Used Offset for sale (814)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

1,034 km

SHEETFEDOFFSET

HeidelbergSpeedmaster SM 52-2+

Call

Condition: good (used), Year of construction: 1999, Heidelberg Autoplate (Automatic Plate Changing System)

+Version

Alcolor Dampening

CP Tronic Control System

Nwjdpfxjw U A Npe Afhob

Automatic Ink Roller Washing Device

Blanket Washing Device

Impression Cylinder Washing Device

Grafix Alphatronic 200: Powder Sprayer

Listing

Schweiz

Schweiz

1,251 km

Sheetfedoffset

HeidelbergSpeedmaster SM 52-4P

Call

Year of construction: 2001, operating hours: 126,000,000 h, condition: good (used), machine/vehicle number: 204750, Perfecting 2/2 - 4/0

CPC 1-04: Off Press Ink & Register Control

Alcolor Dampening

Semi Automatic Plate Change

Grafix Alphatronic 200: Powder Sprayer

Technotrans Cooling Device

Automatic Ink Roller Washing Device

Blanket Washing Device

Staticstar Compact: Antistatic Device

Impression Account: 126 Mio.

Nodpfx Aolml Nhsfhowb

Listing

Topkapı

Topkapı

2,844 km

SHEETFEEDOFFSET

HeidelbergSpeedmaster SM 52-4+LX

Call

Condition: good (used), Year of construction: 2004, functionality: fully functional, Coating Unit

Optional Printing Thickness: 0,5mm

Extended Delivery (X1)

Nwodpfowr T Rtex Afheb

CP 2000: Touch Screen Console

Straight Machine

Alcolor Dampening

Grafix Alphatronic 200: Powder Sprayer

Ink unit Temperature Control Technotrans (Aircooled)

Automatic Impression Cylinder Washing Device

Automatic Ink Roller Washing Device

Automatic Blanket Washing Device

Semi Automatic Plate Change

High Pile Delivery

IR Dryer Heidelberg

Impression Account: 98 Mio.

Auction

Ends in

d

h

min

s

Auction ended

Bayern

Bayern

1,167 km

Horizontal machining center

MakinoA500 z

Condition: ready for operation (used), Year of construction: 2023, functionality: fully functional, spindle speed (max.): 14,000 rpm, number of slots in tool magazine: 133, TECHNICAL DETAILS

Spindle speed: 14,000 rpm

Coolant supply through the spindle: 70 bar

MACHINE DETAILS

Year of manufacture: 2023

EQUIPMENT

Direct tapping

Tool magazine with 133 storage positions

Pallet changer

Two pallets with tapped hole grid

Eight adjustable rinse nozzles at the spindle

Flow monitor for coolant through the spindle

Cooling system with chip conveyor BSW880

Interface for mist extraction

Visual tool breakage monitoring BTS

Toolholder HSK-A63

Nsdpeyarhrsfx Afhewb

Coolant temperature control unit

Direct measuring systems (glass scales) for X, Y, Z axes

Three-axis workpiece probe (Marposs Mida T25G)

Double-layer cooling system (BDW 880)

Automatic central lubrication

Programmable axis mirroring

Tool offset storage with 400 memory slots

54 (6+48) freely selectable workpiece coordinate systems

Three-color signal lamp

Auction

Ends in

d

h

min

s

Auction ended

Lombardia

Lombardia

1,368 km

Edgebander

BRANDTAmbition 1650 KDF 650

Condition: ready for operation (used), Year of construction: 2011, functionality: fully functional, machine/vehicle number: 0-261-20-5976, feed rate X-axis: 20 m/min, workpiece height (max.): 60 mm, controller model: POWER CONTROL PC 20+, TECHNICAL DETAILS

Panel height: 60 mm

PVC-ABS edge thickness: 3 mm

Solid wood edge thickness: 12 mm

Feed speed: 20 m/min

MACHINE DETAILS

Control system: POWER CONTROL PC 20+

Nwodpfx Aoydihdsfhsb

Operating current at full load: max. 33 A

Largest motor: 9.7 A

Largest heating circuit: 2.7 A

Fuse: 35 A

Frequency: 50 Hz

EQUIPMENT

Upper motorized rubberized belt

Manual infeed guide

Anti-adhesive unit

Jointing unit

Gluing with EVA adhesive

Edge support plate

End trimming unit with automatic tilt adjustment

Offset trimming and corner rounding unit with two motors

Linear corner rounding unit with 2 motors

Edge scraper unit

Glue scraper unit

Brushing unit

Listing

Wakefield

Wakefield

228 km

Slitter/Stacker - digital printed sheets

HorizonSmartStacker

Call

Condition: excellent (used), Year of construction: 2021, Ref: 11062 . 2021 Horizon SmartStacker

Only 1.1m books on the counter!

Nwedpfsycb Srox Afhob

The latest, innovative way to process B2 (20” x 29”) digitally printed sheets to finished format size.

