Used bale presses for sale (199)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Waste management & recycling equipment Presses Bale presses

Listing

Zuidbroek

Zuidbroek

712 km

Bollegraaf Baler HBC60 (30kW)

BollegraafHBC60 (30kW)

Call

Condition: reconditioned (used), Year of construction: 2008, operating hours: 23,000 h, machine/vehicle number: 00834, pressing force: 60 t, filling opening width: 1,100 mm, filling opening length: 1,315 mm, bale width: 1,100 mm, bale height: 720 mm, warranty duration: 3 months, power: 30 kW (40.79 HP), year of last overhaul: 2025, Equipment: documentation/manual, Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler, hereby offers the following machine(s)

A repaired HBC60 (30kw)

Repaired – in very good technical condition

Year of construction: 2008

Volume capacity m3/hr max. 365 334 321 301

Volume weight kg/m3 max. 15 30 50 80

Weight capacity T/hr max. 5.5 10 16 24

Bale weight 400 – 800 kg, depending on S.G. of material and bale length

Bale length - adjustable

Bale height - 720 mm

Bale width - 1100 m

Filling opening - 1100 mm x 1320 mm

Max. size supply - 1500 mm x 1200 mm

Pressure force ram - max 60 tonf.

Pressure force pre-press flap - max 25 tonnes

Cycle time - 18 seconds

Motor - 45 kW

Motor Twistomat - 2.2 kW

Motor counter pressure pump - 1.1 kW

Following repairs have been done in our official Bollegraaf OEM Refurbishment Workshop:

* Safety doors needle installation replaced with new

* Ram wheels behind replaced with new

* Bronze strip above ram replaced with new

Klodpfxjxck U Uj Addel

* Movable beam position switch ram replaced with new

* Scraper above ram replaced with new

* Sealing pre press cylinders replaced with new

* New steel beams channel cylinder

* nieuwe buisjes oplassen en wielen gangbaar maken

* New pusher cylinder underneath vertical tying unit

* Safety hatch behind needle installation replaced with new

* Several cables and asi modules replaced with new

* New air filter

* New oil filters

Listing

France

France

714 km

Baler incl. conveyor VK 8818 R-FU

HSM GmbH + Co. KG, GermanyHSM VK 8818 F-RU

Call

Condition: good (used), Year of construction: 2012, operating hours: 12,078 h, functionality: fully functional, pressing force: 88 t, filling opening width: 1,100 mm, filling opening length: 1,800 mm, bale width: 1,100 mm, bale height: 750 mm, bale weight: 750 kg, overall weight: 30,000 kg, oil tank capacity: 2,000 l, power: 98 kW (133.24 HP), volume flow: 643 m³/h, Technical data baler:

Manufacturer HSM GmbH + Co. KG, Germany

Kodpfoxcngnjx Addjll

Type VK 8818 R-FU

Year of construction 2012

Total operating hours: 12,078 hours, as of September 2025

Pump operating hours 6,616 hours (effective pump running time)

Number of bales pressed: 65,792 bales, as of September 2025

Main press force 880 kN

Specific pressing force 120 N/cm²

Pressing force cutting edges free rammer 120 kN

Dimensions of feed chute 970 x 1,800 mm

Theoretical cycle time in idle mode 8.3 seconds

Theoretical throughput capacity 643 m³/hour

Bale dimensions 1,100 x 750 mm, the length is variable 600 up to 2000 mm

Drive power 2 x 45 kW frequency-controlled

Connected load 98 kW

Total current consumption 192 A

Fuse protection 250 A slow-blow

5-fold horizontal tying, fully automatic

Throughput rates with a

bulk density of 20 kg/cbm 12.86 t/hour

Bulk weight of 50 kg/cbm 32.15 t/hour

Bale weights with a bale length of approx. 1.2 m 650 up to 750 kg/bale, depends on materiel

Hydraulic oil tank capacity 2000 litres

PLC control Siemens S7-300

Siemens TP 700 control panel

Press dimensions assembled 18,000 x 4,300 x 3.270 mm (l x w x h)

Press dimensions with conveyor system 18,000 x 22,000 x 5,765 mm (l x w x h)

