic module

-Manufacturer: Power Automation / Innovance Technology, Control

-Type: Replacement device ArtNo. 181998

-Individual components: see photos

-Dimensions: 255/330/H140 mm

Lodpfx Aewt R Irehzohb

-Weight: 5.7 kg

Listing

Wiefelstede

Wiefelstede

785 km

CNC control

Power Automation / Innovance TechnologyPA8000 LW

Call

Condition: good (used), Year of construction: 2008, CNC control, control rack, electronic module

-Manufacturer: Power Automation / Innovance Technology, CNC control

-Type: PA8000 LW

-Dimensions: 330/250/H130 mm

Lodpowubtnsfx Ahzshb

-Weight: 5.9 kg

Discover more used machines

Listing

Wasbek

Wasbek

869 km

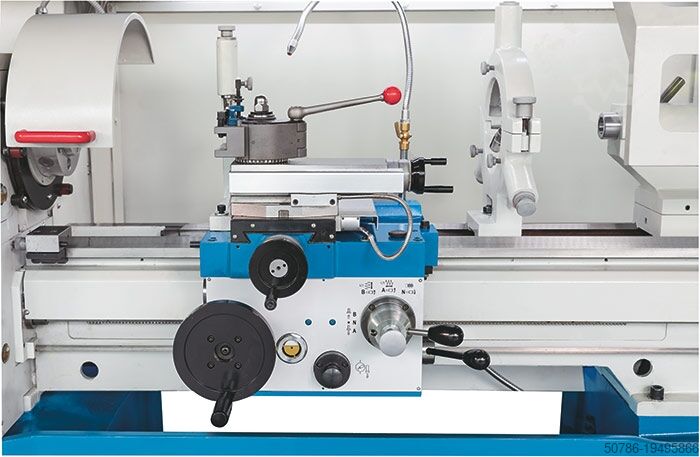

Conventional Lathe - V-Turn 410 PRO

KnuthV-Turn 410 PRO

Call

Condition: new, The V-Turn 410 PRO, a cutting-edge Conventional Horizontal Lathe from KNUTH, represents the latest in the Engine Lathes product group, designed for both efficiency and precision. This machine boasts improved ergonomics alongside enhanced safety features, making it user-friendly while maintaining top-tier performance. Equipped with a powerful 5.5 kW spindle motor and an innovative inverter, it reaches speeds of up to 3,000 revolutions per minute, allowing efficient machining of workpieces with varying diameters. Its constant cutting speed function automatically adjusts the spindle speed during face turning, achieving results comparable to CNC lathes. With a robust and rigid construction, including a heavily ribbed machine bed and pre-loaded spindle bearings, this lathe ensures exceptional stability and precision. The standard equipment includes a 3-axis position indicator, coolant system, and various tool holders, enhancing its functionality for diverse machining tasks. You can buy now to elevate your machining capabilities with the V-Turn 410 PRO, a remarkable addition to the Conventional Horizontal Lathes and Engine Lathes by KNUTH.

Ledpfx Ahoww T S Ijzshb

Listing

Paderborn

Paderborn

902 km

Panel van

PeugeotBoxer Kastenwagen 335 L3H2 BlueHDi 140 AT BT

Call

Condition: new, power: 103 kW (140.04 HP), fuel type: diesel, overall weight: 3,500 kg, fuel: diesel, color: white, driver cabin: other, gearing type: automatic, emission class: euro6, number of seats: 3, Equipment: ABS, air conditioning, cruise control, navigation system, onboard computer, Vehicle No.: 502881. Equipment Packages: City Package Plus, Safety Package, Techno Package. Warranty & Quality Seal: Warranty. Assistance Systems: Traffic sign recognition, rear parking assist, rearview camera, driver fatigue detection/attention assist, speed limiter, cruise control, light sensor, rain sensor, front parking assist, multifunction camera, crosswind assist. Lighting: Cornering lights, turning lights, fog light function, daytime running lights. Media & Infotainment: Navigation/online navigation, Bluetooth interface, hands-free system. Safety & Technology: Electronic Stability Program (ESP), passenger airbag, driver airbag, Anti-lock Braking System (ABS), traction control (ASR), trailer stability assist, seatbelt reminder. Comfort & Climate: Electrically folding mirrors, onboard computer, lumbar support, heated electric mirrors, electric windows, automatic climate control, central locking with remote control, dual passenger bench, 270-degree rear barn doors, center armrest, sliding door right, power steering, seat height adjustment. Tires & Rims: All-season tires, tire pressure monitoring. Cargo/Loading Aids: Lashing eyes. Environment & Charging: EURO 6d, particulate filter, start/stop automatic, emissions sticker 4. Transmission: Automatic. Further Information: Partition, accident-free. Driving assistant system, roll-over mitigation system (ERM)

Lhodextk I Aopfx Ahzsb

----Discover the Rosier Online Shop – your expert for top-quality car accessories and exclusive lifestyle items at attractive prices! From stylish rims to innovative vehicle technology – we offer everything to make your car unique. Benefit from unbeatable value for money and fast delivery. Secure your favorites now and order immediately! Visit us online and make your vehicle a highlight on the road!

