Used Scraper for sale (713)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Nattheim

Nattheim

1,192 km

Edge banding machine with joining

HebrockAKV 3005 DK - F Airtronic

Call

Condition: used, Year of construction: 2011, Pneumatic milling adjustment (Straight/Radius) Combination milling station R=2 Corner rounding cutter R=2 to 40 mm Jointing cutter up to 40 mm Flat scraper Profile scraper R=2 Short workpieces PLC control with Pro Face touchscreen Nesting Cooling/antistatic spray - airtronic Protective spraying Kante Riepe incl. interchangeable tank Workpiece thickness 8 - 60 mm Mechanical edge clamping Extraction nozzle: 140 mm Dimensions: Length with extension: 4984 mm Depth with roller table: 1425 mm Max. height: 1618 mm Worktable height: 888 mm Weight: 1400 kg

Gtodpfxexyiils Aadsu

Storage location: Nattheim

Listing

Nattheim

Nattheim

1,192 km

Edge banding machine

HOLZ-HERUno 1302

Call

Condition: used, Year of construction: 2006, EVA glueing, 2 pressure rollers, cross-cutting station, pre-milling cutter and rounding cutter, surface scraper, transport device

Storage location: Nattheim

Gedpfxjvvkg Is Aadjtu

Listing

Lennestadt

Lennestadt

897 km

Adapter unit cutter saw tiltable change

IMABFAF Adapteraggregat Wechselaggregat

Call

Condition: reconditioned (used), functionality: fully functional, IMA Adapter Unit with Interchangeable Flush Trimming Head and Flat Scraper Blade

The IMA adapter unit is a refurbished interchangeable unit designed for flush trimming operations and equipped with a flat scraper blade. Featuring the article number 10 237 069 and an HSK 63 F clamping system, this unit is ideal for precise and secure machining tasks. The unit’s rotation is synchronized with the drive rotation, and it includes a 57 mm opening. Specifically designed for use with IMA machines, it supports tools with chamfer milling cutters.

Included in the package is a flat scraper blade. The bolt dimensions are 16/18.1 mm. The unit can reach a maximum speed of 9000 revolutions per minute and has a maximum probing depth of 1.5 mm. Following a comprehensive refurbishment, which includes inspection, replacement of bearings, and new pneumatic hoses, the unit offers maximum safety, precision, and a nearly new condition.

Used adapter units are taken from operational systems and are fully functional. Any age-related wear or significant precision limitations are clearly noted.

Technical Description

• Product: IMA Adapter Unit with Interchangeable Flush Trimming Head and Flat Scraper Blade

• Article Number: 10 237 069

• Clamping System: HSK 63 F

• Condition: Refurbished

• Rotation: Synchronized with drive rotation

• Opening: 57 mm

• Support Bolt: For IMA machines

• Tools: Compatible with chamfer milling cutters

• Flat Scraper Blade: Included

• Bolt Dimensions: 16/18.1 mm

• Maximum Speed: 9000 RPM

• Maximum Probing Depth: 1.5 mm

• Special Features:

• Inspected and fully re-bearings for maximum safety and precision

• Pneumatic hoses replaced

Gtsdjudl Idspfx Aadou

• Nearly new condition

Note: Used adapter units are fully functional, extracted from operational systems. Explicit notice is provided for excessive wear or significant precision reductions due to aging.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Nattheim

Nattheim

1,192 km

Edge banding machine with joining

SCMME 40 TR

Call

Condition: used, Year of construction: 2022, Incl. 2nd glue pot. Glue thickness for roll edges: 0.4 - 3 mm. Glue thickness for strip edges: 5 mm. Min. - Max. workpiece height: 8 - 50 mm. Feed speed: 9 m/min. Pre-milling unit. Glue unit. Trimming unit. Rounding unit. Flush trimming unit. Radius scraper. Flat scraper. Buffing unit. Spraying unit.

Storage location: Customer.

Gjdow Aig Sepfx Aadstu

Listing

Lenggries

Lenggries

1,351 km

Horizontal machining center

WMW HECKERTCWK800

Call

Condition: ready for operation (used), Year of construction: 1999, functionality: fully functional, machine/vehicle number: 14023, travel distance X-axis: 1,140 mm, travel distance Y-axis: 910 mm, travel distance Z-axis: 875 mm, rapid traverse X-axis: 60 m/min, torque: 1,000 Nm, controller manufacturer: Siemens, controller model: 840 D, spindle speed (min.): 6,000 rpm, coolant supply: 60 bar, distance table center to spindle nose: 240 mm, Equipment: chip conveyor, documentation/manual, Siemens 840 D with network connection