Transport weight baler approx 30 t (Main press approx. 20 t, press channel with bale clamp approx. 10 t)

Special machine equipment:

Access locking by means of key transfer system

Electro-hydraulic locking of the press carriage during the tying process so that the press plunger does not change position with highly expansive materials

Additional optional equipment ordered:

Frequency-controlled main drive, 2 x 45 kW, with up to 40 % energy savings compared to the standard motorisation 2 x 45 kW, with the same power output

Manual switch-off or switch-on of the number of strapping wires to save on strapping wire for non-expansive material

Cutting-edge frei rammer with 121 kN pressing force

Sensory wire monitoring, with press switch-off in the event of wire breakage or wire end

Bale chute

Visual warning signal, mounted on the control cabinet

Condition of the baler:

The entire baling system (baler and conveyor belt) is in good, operational condition.

Technical data for the chain belt conveyor:

Manufacturer Stadler Anlagenbau GmbH

Typ chain belt conveyor KF 1800

Year of construction 2012

Drive power 7.5 kW

Belt speed 0.05 – 0.4 m/second

Length of feeding conveyor 6,000 mm

Height of side wall from feeding conveyor 400 mm

Length of incline conveyor 9,000 mm

Height of side wall from incline conveyor 800 mm

Length of gooseneck 1,500 mm

Incline 30°

Nominal width 1,800 mm

Useful width 1,700 mm

Belt quality EP-500/4

Steel cleats on the rubber belt 50 x 50 mm

Hollow pin chain, pitch 125 mm, rollers 36 mm

Height of drive axle above ground 4,284 mm

Overall height of conveyor belt 5,765 mm

Transport dimensions of feeding conveyor approx. 7,000 x 2,200 x 1,250 mm (l x w x h)

Transport dimensions of the incline conveyor 13,000 x 2,500 x 2,900 mm (l x w x h)

Pit dimensions for the conveyor belt 14,765 x 3,260 x 1,250 (l x w x h)

Scope of delivery:

The conveyor belt, baling press with bale chute, and wire drawing stations are available for sale, but without the wire.

Comments:

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Siddeburen

Siddeburen

710 km

Bollegraaf HBC120s (90kW) crosswires

BollegraafHBC120S (90kW) + crosswires

Call

Condition: reconditioned (used), Year of construction: 2014, operating hours: 24,967 h, functionality: fully functional, machine/vehicle number: 004283-0030, pressing force: 122 t, filling opening width: 1,100 mm, filling opening length: 1,600 mm, bale width: 1,100 mm, bale height: 1,100 mm, warranty duration: 24 months, year of last overhaul: 2026, Equipment: documentation/manual, Sold by Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler.

This is a baler HBC120s (90kW) with crosswires.

At the time of writing this baler is being completely refurbished in our refurbishment workshop.

This refurbishment takes place on the basis of the very strict Bollegraaf OEM Refurbishment Guidelines.

Kjdpjxcir Ejfx Addsll

After refurbishment, this baler is sold with a 2-year warranty.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Netherlands

Netherlands

714 km

Baler HBK 100 45 kW

Bollegraaf Recycling Solutions B.V.Baler HBK 100 45 kW

Call

Condition: excellent (used), Year of construction: 2004, operating hours: 34,480 h, functionality: fully functional, pressing force: 100 t, filling opening width: 1,100 mm, filling opening length: 1,600 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 750 kg, overall weight: 19,000 kg, transport height: 3,300 mm, oil tank capacity: 750 l, power: 45 kW (61.18 HP), Technical data baler:

Manufacturer Bollegraaf

Typ HBK 100

Year of construction 2004

Hours of operation 34,480 hours

Press power main press 100 tons

Press power of pre-press max. 42 tons

Feed channel 1,600 x 1,100 mm

Filling volume 3.15 m³

Theoretic cycle time 22 sec.

