Used Stator for sale (238)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Herentals

Herentals

723 km

Pumps

NetzschNM038BY01L06B

Call

Condition: new, Year of construction: 2024, 2 x New worm pumps type NM038BY01L06B

Min flow rate: 1.5 m3/h at 2 bar and 65 rpm

Max flow rate: 8 m3/h at 2 bar and 341 rpm

Rotor: Chrome steel hardened

Stator: Nemolast®O62L IFD 2.0

Seal: uNS-Seal 100 Q1QVGG

Drive: NORD SK20-100LP/4

Motor: 3 kW 230/400 V

I ratio: 6.86

Iedovtmh Nopfx Addetb

The stated price is per piece

Listing

Meerhout

Meerhout

738 km

Mondomix aerator A05 Minimondo Buhler

mondomixminimondo A05

Call

Year of construction: 2013, condition: excellent (used), functionality: fully functional, machine/vehicle number: A05, Mondomix - Minimondo A05 Buhler

Model A 05. (2013)

(previous used : food products)

Capacity : 5 - 45 Litres/Hr.

Density produit : Input: 1,0 kg/l - Output: 0,4-0,5 kg/l

Jacketed stator

System complete:

- Systèmes de dosage manuel et automatique de l'air System with airinjection manual and automatique

- with stainless steel control cabinet

Iodpfjvv S Itjx Addstb

- 2 stainless steel hoppers capacity 12,5 litres

- indag inline mixer type DLM1

Last used in a Pilot Plant

220v 1 phase 50/60hz.

8 Bar.

Listing

Remscheid

Remscheid

847 km

Component

Dittel / Marposs O3PL0054004 ( F22028 ) SN:O19LV1960 - ! -

Call

Condition: new, Dittel / Marposs O3PL0054004 ( F22028 ) WB-Stator-SP64 DSG CV 5,0 SN:O19LV1960 ,unused, 100% functional, scope of delivery acc. photos

Isdpjlcf Rmjfx Addetb

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Herzogenburg

Herzogenburg

1,527 km

Grinding plant

JehmlichREKORD 630-SSt

Call

Condition: new, Year of construction: 2024, functionality: fully functional, nominal power: 90 kW (122.37 HP), rotational speed (max.): 5,760 rpm, rotational speed (min.): 1,592 rpm, total height: 3,437 mm, total length: 3,275 mm, total width: 2,500 mm, type of cooling: air, compressed air connection: 6 bar, Equipment: rotational speed infinitely variable, The impact mills of the REKORD 212-630 series in the welded housing design are robust universal mills for demanding industrial applications in continuous operation.

● Size: 630 mm (nominal rotor diameter)

● Mill housing: Heavy-duty welded stainless steel housing, pressure surge resistant up to 10 bar (AISI316L), with product-contacting surface finish Ra ≤ 1.6 μm for easy cleaning, equipped with a pivoting door and safety interlock type HAAKE (key transfer system); monitoring of housing and bearing temperature, vibration monitoring

● Mill inlet: JACOB pipe; DN 150 mm

● Mill outlet: Ground material and air discharge downward into a suction hopper, optimized for connection to the conveying line to the total separator

● Mill drive: Belt drive, three-phase motor, energy efficiency class IE3 (manufacturer SIEMENS), 90 kW, 3~ 400 V, IP55; suitable for operation with frequency inverter

● Sealing materials: Silicone; PTFE, sealing material conforms to EU and FDA food hygiene standards

● Grinding elements: Pin rotor: 4 pin rows, pin Ø 7 mm (wear-reduced); Pin stator: 3 pin rows without external pin circle, pin Ø 7 mm

● Bearings: Designed for toughest operational demands in continuous industrial service, heavy-duty bearing housings with temperature and vibration monitoring (early detection of potential bearing failure and avoidance of hot surfaces)

● Inert gas supply/monitoring for shaft seal on product chamber side

● Run monitoring to detect operating faults

● Machine frame: The complete unit – mill, drive with motor, tensioning rails, belt drive, and belt guard – is installed ready for use on a sturdy machine frame with height-adjustable machine feet