Renishaw measuring probe OMP60

SK50 DIN69871 – pull studs DIN69872

6000 rpm, 2 gearbox stages, max. torque 1000 Nm

Tool chain magazine with 80 positions

2 pallets 800x800 mm, M16 hole grid

Coolant high pressure through spindle 50 bar

Knoll paper band filter and chip scraper conveyor

Gsdpfxov Npm Hj Aadjtu

Year of manufacture Dec. 1999 (max. single-shift operation)

Listing

Lambsborn

Lambsborn

994 km

Edge banding machine

HOLZ-HER1436 SE

Call

Condition: used, Year of construction: 1997, HolzHer Edge Banding Machine 1436SE

Year of manufacture: 1997

- PVC Primus, 3mm PVC cartridge system

- Edge banding, flush cutting, flush milling, chamfer milling, radius milling

- Scraper, buffing unit

- Dimensions: 4700mm x 1400mm; Height: 1650mm

- Weight: 1300kg

- Working dimensions:

Length: 4500mm

Depth: 1020mm

Height: 1630mm

- Connection nozzle: 140mmØ

Gsdpfx Aajwv Uq Aodetu

- Minimum workpiece width: 60mm

- Feed speed: 11m/min

- 6 bar

- 400 Volt compressed air

- Edge thickness: 8mm for strip material, 2mm for coil material

- WITHOUT pre-milling unit

Listing

Warstein

Warstein

891 km

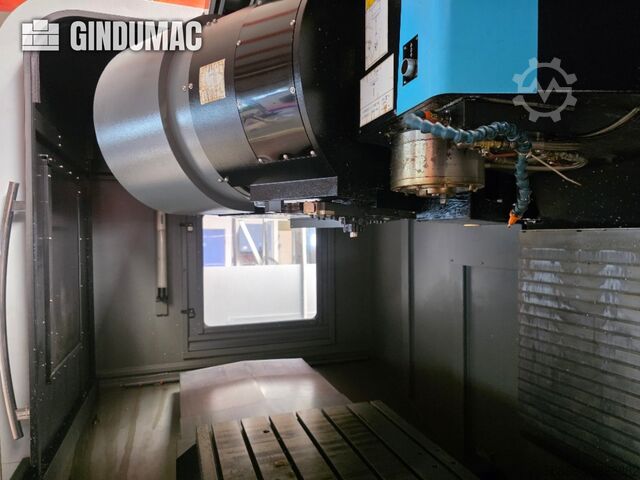

Vertical machining center

StarragHEC 400 F

Call

Condition: good (used), Year of construction: 2016, operating hours: 27,412 h, functionality: fully functional, travel distance X-axis: 650 mm, travel distance Y-axis: 650 mm, travel distance Z-axis: 680 mm, controller manufacturer: Siemens, controller model: 840D sl, table width: 400 mm, table height: 30 mm, table length: 500 mm, table load: 500 kg, spindle speed (max.): 18,000 rpm, operating hours of spindle: 9,956 h, coolant supply: 80 bar, spindle motor power: 32,400 W, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, For sale is a Starrag HEC 400 F 4-axis machining center, which was fully inspected and overhauled at the Starrag factory in 2022. All relevant components were checked and replaced or adjusted as needed during this process.

Since its installation in 2022, the machine has been in operation at our facility and is currently under power for ongoing production. It is in well-maintained technical condition and has been serviced regularly.

Technical Highlights

• Starrag HEC 400 F – 17211, 4-axis machining center for milling / drilling / turning

• Control: Siemens Sinumerik 840 D solution Line with NCU710 and PLC integration

• Spindle: HSK-A63 motor spindle, speed range 50 – 18,000 rpm, torque 130 Nm (25% duty cycle), power 32.4 kW / 24 kW (100% duty cycle)

• Factory inspection in Chemnitz (2022): all assemblies checked, adjusted, and renewed as needed

• Direct-drive NC rotary table, 80 rpm, 400 Nm drive torque, 3,000 Nm tangential torque

• Siemens spindle diagnostics & remote diagnostics (TeamViewer)

• Energy-efficient system with regeneration and standby mode for energy savings

Working Area & Dimensions

• Travels (X/Y/Z): 650 / 650 / 680 mm

• Pallet size: 400 × 500 mm with 57 × M12 threaded holes

• Max. workpiece height: 850 mm

• Max. load per pallet: 500 kg

• Pallet changer: 2 pallets – automatic, changeover time approx. 8 s

• Tool magazine: 60 tool positions (chain magazine), chip-to-chip time 3 – 4 s

• Chip conveyor: scraper belt conveyor with vacuum gap sieve, discharge height 1,050 mm