Features:

Near-line operation with Sheet Feeder – can be operated as a near-line system.

Newly designed sheet feeder accommodates B2 (20” x 29”) sheets at up to 4,500 sheets per hour.

Finishing Line Controller (FLC) controls all setup and operation of the SmartStacker by use of JDF workflow.

Can serve multiple HP Indigo 10000 Digital Press units and other HP Indigo presses.

Can be connected directly inline to an HP Indigo 10000 Digital Press.

Print submission, print, and sheet processing performed without any manual operation for higher sheet integrity & efficient workflow.

Can be connected with an Horizon signature folder, saddle-stitcher or perfect binder to achieve total finishing automation.

Specification:

Sheet Size (Before Cut)

Max. 762 x 530 mm or 30.000" x 20.865"

Min. 279.4 x 330 mm or 11.000" x 12.995"

Piece Size (After Cut)

Max. 381 x 530 mm or 15.000" x 20.865"

Min. 100 x 105 mm or 3.940" x 4.135"

Sheet Weight Range:

Normal Paper: 81.4 to 370 gsm

Coated Paper (for Merge Stacker): 90 to 360 gsm

Paper Thickness:

4 to 15 pt or 0.1 to 0.381 mm

*1 pt=1/1,000"

Sheet Stacking:

Straight Stack or 10 mm or 0.39" Offset Stack

Maximum Stack Height: 254 mm or 10.00"

Number of Cuts:

1st Process Unit: 1 to 7 columns (14 cutters)

2nd Process Unit: 1 to 4 rows (8 cutters)

Production Speed: Up to 4,600 sheets per hour

* Production speed differs depending on number of cuts in 1st Process Unit and type/condition of sheets.

* HP Press may need to slow down depending on the sheet condition in case of inline configuration.

Listing

Wakefield

Wakefield

228 km

Endsheet Paster

HunkelerVEA 520-K-HHS 3000 Endsheet Paster

Call

Condition: excellent (used), Year of construction: 2000, Ref:11056 . 2000 Hunkeler VEA 520-K-HHS 3000 Endsheet Paster.

For inside & outside gluing of end sheet papers, greetings cards inserts and glue-on mounts.

Comprising:

1 x product feed (spare feed arm for large format products)

1 x sheet/card feed

Sheet counter

PVA cold glue system

Robatech glue system

Table delivery

Integral compressor

I.R. light beam guard

Including tools & accessories.

Specification:

Product sizes, outside gluing, Max: 520 x 310 mm

Nwodpfxjx Uwzns Afhjb

Min: 100 x 70 mm

inserting/tipping-in, Max: 320 x 260 mm (with accessories)

Offset gluing (for outside gluing only):

- Maximum 50 mm from the fold

- No restrictions in travel direction

Mechanical speed, Max: 8,400 cycles/hr.

Listing

Tadley

Tadley

474 km

Laminator

D&KD&K Acculam 2760 Laminator with Feeder

Call

Year of construction: 2003, condition: used, functionality: fully functional, D&K Acculam 2760 Laminator with Feeder, Exit tray and Transformer.

Recently removed from a printshop.

Machine has been in full working order and producing live jobs.

Machine is sold Ex works.

No cutting unit is included.

Machine is located in my warehouse in Tadley/Reading UK.

Video in production on request.

The D&K System 2760 (often referred to as the Acculam series) is a fully automated one-sided lamination system designed for high-volume, short-run digital and offset printing. It typically includes an automatic feeder, a laminator with curl management, and a flying knife separator.

Technical Specifications

Nsdpfxox Nawns Afhewb

Max Lamination Speed Up to 60 fpm (18 meters per minute)

Max Sheet Size 26" x 30" (standard) or up to 28" x 40" (B1 version)

Min Sheet Size 8.5" x 11" (21.6 cm x 27.9 cm)

Paper Weight Range 80 lb. Text to 18 pt. Board (approx. 115–350+ gsm)

Temperature Range 180°F – 300°F (70°C – 140°C)

Warm-up Time Approximately 20 minutes

Electrical Requirements 230 Volt, 30 Amp, Single Phase

Air Requirements 6 cfm (some models may require up to 8 cfm)

System Dimensions 5' W x 14' L x 5' H

Key Features

Feeding System: Utilizes a state-of-the-art automatic suction feeder and belt table to ensure accurate sheet registration.

Adhesion Technology: The System 2760 DN variant features two sets of heated nip rollers specifically for better adhesion to difficult digital prints like Xerox iGen or HP Indigo.

Curl Management: A patented decurling system ensures sheets lay flat even when using thin paper or thick films like polyester and nylon.

Versatility: Supports both thermal (heat) and pressure-sensitive (cold) lamination with optional release liner take-up for PSA products.