----Manufacturer: PEUGEOT DEUTSCHLAND GMBH Bahnhofsplatz 65423 Rüsselsheim Telephone contact – Subject to prior sale and errors excepted. The vehicle description serves solely for general vehicle identification and does not constitute a legally binding warranty. Only the agreements in the purchase contract and order confirmation are binding. Please note that certain optional equipment may incur additional costs. For detailed information on equipment scope, please contact our sales staff.

Listing

Paderborn

Paderborn

902 km

High top van

MaxusDELIVER 9

Call

Condition: new, mileage: 5 km, power: 109 kW (148.20 HP), fuel type: diesel, overall weight: 3,500 kg, fuel: diesel, color: black, driver cabin: other, gearing type: mechanical, emission class: euro6, number of seats: 3, total length: 59,400 mm, Year of construction: 2024, Equipment: ABS, air conditioning, cruise control, onboard computer, Vehicle No.: 324868. Warranty & Quality Seal: Warranty. Assistance systems: Lane departure warning, lane change assistant, blind spot monitor, traffic sign recognition, rear parking assist, reversing camera, autonomous emergency braking assistant, cruise control, light sensor, rain sensor, front parking assist, multifunction camera. Lighting: LED daytime running lights, fog lights/function, side indicators integrated into exterior mirrors, LED (partial) indicators. Media & Infotainment: Touchscreen display, radio, MP3-compatible audio system, DAB tuner, iPod®/iPhone®/Android interface, Bluetooth interface, hands-free system, telephone preparation with Bluetooth, Apple CarPlay / preparation, Android Auto / preparation, integrated music streaming. Safety & Technology: Electronic Stability Programme (ESP), passenger airbag, driver airbag, front side airbags, Anti-lock Braking System (ABS), traction control (ASR), brake assist (BAS). Comfort & Climate: Telematics/emergency call system (preparation), onboard computer, heated electric mirrors, electric windows, air conditioning, central locking with remote control, ATA / outside temperature display, automatic door locking after driving off and unlocking in case of an accident, front passenger double bench seat, rear wing doors with window, right sliding door, keyless engine start, power steering. Tyres & Wheels: Spare wheel, tyre pressure monitoring. Interior & Design: Multifunction steering wheel, steering wheel controls, adjustable steering column. Environment & Charging: EURO 6d, particulate filter, start/stop automatic, emissions sticker 4. Transmission: Manual gearbox. Further information: High roof, rubber/plastic floor, accident-free. * Delivery costs charged separately (EUR 1,290 * net). ----Discover the Rosier Online Shop – your expert for high-quality car accessories and exclusive lifestyle products at attractive prices! From stylish wheels to innovative vehicle technology – we offer everything to make your car unique. Benefit from unbeatable value for money and fast delivery. Secure your favourites now and order immediately! Visit us online and make your vehicle the highlight of the road!

Product safety information: Manufacturer: Maxomotive Deutschland GmbH, Ferdinand-Porsche-Str. 1, 51149 Cologne, phone: , email: . Subject to prior sale and errors. The vehicle description serves solely to generally identify the vehicle and does not constitute a legally binding warranty. Only the agreements in the purchase contract and order confirmation are binding. Please note that certain optional equipment may incur additional costs. For detailed information on the range of equipment, please contact our sales staff.

Ledpoycgv Njfx Ahzshb

Listing

Paderborn

Paderborn

902 km

Pick-up

MaxuseTerron 9

Call

Condition: new, mileage: 5 km, power: 325 kW (441.88 HP), fuel type: electric, gearing type: automatic, axle configuration: 4x4, overall weight: 3,500 kg, emission class: euro6, color: black, driver cabin: other, number of seats: 5, Year of construction: 2025, total length: 55,000 mm, fuel: electricity, Equipment: ABS, air conditioning, all wheel drive, cruise control, onboard computer, Vehicle No.: 110025X. Warranty & Quality Seal: Warranty. Assistance Systems: Adaptive cruise control, lane assist, lane change assist, blind spot assist, 360-degree camera, high beam assist, traffic sign recognition, rear parking aid, front camera, cross traffic alert, reversing camera, forward collision warning, autonomous emergency brake assist, lane keeping assist. Lighting: LED headlights, LED (partial) taillights, LED daytime running lights. Media & Infotainment: APPS, touchscreen display, integrated music streaming. Safety & Technology: seatbelt control. Comfort & Climate: electric seat adjustment for driver with memory, keyless entry, memory package, electrically folding mirrors, onboard computer, electric parking brake, power steering. Tires & Wheels: spare/emergency wheel. Exterior & Design: roof rails. Interior & Design: electric panoramic roof, multifunction steering wheel, leather package. Environment & Charging: Emission sticker 4. Transmission: automatic. Further information: accident-free. * Transfer costs are calculated separately - EUR 1,290, * -- plus VAT.

----Discover the Rosier Online Shop – your expert for high-quality car accessories and exclusive lifestyle items at attractive prices! From stylish rims to innovative vehicle technology – we offer everything to make your car unique. Benefit from unbeatable value for money and fast delivery. Secure your favorites now and order immediately! Visit us online and make your vehicle a highlight on the road!