• Machine dimensions (L × W × H): approx. 5,150 × 2,800 × 3,025 mm

• Machine weight: approx. 11,500 kg

Gedpfex H Idkox Aadetu

• Noise emission: ≤ 80 dB(A) according to EN ISO 3744

Additional Equipment

• 6-channel clamping hydraulics (90 bar) at setup and working positions

• Increased spindle torque (130 Nm) for high-performance cutting

• Torque support with axial supports

• Coolant system: connection to central supply incl. return and temperature compensation

• Increased coolant pressure to 80 bar through spindle center

• Optical measuring probe Renishaw OMP60 incl. Siemens measuring cycles

• Tool breakage detection (mechanical, parallel to main time)

• Pallet sequence operation + crane loading/unloading (software)

• Signal lamp (4-color) for operating status

• Work area/machine equipment: shower nozzle, rinsing pistol, vortex nozzle, extraction interface, foot switch blow nozzle

• Documentation: fully digital (PDF)

Operating Hours / Run Times

• Power-on hours: approx. 27,412 h (as of Oct 2025). The counter runs as soon as the machine is switched on – including during setup, maintenance, or idle times.

• Total spindle running time: 9,956 h

Special Features

• OPTIONAL: With perfect post-processor and CAD/CAM software TOP Solid (at extra cost)

• Under power – demonstration possible at any time

• Directly from production – not a dealer sale

• Complete technical documentation available

• Support with dismantling, loading and transport available (at extra cost)

The tool holders and vise visible in the photos are not included in the offer, but can be purchased separately if desired.

Price: €135,000 net, negotiable for quick completion.

All information has been provided to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

Listing

Ubstadt-Weiher

Ubstadt-Weiher

1,070 km

Machining center

Deckel MahoDMU 50 EVO linear

Call

Condition: excellent (used), Year of construction: 2006, functionality: fully functional, Equipment: chip conveyor, documentation/manual, Deckel Maho DMU 50 evo Linear with TNC 530 control from Heidenhain, TOP condition

Technical data:

>> Year of manufacture 2006

>> Manufacturer Heidenhain, type iTNC 530

>> Travel paths X500/Y450/Z400

>> C-axis 360 degrees

>> B-axis 0 degrees to 161.955 degrees

>> Tool holder HSK A63

>> Max. spindle speed up to 18000 rpm

>> Feed continuously programmable up to X, Y, Z 20000 mm/min

C-B axis continuously programmable up to rapid traverse speed

>> Rapid traverse Y- Z axis 50 m/min

X-axis 80 m/min (linear drive)

B-axis 40 rpm

C-axis 50 rpm

>> Tool magazine: Double gripper 60 magazine spaces

>> Table clamping area Ø 500 x 380 mm

T-slot spacing 63/14H7

>> Table load 200 KG

Gedpfjvyr Tdjx Aadotu

>> Dimensions and weight: approx.

Machine without control and attachments

Depth 3.0 meters Width 2.4 meters Height 2.6 meters

Weight approx. 7000 kg

>> Operating voltage 400 V

>> electr. Handwheel Heidenhain HR 410

>> Power connection 17 KVA

>> Chip conveyor

>> Active spindle cooling

>> Mist extraction

>> IKZ 40 bar

>> Coolant lubricant cleaning system (fleece filter system)

>> Spray gun

>> Visiport

>> Sealing air on the measuring system

>> Preparation for robot loading

>> 3D probe Heidenhain TS640

>> 3D Quick Set

>> Kinematics

>> Blum laser for tool measurement and breakage control

Cpvnunmsoi

>> Complete documentation

Dn2F2R

The following work was carried out:

>> Generally overhauled main work spindle

>> Complete maintenance: All cooling hoses and pneumatic hoses replaced, new filters, fluids and belts replaced. Scrapers, etc. Complete cleaning.

>> Geometrically measured (acceptance protocol)

About the machine:

A Deckel Maho DMU 50 evo Linear machining center with a TNC 530 3D path control from Heidenhain is offered. The machine is in very good condition. The main spindle on the DMU was overhauled (replacement spindle), completely serviced and an acceptance protocol was created. Take advantage of the opportunity to view and try out the machine on site with power on.

Listing

Edewecht

Edewecht

783 km

Felder edge bander

FelderPERFECT 710

Call

Condition: used, Year of construction: 2010, The machine operates perfectly; the front glue unit requires cleaning.