Listing

Baughurst

Baughurst

472 km

Digital print machine

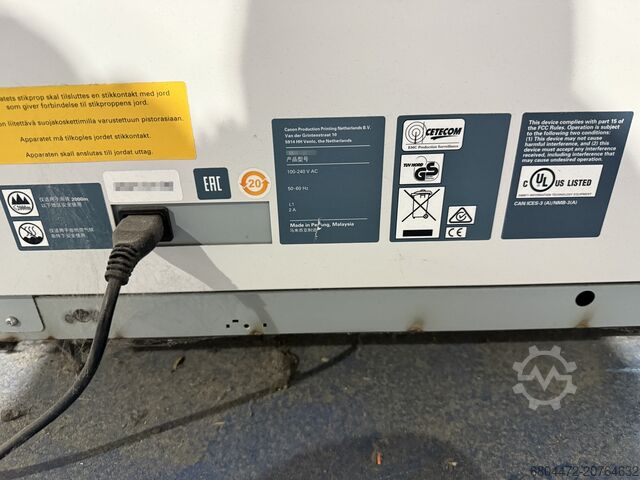

CanonOce VarioPrint 6330

Call

Condition: used, Year of construction: 2018, functionality: fully functional, FOR SALE:

Canon Océ VarioPrint 6330 TP Titan – High-Speed Monochrome Production Press

Boost Print Production & Efficiency

A fully functional, high-speed Canon Océ VarioPrint 6330 TP Titan digital production printer is for sale. This machine is known in the commercial print industry for its productivity, offset-like quality, and media versatility.

It is ideal for high-volume environments, commercial print shops, and in-house operations. These operations focus on books, manuals, transactional documents, and direct mail.

Key Features & Benefits:

Ultra-High Speed: It can achieve speeds of up to 328 A4 impressions per minute with Océ Gemini Instant Duplex Technology. This technology prints both sides at once in a single pass.

Superior Print Quality: It delivers quality with a 600 x 1200 dpi resolution. It uses advanced Océ Copy Press technology for a matte finish and precise registration.

Wide Media Versatility: It handles media weights from 50 gsm up to 300 gsm (and up to 350 gsm for validated stock). This includes specialty and textured papers, tabs, and carbonless forms.

Robust Paper Handling: It comes with a high-capacity system, expandable to multiple trays. It has a paper input capacity of up to 24,000 sheets.

Eco-Friendly Operation: It features low power consumption, minimal ozone emissions, and low heat output. This makes it efficient and operator-friendly for any print room.

Workflow Integration: It is managed by the PRISMAsync controller. It includes DFD interface support for connection to third-party finishing options (binding, saddle-stitching, punching).

Machine Specifications:

Model: Canon Océ VarioPrint 6330 TP Titan

Condition: Ready for operation (used), fully functional

Year of Manufacture: Year 2018

Resolution: 600 x 1200 dpi (up to 180 lpi)

Max Monthly Volume: Up to 10,000,000 A4 images

Max Paper Size: Up to 350 mm x 500 mm (13.8" x 19.7")

Nedpfjx Hz T Ejx Afhjwb

Configuration Includes: (Please check photos to be sure)

Paper Input Modules, 8x Duo Paper Trays]

2x High Capacity Stackers]

PCL, IPDS, PostScript language support]

PRISMAsync Controller]

Current Meter Readings:

See Photo.

Price:

(Negotiable)

The original price for this configuration was over €140,000!

Logistics:

The buyer is responsible for arranging shipping. . The machine is located in [UK].

Listing

Bremen

Bremen

835 km

420 liter agitator tank made of V2A stainless steel with propeller agitator

9727

Call

Condition: used, tank capacity: 420 l, GENERAL

Equipment: Level indicator (without guarantee), spray head

Design: upright

Remarks: 2 sight glasses in the cylinder are missing; feet made of painted Fe (with reinforcements made of V2A); an additional pipe with a diameter of approx. 25 mm branches off from the outlet pipe (see photos)

Internal diameter: 890 mm

Total height: 1,850 mm

Nwedpfx Asyckdqefhjb

Agitator: propeller

Location: Bremen

Volume: 420 liters

Product-contact material: V2A 1.4301 (AISI304)

Condition: used

Cylindrical height: 560 mm

Last application: pharmaceutical

TANK

Support type: feet

Number of feet: 3 pcs

EQUIPMENT

Outlet: 48 mm

Note: slight residues/adhesions

AGITATOR

Agitator arrangement: offset in the top cover

Agitator equipment: Agitator data no longer readable; in addition to the propeller at the bottom there is a type of flow breaker (see photos)

Listing

United Kingdom

United Kingdom

325 km

Wire brush descaling machine

GSG GmbH & Co. KGRWCB / 400-3

Call

Year of construction: 2003, condition: good (used), functionality: fully functional, machine/vehicle number: 03234, 6 Brush ( 3 pairs) descaling machine for steel wire size 5.5mm - 16.0 mm max (low carbon)

Brush pairs arranged in a 60 degree offset for maximum effect.

A very clean looking machine.