----More storage space for your trips! In the Rosier Online Shop you will find original roof boxes from Mercedes-Benz, Audi, Volkswagen, and Kamei. These high-quality roof boxes provide additional space for luggage, sports equipment, and more – ideal for any journey. Installation is child's play, and you can also order matching base racks directly from us. Order online now and enjoy your next trip relaxed! Equip your vehicle with a practical roof box and start your journey perfectly prepared.

----Charge your electric vehicle conveniently at home! In the Rosier Online Shop you will find high-quality wallboxes from Mercedes-Benz, Audi, and Volkswagen. These wallboxes allow fast and safe charging right at your home, so you are always ready to go. They offer the latest technology and are perfectly matched to your vehicle. Order your wallbox online now and enjoy the flexibility of charging your electric vehicle conveniently at home at any time! Subject to prior sale and errors excepted. The vehicle description serves solely for the general identification of the vehicle and does not constitute a legally binding warranty. Only the agreements in the purchase contract and order confirmation are binding. Please note that certain special equipment may incur additional costs. Detailed information regarding the equipment scope can be obtained from our sales staff.

Ledjyba Tfepfx Ahzohb

Listing

Walton-on-the-Naze

Walton-on-the-Naze

501 km

Thermo Labsystems Multiskan Ascent Microplate Reader

Thermo LabsystemsMultiskan Ascent

Call

Condition: used, This listing is for a Thermo Labsystems Multiskan Ascent Microplate Reader The Thermo Labsystems Multiskan Ascent is an advanced, compact, one-channel vertical light path filter photometer designed to perform standard photometric measurements. The measurement types include end point, two point and kinetic measurements. Due to the innovative optical system of the Multiskan Ascent, the instrument can read both 96- and 384-well microplates and is linear to 4.0A. The instrument is a rapid reading microplate reader.

Lsdoxzhctopfx Ahzohb

Listing

Völklingen

Völklingen

976 km

Oil-free crosshead reciprocating compressor for H2/Ar

HYCOMP2WN137F1

Call

Year of construction: 2013, operating hours: 50 h, condition: like new (used), functionality: fully functional, machine/vehicle number: Model #2WN137F1-H23Z-BJMVA-21/50T, Crosshead piston compressor for small-molecule gases such as hydrogen or argon. Oil-free! Installed as a backup unit but never put into production, so it is in like-new condition. Current new price: €190,000.

Ledpfx Ahev Uyqmszohb

Inlet pressure: 5 psi = 34.5 kPa (0.345 bar gauge)

Outlet pressure: 60 psi = 413 kPa (4.13 bar gauge)

Flow rate: 148 scfm = 240 m³N/h

Power requirement: 30 kW

Listing

Paderborn

Paderborn

902 km

Minibus

MaxuseTerron 9

Call

Condition: new, mileage: 5 km, power: 325 kW (441.88 HP), fuel type: electric, gearing type: automatic, axle configuration: 4x4, overall weight: 3,500 kg, emission class: euro6, color: black, driver cabin: other, number of seats: 5, Year of construction: 2025, total length: 55,000 mm, fuel: electricity, Equipment: ABS, air conditioning, all wheel drive, cruise control, onboard computer, Vehicle number: 110025. Warranty & quality seal: Warranty. Assistance systems: Adaptive cruise control, lane assist, lane change assist, blind spot assist, 360-degree camera, high beam assist, traffic sign recognition, rear parking aid, front camera, cross-traffic alert, reversing camera, forward collision warning, autonomous emergency braking, lane keeping assist. Lights: LED headlights, LED (partial) taillights, LED daytime running lights. Media & infotainment: Apps, touchscreen display, integrated music streaming. Safety & technology: Seat belt reminder. Comfort & climate: Electric seat adjustment for driver with memory, keyless entry, memory package, electrically folding mirrors, on-board computer, electric parking brake, power steering. Tires & rims: Spare/reserve wheel. Exterior & design: Roof rails. Interior & design: Electric panoramic roof, multifunction steering wheel, leather package. Environment & charging: Environmental sticker 4. Transmission: Automatic. Further information: Accident-free. *Transfer costs are charged separately - EUR 1,290.00 * -- plus VAT.

Ljdpfx Ajyaw D Eshzehb

----Discover the Rosier online shop - your expert for high-quality car accessories and exclusive lifestyle items at attractive prices! From stylish rims to innovative vehicle technology - we offer everything that makes your car unique. Benefit from unbeatable value and fast delivery. Secure your favorites now and order immediately! Visit us online and make your vehicle the highlight of the road!

---More storage space for your travels! In the Rosier online shop, you will find original roof boxes from Mercedes-Benz, Audi, Volkswagen, and Kamei. These high-quality roof boxes offer additional space for luggage, sports equipment, and more - ideal for every trip. Installation is child's play, and you can also order the matching roof bars directly from us. Order online now and enjoy your next trip in peace! Equip your vehicle with a practical roof box and start off well prepared.

---Charge your electric vehicle conveniently at home! In the Rosier online shop, you'll find high-quality wallboxes from Mercedes-Benz, Audi, and Volkswagen. These wallboxes enable fast and safe charging directly at home, so you're always ready to go. They offer state-of-the-art technology and are perfectly tailored to your vehicle. Order your wallbox online now and enjoy the flexibility of conveniently charging your electric vehicle at home at any time! Subject to prior sale and errors. The vehicle description serves solely as a general identification of the vehicle and does not constitute a legally binding warranty. Only the agreements in the purchase contract and the order confirmation are binding. Please note that certain optional equipment may incur additional costs. Detailed information on the scope of equipment is available from our sales staff.

