Used Scrap for sale (370)

Wiefelstede

Wiefelstede Lubrication bolt

unbekanntSchaft Ø 70 mm M48

Wiefelstede

Wiefelstede Tipping container with lid

Stahl0,8 m³

Wiefelstede

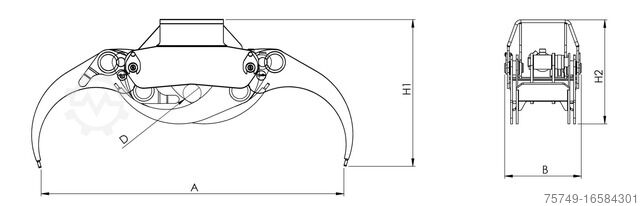

Wiefelstede Four-rope orange peel grapple

LAUDI GVE6-Schalen-Greifer 6,3 m³

+44 20 806 810 84

Wiefelstede

Wiefelstede Rope lock

unbekanntETL914-23g P.09 MKräne

Meckesheim

Meckesheim Cutting Mill

HERBOLDHGM 60/145

Discover more used machines

Meckesheim

Meckesheim Cutting Mill

HERBOLDHGM 60/145

Stadum

Stadum Tipper semitrailer

KEMPFca. 60m³ Stahlmulde für Schrott / HARDOX / Miete

Sottrum

Sottrum Tipper semitrailer

LückSKF 35 55m³ Hardox Schrott - Recycling Mulde SAF

Wiefelstede

Wiefelstede Grease bolts

unbekanntSchaft: Ø 60 mm M48

Bad Salzungen

Bad Salzungen Primary shredder

HammelVB 650 D

Cantù

Cantù Cut off saw

CMS SCARPARI - ITALYMI 120/EL

Bad Salzuflen

Bad Salzuflen Other

ungesetztGreifer Holz Schrott Zweischallen m. Rotator

Pelt

Pelt Horizontal machining center

SOENEN HENDRIKDEM Alu

Bakkeveen

Bakkeveen Finger Jointer

Marinus MachineryPowermax Finger Jointer & Defect Saw

Bergeijk

Bergeijk Deburring machine

Q-Fin Quality Finishing SolutionsDS1200 - MAG

Wiefelstede

Wiefelstede Rope pulley 1-groove

unbekanntØ 570 mm Nutbreite 50 mm

Petrovče

Petrovče Shredder ID1400

RobustID 1400

South Korea

South Korea Used injection molding machine H160 - 2009

HuskyH160 RS45/42

Lombardia

Lombardia Veneer bundle cutting machine

CASATI MACCHINEBIG 3200

Trenčianske Stankovce

Trenčianske Stankovce RAS type 83.20. (1994)

RAStype 83.20.

Radom

Radom Label punching machine, die cutter

Blumer Atlas D-18 MLabel punching machine

Località San Benedetto

Località San Benedetto High top van

OPELMOVANO 33 L3H2 HDI 140 S&S HACCP ALIMENT

Werdau

Werdau Plate shear

DURMA

Schleswig-Holstein

Schleswig-Holstein Laser cutting machine

TRUMPFTruLaser 5030 7kW (L16)

Sinsheim

Sinsheim Hammer-mill

NEUE HERBOLDHM 450/300

Used Scrap (370)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84