Used Turbocharger Balancing for sale (981)

Ahaus

Ahaus Pillar Drilling Machine

BERNARDOB 610 PRO / 400 V - R/L

Ahaus

Ahaus Polishing Machine

BERNARDOPS 250 S / 400 V

Ahaus

Ahaus Deburring Machine

OPTIMUMGB 250 B

+44 20 806 810 84

Germany

Germany Cylindrical Grinding Machine - Universal

KELLENBERGER600UR

Wiefelstede

Wiefelstede V-belt pulley 8 grooved

GussSPB 322-8 (17 mm)

Discover more used machines

Wiefelstede

Wiefelstede V-belt pulley 8 grooves

GussSPB 507-8 (17 mm)

Wiefelstede

Wiefelstede Crane beam 15t

Sietas8520/240/H620 mm

Wiefelstede

Wiefelstede V-belt pulley, 10 grooves

GussSPC 460-10 (22 mm)

Wiefelstede

Wiefelstede V-belt pulley 7 grooves

GussSPC 510-7 (22 mm)

Wiefelstede

Wiefelstede Safety relief valve

DungsFRSBV 1010

Wiefelstede

Wiefelstede V-belt pulley 12 grooves

GussSPC 570-12 (22 mm)

Wiefelstede

Wiefelstede V-belt pulley 6 grooved

unbekanntSPB 500-6 (17 mm)

Wiefelstede

Wiefelstede Cardboard closure booklet

Josef KihlbergJK561-

Wiefelstede

Wiefelstede Strangregulierventil

TA HydronicsSTAF-SG DN50 PN25

Wiefelstede

Wiefelstede Screw press 10 ton

KaliszYB-1

Wiefelstede

Wiefelstede Control valve flow switch

Alfa LavalRV4 1762570-80 DN25

Wiefelstede

Wiefelstede Workshop press 15 ton

unicraftWPP 15 E

Wiefelstede

Wiefelstede Crane fork

KrögerZinkenlänge 730 mm

Wiefelstede

Wiefelstede V-belt pulley 9 grooved

GussSPC 570-9 (22 mm)

Wiefelstede

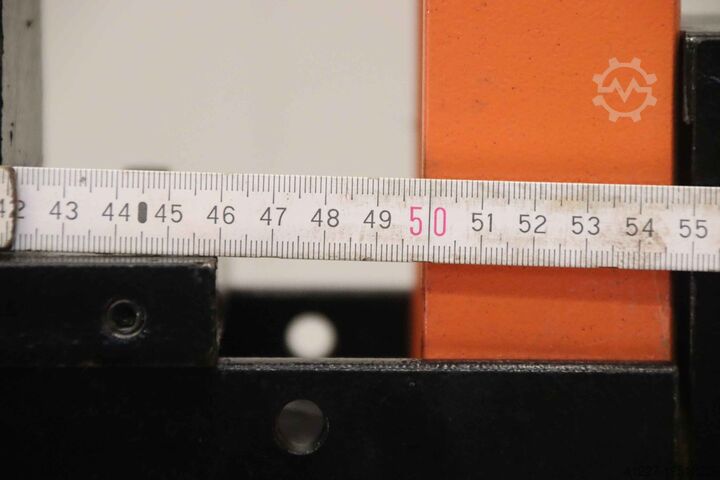

Wiefelstede Calibration weight

unbekannt1 kg

Wiefelstede

Wiefelstede V-belt pulley 9 grooved

GussSPC 480-9 (22 mm)

Wiefelstede

Wiefelstede V-belt pulley 6 grooved

GussSPB 450-6 (17 mm)

Wiefelstede

Wiefelstede Ball shut-off valve

AlcoBVA M28 / 805 793

Czech Republic

Czech Republic TOS WHN 13.8 CNC

TOSWHN 13.8 CNC

Germany

Germany STUDER S33

STUDERS33

Used Turbocharger Balancing (981)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84