Listing

Paderborn

Paderborn

902 km

Minibus

MaxuseTerron 9

Call

Condition: new, mileage: 5 km, power: 325 kW (441.88 HP), fuel type: electric, gearing type: automatic, axle configuration: 4x4, overall weight: 3,500 kg, emission class: euro6, color: yellow, driver cabin: other, number of seats: 5, Year of construction: 2024, total length: 55,000 mm, fuel: electricity, Equipment: ABS, air conditioning, all wheel drive, cruise control, onboard computer, Vehicle No.: 324873. Warranty & Quality Seal: Warranty. Assistance systems: Adaptive cruise control, lane assist, lane change assistant, blind spot assist, 360-degree camera, high beam assistant, traffic sign recognition, rear parking sensors, front camera, reversing camera, lane keeping assist. Lighting: LED headlights, LED daytime running lights. Media & Infotainment: apps, integrated music streaming. Safety & Technology: seat belt monitoring. Comfort & Climate: electric driver's seat adjustment with memory, keyless entry, memory package, electrically folding mirrors, onboard computer, power steering. Tires & Wheels: spare wheel. Exterior & Design: roof rails. Interior & Design: electric panoramic roof, leather package. Environment & Charging: emissions sticker 4. Transmission: automatic. Additional information: accident-free. * Transfer costs are charged separately - EUR 1,290, * -- plus VAT.

Ljdoyaw Dxjpfx Ahzjhb

----Discover the Rosier Online Shop – your expert for premium automotive accessories and exclusive lifestyle products at attractive prices! From stylish alloy wheels to innovative vehicle technology – we offer everything to make your car stand out. Benefit from unbeatable value for money and fast delivery. Secure your favorites and order now! Visit us online and turn your vehicle into a highlight on the road!

----More storage for your journeys! At the Rosier Online Shop, find genuine roof boxes from Mercedes-Benz, Audi, Volkswagen, and Kamei. These high-quality roof boxes provide extra space for luggage, sports equipment, and more – ideal for any trip. Installation is simple, and matching base racks can also be ordered directly from us. Order online now and enjoy your next trip in comfort! Equip your vehicle with a practical roof box and start your journey well-prepared.

----Charge your electric vehicle conveniently at home! In the Rosier Online Shop, you’ll find premium wallboxes from Mercedes-Benz, Audi, and Volkswagen. These wallboxes enable fast and safe charging right at home, so you’re always ready to go. Featuring state-of-the-art technology, they are perfectly suited to your vehicle. Order your wallbox online now and enjoy the flexibility of conveniently charging your EV at home at any time!

Product safety information: Manufacturer: Maxomotive Deutschland GmbH, Ferdinand-Porsche-Str. 1, 51149 Cologne. Telephone: E-Mail: Subject to prior sale and errors. The vehicle description serves solely for general identification of the vehicle and does not constitute a legally binding warranty. Only the terms in the sales contract and order confirmation are binding. Please note that certain optional equipment may incur additional costs. For detailed information on equipment scope, please contact our sales staff.

Listing

Wasbek

Wasbek

869 km

Guillotine Shear - KHT H 3010 CNC + sheet holding device

KnuthKHT H 3010 CNC mit Blechhochhaltevorrichtung

Call

Condition: as good as new (ex-display), The KHT H 3010 CNC + sheet holding device is a state-of-the-art guillotine shear from KNUTH, designed for precise and powerful cutting within the category of Guillotine Shears and the product group of Hydraulic Guillotine Shears. Built with a highly rigid frame and guided cutter bar, it minimizes twisting in the workpiece, ensuring optimal cutting accuracy while reducing rework. The user-friendly Cybelec Touch 8 control system operates via a touchscreen, allowing you to input the length, thickness, and strength of the plate material to automatically adjust kerf, cutting angle, and length for optimal results. This robust machine accommodates materials up to 10 mm thick, making it suitable for stainless steel sheets, while features like hydraulically regulated hold-downs guarantee steady fixation of materials during the cutting process. Safety is prioritized with advanced features like a light barrier and foot pedal emergency switch, adhering to the latest CE regulations. To expand the functionality of this Hydraulic Guillotine Shear, the innovative plate hold-up feature supports the plate during positioning for high precision. For further information, you can request a quote or order online.

Lodpfoq I Nb Tsx Ahzjhb

Listing

Janville

Janville

878 km

Turbine d’enrobage

Manesty Accela CotaAC 150 / 48

Call

Year of construction: 1982, condition: used, Manesty – ACCELA COTA Coating machine Model 150 (45 inch)

This high quality coating equipment, designed to cover a wide range of production batches from medium scale to large scale, has an unbeatable combination of a very efficient coating process coupled with a high rate of return on investment.

Innovative science based developments in the four key areas of; tablet mixing, spraying, drying efficiency and control system technology, guarantee that the XLTMCota provides a very effective solution to obtaining a highly controlled process, ensuring the delivery of high quality end product.

