Used Automation for sale (12,584)

Dornhan

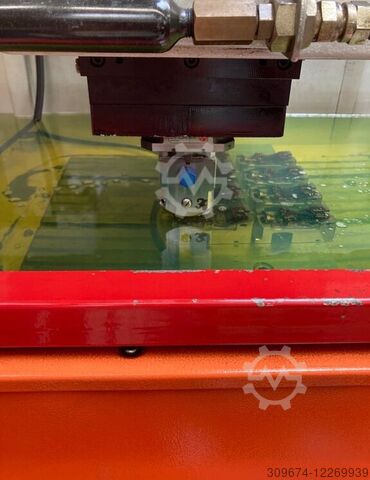

Dornhan Sinker EDM machine with automation

ExeronEDM312MF30+AWEX100/5

Germany

Germany Automated Small Parts Storage System

SiemensDematic SR-M100

Germany

Germany Automated Optical Inspection Machine

GöpelOpticon BasicLine NP

+44 20 806 810 84

Germany

Germany Automated Optical Inspection System

Vi technology5K SPECTRO

Wehr

Wehr Autom. gluing and strapping machine

NormpackX67-70-2175-NPS-504-L

Discover more used machines

Bayern

Bayern Automation system for injection molding

WITTMANNW833PRO

Bayern

Bayern Jig

CHARMILLESRoboform 35 P Roboter Automation

Viechtach

Viechtach Fiber tube laser - automated - 6 m

DURMAHD-TC 60170

Germany

Germany CNC machining center with automation

Holz-HerDynestic 7521

Bayern

Bayern Automation

EROWARoboSpa 3.0

Donzdorf

Donzdorf Automation machining center with integrated palletizing.

CHIRONFZ 08 KS high speed

Schwabach

Schwabach Automated box production line

ZematAutomatische Schachtelproduktionslinien

Châteauneuf-du-Rhône

Châteauneuf-du-Rhône Automated Guided Vehicle for Cylindrical Loads Handling

ROCLAAGV AWTsc – 40TF8300E

Alojzov

Alojzov Automated tube bending machine

WegenerPBM 7074

Ursberg

Ursberg Automated magnetic filtration system

die magnetprofisAPMA400

Olching

Olching Automation system

RoboJobTurn-Assist 270 i

Karlholmsbruk

Karlholmsbruk Industrial Automation & Electrical Equipment

Rema Sawco

Kežmarok

Kežmarok Pressing line for glued solid wood panel

Weinig ItalpresseUnimat - GB/13 Super - automation

Ploiesti

Ploiesti Industrial automated cutter Yin

YinHY

Malax

Malax Semi-automated chamfering machine

MychromeCHAMFERING MACHINE MFR

Pohjanmaa

Pohjanmaa Laser cutting machine + automation

Finn-Power OyL6 Laser + LU3000

Székesfehérvár

Székesfehérvár Frequency converter VLT Automation Drive

DanfossFC-302P1K5T5E20H1

Székesfehérvár

Székesfehérvár Frequency converter - 7,5 kW

DanfossVLT Automation drive FC 302

Székesfehérvár

Székesfehérvár Frequency converter VLT Automation Drive

DanfossFC-302P3K0T5E20H1B

Székesfehérvár

Székesfehérvár Frequency converter 1,5 kW

DanfossVLT Automation Drive FC302

Used Automation (12,584)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84