Main components of the offered system include:

● Product feed/transfer from customer’s upstream process and transfer to a rotary valve (certified ATEX protection system);

● Industrial pin mill type REKORD 630-SSt with welded housing and ground surfaces;

● Product separator with discharge rotary valve (certified ATEX protection system);

● Pneumatic conveying line with air inlet/outlet, including suction blower;

Isdpfox Ac Rbox Addstb

● WITHOUT control system, without frequency inverter

Listing

Zuzenhausen

Zuzenhausen

1,070 km

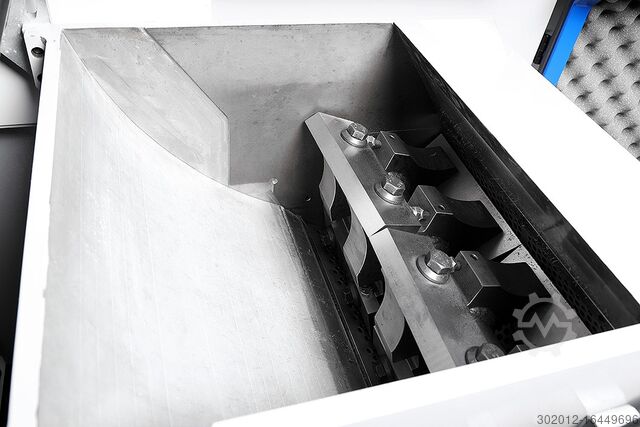

Shredder

ZERMAZXS 1500

Call

Condition: used, machine/vehicle number: 13298, Rotor diameter: 750 mm

Rotor width: 1500 mm

Rotor blades: 76

Itedpfx Aowqyh Aoddsb

Stator blades: 1 row

Inlet cross-section approx. 1500 x 1500 mm

Drive motor: 2 x 45 kW

Discover more used machines

Listing

Bockhorn

Bockhorn

773 km

DREHER MILL S26/41 VS

DREHERS26/41VS

Call

Condition: excellent (used), DREHER MILL S26 / 41 VS with cyclone and fan

Iodpsgphqcefx Addstb

Power: 11 KW

Rotor diameter: 260 mm

Rotor width: 410 mm

4 rotor knives, 2 rows of stator knives

Inlet cross section approx. 260 x 410 mm

Brqvu3zxfl

Cutting mill with integrated noise protection.

For plastic processing pipes, profiles, injection molding

Listing

Zuzenhausen

Zuzenhausen

1,070 km

Shredder

ZERMAZXS 1500

Call

Condition: used, machine/vehicle number: 13299, Rotor diameter: 750 mm

Rotor width: 1500 mm

Rotor blades: 76

Itedpfjwqyh Njx Addsb

Stator blades: 1 row

Inlet cross-section approx. 1500 x 1500 mm

Drive motor: 2 x 45 kW

Listing

Borken

Borken

777 km

Power UV dip impregnation unit

ThummSU100 P

Call

Year of construction: 2010, condition: excellent (used), Thumm SU100 P current UV dip impregnation system with exhaust air cleaning system

Current UV impregnation is an innovative dip process for low-voltage round wire windings.

In this process, a low DC voltage is applied to the winding and the required process heat is generated very effectively by current flow.

When the heated winding is immersed, the impregnating agent becomes thin and can thus penetrate into the smallest cavities.

With continuous heating, the impregnating resin gels on the hot conductors of the winding, whereby the resin can flow off again after dipping on the cooler stack of sheets.

The winding is heated and dried by means of electricity. UV lamps cure the light-sensitive resin on the stack of sheets.

The elimination of conventional oven drying saves energy and time. Together with the use of a low-emission impregnating agent, the environmental balance is very positive.

Thumm electric UV dip impregnation system

Type: SU100 P

Stators: max. 250 mm Ø

Connected load: 15 kVA

Itodpfxjhuffco Addjb

Fuse: 32A

Connection: 3 phase 400 Volt 50 Hz

Power supplies 2 x 50V / 280 A

Thumm aerosol separator

400 V

1.85 KVA

Complete plant closure,

large selection of storage platforms, pallet racks, shelf racks, paternosters.