Interchangeable baffles to suit all processes

A range of three baffles to suit different applications are offered. Oystar Manesty identified the product movement in the coating pan to be a key attribute in reaching optimal coating efficiency. Baffles can be easily removed and interchanged.

Efficient CIP system to guarantee fast return to production

In conjunction with our m-tecTM control system, Oystar Manesty provides a fully validatable Clean in Place (CIP) option.

From the initial rinse through to compressed air cleaning of solution tubes, the XLTMCota Clean in Place (CIP) was designed to promote fast return to production by eliminating the need for manual cleaning.

Simple and fast loading and unloading facility

Tablets can be loaded with the front door closed or open using simple load chutes designed to suit different types of containers. Tablets are discharged by reversing the direction of the drum. This method has been proven to be extremely fast and gentle at the same for safe handling of the finished product.

TECHNICAL INFORMATION

Lhsdex Rz R Eopfx Ahzsb

Weight : 1590 kg Coater

Dimensions : H 2065 x W 1665 x D1475

Spray Guns : 3

Working Volume : 170 L

Compressed Air Consumption (5bar from Coater) : 7.9

Air Volume Range (m3/hr) : 1500 – 2500

Main Heater Temperature Range (°C) : 10 – 85

Main Heater Steam Consumption ( kg/hr ) : 117

Sold with : Donaldson Torit – Dust collector DCE DF02 12R

Listing

Dinslaken

Dinslaken

799 km

Electric 4-wheel forklift

EPEFL302X4

Call

Condition: new, functionality: fully functional, Year of construction: 2024, load capacity: 3,000 kg, lifting height: 4,800 mm, mast type: triplex, construction height: 2,200 mm, power: 8 kW (10.88 HP), fork length: 1,200 mm, drive type: Lithium-Ionen, Electric 4-wheel forklift

Load centre: 500

ISO Class: ISO Class 3 = 2,500 - 4,999 kg

Lhsdpfsx Tm Nrjx Ahzob

Mast type: Triplex

Condition: New machine

Technical condition: New

Battery voltage: 80V

Battery type: Lithium-ion

Battery year: 2024

Battery condition: New

Description: Battery system: Innovative lithium-ion quick-change system with modular 26kg battery packs. Fast, tool-free battery exchange in just a few minutes. Expandable up to 6 modules for maximum operating time. Ideal for multi-shift operation and use without fixed charging infrastructure. The machine comes with 6 batteries.

Sideshifter,

3rd valve, 4th valve,

Partial cab, battery exchange system

Listing

Dinslaken

Dinslaken

799 km

Electric 4-wheel forklift

NobleliftCPD25-A

Call

Condition: new, functionality: fully functional, machine/vehicle number: CPD25ANEU6000, Year of construction: 2025, load capacity: 2,500 kg, lifting height: 6,000 mm, mast type: triplex, construction height: 2,865 mm, fork length: 1,200 mm, empty load weight: 3,550 kg, total length: 2,628 mm, drive type: Lithium-Ionen, Electric 4-wheel forklift

Chassis number: CPD25ANEU6000

Lodpfox Tm H Rjx Ahzjhb

Load center: 500 mm

ISO class: ISO Class 2 = 1,000 - 2,500 kg

Mast type: Triplex

Condition: New machine

Technical condition: New

Front tires type: Non-marking

Front tires condition: New

Rear tires type: Non-marking

Rear tires condition: New

Battery voltage: 80V

Battery capacity: 175Ah

Battery type: Lithium-ion

Battery year: 2025

Battery condition: New

Description: The A-Series lithium-ion forklift is an innovative electric forklift, based on the proven architecture of internal combustion engine forklifts and combined with the advantages of advanced lithium battery technology. This lithium-battery-powered electric forklift brings together a robust design with cutting-edge energy systems, offering a powerful alternative to conventional diesel or LPG forklifts. The A-Series stands out for its superior vehicle performance, high level of ergonomics, excellent reliability, and minimal maintenance costs. Thanks to its high lifting capacity and optimum suitability for outdoor use, it is the ideal solution for standard and heavy-duty applications in warehousing, logistics, or industrial environments. The A-Series lithium forklift is designed for companies seeking to electrify their material handling fleet—without compromising on power or endurance. It meets all the requirements of traditional IC engine forklifts and enables a seamless transition from fossil fuels to electric operation.

Side shifter, third valve, fourth valve, heater, full cabin, interior mirror, wiper, LED lighting, integrated charger.

Listing

Dinslaken

Dinslaken

799 km

Electric 4-wheel forklift

NobleliftCPD25-A

Call

Condition: new, functionality: fully functional, Year of construction: 2025, load capacity: 2,500 kg, lifting height: 4,800 mm, mast type: triplex, fork length: 1,200 mm, empty load weight: 3,550 kg, total length: 2,628 mm, drive type: Lithium-Ionen, Electric 4-wheel forklift