Theoretic throughput capacity up to 450 m³/hour

Bale size 1,100 x 720 mm, lenght variable

Driving motor 45 kW

Connected load 60 kW

Tying system 5-fold vertical, fully automatic

Throughput rate at a

bulk weight of 30 kg/cbm approx. 13 tons/hour

bulk weight of 50 kg/cbm approx. 20 tons/hour

Kjdpjxbgnhofx Addsll

bulk weight of 100 kg/cbm approx. 30 tons/hour

Throughput rate with ruffler approx. 20 tons/hour

Bale weight 550 up to 750 kg, depends on material

Volume hydraulic oil tank 750 l

SPS controller Telemecanique TSX Micro

Transport dimensions only baler 10,900 x 2,320 x 3,300 mm (l x w x h)

Machine weight baler approx. 19 tons

Comments:

Unlike the standard HBC press series from Bollegraaf, this machine does not have a pre-press flap but cuts the material between blades on the press ram and the counter blade in the frame. This makes it a cutting edge press, similar to a Paal, unoTech, etc. The press is in very good condition for its age, as it was used exclusively for compressing paper from document destruction.

The documentation (Manual, CE, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Tatabánya

Tatabánya

1,738 km

Baler paper press waste press

HSMHL 4010 (3381)

Call

Condition: ready for operation (used), Year of construction: 2012, pressing force: 40 t, Manufacturer: HSM

Kedpfxex D U N So Addsll

Model: HL 4010

Year of manufacture: 2012

Discover more used machines

Listing

Dordrecht

Dordrecht

667 km

Bollegraaf HBC140s (2x75kW) 2008

BollegraafHBC 140

Call

Year of construction: 2008, operating hours: 40,000 h, condition: good (used), machine/vehicle number: HBC 140 2x75kW 2008 (00191), Sold by Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler and conveyor:

Bollegraaf HBC140s Baler (2x75kW).

Baler:

Weight: 47.100 kg

Construction year: 2008

Hardox bottom floor plate only

Variable channel pressure control

Plastic valve

Hydraulic pump driven by frequency inverter

Anti-rat cabling

Oil in-depth filtration

Modem

Hours 40.000

This baler can also be sold fully refurbished according to the 'Bollegraaf OEM Certified Refurbishment standards'. This includes 2 year guarrantee.

Contact us for more information or a quotation.

General principles of refurbishment

Cleaning & disassembly

Before the actual refurbishment takes place the baler is completely cleaned and disassembled in our refurbishment workshop.

Tolerances

After the disassembly the tolerances of all steel components are measured and re-welded where necessary, this at least applies to the following components;

• Ram,

• Frame,

• Channel,

Ksdpfx Aekcgf Hsddsll

• Pre-press-flap

After disassembly and inspection the ram is welded-up again and fitted with new ram wheels.

The protective grids and the pre-press flap are made dent-free and repaired where necessary.

Repainted

After measuring the tolerances and any repair- and welding work, all components are being blasted and coated again.

Hydraulics:

The hydraulic tank is cleaned.

The hydraulic lines & hoses are replaced.

The hydraulic components are repackaged.

The hydraulic oil is replaced.

Cabling:

All cabling is checked and replaced if necessary.

All junction boxes are replaced and placed back in easily accessible positions.

Wear parts:

All wearing parts are replaced.

The pins and shafts of the cylinders and the channel are replaced with new ones.

All wearing parts of (both) needle installations and knotters are replaced for new.

Cylinders:

The cylinders are repackaged and, if necessary, provided with a new chrome layer or a new cylinder rod.

MCC Cabinet

The switch box is checked and cleaned.

If necessary, electronic components are replaced with new ones.

The PLC and HMI (human interface) are replaced with the latest Schneider M340 version including the latest software.

Listing

Dordrecht

Dordrecht

667 km

Bollegraaf HBC140s (2x75kW) 2003

BollegraafHBC 140

Call

Year of construction: 2003, operating hours: 43,000 h, condition: repair required (used), machine/vehicle number: HBC 140 2x75kW 2003 (W230-005), Sold by Bollegraaf Recycling Solutions, the original manufacturer of this Bollegraaf baler and conveyor:

Bollegraaf HBC140s Baler (2x75kW).

Baler:

Weight: 47.100 kg

Construction year: 2003

Hardox bottom floor plate only

Plastic valve

Anti-rat cabling

Hours 43.000

This baler can also be sold fully refurbished according to the 'Bollegraaf OEM Certified Refurbishment standards'. This includes 2 year guarrantee.