High-quality industrial machines, lathes, grinding machines, hand machines.

Further articles - new and used - you will find in our shop!

International shipping costs on request!

Listing

Dortmund

Dortmund

836 km

Granulator GA 75

KochGA75 /9

Call

Condition: reconditioned (used), We manufacture the original

We offer you a used, workshop overhauled

Iedpfxoh S U Ryo Addotb

pelletizer GA75 / 9 for sale.

- Engine power either 55 kw or 75 kw

- 9 rotor knife rows, 4 stator knives

- new rotor with completely new bearings and new hardened wear parts . Inquiries please only from tradesmen!

Listing

Dortmund

Dortmund

840 km

GA37- 450

KochGA 37- 450 Granulator

Call

Condition: new, +++++ We manufacture the original +++++

Non-binding offer

Copper cable recycling machine

1 piece GA 37- 450 granulator cutting unit

Iodpfx Adoflkz Hsdjtb

- completely mounted

-incl. motor ( 37 KW )

- with inlet hopper, outlet hopper and belt protection cover

- 1 set of knives ( 5 rotor knives and 2 stator knives )

- 1 sieve

- mounting, system - integration in your plant

- ex our factory

Our general terms and conditions apply

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

890 km

Shredding machine

ZermaGST 250/450

Call

Condition: new, Year of construction: 2024, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

98T8Mrx

Optional rear panel with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Iodpfet Aagajx Addotb

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM H 100 Cutting Mill

CrushmasterH 100

Call

Year of construction: 2025, condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

Isdpfx Adjp N Dv Hjdjtb

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 400

Rotor width (mm) 1000

Drive capacity (hp) 40

Rotor blades (pieces) 3(5) x 1

Stator knives (rows) 2

Hopper opening (mm) 490 x 990

Total length (mm) 1348

Length machine (mm) 1120

Width total (mm) 1577

Width machine (mm) 1216

Height (mm) 1914

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM S 60 Cutting Mill

CrushmasterS 60

Call

Year of construction: 2025, condition: new, APPLICATIONS

The S-Series granulators are mainly used as large central granulators for

In-house recycling applications for processing large thick-walled parts in one

stage or as a second-stage granulator after a shredder to achieve higher results or throughput rates

GENERAL DESCRIPTION

The high-performance S-Series granulators offer widths from

600 to 1000 mm with diameters of 400 and 560 mm.

The all-welded heavy steel construction is designed to withstand

the most demanding and universal applications. Rotor bearings, blades

brackets and rotor shaft are oversized. The standard V-cut ensures a high

quality grind with a very low percentage of fines in the starting material.

The removable third stator blade (optional) acts as a deflection wedge

and allows the machine to be quickly adapted to different application

scenarios. Other standard equipment also includes easily adjustable blades

from the outside, reducing the risk of contamination.

S-SERIES - HIGH PERFORMANCE GRANULATORS ADVANTAGES:

"The easily removable deflector wedge acts as a third stator blade and can

be used to adjust the aggressiveness of the rotor at the first cut point.

The V-Cut technology produces a high quality regrind, with simultaneous

reducing energy consumption and noise.

The high performance bearings are separated from the cutting chamber to prevent lubricant ingress and bearing failure to prevent material contamination.

"Both rotor and stator knives are externally adjusted.

Rotor diameter (mm) 400

Itodpfxjp N D N Se Addjb

Rotor width (mm) 600

Drive capacity (HP) 50

Rotor knives (pieces) 5 x 2

stator knives (rows) 2 + 1

Hopper opening (mm) 630 x 600

Total length (mm) 1950

Length machine (mm) 1876

Width total (mm) 1359

Width machine (mm) 1000

Height (mm) 3040

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Shredding machine

ZERMAGSL 180/300

Call

Condition: new, Year of construction: 2025, Slow-running mill for storage

Rotor diameter (mm) 180

Rotor width (mm) 300

Rotor speed (rpm) 150

Drive (kW) 4

Number of rotor blades 30

Number of stator blades 2

Screen perforation (mm) >5

Approx. weight (kg) 180

The slow-running mills of the GSL 180 series have a rotor diameter of 180 mm and working widths from 120 to 430 mm.