On site viewing and inspection recommended

Njdpfox R Uzdsx Afhjwb

Listing

Ennepetal

Ennepetal

847 km

Lead/traction spindle lathe

GERD WOLFFG2930

Call

Condition: new, Year of construction: 2025, functionality: fully functional, turning diameter: 290 mm, turning length: 750 mm, total length: 1,400 mm, total width: 700 mm, total height: 1,030 mm, rotational speed (max.): 1,800 rpm, spindle mount: MK 3, The following features and characteristics make the G2930 combination lathe unique and competitive in the market:

1. V-shaped guideways provide superior stability and are securely anchored.

2. The gearbox is fixed for maximum stability and offers comprehensive feed and thread cutting functions.

3. State-of-the-art tapered roller bearings support the D1-4 spindle with the highest precision.

4. Automatic vertical feed enables maximum threading capabilities.

5. The cross-slide is equipped with T-slots.

6. Guideways are effectively controlled by adjustable gibs.

7. Advanced gearbox design with maximum functionality.

8. Maximum working area due to the lowered bed section.

9. Carriage-mounted spindle is operated by a lever arm.

10. Two feed screws are integrated.

11. User-friendly forward/reverse interface with zero backlash.

12. Versatile tailstock that can be offset for taper turning.

13. Emergency stop button, load switch, process control, etc., are installed.

TECHNICAL DATA

Max. turning diameter over bed: 290 mm

Max. turning diameter over cross slide: 165 mm

Distance between centers: 750 mm

Spindle taper: MT5

Spindle bore: 38 mm

Max. tailstock travel: 80 mm

Tailstock taper: MT3

Longitudinal carriage travel: 560 mm

Cross-slide travel: 140 mm

Compound slide travel: 80 mm

Cross feed: 0.017~0.25 mm/rev, 15 steps

Longitudinal feed: 0.07-1.0 mm/rev, 15 steps

Metric thread: 0.2-3.5 mm, 18 steps

Imperial thread: 8-56 TPI, 21 steps

Nwedpfx Afjxb Up Tohsb

Spindle speed range/steps: 50~1800 RPM, stepless

Motor power: 1.5 kW

Further dimensions and weight:

Overall dimensions: 1400 x 700 x 1030 mm

Packing size: 1450 x 750 x 970 mm

Net weight: 290 kg

Gross weight: 310 kg

Listing

Germany

Germany

848 km

Lathe-conventional-electronic

GERD WOLFFG2930

Call

Condition: new, Year of construction: 2025, turning diameter over bed 290 mm

turning diameter / mm

turning length / mm

swing diameter over bed slide / mm

Number of sanding units / st.

sanding width / mm

Sanding height max. / mm

total power requirement / kW

weight of the machine ca. 310 kg

required space 1400 x 700 x 1030 mm

The following features and characteristics make the G2930 combination lathe unique and competitive in the market:

1. V-shaped guides provide higher stability and are firmly anchored.

2. The gearbox is fixed for maximum stability and offers comprehensive feed and threading functions.

3. Advanced tapered roller bearings support the D1-4 spindle with high precision.

4. Automatic vertical feed enables maximum threading capabilities.

5. The cross slide is equipped with ‘T’-shaped slots.

6. The slideways are effectively controlled by adjustable gibs.

7. Advanced gearbox design with maximum functionality.

8. Maximum working area thanks to the lowered bed section.

9. The spindle with carriage mounting is controlled by a lever arm.

10. Two lead screws are integrated.

11. User-friendly interface for forward/reverse with zero tolerance.

12. Versatile tailstock that can be offset for turning tapers.

13. Equipped with an emergency stop button, load switch, process control, etc.

TECHNICAL SPECIFICATIONS

- Max. swing over bed: 290 mm

- Max. swing over cross slide: 165 mm

- Distance between centers: 750 mm

- Spindle taper: MT5

- Spindle bore: 38 mm

- Max. travel of tailstock: 80 mm

- Tailstock taper: MT3

- Large carriage travel: 560 mm

- Middle carriage travel: 140 mm

- Small carriage travel: 80 mm

- Transverse feed: 0.017~0.25 mm/r, 15 steps

- Longitudinal feed: 0.07-1.0 mm/r, 15 steps

- Metric thread: 0.2-3.5 mm, 18 steps

- Inch thread: 8-56 T.P.I, 21 steps

- Spindle speed range/steps: 50~1800 RPM, infinitely variable

- Motor power: 1.5 kW

Other dimensions and weight:

