Used Roles Paternoster for sale (297)

Mönchweiler

Mönchweiler High-bay warehouse

SSI SchäferSHUTTLE 1850 X 825

Borken

Borken Aluminium Measuring Table Marking Plate

Drawer cabinet: Garant (Hoffmann Group)50 mm Aluminium plate

Halver

Halver Manual folding bench 2 m / 0.8 mm square Bank

Prod-MaszZGR2000/0,8

+44 20 806 810 84

Bitburg

Bitburg Thickness Planers

SCM / CasadeiPS 52 Tersa

Borken

Borken Mobile plasticiser Thermoplastics

KMH60 S

Discover more used machines

Kungälv

Kungälv Schäfer Logimat SSL 3225-625-6950/200

Schäfer Logimat3225-625-6950/200

Köpenhamn

Köpenhamn Storage elevator

Kardex RemstarMegamat RS 350.1.3050.6.5

Borken

Borken Chamber dryer Oven

GFOTyp Ke/SO 2,2 qm 100°C 3208.3319

Borken

Borken Automated Vertical Storage System 06

ModulaML50D

Sindelfingen

Sindelfingen Storage lift

KardexShuttle XP-500-2450-813

Falkenberg

Falkenberg Carpentry machine

Randek ABSPL728 Cut Saw

Hilden

Hilden Measuring Machine

KLINGELNBERG-OERLIKONCS 200

Hohenstein-Ernstthal

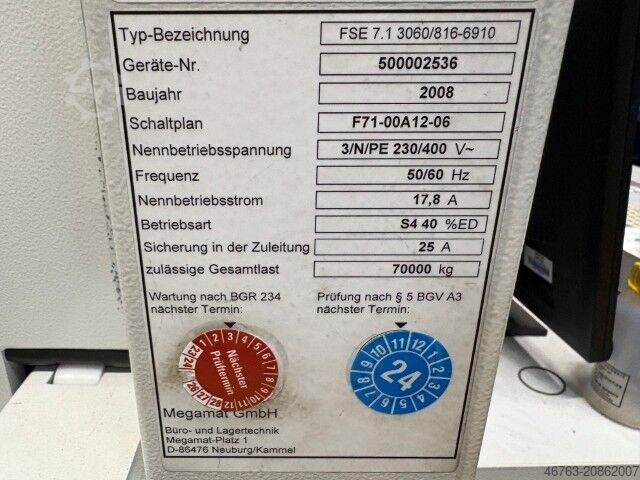

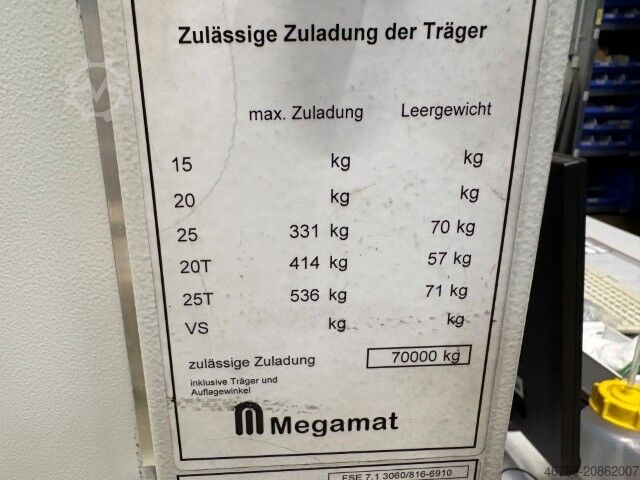

Hohenstein-Ernstthal Storage lift

MegamatFSE 7.1 3060/816-6910

Braunschweig

Braunschweig Palletizer

KolbusPL 771

Braunschweig

Braunschweig Palletizer

KolbusPL 770

Würzburg

Würzburg Curved roller conveyor 90° + straight section

Transnorm665-600-IR800

Würzburg

Würzburg Curved roller conveyor 45° driven + insertion unit

Transnorm500

Würzburg

Würzburg Roller conveyor, roller conveyors

Budde1850-560-540

Würzburg

Würzburg Curved roller conveyor 90° driven roller curve

Dematic500-430 IR765

Würzburg

Würzburg Curved roller conveyor driven

Transnorm90°-680-600 IR800

Würzburg

Würzburg Curved roller conveyor 90° non-driven roller curve

Dematic600-540 IR765

Würzburg

Würzburg Curved roller conveyor 90° right driven roller...

Dematic500-440 IR765

Würzburg

Würzburg Roller curve conveyor left with straight section

SchulzSchzlz 90°-450-390 IR795 + 1875-450-390

Würzburg

Würzburg Curved roller conveyor 90° left driven +...

Dematic500-440 IR765 + 880-500-440

Neubrandenburg

Neubrandenburg Blade block / distributor block

SiemensZCH 565227

Used Roles Paternoster (297)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84