Fully operational

Year of manufacture: 2010

Radius scraper

Surface scraper

Cleaning unit

Jointing cutter up to 3 mm

Nesting milling unit

Pneumatic feed stop

Gsdpfxex Hqdmj Aadotu

Polishing

Machine no.: 200.07.011.10

Listing

Lambsborn

Lambsborn

994 km

Edgebander

IMAAdvantage 4612F

Call

Condition: excellent (used), Edgebanding Machine Advantage 4612F

- Regularly maintained, year of manufacture 2002

- Total length 6000 mm

- Width 1100 mm

- Height 1900 mm

- Weight 3100 kg

- Feed rate: 12 m/min

- Workpiece dimensions: width 65 mm, max. thickness 45 mm, min. thickness 10 mm, length 150 mm, edge height 55 mm, 7 bar pressure

Godpsx Srp Ijfx Aadjtu

- With two interchangeable glue pots

- Pre-milling, flush trimming saw, multifunction unit, profile & surface scraper, buffing

- With pre-milling unit

Listing

Hungary

Hungary

1,006 km

Hurco VMX84i

HurcoVMX84i

Call

Condition: ready for operation (used), Year of construction: 2015, travel distance X-axis: 2,135 mm, travel distance Y-axis: 865 mm, travel distance Z-axis: 762 mm, table load: 2,270 kg, overall weight: 17,000 kg, spindle speed (max.): 12,000 rpm, spindle motor power: 18,000 W, tool weight: 7,000 g, number of axes: 3, This 3-axis Hurco VMX84i was manufactured in 2015. It features a WinMax control system, a table size of 2185 × 865 mm, and a maximum table load of 2270 kg. The machine offers a travel range of 2135/865/762 mm and a spindle speed up to 12000 RPM. It includes a 40-position automatic tool changer and through-spindle coolant. If you are looking to get high-quality milling capabilities, consider the Hurco VMX84i machine we have for sale. Contact us for more information.

• Control: WinMax

• Table working surface (W x D): 2185 x 865 mm

• Spindle nose to table: 127 – 887 mm

• T-slots (DIN 650): 8 slots, 18 mm, 125 mm spacing

Gtjdex Stlwepfx Aadju

• Max spindle torque: 239 Nm (SK40)

• Rapid traverse (X/Y/Z): 18 / 18 / 13.5 m/min

• Automatic tool changer: 40 stations (SK40)

• Max tool diameter: 75 mm (SK40)

• Max tool length: 300 mm

• Through-spindle coolant: yes

• Workpiece probing: yes

• Tool wear measurement: none

• Coolant tank capacity: 867 l

• Required floor space (with open doors, control, and chip conveyor): 7574 x 4450 x 3310 mm

Additional equipment

• Scraper-type chip conveyor (standard)

• Workpiece probing system

Technical Specification

Taper Size SK 40

Listing

Pfullingen

Pfullingen

1,157 km

HDC 3000 Universal Machine Tool

Stadler Keppler Maschinenbau GmbHHDC 3000, 5-achsig

Call

Condition: reconditioned (used), Year of construction: 2010, • Traveling distances X=3100 mm, Y=1950 mm, Z=1390 mm

• Heidenhain iTNC 530 with handwheel HR 410

• Machine table for multi side working 3000 mm x 1600 mm

• 2-axis NC-universal milling head, for simultaneous and positioning

working

• Spindel 10.000 U/min HSK 100, 130 Nm Spindle torque

• Tool change system HSK 100 / 40 places for 750 mm long tools

Gtedpfx Aasx U Sfnodou

• Chip conveyor (screw type) in X-axis, for transport into

• Chip conveyor scraper belt type (traverse conveyor), Fabr. Knoll

• Coolant container 900 l, Fabr. Knoll

• Outside air at spindle

• IKZ 60 bar for deep hole drilling function

• Covering with safety glass pane, open at the top for loading by

crane

• 2 part sliding doors at the operator side

• 2 part sliding doors at the front side, for easy loading

• Radio-controlled measuring probe RMP 60

• incl. washing gun

• incl. podiums at the front side and operator side

• complete factory overhauled and painted new

• short time delivery after arrangement

• used machine

• Y-axis ball screw in September 2021 incl. bearings renewed

• X-axis new linear guiding system, July 2023 changed, renewed

• Spindle overhauled at Mai 2023 (clamping system new, clamping

cartridge new, rotation unit new, general tests) (at 23105 spindle

hours))

• can be visited under power at 72793 Pfullingen

• optional fixators

• optional installation at customers plant

• optional transport

• 23122 spindle hours in total

• 53991 machine hours in total

• Year of construction 2010

Subject to prior sale

Listing

France

France

1,093 km

HORIZONTAL MACHINING CENTER MAKINO A55e A60 – 2003

MAKINOA55e A60

Call

Condition: refurbished (used), Year of construction: 2003, Table size: 400x400 mm• 2 pallets• Pallet change time: 10 sec• Maximum table load: 500 kg• Working diameter: 630 mm• X axis: 560 mm• Y axis: 560 mm• Z axis: 600 mm• Continuous B axis• CNC control: Fanuc 16 iMA• Spindle torque: 156 Nm• Spindle speed: 50–14,000 rpm• Spindle power: 22 kW• Rapid feed X/Y/Z: 84/84/94 m/min• Distance spindle center – pallet: 80–640 mm• Distance spindle nose – pallet center: 70–670 mm• Tool magazine capacity: 60• Tool holder: HSK-A 63• Max. tool weight: 8 kg• Max. tool diameter: 70/170 mm• Options: Linear scales X/Y/Z, scraper-type chip conveyor, internal coolant 50 bar through spindle, Knoll VRF connection