Load center: 500 mm

ISO class: ISO Class 2 = 1,000 - 2,500 kg

Mast type: Triplex

Lhodpox Tm H Defx Ahzob

Condition: New machine

Technical condition: New

Front tires type: Non-marking

Front tires condition: New

Rear tires type: Non-marking

Rear tires condition: New

Battery voltage: 80V

Battery capacity: 175Ah

Battery type: Lithium-ion

Battery year of manufacture: 2025

Battery condition: New

Description: The A-Series lithium-ion forklift is an innovative electric forklift based on the proven architecture of internal combustion engine forklifts while combining the advantages of state-of-the-art lithium battery technology. By merging a robust chassis with a forward-thinking energy system, this lithium battery electric forklift delivers a powerful alternative to traditional diesel or LPG trucks. The A-Series stands out with superior vehicle performance, high ergonomics, outstanding reliability, and minimal maintenance costs. Thanks to its high load capacity and optimal suitability for outdoor applications, it is the ideal solution for standard and heavy-duty operations in warehousing, logistics, or industrial environments. The A-Series lithium forklift is designed for companies aiming to electrify their material handling fleets—without compromising on power or endurance. It meets all the requirements of conventional IC forklifts, enabling a seamless transition from fossil fuels to electric operation.

Side shifter,

3rd valve, 4th valve, heating, full cabin, interior mirror, windscreen wiper, LED lighting,

Integrated charger

Listing

Wakefield

Wakefield

228 km

Case maker

KolbusDA-270 Casemaker

Call

Condition: excellent (used), Year of construction: 2012, Ref:11025 . 2012 Kolbus DA-270 Casemaker

For high-speed production of hard book covers, Lever Arch files and games boards.

Comprising:

‘Co-pilot’ system with touch screen for automatic size setting, menu guided make-ready and fault indication.

Twin board magazine feeders - manual loading

Central soft spine feeder with double reel holder for auto-splice and cutter for waste

Magazine feeder of pre-cut cloth with miss control

Mobile hot-melt gluing unit

Heated glue application roller with scraper roller

Cloth cylinder with grippers & exchangeable plates for rubber pad

Counter shingle delivery with roller conveyor

External glue application adjustment

Glue viscosity device for automatic water supply control

Pressing roller for crease-free cover to board application

Single case request for operator set-up

Variable DC drive

Automatic lubrication

Including accessories & manuals.

N.B. Compressed air and water supplies to client’s account.

Accessories:

2017 Kolbus ECK 100 Corner cutter

Specification:

Size of opened case, Max: 670 x 390 mm

Min : 205 x 140 mm

Centre strip width : 6 - 90 mm, thickness 1 – 4 mm

Joint width : 4 - 15 mm

Turn-in width, closed : 8 – 15 mm

Lhjdpoxx Uyyefx Ahzeb

Output, variable : up to 65 cycles/min

Floor space : L: 6700 x W: 3000 x H: 2,200 mm

Electrical loading : 15 kW (3ph, 400V, 50 Hz)

Air requirement : 33 Nm3/h 6 bar.

Listing

Gifhorn

Gifhorn

966 km

FDM 3D printer

StratasysFortus 400mc - T1993

Call

Condition: refurbished (used), machine/vehicle number: T1993, Year of construction: 2012, Experience the power and versatility of the Fortus 400mc, a cutting-edge 3D printer designed to revolutionize your manufacturing process. Crafted by Stratasys, a pioneer in the 3D printing industry, this exceptional machine is engineered to meet the most demanding production needs, from functional prototypes to end-use parts.

With its large build volume of 406 x 355 x 406 mm, the Fortus 400mc opens up a world of possibilities for 3D printing applications. Its selectable layer thicknesses, ranging from 0.127mm to 0.330mm, allow for precise control over your print, ensuring accuracy and quality in every detail.

Thanks to its compatibility with various materials like ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010, the Fortus 400mc empowers you to choose the perfect material for your specific project requirements. Whether you’re aiming for robust functional parts or intricate prototypes, this printer delivers exceptional results.

Baux8frhx3y

What sets the Fortus 400mc apart is its user-friendly operation. The free GrabCAD software simplifies the 3D printing process, enabling even newcomers to dive into their projects effortlessly. Additionally, the system uses soluble support material SR30 or Break-Away support material, allowing for the creation of complex geometries and reducing the need for post-processing.

Rest assured, the Fortus 400mc is designed with safety and efficiency in mind. Its installation is hassle-free, requiring no special ventilation or setup conditions, as it produces no harmful emissions or waste.

Don’t miss the chance to optimize your production with the Fortus 400mc 3D printer. Unlock unparalleled potential and elevate your manufacturing capabilities. Download our site preparation guide now to witness the future of 3D printing. Embrace innovation with the Fortus 400mc and shape the world like never before!

This printer is part of the Certified Pre-Owned (CPO) program.

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts. If you opt for installation and training by one of our certified service technicians, you will also receive a 6-month warranty on your 3D printer. Additionally, we can provide you with all the accessories and consumables, tailored to your purchased 3D printer, from a single source.

Lhsdpfx Ahjvmgcajzsb

This means that you take no risks with your purchase.

Listing

Gifhorn

Gifhorn

966 km

FDM 3D printer

StratasysFortus 400mc - T2631

Call

Condition: refurbished (used), functionality: fully functional, machine/vehicle number: T2631, Year of construction: 2013, Experience the power and versatility of the Fortus 400mc, a cutting-edge 3D printer designed to revolutionize your manufacturing process. Crafted by Stratasys, a pioneer in the 3D printing industry, this exceptional machine is engineered to meet the most demanding production needs, from functional prototypes to end-use parts.