Contact us for more information or a quotation.

General principles of refurbishment

Cleaning & disassembly

Before the actual refurbishment takes place the baler is completely cleaned and disassembled in our refurbishment workshop.

Tolerances

After the disassembly the tolerances of all steel components are measured and re-welded where necessary, this at least applies to the following components;

Ksdekcgynopfx Addoll

• Ram,

• Frame,

• Channel,

• Pre-press-flap

After disassembly and inspection the ram is welded-up again and fitted with new ram wheels.

The protective grids and the pre-press flap are made dent-free and repaired where necessary.

Repainted

After measuring the tolerances and any repair- and welding work, all components are being blasted and coated again.

Hydraulics:

The hydraulic tank is cleaned.

The hydraulic lines & hoses are replaced.

The hydraulic components are repackaged.

The hydraulic oil is replaced.

Cabling:

All cabling is checked and replaced if necessary.

All junction boxes are replaced and placed back in easily accessible positions.

Wear parts:

All wearing parts are replaced.

The pins and shafts of the cylinders and the channel are replaced with new ones.

All wearing parts of (both) needle installations and knotters are replaced for new.

Cylinders:

The cylinders are repackaged and, if necessary, provided with a new chrome layer or a new cylinder rod.

MCC Cabinet

The switch box is checked and cleaned.

If necessary, electronic components are replaced with new ones.

The PLC and HMI (human interface) are replaced with the latest Schneider M340 version including the latest software.

Listing

Almelo

Almelo

741 km

Baler

BOA2040

Call

Condition: refurbished (used), Year of construction: 1999, functionality: fully functional, pressing force: 71 t, filling opening width: 1,080 mm, filling opening length: 1,620 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 600 kg, total width: 3,450 mm, total height: 4,090 mm, total length: 10,020 mm, input voltage: 400 V, overall weight: 27,000 kg, noise level: 85 dB, pressure: 300 bar, transport height: 2,300 mm, power: 37 kW (50.31 HP), Fully automatic channel baler with pre-press flap available immediately. The machine includes a conveyor belt with a floor-mounted section. The baler is supplied in refurbished condition and the conveyor belt underwent a belt overhaul at the beginning of this year. The machine was taken out of production at the beginning of October and is currently stored in our facility. It can be demonstrated in operation at our location. This machine is particularly suitable for baling paper/cardboard and various types of plastics such as PET, HDPE, and big bags.

Technical specifications baler:

Drive: 37 kW

Press force: 71 tons

Bale dimensions: 1100 x 720 x 1300 mm (length adjustable)

Number of wires: 4 vertical

Filling hopper dimensions: 1620 x 1080 mm

Bale weight: up to 600 kg (depending on material)

Capacity: up to 20 tons per hour (depending on material)

Kodpsxl Rqbjfx Addsll

Transport weight: 27,000 kg

Technical specifications conveyor belt:

Length of horizontal section: 3,000 mm

Length of inclined section: 7,424 mm

Angle: 29°

Filling option: at floor level

Listing

Ettinghausen

Ettinghausen

930 km

HSM V-Press 1160 plus

HSM Pressen GmbH+Co.KGHSM V-Press 1160 plus

Call

Condition: excellent (used), Year of construction: 2019, HSM V Press 1160 plus

Pressing force 532 kN, opening width 1,195 m, opening height 0.65 m, drive power 4 kW, press type BP, dead weight 2.43 t, transport length 1.78 m, transport width 1.568 m, transport height 2.995 m, press type baler.

Press immediately ready for use.