The rotor is driven directly by a gear motor. The low rotor speed ensures a pleasant noise level and a high-quality product.

The special rotor blades can be resharpened several times, eliminating the need for complex adjustment work. The mills are fed via a noise-reducing sandwich-type hopper. Depending on the task, the machines can be equipped with various hopper variants.

Low and high base frames are available as options. The ground material is either vacuumed or filled into bags or a plastic container.

Iodpfxet Aam Hj Addotb

Good accessibility for simple and quick maintenance work is ensured by the Quick Snap locking system.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM S 70 Granulator

CrushmasterS 70

Call

Year of construction: 2025, condition: new, APPLICATIONS

The S-Series granulators are mainly used as large central granulators for

In-house recycling applications for processing large thick-walled parts in one

stage or as a second-stage granulator after a shredder to achieve higher results or throughput rates

GENERAL DESCRIPTION

The high-performance S-Series granulators offer widths from

600 to 1000 mm with diameters of 400 and 560 mm.

The all-welded heavy steel construction is designed to withstand

the most demanding and universal applications. Rotor bearings, blades

brackets and rotor shaft are oversized. The standard V-cut ensures a high

quality grind with a very low percentage of fines in the starting material.

The removable third stator blade (optional) acts as a deflection wedge

and allows the machine to be quickly adapted to different application

Ijdpfop N D Sbsx Addetb

scenarios. Other standard equipment also includes easily adjustable blades

from the outside, reducing the risk of contamination.

S-SERIES - HIGH PERFORMANCE GRANULATORS ADVANTAGES:

"The easily removable deflector wedge acts as a third stator blade and can

be used to adjust the aggressiveness of the rotor at the first cut point.

The V-Cut technology produces a high quality regrind, with simultaneous

reducing energy consumption and noise.

The high performance bearings are separated from the cutting chamber to prevent lubricant ingress and bearing failure to prevent material contamination.

"Both rotor and stator knives are externally adjusted.

Rotor diameter (mm) 560

Rotor width (mm) 700

Drive capacity (HP) 75

Rotor knives (pieces) 5 x 2

Stator knives (rows) 2 + 1

Hopper opening (mm) 700 x 650

Total length (mm) 2300

Length machine (mm) 2200

Width total (mm) 1600

Width machine (mm) 1060

Height (mm) 3509

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Single-shaft shredder

CrushmasterQ 110

Call

Condition: new, Year of construction: 2025, APPLICATIONS

The Q-Series single-shaft shredders are suitable for processing almost all types of

plastics. The machines shred production waste, pipes, car parts,

blow-molded materials such as PET bottles, PE/PP bottles, containers or

buckets. In addition, materials such as wood, paper, cardboard can be used

shredded without any problems.

GENERAL DESCRIPTION

Q series is single shaft shredder with powerful hydraulic horizontal system

in inclined position. The machine is very versatile and can be used to shred any kind of material, it is well suited for various industries.

The rotors have a diameter of 400 mm and a width from 600 to 1700 mm

driven by a gearbox drive with low speed and high torque.

The hydraulic power unit is well integrated into the machine housing

saves space and protects it from damage, but is still easily accessible or removable

for maintenance.

ADVANTAGES

" The cutting crowns are concave ground square blades, producing

high quality performance. Knives can be rotated as one side wears.

Easily removable screen for quick access to the rotor"

and screen replacement.

Itodpjp N Enpjfx Addjb

Rotor diameter (mm) 400

Rotor width (mm) 1140

Drive capacity (hp) 40

Rotor knives (pieces) 27

Stator knives (rows) 1 x 4

Hopper opening (mm) 1880 x 1140

Total length (mm) 3170

Width total (mm) 1900

Width machine (mm) 1210

Height (mm) 1982

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Single-shaft shredder

CrushmasterQ 80

Call

Condition: new, Year of construction: 2025, APPLICATIONS

The Q-Series single-shaft shredders are suitable for processing almost all types of

plastics. The machines shred production waste, pipes, car parts,

blow-molded materials such as PET bottles, PE/PP bottles, containers or

buckets. In addition, materials such as wood, paper, cardboard can be used

shredded without any problems.