Gtodpsu Rr Exsfx Aadeu

Listing

Schömberg

Schömberg

1,156 km

Vertical machining center

HERMLEC250 V G2

Call

Condition: new, Year of construction: 2025, operating hours: 671 h, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 550 mm, travel distance Z-axis: 450 mm, rapid traverse X-axis: 35 m/min, rapid traverse Y-axis: 35 m/min, rapid traverse Z-axis: 35 m/min, controller manufacturer: Heidenhain, controller model: Heidenhain TNC7, workpiece weight (max.): 1,100 kg, table width: 800 mm, table length: 616 mm, rotational speed (min.): 20 rpm, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, Heidenhain TNC7

Spindle HSK-A63 16,000 rpm

30 tool positions

Rigid clamping table 800x616

Internal coolant supply 40 bar with paper band filter

Scraper belt conveyor

Handwheel

BLUM LC53-Digilog for tool breakage detection/measurement

Touch probe BLUM TC

Machine ON: 671 h Spindle ON: 61 h

Machine is approx. 6 months old.

Offered for sale on behalf of customer.

Gtodpeyf E Atefx Aadju

Inspection possible by prior arrangement.

Listing

Freilassing

Freilassing

1,405 km

Stoner

ISARIPE4MAX

Call

Year of construction: 2026, condition: new, The pitting and straining system is ideal for processing fruit and vegetables. With interchangeable sieves and an adjustable rotating rotor, stone fruit, pome fruit, and various fruits and berries can be processed. The pulp and seeds are ejected separately. Replacing the sieves is quick and easy. One sieve is included as standard; additional sieves can be ordered upon request.

• Food-safe rubber scraper for hygienic processing

• The distance between the sieve and scraper is individually adjustable

• Machine feet with casters, rotatable and with brakes for easy handling

⚙️ Technical information

• Rated capacity: up to 4000 kg per hour

• Power requirement: 4 kW, 400 V, 16 A

• Material: Wnr. 1.4301, AISI 304 stainless steel

Sieve sizes:

• 0.8 mm: Berries, puree

• 1.5 mm: Berries, puree

• 3 mm: Apple, pear puree

• 5 mm: Cherry

• 8 mm: Plum, apricot

• 10 mm: Peach, mango

Dimensions:

Length: 1130 mm

Width: 574 mm

Height: 1138 mm

Weight: 125 kg

Godpfx Aaev Srdtedotu

Listing

Schwanberg

Schwanberg

1,610 km

Edge milling machine

SCM / HOLZKRAFTformula VFK 160

Call

Condition: new, Clean air extraction / dust extractor

Dust-tested to H3, residual dust content less than 0.1 mg/m³

Suitable for extracting and separating dry wood and plastic chips

High extraction performance with low space requirement

Maximum performance in this class

Very quiet

Godpfor A Eq Rjx Aadetu

Designed for commercial use

Robust and compact housing made of galvanized sheet steel

Extraction nozzle can be easily converted from left to right for flexible use

Large inspection openings

Large, mobile chip container with clamping bracket and chip collection bag

Dust extractor already fully assembled on delivery, so can be used quickly

All models are mobile

Polyester fleece filter material, aluminized, therefore with long service life

Antistatic filter tested and approved to category M-BIA as standard

The fan is connected downstream of the filter

Efficiency class extraction motor IE3

Nominal volume flow 1448 m³/h

Nominal negative pressure 2242 Pa

Power drive motor 2.2 kW, 400 V, 50 Hz

Chip collection volume 2 x 165 l

Nominal width of external suction connection inlet 160 mm

Filter area 9.21 m²

Residual dust content < 0.1 mg/m³

Sound pressure level max. 73 dB(A)

L x W x H approx. = 1618 x 830 x 1653 mm

Weight approx. 268 kg

VERSION PM

Automatic filter cleaning with pneumatic system that moves a scraper frame

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

HEBROCKF2 next

Call

Condition: new, Hebrock

Model F 2 next

Offer type: New machine, SALE ONLY IN AUSTRIA! Immediately available new machine with special offer price and full manufacturer warranty.