Kodpfol Uvukex Addell

Listing

Öpfingen

Öpfingen

1,202 km

VERTICAL BALING PRESSES

HUNKELERV 15

Call

Year of construction: 1982, condition: good (used), machine/vehicle number: 14320, Vertical Baling Press

Kjdpfx Adsiuky Iedell

Listing

Netherlands

Netherlands

714 km

LP 60 VH1

Presona AB, SchwedenBallenpresse, LP 60 VH1

Call

Condition: reconditioned (used), Year of construction: 2015, operating hours: 28,748 h, functionality: fully functional, pressing force: 60 t, filling opening width: 1,100 mm, filling opening length: 1,500 mm, bale width: 1,100 mm, bale height: 750 mm, bale weight: 570 kg, overall weight: 20,000 kg, oil tank capacity: 600 l, power: 37 kW (50.31 HP), volume flow: 350 m³/h, Technical data baler:

Manufacturer Presona AB, Sweden

Type LP 60 VH1

Year of construction 2015

Total operating hours, 30,143 hours, as of July 2025

Effective pump running time onl 6,527 hours, as of July 2025

Number of pressed bales 115,193 bales, as of July 2025

Press force pre press 25 t

Main press force 60 tonnes

Specific pressing force 73N/cm²

Dimensions of feed chute 1,500 x 1,100 mm

Filling volume / pressing cycle 2.7 m³

Theoretical throughput capacity 800 m³/hour

Throughput capacity under operating conditions 350 m³/hour

Bale dimensions 1,100 x 750 mm

Drive power 37 kW

Tying 5-fold vertical, fully automatic

Throughput capacity with a

Bulk weight of 50 kg/cbm 11 to 14 tonnes/hour

Bale weights 420 to 570 kg, depending on material

Hydraulic oil tank volume 600 litres

Baler dimensions assembled with hopper 10,100 x 3,750 x 4,310 mm (l x w x h)

Transport dimensions excluding press 10,100 x 2,400 x 3,000 mm (l x w x h)

Machine weight press approx. 20 tonnes

Condition of the press:

The press was partially overhauled in our workshop and then tested in manual and automatic mode.

The following overhaul work was carried out:

Machine cleaned, partially derusted and partially repainted

Hydraulic oil tank emptied and cleaned

Oil filter and air filter replaced, new hydraulic oil filled

Press ram dismantled and cleaned

All four rollers removed from the press ram and replaced

Grease cartridges of the automatic roller lubrication system replaced

Slide rails cut out from the press floor in the press room

Underbody reinforced with welded sheets

New HARDOX slide rails welded in

Wire station with deflection rollers for the lower wire cleaned and made operational

Slide rails cut out from the floor in the press channel

New HARDOX slide rails welded in

Both side walls of the press channel dismantled, derusted

Worn side wall plates cut out

Complete side walls covered with new wear plates and welded

Main hydraulic cylinder dismantled and disassembled for inspection

Piston rod replaced, cylinder tube honed

Complete seal set replaced, pressure test carried out

Vertical needle system for binding dismantled, cleaned, wire deflection rollers made functional and serviced

Chain cleaned, greased, chain tension readjusted

Kledpfxovn Tg Io Addjl

Drillomat cleaned, wire knife, drill shafts and drill fingers checked, retightened with torque and serviced

Machine checked, general maintenance work carried out and press tested in manual and automatic mode

Comments:

The press is sold without a conveyor belt and without wire stations. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Netherlands

Netherlands

714 km

Baler with pre-press flap LP 50 EH1

Presona ABLP 50 EH1

Call

Condition: reconditioned (used), Year of construction: 2005, operating hours: 30,408 h, functionality: fully functional, pressing force: 50 t, filling opening width: 1,100 mm, filling opening length: 1,250 mm, bale width: 1,100 mm, bale height: 720 mm, bale weight: 550 kg, overall weight: 16,000 kg, oil tank capacity: 600 l, year of last overhaul: 2024, Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Kledpfx Aeu Thhreddjl