Itodpfop N El Rjx Addob

GENERAL DESCRIPTION

Q series is single shaft shredder with powerful hydraulic horizontal system

in inclined position. The machine is very versatile and can be used to shred any kind of material, it is well suited for various industries.

The rotors have a diameter of 400 mm and a width from 600 to 1700 mm

driven by a gearbox drive with low speed and high torque.

The hydraulic power unit is well integrated into the machine housing

saves space and protects it from damage, but is still easily accessible or removable

for maintenance.

ADVANTAGES

" The cutting crowns are concave ground square blades, producing

high quality performance. Knives can be rotated as one side wears.

Easily removable screen for quick access to the rotor"

and screen replacement.

Rotor diameter (mm) 400

Rotor width (mm) 860

Drive capacity (HP) 30

Rotor knives (pieces) 20

Stator knives (rows) 1 x 3

Hopper opening (mm) 1620 x 560

Total length (mm) 2690

Width total (mm) 1620

Width machine (mm) 930

Height (mm) 1876

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Granulator

ZERMAGSL 300/600

Call

Year of construction: 2025, condition: new, GSL - Slow speed granulator GSL 300

Rotor diameter (mm) 300

Rotor width (mm) 600

Rotor speed (rpm) 150

Drive capacity (kW) 11

Rotor knives (pcs) 48

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 950

The slow speed granulators in the GSL range are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The machines can be used for rejected products in the inline recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots.

Driven by gear motor

Unique knife design eliminates adjustment after resharpening.

Simple tool less access for maintenance and cleaning

Ijdpfx Adsi Hpf Nodjtb

Customizable hopper and base frame

The slow speed granulators in the GSL 300 range feature a staggered 300 mm diameter rotor with widths ranging from 400 to 800 mm.

The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding.

The special design knives of the GSL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound absorbing feed hopper that can be tailored to fit various applications and feeding ways.

Depending on the requirements the machines can be fitted with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters.

Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy.

Applications

The GSL slow speed granulators of the 300 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues.

But they can be used as low noise central granulators for small throughput requirements as well.

The stronger design of the 300 series GSLs allow them to be used for stronger and thicker materials while offering the same advantages regarding low noise and dust as the smaller GSL machines.

All GSL models can be equipped with a built in blower system in case a vacuum loading system is not available, or to transport the ground material to bags for storage.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Single shaft shredder

ZermaGST 400/600

Call

Condition: new, Year of construction: 2025, functionality: fully functional, overall weight: 2,000 kg, rotor diameter: 400 mm, number of blades: 6, rotor length: 600 mm, rotor width: 400 mm, power: 22 kW (29.91 HP), filling opening width: 490 mm, filling opening length: 590 mm, warranty duration: 12 months, input voltage: 400 V, The compact inline granulators of the GST series are designed for use in injection molding and blow molding operations. They are suitable for recycling, for example, voluminous parts such as bottles, canisters, crates, sprues, and molded parts. Thanks to the low feed height, the machines can be easily loaded by hand or with a small conveyor belt. The low noise emissions and space requirements make the GST series the ideal solution for inline size reduction.

All GST series machines feature a compact, soundproofed housing and a noise-insulated feed hopper. The feed hopper can be tilted open and closed via a gas strut. The compact granulators are available with two rotor diameters (250 mm, 400 mm) and rotor widths from 300 to 1000 mm. The smaller models feature an open F-rotor, while the larger machines come equipped with the heavier S-rotor. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. Thanks to the modular design, the granulator can be easily upgraded with additional options such as replaceable wear plates. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine to minimize downtime during maintenance. A setting gauge is included in the delivery. The control cabinet is mounted externally on the noise protection enclosure, with internal wiring throughout the system.