The 3.3 m long F 2 is not only inexpensive and space-saving. It also has the equipment you need to process perfect edges right from the start: diamond-tipped jointing cutters guarantee excellently prepared workpieces for edging. The equipment includes a jointing unit (up to 2 mm milling depth), the top-mounted fast heating glue container, cross-cut saw and combination router. Optionally, the F 2 can also be equipped with a surface scraper.

max. edge thickness: 3 mm

max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Feed rate approx. 10 m/min

Equipment:

Edge banding machine F2 next

With PLC control (incl. touch screen)

Hot melt glue application to the workpiece for edgebanding material up to 3 mm

Godpol D Rp Eofx Aadetu

jointing cutter (incl. slide - tool) up to 2 mm milling depth

maintenance-free glue basin with change basin pre-equipment incl. glue discharge device

HF crosscut saw station (approx. 12000 rpm)

HF milling station (approx. 12000 rpm) with separate pneumatic milling adjustment and interchangeable plate milling cutter (combination version)

robust chain drive

ball bearing mounted double roller top pressure

viewing window from rear side of machine

extractable workpiece support

Including special equipment:

F2/12 surface scraper (incl. pneum. lift)

F2/30 pneumatic 3-point adjustment (radius- ,chamfer-, flush milling)

F2/27 Nesting for milling stations

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

OTTTornado

Call

Condition: excellent (used), Year of construction: 2007, Edge thickness 0.2 - 12 mm

Workpiece thickness 8 - 52 mm

Workpiece width min. 70 mm

Workpiece length min. 150 mm

Automatic edge magazine

milling unit 2 x 1.5 kW, application-controlled

Cut-off unit 2 x 0.3 kW

Flush trimming unit 2 x 0.7 kW, scanning on one side

Fine trimming unit 2 x 0.35 kW, tiltable 15/ 30/ 45 degrees

Fine trimming unit 2 x 0.3 kW, R=2, scanning on both sides

Corner copying unit 2 x 0.3 kW

Scraper unit, autom. in/ out

Flat scraper unit

Buffing unit 2 x 0.2 kW, oscillating

5 x spray device (2 x release agent, 1 x lubricant, 2 x cleaning agent)

Color touch screen control OTT C3

Gsdpfjlc Ewiox Aadotu

Motorized height adjustment

Feed 10 - 14 m/min

COMBI MELT gluing part for EVA/ PUR, volume 1.5 l

CE mark

Total connection 12.6 kW

Dimensions L x W x H approx. = 6120 x 840 x 1500 mm

Weight approx. 2,900 kg

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HEBROCKF 5 - sofort verfügbar -

Call

Condition: new, Year of construction: 2025, The Hebrock F 5

If you want maximum performance, the Hebrock F 5 is the solution for edgebanding in demanding craft operations. The F 5 guarantees edgebanding in all steps, as it is equipped with all the components you need to meet your requirements: Joint trimmer, cross-cut saw, trimming unit, radius scraper, corner trimmer, surface scraper, fettling station. For even more flexibility on the way to the perfect finish, the F 5 can be optionally equipped with a practical multi-radius scraper.

max. edge thickness: 3 mm

Max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Equipment:

Hebrock F5 Next - 10 m/min

Edge banding machine F5 Next

With PLC control (incl. touchscreen) and with hot-melt glue application to the workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide tool) up to 2 mm cutter depth, maintenance-free glue tray with change tray pre-equipment incl. glue discharge device, HF cross-cut saw station (approx. 12000 rpm), HF trimming station (approx. 12000 rpm) with separate pneumatic routing adjustment and exchangeable panel router (combination version), corner rounding router, radius scraper, surface scraper (incl. pneumatic lift), cleaning station, robust chain drive, ball bearing mounted double roller top pressure, viewing window from the rear of the machine, extendable workpiece support, feed rate approx. 10 m/min.

Gedolht Hwjpfx Aadstu

F5/08/4 Quick-change attachment for corner router

F5/08/5 additional exchangeable motor corner router with tool assembly

F5/09/4 Multi-radius scraper (R1/R2)

F5/24/1 Spraying device for release agent

F5/24/2 Spraying device for cleaning agent

F5/25 Edge spraying device

F5/27. nesting for router and radius scraper

F5/30. Pneumatic 3-point adjustment (radius, chamfer, flush trimming)

Location: From stock 54634 Bitburg

- available in CW4 -

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HEBROCKF2 - sofort verfügbar -

Call

Condition: new, Year of construction: 2025, The Hebrock F 2

The 3.3 m long F 2 is not only inexpensive and space-saving. It also has the equipment you need to process perfect edges right from the start: diamond-tipped jointing cutters guarantee excellently prepared workpieces for edging. The equipment includes a jointing unit (up to a milling depth of 2 mm), the top-mounted fast heating glue container, cross-cut saw and combination router. Optionally, the F 2 can also be equipped with a surface scraper.