With its large build volume of 406 x 355 x 406 mm, the Fortus 400mc opens up a world of possibilities for 3D printing applications. Its selectable layer thicknesses, ranging from 0.127mm to 0.330mm, allow for precise control over your print, ensuring accuracy and quality in every detail.

Thanks to its compatibility with various materials like ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010, the Fortus 400mc empowers you to choose the perfect material for your specific project requirements. Whether you’re aiming for robust functional parts or intricate prototypes, this printer delivers exceptional results.

Baux8frhx3y

What sets the Fortus 400mc apart is its user-friendly operation. The free GrabCAD software simplifies the 3D printing process, enabling even newcomers to dive into their projects effortlessly. Additionally, the system uses soluble support material SR30 or Break-Away support material, allowing for the creation of complex geometries and reducing the need for post-processing.

Rest assured, the Fortus 400mc is designed with safety and efficiency in mind. Its installation is hassle-free, requiring no special ventilation or setup conditions, as it produces no harmful emissions or waste.

Don’t miss the chance to optimize your production with the Fortus 400mc 3D printer. Unlock unparalleled potential and elevate your manufacturing capabilities. Download our site preparation guide now to witness the future of 3D printing. Embrace innovation with the Fortus 400mc and shape the world like never before!

Lhedpfovmgnvjx Ahzjb

This printer is part of the Certified Pre-Owned (CPO) program.

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts. If you opt for installation and training by one of our certified service technicians, you will also receive a 6-month warranty on your 3D printer. Additionally, we can provide you with all the accessories and consumables, tailored to your purchased 3D printer, from a single source.

This means that you take no risks with your purchase.

Trust Seal

Dealers certified through Machineseeker

Listing

Gifhorn

Gifhorn

966 km

FDM 3D printer

StratasysFortus 400mc - T3249

Call

Condition: refurbished (used), functionality: fully functional, machine/vehicle number: T3249, Fortus eT 3D Printer with an upgrade to Fortus 400mc

Experience the power and versatility of the Fortus 400mc, a cutting-edge 3D printer designed to revolutionize your manufacturing process. Crafted by Stratasys, a pioneer in the 3D printing industry, this exceptional machine is engineered to meet the most demanding production needs, from functional prototypes to end-use parts.

With its large build volume of 406 x 355 x 406 mm, the Fortus 400mc opens up a world of possibilities for 3D printing applications. Its selectable layer thicknesses, ranging from 0.127mm to 0.330mm, allow for precise control over your print, ensuring accuracy and quality in every detail.

Thanks to its compatibility with various materials like ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010, the Fortus 400mc empowers you to choose the perfect material for your specific project requirements. Whether you’re aiming for robust functional parts or intricate prototypes, this printer delivers exceptional results.

Baux8frhx3y

What sets the Fortus 400mc apart is its user-friendly operation. The free GrabCAD software simplifies the 3D printing process, enabling even newcomers to dive into their projects effortlessly. Additionally, the system uses soluble support material SR30 or Break-Away support material, allowing for the creation of complex geometries and reducing the need for post-processing.

Rest assured, the Fortus 400mc is designed with safety and efficiency in mind. Its installation is hassle-free, requiring no special ventilation or setup conditions, as it produces no harmful emissions or waste.

Don’t miss the chance to optimize your production with the Fortus 400mc 3D printer. Unlock unparalleled potential and elevate your manufacturing capabilities. Download our site preparation guide now to witness the future of 3D printing. Embrace innovation with the Fortus 400mc and shape the world like never before!

This printer is part of the Certified Pre-Owned (CPO) program.

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts. If you opt for installation and training by one of our certified service technicians, you will also receive a 6-month warranty on your 3D printer. Additionally, we can provide you with all the accessories and consumables, tailored to your purchased 3D printer, from a single source.

This means that you take no risks with your purchase.

Lhodem Uc I Ijpfx Ahzsb

Listing

Gifhorn

Gifhorn

966 km

FDM 3D printer

StratasysFortus 400mc - T2837

Call

Condition: refurbished (used), machine/vehicle number: T2837, Year of construction: 2015, operating hours: 3,956 h, Experience the power and versatility of the Fortus 400mc, a cutting-edge 3D printer designed to revolutionize your manufacturing process. Crafted by Stratasys, a pioneer in the 3D printing industry, this exceptional machine is engineered to meet the most demanding production needs, from functional prototypes to end-use parts.

With its large build volume of 406 x 355 x 406 mm, the Fortus 400mc opens up a world of possibilities for 3D printing applications. Its selectable layer thicknesses, ranging from 0.127mm to 0.330mm, allow for precise control over your print, ensuring accuracy and quality in every detail.

Thanks to its compatibility with various materials like ABS, ABS-ESD, ABS-CF, ASA, PC-ABS, PC, ULTEM 9085, and ULTEM 1010, the Fortus 400mc empowers you to choose the perfect material for your specific project requirements. Whether you’re aiming for robust functional parts or intricate prototypes, this printer delivers exceptional results.

What sets the Fortus 400mc apart is its user-friendly operation. The free GrabCAD software simplifies the 3D printing process, enabling even newcomers to dive into their projects effortlessly. Additionally, the system uses soluble support material SR30 or Break-Away support material, allowing for the creation of complex geometries and reducing the need for post-processing.