- Overall dimensions: 1400 x 700 x 1030 mm

- Package size: 1450 x 750 x 970 mm

- Net weight: 290 kg

Nodpfxoxb Eids Afhewb

- Gross weight: 310 kg

Listing

Limburg

Limburg

777 km

Machining center

AESEXTREME LINE 2132

Call

Condition: as good as new (ex-display), Year of construction: 2020, operating hours: 50 h, functionality: fully functional, travel distance X-axis: 3,200 mm, travel distance Y-axis: 2,100 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, feed length X-axis: 3,200 mm, feed length Y-axis: 2,100 mm, feed length Z-axis: 200 mm, nominal power (apparent): 25 kVA, controller manufacturer: OSAI, controller model: OSAI ITALY, workpiece length (max.): 3,200 mm, workpiece width (max.): 2,100 mm, total height: 2,000 mm, total length: 5,100 mm, total width: 3,100 mm, table length: 3,200 mm, overall weight: 8,000 kg, spindle speed (max.): 24,000 rpm, operating hours of spindle: 10 h, number of spindles: 1, number of slots in tool magazine: 12, type of input current: three-phase, Equipment: chip conveyor, Showroom Demonstration Machine – EXTREME LINE 2132

The EXTREME LINE 2132 offered for sale has been used exclusively as a showroom demonstration machine, with total operating hours of less than 50 hours. The machine has never been used in production conditions.

In 2022, the complete electrical cabinet was fully renewed and reassembled with a new-generation cabinet, bringing the machine fully in line with the latest technical standards.

The machine was installed and displayed in our Bilzen showroom solely for demonstration purposes. Its condition is comparable to a factory-built new machine.

1. CENTRALIZED LUBRICATION UNIT

2. AUTOMATIC TOOL OFFSET

3. OSAI CNC CONTROL UNIT

4. HSD BORING UNIT – 10 VERTICAL – 3x2 HORIZONTAL – 1 SAW BLADE

5. HSD SPINDLE MOTOR 9 kW

6. ROTARY MAGAZINE UNIT (12 TOOLS CAPACITY)

7. 2.100 MM X 3.200 MM LIFT UNIT + LOADING UNIT + UNLOADING UNIT

Nwedpfx Afeydcwljhjb

8. 2.100 MM X 3.200 MM CONVEYOR UNIT

9. 9 VACUUM ZONES

10. 1 * 250 m"/h BECKER VACUUM PUMP and PREPARATION OF 2nd VACUUM PUMP AVAILABLE ON THE MACHINE

Listing

Friedrichsdorf

Friedrichsdorf

991 km

Articulated Jib Platforms

Manitou120 AETJ 12mtr

Call

Condition: used, functionality: fully functional, Year of construction: 2021, operating hours: 110 h, load capacity: 200 kg, empty load weight: 6,550 kg, construction height: 1,990 mm, fuel type: electric, total length: 5,480 mm, drive type: Elektro, arm reach: 7,000 mm, construction width: 1,200 mm, working height: 11,950 mm, Articulated telescopic platform

Technical condition: very good

Front tires type: solid rubber

Nodpfx Ajv I Hipefhowb

Front tires Condition: 80 - 100%

Rear tires Type: Solid rubber

Rear tires Condition: 80 - 100%

Description: The Manitou 120 AETJ-C electric articulated platform has a lifting capacity of 200 kg at a working height of up to 11.95 m. It meets all your requirements for working at height. It meets all your requirements for indoor and outdoor work. The overhang height of 4.77 m in combination with the 7 m offset of the work surface offers a wide range of possible applications. The narrow design of the chassis (1.2 m) and the lifting structure ensure high maneuverability in narrow and congested areas. The standard drive battery guarantees many operating cycles and a long service life. For better access to work areas, a 3D version of the 120 AETJ-C slewing device is available (as an option).

Listing

Liévin

Liévin

688 km

Konica Minolta PB 503

Konica MinoltaPB-503

Call

Condition: excellent (used), PB 503 : Console, hot-melt type perfect binder for Konica Minolta Press C 2060 / C 1100 / C 1060 / C 6100/ C 6085 / C 3080/ C 3070 ...

Njdpfx Ajfyfgnofhjwb

Function :

Perfect binding : Outputs perfect-bound books to the perfect binder tray.

Secondary (sub) tray : Outputs non-offset sets to the secondary (sub) tray.

Connective delivery : Outputs non-processed sheets to another finishing equipment (Finisher FS-532).

As an experienced retailer of second hand copiers, we have developed a real expertise in packing and pallet shipping, to guarantee our customers machines in perfect condition upon receipt.

We ship copiers coming from, and maintained by Konica Minolta France.

Our company offers the largest range of Konica Minolta production copiers, and handle world-wide deliveries on request.

Listing

Neuhausen

Neuhausen

1,105 km

HeidelbergKS - Zylinder 38 x 52 cm

Call

Condition: used,

Listing

Henstedt-Ulzburg

Henstedt-Ulzburg

883 km

HeidelbergCD 102-5+L(X1)

Call

Condition: like new (used), Year of construction: 2019,

Listing

Denmark

Denmark

1,006 km

HAAS UMC 1500 DUO

HAASUMC 1500 DUO

Call

Condition: ready for operation (used), Year of construction: 2021, operating hours: 295 h, controller manufacturer: HAAS, spindle speed (max.): 15,000 rpm, number of axes: 5, This 5-axis HAAS UMC 1500 DUO was manufactured in 2021, featuring a high-speed 15,000 rpm spindle, Din 69871, and a 50+1 side-mounted tool changer. It includes internal cooling at 21 bars, chip conveyor, and full 5-axis capabilities for complex machining tasks. Air through and around spindle. Probe for workpiece measurement and tool setter. Consider the opportunity to buy this HAAS UMC 1500 DUO vertical machining centre. Contact us for more information about this machine.