max. edge thickness: 3 mm

max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Equipment:

F2 - 10 m/min

Gtsdpfx Aajlht Hzodju

Edge banding machine F2 next

With PLC control (incl. touch screen) and hot-melt adhesive indication to the workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide - tool) up to 2 mm milling depth, maintenance-free glue basin with exchangeable basin pre-equipment incl. adhesive discharge device, HF cross-cut saw station (approx. 12000 rpm), HF-milling station (approx. 12000 rpm) with separate pneumatic milling adjustment and interchangeable plate cutter (combi design), robust chain drive, ball bearing mounted double roller top pressure, viewing window from rear side of machine, extendable workpiece support, feed rate approx. 10 m/min.

F2/10 undercarriage

F2/30 pneumatic 3-point adjustment

(radius- ,chamfer-, flush milling)

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HEBROCKF2 Next - sofort verfügbar

Call

Condition: new, Year of construction: 2025, The Hebrock F 2

The 3.3 m long F 2 is not only inexpensive and space-saving. It also has the equipment you need to process perfect edges right from the start: diamond-tipped jointing cutters guarantee excellently prepared workpieces for edging. The equipment includes a jointing unit (up to a milling depth of 2 mm), the top-mounted fast heating glue container, cross-cut saw and combination router. Optionally, the F 2 can also be equipped with a surface scraper.

max. edge thickness: 3 mm

max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Equipment:

Gtedsi Am U Depfx Aadju

F2 - 10 m/min

Edge banding machine F2 next

With PLC control (incl. touch screen) and hot-melt adhesive indication to the workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide - tool) up to 2 mm milling depth, maintenance-free glue basin with exchangeable basin pre-equipment incl. adhesive discharge device, HF cross-cut saw station (approx. 12000 rpm), HF-milling station (approx. 12000 rpm) with separate pneumatic milling adjustment and interchangeable plate cutter (combi design), robust chain drive, ball bearing mounted double roller top pressure, viewing window from rear side of machine, extendable workpiece support, feed rate approx. 10 m/min.

F2/10 undercarriage

F2/30 pneumatic 3-point adjustment

(radius- ,chamfer-, flush milling)

Trust Seal

Dealers certified through Machineseeker

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HebrockF4 - Kurzfristig verfügbar -

Call

Condition: new, Year of construction: 2025, Hebrock F 4

For complete processing of your panels

For all those who don't want to do things by halves. With the F 4, we offer you a model with which you can produce fully processed edges on a machine length of just 4 m. The F 4 is not only space-saving, but also extremely attractive in terms of price-performance ratio.

Max. Edge thickness 3 mm

Min/Max. Workpiece thickness 8 - 50 mm

Min. workpiece length approx. 160 mm

Feed speed approx. 7 m/min.

Ready for operation approx. 3.5 min.

Max. Power consumption Ø approx. 7.4 kW

Electrical connection 400 V - 3 Ph - 50 Hz

Work table height approx. 900 mm

Machine dimensions approx. 4050 x 1300 x 1400 mm (LxWxH)

Weight approx. 820 kg

Suction nozzle Ø 1 x 140 mm

PLC control 10″ touchscreen

Top-mounted rapid-heat adhesive container (maintenance-free)

Godshqadcspfx Aadjtu

Support plate for edging material

Automatic central lubrication (cross-cut saw, corner router)

Visual display for workpiece sequence

Extension arm (can be pulled out to the front)

Interchangeable basin pre-equipment incl. adhesive changing device for PUR processing

Surface scraper with dual tracing

Pneumatic roller capping (scissor cut design, Hebrock system)

Double roller top pressure (ball bearing)

Transport chain with bolted special chain plates

Jointing cutter

Milling unit

cross-cut saw

Corner cutter

Accessories:

F4/09 Radius scraper (incl. pneumatic lift)

F4/09/4 Multi radius scraper (R1/R2)

F4/30 Pneumatic 3-point adjustment

Location: From stock 54634 Bitburg

- available at short notice -

Listing

Bitburg

Bitburg

902 km

Edge banding machine

Casadei Industria WoodE450 PMVR

Call

Condition: like new (used), Year of construction: 2022, E450PM - AUTOMATIC EDGE BANDING MACHINE

