Used Turning And Milling for sale (21,583)

Mechernich

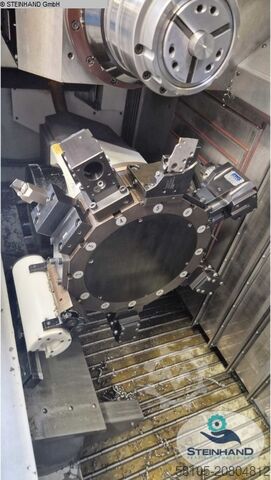

Mechernich CNC turning and milling center

DMG MORICLX350 V4

Halberstadt

Halberstadt CNC Turning and milling machine - 4 Axes - C Axis (Sup-Spindle)

DOOSANDAEWOO PUMA 300 MSC

Halberstadt

Halberstadt CNC turning and milling center - 5-axis

DMGDMC 210 FD

+44 20 806 810 84

Lontzen

Lontzen CNC turn-mill center

OkumaMULTUS B400-C

Germany

Germany CNC turning and milling center

WeilerDZ 40

Discover more used machines

Aach

Aach CNC turn-mill center

GILDEMEISTERNEF 520

Hemer

Hemer CNC turn-mill center

HARDINGEConquest H51T

Tamworth

Tamworth CNC turning and milling center

DMG MoriNTX2000/1500SZM

Tamworth

Tamworth CNC turning and milling center

Mori SeikiNTX2000/1500

Dortmund

Dortmund CNC turning and milling center

GILDEMEISTERNEF CT 60 mit angetriebenen WZ

Birmingham

Birmingham CNC turning and milling center

MazakQuick Turn Smart 200M

Kaufungen

Kaufungen CNC turning-milling machine

GildemeisterTwin 65 RG 2

Kaufungen

Kaufungen CNC turn-mill center

WeisserARTERY M-2 5X

Kaufungen

Kaufungen CNC turn-mill center

DOOSANPuma MX 2000 T

Neuss

Neuss CNC turning and milling center

SAMSUNG SMECSAMSUNG SMEC PL-60L

Düsseldorf

Düsseldorf CNC turning and milling center

EMCOEMCOTURN E 45

Alblasserdam

Alblasserdam CNC turning and milling center

Mori SeikiSL-150 SMC

Alblasserdam

Alblasserdam CNC turning and milling center

Mori SeikiZT1000Y

Düsseldorf

Düsseldorf CNC turning-drilling-milling center

KlaaßenSDM15-5

Germany

Germany CNC Turning- and Milling Center

NAKAMURA TOMESuper NTJ

Velbert

Velbert CNC turning and milling center

DMG MORICLX 450 TC

Bremen

Bremen CNC turning and milling center

TRAUBTNX 65/42 DGY

Bremen

Bremen CNC turning and milling center

TRAUBTNA 480

Hattingen

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Dieburg

Dieburg CNC turning and milling center

MTRENTMTCUT T20MC

Used Turning And Milling (21,583)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84