• Sidemonteret værktøjsveksler 50+1

• 21 bars indvendig køling (TSC)

• Top afskærmning

• Automatisk værktøjs- og emneudmåling (probing)

• Automatisk kalibrering

• Dynamic Work Offsets (DWO)

• Ethernet interface

• Haas Connect

Nodpfx Aex D I Sgofhjwb

• Media Display

• 1 GB programhukommelse

• Finmasket filter til kølevand

• Auxillary filter

• Remote Jog håndhjul

• Synkrongevindskæring (rigid tapping)

• Programmerbar kølevandsdyse

• High Speed Machining

• Fuld 5-akset

Additional equipment

• Spåntransportør (chip conveyor)

Listing

Wasbek

Wasbek

869 km

Radial Drilling Machine - R 60 V

KnuthR 60 V

Call

Condition: new, The KNUTH R 60 V is a powerful and versatile radial drilling machine designed for exceptional drilling, reaming, and countersinking in steel or cast iron, making it a preferred choice among professionals in production and construction companies. This robust machine features a premium construction with a large column and a highly torsion-resistant boom, ensuring maximum rigidity and minimal clamping offset. With its motorized boom height adjustment and oil-bath lifting gears, operators experience smooth handling, even with large and heavy workpieces. Additional highlights include infinitely variable spindle speeds with a digital display and an integrated coolant system, ensuring reliability and cost-effectiveness. The R 60 V, part of the renowned Radial Drilling Machines group, stands out for its modern design and user-friendly operation. Contact us to request a quote and elevate your drilling capabilities with KNUTH’s exceptional machinery.

Nodpfx Asuyic Hsfhewb

Listing

Sweden

Sweden

1,006 km

DOOSAN PUMA TT 1800 SY

DOOSANPUMA TT 1800 SY

Call

Condition: ready for operation (used), Year of construction: 2014, spindle speed (max.): 5,000 rpm, travel distance X-axis: 165 mm, travel distance Y-axis: 100 mm, travel distance Z-axis: 770 mm, spindle motor power: 18,500 W, controller manufacturer: FANUC, controller model: 31i-MODEL B, number of axes: 9, This 9-axis DOOSAN PUMA TT 1800 SY was manufactured in 2014, offering advanced capabilities for horizontal turning. Ideal for complex machining tasks, this machine ensures precision and efficiency. If you are looking to get high-quality turning capabilities, consider the DOOSAN PUMA TT 1800 SY machine we have for sale. Contact us for more information.

Additional equipment

• LNS bar interface

• the robot is not included

Machine Benefits

Qualitative Machine Benefits

• Part ejector + internal cooling for sub-spindle

• Automatic electric tool measurement

• Air conditioning in the electrical cabinet

• Lns lamella-type chip conveyor

• Auto door for robot application

• Absolent air system mounted on the machine

• 3 pcs driven tools radially

Njdpfxjyaqq Ej Afhowb

• 4 pieces of m-l21590377d triple holders with v-offset, 2 pieces of m-l21590337e axial external holders, 2 pieces of m-l21590347d double holders (single l/h), 4 pieces of m-l21590367d double holders (external), 6 pieces of m-l21590317 single holders (external), 2 pieces of m-l21590387c single holders (external), and 6 pieces of m-l21590327b internal holders

• 3 pcs hard jaws

Technical Machine Benefits

• Max turning diameter: 230 mm

• Max turning length: 230 mm

• Bar capacity: 65 mm

• C1-c2 axis: 360, x2: 190 mm, z2: 720 mm

• 2 x 12 position turrets, all positions driven (24/24 index)

• Tool holder: bmt 55 p

• Driven tools: 5. 5 kw, max: 5000 rpm

• Coolant pump for main turret: 3. 7 kw, 14 mpa, 30 l/min

• Coolant supply via sub-/right spindle

• Belt-type oil skimmer, part ejector

Extra Information

Machine still under power

Trust Seal

Dealers certified through Machineseeker

Listing

Petershagen

Petershagen

875 km

Tipper semitrailer

BENALUBulkliner S 95 50m³ Kombiklappe

Call

Condition: used, maximum load weight: 30,120 kg, overall weight: 36,000 kg, axle configuration: 3 axles, first registration: 09/2022, next inspection (TÜV): 10/2025, loading space length: 9,500 mm, loading space width: 2,410 mm, loading space height: 2,100 mm, loading space volume: 50 m³, total width: 2,550 mm, total height: 3,780 mm, Year of construction: 2022, Equipment: ABS, Used Benalu Tipper Semi-Trailer