Technical specifications:

Rotor diameter (mm): 400

Rotor width (mm): 600

Drive (kW): 22

Rotor knives (rows): 3 x 2

Stator knives (rows): 2

Itodpfxjvgncuo Addsb

Screen perforation (mm): > 6

Cutting chamber size (mm x mm): 400 x 600

Weight (approx. kg): 2000

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM G 30 Cutting Mill

CrushmasterG 30

Call

Year of construction: 2025, condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive capacity (hp) 10

Rotor knives (pieces) 3 x 1

Stator knives (rows) 2

Iedep N Dqtspfx Addetb

Chuck opening (mm) 340 x 300

Total length (mm) 1207

Length machine (mm) 860

Width total (mm) 870

Width machine (mm) 440

Height (mm) 1712

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM G 60 Cutting Mill

CrushmasterG 60

Call

Year of construction: 2025, condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive capacity (hp) 20

Rotor blades (pieces) 3 x 1

Stator knives (rows) 2

Hopper opening (mm) 340 x 600

Total length (mm) 1348

Length machine (mm) 1000

Width total (mm) 1165

Isdop N Dtrepfx Addotb

Width machine (mm) 834

Height (mm) 1712

Trust Seal

Dealers certified through Machineseeker

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Single shaft shredder

CrushmasterQ170

Call

Condition: new, Year of construction: 2025, overall weight: 6,100 kg, rotor diameter: 400 mm, number of blades: 41, total length: 43,230 mm, total height: 23,660 mm, total width: 27,330 mm, rotor length: 1,700 mm, power: 55.16 kW (75.00 HP), APPLICATIONS

The single-shaft shredders in the Q series are suitable for processing almost all types of plastics.

plastics. The machines shred production waste, pipes, car parts,

blow-molded materials such as PET bottles, PE/PP bottles, containers or buckets.

buckets. In addition, materials such as wood, paper and cardboard can be

shredded without any problems.

GENERAL DESCRIPTION

The Q series is a single-shaft shredder with a powerful hydraulic horizontal system in an inclined position.

in inclined position. The machine is very versatile and can be used for shredding any type of material and is well suited for various industries.

The rotors have a diameter of 400 mm and a width of 600 to 1700 mm

driven by a gear drive with low speed and high torque.

Isdpfxotz U Naj Addstb

The hydraulic unit is well integrated into the machine housing

saves space and protects it from damage, but is still easily accessible or removable

for maintenance.

ADVANTAGES

" The cutting crowns are concave ground square knives and thus produce

high-quality performance. Knives can be rotated after one side is worn.

Easily removable screen for quick access to the rotor"

and screen change.

Rotor diameter (mm) 400

Rotor width (mm) 1700

Drive capacity (HP) 75

Rotor knives (pieces) 41

Stator knives (rows) 1 x 6

Hopper opening (mm) 2380 x 1700

Total length (mm) 4323

Total width (mm) 2733

Issvpry

Width machine (mm) 1981

Height (mm) 2366

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Slow speed granulator

ZERMAGSL 300/800

Call

Year of construction: 2025, condition: new, Direct driven staggered rotor

Special knife design makes adjustment unnecessary

Itjdpfx Asn Hqv Deddeb

Easy access for maintenance and cleaning

Slow rotor speed creates less noise and dust

Easily customizable to suit different applications

Rotor diameter (mm) 300

Rotor width (mm) 800

Rotor speed (rpm) 150

Drive capacity (kW) 18.5

Rotor knives (pcs) 66

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 1100

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

ZERMA GST250/450 granulator hollow body

ZERMAGST 250/450

Call

Year of construction: 2025, operating hours: 1 h, condition: new, functionality: fully functional, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

98T8Mrx

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Itjdpfeum Rnvox Addob

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

High speed granulator

ZERMAGST 250/600

Call

Year of construction: 2025, condition: new, Size reduction of large-volume blow molded parts as well as start and end pieces

Ijdpfxep Sr Iaj Addstb

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

We make it easier for you to find: "stator"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Stator (238)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month