V000047 LME450PM-5 with joint trimming unit

Machine in excellent condition

Gtodpfsxac Hwsx Aadju

VOLTAGE 400/50/3

CONTROL WITH 7" TOUCH SCREEN

EXCHANGEABLE GLUING UNIT

VR - MULTIFUNCTION TRIMMING UNIT

Tool for straight/radius trimming

TOOL KIT R=2 mm

FLAT SCRAPER

RELEASE AGENT UNIT

LED INTERNAL LIGHTING

DOCUMENTATION IN GERMAN

INFRARED LAMP for panel pre-heating

SCRAPER UNIT

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HEBROCKK36 Neumaschine sofort verfügbar -

Call

Condition: new, Year of construction: 2025, The Hebrock K 36 Top equipment with motorized adjustment - Exhibition piece - New machine -

- immediately available -

This Hebrock endurance racer offers unimagined possibilities. Developed for the highest demands, the K 36 stands for absolute reliability and productivity in daily use. With the option of equipping the machine with a step cutter and a multi-radius scraper, Hebrock is setting new standards in the field of perfect edge processing of various edge thicknesses.

max. edge thickness: 3 mm

max. workpiece thickness: 60 mm

Ready for operation in 6 min.

Gtodpfoi Am Uksx Aadju

Max. Edge thickness 3 mm

Min/Max. Workpiece thickness 8 - 60 mm

Min. workpiece length approx. 140 mm

Feed speed approx. 15 m/min.

Ready for operation approx. 6 min.

Max. Power consumption Ø approx. 7.4 kW

Electrical connection 400 V - 3 Ph - 50 Hz

Work table height approx. 900 mm

Machine dimensions approx. 5250 x 1230 x 1430 mm (LxWxH)

Weight 1750 kg

Equipment:

Hebrock K 36 - 15 m/min

Edge banding machine K36

With PLC control (incl. 15'' touch screen), hot melt adhesive application to the workpiece

workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide tool)

up to 3 mm routing depth, maintenance-free, coated glue tray with

HF double-motor cross-cut saw station (approx. 12000 rpm), HF trimming station (approx. 12000 rpm) with pneumatic trimming adjustment and interchangeable panel trimmer (combi version), corner rounding trimmer, radius scraper, surface scraper (incl. cleaning station, robust chain drive, ball-bearing mounted double roller top pressure, unit viewing window from the rear of the machine and operator side, signal lamp for workpiece sequence, extendable workpiece support, feed approx. 15 m.

support, feed rate approx. 15 m/min, gluing up to 60 mm workpiece thickness

36/08/1 Quick-change equipment for corner router

36/08/2/1 additional exchangeable motor corner router R=1

36/09/1 Multi-radius scraper

36/24/1 Release agent spraying device

36/24/2 Cleaning agent spraying device

36/25 Protective spraying edge

36/27 Nesting (1x milling station + 1 x radius scraper)

36/30 Pneumatic 3-point adjustment

36/30/1 Multitool for HF milling station (R2/R1/bevel)

36/45 Axis package Motorized adjustment of panel, edge thickness and joint milling depth

jointing depth adjustment

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HebrockF5 Next - sofort verfügbar

Call

Condition: new, Year of construction: 2025, The Hebrock F 5

If you want maximum performance, the Hebrock F 5 is the solution for edgebanding in demanding craft operations. The F 5 guarantees edgebanding in all steps, as it is equipped with all the components you need to meet your requirements: Joint trimmer, cross-cut saw, trimming unit, radius scraper, corner trimmer, surface scraper, fettling station. For even more flexibility on the way to the perfect finish, the F 5 can be optionally equipped with a practical multi-radius scraper.

max. edge thickness: 3 mm

Max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Equipment:

Hebrock F5 Next - 10 m/min

Edge banding machine F5 Next

With PLC control (incl. touchscreen) and with hot-melt glue application to the workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide tool) up to 2 mm cutter depth, maintenance-free glue tray with change tray pre-equipment incl. glue discharge device, HF cross-cut saw station (approx. 12000 rpm), HF trimming station (approx. 12000 rpm) with separate pneumatic routing adjustment and exchangeable panel router (combination version), corner rounding router, radius scraper, surface scraper (incl. pneumatic lift), cleaning station, robust chain drive, ball bearing mounted double roller top pressure, viewing window from the rear of the machine, extendable workpiece support, feed rate approx. 10 m/min.

Gjdpfsi Anadsx Aadstu

F5/08/4 Quick-change attachment for corner router

F5/08/5 additional exchangeable motor corner router with tool assembly

F5/09/4 Multi-radius scraper (R1/R2)

F5/24/1 Spraying device for release agent

F5/24/2 Spraying device for cleaning agent

F5/25 Edge spraying device

F5/27. nesting for router and radius scraper

F5/30. Pneumatic 3-point adjustment (radius, chamfer, flush trimming)

Location: ex stock 54634 Bitburg

Available in calendar weeks: 4/2024

We make it easier for you to find: "scraper"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Scraper (713)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month