Sidewall: Smooth-walled with hollow chamber profiles in the longitudinal direction

Floor thickness (mm) 5

Sidewall thickness (mm) 3

Universal door with double lock, upper cross member

Smooth-walled door leaves

Continuous welds on the inside of the door

Locking system: single door/swing flap - pneumatic

Grain pusher, right & left

Grain outlet (1 piece)

Side door bracket, hook

2 bucket holders (outside)

Rear stepladder, removable

Hyfix

Fifth wheel coupling height when loaded (mm) 1170

2" kingpin

BPW axles

Offset (mm) 120

Disc brake

Brake system, EBS

Wabco EBS

Anti-roll system (Anti-lock braking system)

EBS control (Infocentre / Smartboard)

Raising and lowering

Automatic lowering when Tipping process

Quick-release valve during tipping

1st lifting axle: Automatic control

Tipping ram, Hyva

Tipping angle: 48 degrees

Aluminum drop legs

Foldable steel underrun protection

24N24S + 15-pin plug connectors

Rectangular taillights with bulbs

4 rear white LED work lights - 11W

1 toolbox

Nwsdpfxsyc Ir Es Afhsb

2 wheel chocks

Insulation between steel and aluminum parts

Tires: 6 x 385/65 R 22.5

Speedline satin-finished rims

Tarpaulin quick-release fastener WITHOUT side straps

Tarpaulin color: Metallic gray (B1070 / B2070) - PVC 650 gr/m²

Listing

Hungary

Hungary

1,006 km

HAAS UMC-1000SS

HAASUMC-1000SS

Call

Condition: ready for operation (used), Year of construction: 2020, spindle speed (max.): 15,000 rpm, travel distance X-axis: 1,016 mm, travel distance Y-axis: 635 mm, travel distance Z-axis: 635 mm, This 5-axis HAAS UMC-1000SS was manufactured in 2020. It features a large working envelope with X, Y, and Z axes measuring 1016 mm, 635 mm, and 635 mm respectively. Ideal for complex geometries and multi-sided machining. Consider the opportunity to buy this HAAS UMC-1000SS universal machining centre. Contact us for more information.

Additional equipment

• Chip Conveyor with Belt Drive

• Export Packaging

• 8-Station Pallet Pool for UMC

• UMC Spare Tool Storage (1 unit)

• Through-Tool Air Blast (TAB)

• Auxiliary Coolant Filter

• Chip Tray Filter Kit

Nwjdpfxsyalh Se Afheb

Machine Benefits

Technical Machine Benefits

• Standard program memory: 1 gb/ coolant tank capacity: 55 gallons/ cnc control cabinet cooler/ dynamic work offsets and tool center point control (dwo/tcpc)/ fast power-failure detection module/ ethernet interface/ haasconnect: remote monitoring/ haasdrop: wireless file transfer

• Second home position/ high-speed machining (hsm)/ media display via m-code (m130)/ remote jog handle with touchscreen/ rotary encoders/ synchronized tapping/ safe run (safety restart feature)/ 1-year standard warranty

• Enclosure with mist extraction preparation/ variable coolant pressure/ wi-fi connectivity to haas control/ wireless intuitive probing system (wips)/high-speed side-mount tool changer – 50+1 tools/ ct (sk) 40 spindle taper

• Through-spindle coolant (tsc): 69 bar (1000 psi)

Extra Information

Machine still under power

Listing

Idstein

Idstein

972 km

Horizontal machining center

AverexHS-540i GTS 2 APC

Call

Condition: new, Year of construction: 2025, AVEREX HS-540i GTS 2-APC, New Machine

Horizontal Machining Center with the option to adapt an

optional pallet rotary magazine (6-APC or 8-APC)

Standard equipment

- AVEREX MPro1 (FANUC 0i-MF Plus)

- 15" color LCD display, MANUAL GUIDE i, QWERTY* keyboard

- iHMI – Intelligent Human-Machine Interface

- Program memory with 2 MB and up to 1,000 programs

- 4-axis simultaneous operation (X, Y, Z, B)

- AICC II Control with 200-block Look Ahead function

- HRV3+ servo drives (digital servo current control)

- JERK Control (jerk regulation)

- Fine Surface Technology (High-Speed High Quality)

- Extended workpiece coordinate system G54.1 P1 - P300

- Workpiece coordinate system G52 - G59

- Memory card (PCMCIA Flash Card) and USB slot

- Network interface RJ45, Embedded Ethernet

- Enhanced embedded Ethernet

- Week timer: Auto. Power On/Off for the machine

- High-speed skip function

- Tool Offset Memory C

- 400 pairs of tool corrections

- 1,000 storable programs

- Programmable data input (G10)

- Programmable spindle load monitoring M37/M38

- Tool life management

- Extended macro variables (#100–#199, #500–#999)