Rest assured, the Fortus 400mc is designed with safety and efficiency in mind. Its installation is hassle-free, requiring no special ventilation or setup conditions, as it produces no harmful emissions or waste.

Don’t miss the chance to optimize your production with the Fortus 400mc 3D printer. Unlock unparalleled potential and elevate your manufacturing capabilities. Download our site preparation guide now to witness the future of 3D printing. Embrace innovation with the Fortus 400mc and shape the world like never before!

This printer is part of the Certified Pre-Owned (CPO) program.

Certified Pre-Owned 3D printers are used 3D printers that have been fully refurbished, serviced, and then verified through a 24-hour test print by our experts.

Maintenance contracts and other services

We offer optimal advice before, during and after the purchase. In addition to our services such as on-site installation and training for your team, we also offer the supply of accessories, spare parts and materials. Sign a maintenance contract with us and benefit from full planning and cost security, fast response times and minimized machine downtimes.

This means that you take no risks with your purchase.

Lhjdpsm Tv R Eofx Ahzeb

Listing

Torcé

Torcé

826 km

Wide belt sander 1350 mm MFA 6

HEESEMANNPONCEUSE DE SURFACE MFA 6 1350 mm

Call

Condition: good (used), Year of construction: 2008, functionality: fully functional, HESSEMANN 3-HEAD SANDER:

Abrasive belt dimensions: 2,620 x 1,400 mm

1 Longitudinal sanding unit

(with contact roller for calibration work (steel))

Roller diameter: 250 mm

Belt speeds: approx. 18 m/s

22 kW

Anti-wear braking unit, automatic band length adjustment

Dust extraction system controlled depending on the workpiece, counter-rotating abrasive belt, abrasive belt grit compensation by computer

Belt speeds:

1.0 - 18 m/s

Drive:

15 kW

1 Longitudinal sanding unit

Belt speeds:

1.0 - 18 m/s

Drive: 15 kW

Includes continuously adjustable sanding speed via electronic frequency inverter, with double number of extraction holes for the dust extraction device.

Anti-wear braking unit, automatic band length adjustment for abrasive belt edges potentially of different lengths; dust extraction controlled by workpiece detection, deactivatable, counter-rotating abrasive belt.

2 Pressure beams with selective pressure adjustment system – CSD® system

Continuously adjustable individual pressure elements, for single and multiple workpiece feeding. Spacing: 32 mm. Tolerance compensation for workpieces up to 2 m by maintenance-free pressure magnets. Working width as well as start and end positions of the pressure beam are electronically adjustable.

Ledpfxjx Rdn Te Ahzohb

The pressure elements are driven by lifting electromagnets capable of continuously varying the force of each sanding pad as the workpiece passes through the machine. This innovative CSD® technology guarantees constantly proportionate pressure relative to pad overlap on the workpiece. The risk of sanding through on the edges is virtually eliminated by this dynamic, continuous pressure force control.

Listing

Weilerswist

Weilerswist

858 km

Open semitrailer with tarp

WIELTONNS-3K Curtainsider QUICK SLIDE mit Speed Curtain

Call

Condition: used, maximum load weight: 29,500 kg, overall weight: 36,000 kg, axle configuration: 3 axles, first registration: 07/2023, loading space length: 13,620 mm, loading space width: 2,480 mm, loading space height: 2,750 mm, total width: 2,550 mm, total height: 4,000 mm, Year of construction: 2023, Wielton Curtainsider Type "QUICK SLIDE" with Speed Curtain.

The Curtainsider trailer with the Quick Slide rapid curtain system is an innovative solution designed to minimize loading and unloading times as much as possible. By replacing horizontal boards and standard stanchions with a specially developed curtain, the handling of the trailer has been significantly improved. Quick Slide is the ideal solution for customers who perform many handling operations daily and value speed and convenience.

Wielton Quick Slide Curtain Master

Includes load securing system for partial loads (2 movable partition walls)

Unladen weight approx. 6,500 kg

Demonstration vehicle – immediately available

First registration 20.07.2023

Saddle height 1,120 mm

Equipment:

Ledpex Uvk Iefx Ahzohb

SAF disc brake axles

First axle as lift axle

Tyres 385/65 R22.5 on steel rims

Tyre brand: BRIDGESTONE

Brake system: KNORR

Lighting system: ASPÖCK

Rear lights: EUROPOINT III

Landing legs: SAF

Side underrun protection made from lightweight composite, foldable

Lamp carrier made from lightweight composite

Toolbox

Rubber rear bumpers

Extendable access ladder

Folding ladder under platform, right

Floor: phenolic plywood panels

EDSCHA sliding roof

Chassis: RAL 7021 black grey

Aluminium body unfinished

Side curtain: RAL 9005 deep black

Roof curtain: white

Used vehicle with age-typical and customary signs of wear.

Interim sale and errors for this offer are expressly reserved.

Some images show optional equipment. Only the agreements in the order confirmation or in the purchase contract are binding. You will receive the exact equipment specification and prices from our sales staff. Please contact us.

We make it easier for you to find: "innovation splicing"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Innovation Splicing (1,189)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month