- Program restart

- Helical interpolation

- Cylindrical surface interpolation (G07)

- Fixed drilling cycles

- Synchronous tapping (G84/G74)

- Rigid tapping with bell-shaped acceleration/deceleration

- Programmable mirroring, scaling

- Polar coordinate programming (G15/G16)

- Chamfering or rounding corners (,C / ,R)

- Optional skip blocks, up to 9

- User-defined macro programming

Axis Travel

- Travels X/Y/Z: 800/800/860 mm

Speeds

- Rapid traverse X/Y/Z: 74/74/74 m/min

- Feed rate during milling: 0–40,000 mm/min

- Rapid traverse B: 66.6 min-1

- 1G+ acceleration

Pallet Changer

- Rotary changer

- Number of pallets 2-APC: 2 (machine / setup station)

- Pallet size: 500 x 500 mm

- Hole grid: 5 x 5 M16 x 25 mm deep, 100 mm pitch

- Loading capacity: 550 kg per pallet

- Workpiece size 2-APC: Ø800 x H1,000 mm

- Workpiece size 6-APC/8-APC: Ø800 x H900 mm

- Mechanical locking of pallet clamping

- Pallet clamping force: 9.8 kN x 4 cones (39.2 kN)

- Pallet height from floor: 1,100 mm

- Standard preparation for retrofit of 4-way pallet storage (HS-540i GTS 2-APC ==> 6-APC, 2 + 4 pallets)

High-Speed Tool Changer

- Tool holder: BBT-40 (optional SK-40 DIN69871 or HSK-A63)

- Number of magazine positions: 80

- Max. tool diameter: Ø95 mm

- Max. tool diameter with adjacent spaces free: Ø185 mm

- Max. tool length: 400 mm

- Max. tool weight: 8 kg

- Type: Fixed place / random

- Speed: 16 s for 80 tools

- Tool change time: 0.9 s / 2.1 s (heavy tool)

- Chip-to-chip time: 3.0 s / 3.5 s (heavy tool)

Spindle

Rotary Axis

- Manufacturer: PARKSON™

- Axis: full 4th axis

- Max. rotation: 66.6 rpm

- Indexing: 0.001°

- Clamping torque: 5,000 Nm

- Holding torque: 1,973 Nm

Nsdpfewxdpgjx Afhjwb

Linear Guides

- Manufacturer: THK™

- Width: 45 mm

- Guide shoes X/Y/Z: 190 x 120 / 120 x 70 / 154 x 86 mm

Ball Screws

Coolant, chip, and compressed air management

Listing

Germany

Germany

1,034 km

Center Lathe

PADOVANILABOR 230

Call

Condition: used, turning diameter / mm

turning length / mm

swing diameter over bed slide / mm

Technical data - Model 230

DIMENSIONS

Centre height on the bed: 230 mm

Spacing between centres:

1000-1500 mm

2000-2500 mm

3000 mm

Bed width: 360 mm

Largest turning Ø:

on the bed: 465 mm

on the carriage: 278 mm

on fixed steady rest: 200 mm

on travelling steady rest: 160 mm

CROWNING

Width of the crank: 300 mm

Distance between face plate edge and offset: 150 mm

Largest turning Ø on the offset: 690 mm

SPINDLE

Ø of front bearing (inside): 110 mm

Ø of rear bearing (inside): 95 mm

Ø of hole: 77 mm

Mounting Type - Cam Lock: 6"

Internal spindle taper - taper: 1 : 20

Spindle taper - C. M. - N.: 5

Speed ranges:

Slow feed - rev. 1': 15÷1000

Normal feed - rev. 1': 22÷1500

Fast feed - rev. 1': 30÷2000

FEEDS (without gear change)-N.: 108

Longitudinal feed range at revs. : 0.04÷4 mm

Transverse feed range at revolution: 0.02÷2 mm

Lead screw - Ø: 40 mm

Lead screw pitch: 12 mm

THREAD (without gear change)

Metric - N. 54 to: 0.5÷28 mm

Module - N. 54 to Module: 0.25÷14

Whitworth - N. 54 to Wt. x 1": 56÷1

Diametral Pitch - N. 54 to D.P.: 112÷2

Inch - N. 54 to Inch: 1/32 ÷ 13 3/4"

Nsdpfjwz Rywsx Afhswb

SPINDLE PIT

Quill Ø: 75 mm

Quill barrel: 220 mm

Quill taper - vices N. 5

POWER

Main motor - HP: 10

Pump motor - HP: 0.25

WEIGHT approx. - kg

2000-2220

2530-2720

2920

ON REQUEST

Main motor - HP

We make it easier for you to find: "offset"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Offset (814)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- 2 Color Offset

- 2 Color Offset Press

- 2 Color Offset Printing Machine

- 2 Color Offset Printing Press

- 2 Colour Offset

- 4 Color Offset

- Heidelberg Offset

- Offset Heidelberg

- Offset Machine

This may be of interest to you