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

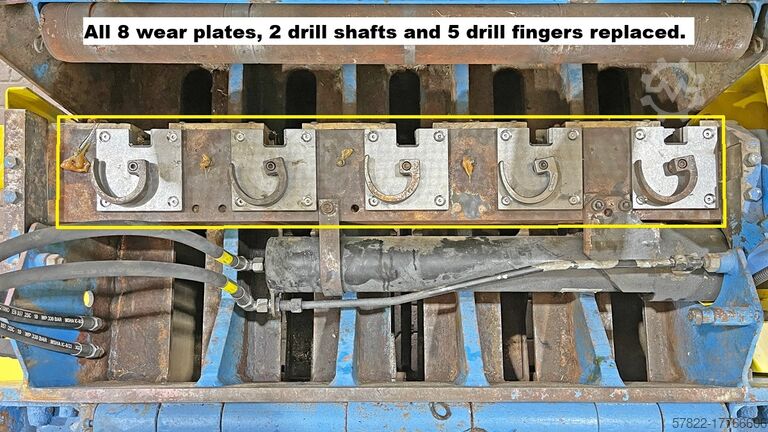

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Netherlands

Netherlands

714 km

Baler with 8-fold cross tying system

Presona ABLP 80 VHK 1

Call

Condition: reconditioned (used), Year of construction: 2012, operating hours: 25,895 h, functionality: fully functional, pressing force: 78 t, filling opening width: 1,100 mm, filling opening length: 1,500 mm, bale width: 1,100 mm, bale height: 750 mm, bale weight: 600 kg, overall weight: 24,000 kg, oil tank capacity: 1,000 l, power: 55 kW (74.78 HP), volume flow: 930 m³/h, Technical data baler:

Manufacturer Presona AB

Typ LP 80 VHK 1

Year of construction 2012

Total machine operating hours 25,895 hours, as of July 2025

Pump operating hours, effective 14,135 hours, as of July 2025

Number of bales pressed 235,597 pieces, as of July 2025

Press power main press 78,5 tons

Specific press capacity 95 N/cm²

Press power of pre-press 28 tons

Volume of pressing chamber 2,7 m³

Feed channel1,500 x 1,100 mm

Theoretic throughput rate 930 m³/h

Throughput rate under operating conditions 410 m³/h

Bale size 750 x 1,100 mm

Driving motor 55 kW

Tying system 5 fold vertical, 3-fold horizontal, full automatic

Throughput rate with a bulk density of

30 kg/m³ approx. 9 to 12 tonnes/hour, depending on material

50 kg/m³ approx. 14 to 17 tonnes/hour, depending on material

100 kg/m³ approx. 16 to 25 tonnes/hour, depending on material

Throughput capacity with MSW (Municipal Solid Waste) approx. 20 to 27 tonnes/hour, depending on material

Bale weight 450 up to 600 kg, depends on material and bale length

Volume hydraulic oil tank 1,000 l

Baler dimensions built up with hopper 10,985 x 3,750 x 4,310 mm (l x w x h)

Transport dimensions only baler 10,985 x 2,300 x 2,900 mm (L x w x h)

Kljdovwlqqopfx Addel

Machine weight baler approx. 24 tons

Condition of the press:

The machine was partially overhauled and serviced in our workshop and, once the work was complete, tested in manual and automatic mode during operation.

The following overhaul work was carried out:

Machine cleaned, partially derusted and partially repainted

Hydraulic oil tank emptied and cleaned

Oil filter and air filter replaced, new hydraulic oil filled

Press ram dismantled and cleaned

All four rollers removed from the press ram and replaced

Wire station with deflection rollers for the lower wire cleaned and made operational

Side guides removed from the press ram, smoothed, mounted and readjusted

Main hydraulic cylinder dismantled and disassembled for inspection

Piston rod replaced, cylinder tube honed

Complete seal set replaced, pressure test carried out

Vertical and horizontal needle system for binding dismantled, cleaned, wire deflection rollers made functional and serviced

Chain cleaned, greased, chain tension readjusted

Drillomat cleaned, wire knife, drill shafts and drill fingers checked, retightened with torque and serviced

Door contact switch checked and partially replaced.

Emergency stop switch checked.

Complete electrical wiring checked and partially replaced.

Bearings of the wire guide rollers under the press replaced.

New safety grilles for vertical and horizontal binding manufactured and installed.

Machine checked, general maintenance work carried out and press tested in manual and automatic mode

Scope of delivery:

Only the baler will be sold.

Comments:

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Listing

Ystad

Ystad

1,087 km

Heating tunnel

HiTec Food SystemsSteamer 45/400E

Call

Condition: like new (used), Year of construction: 2021, functionality: fully functional, machine/vehicle number: 20212531, The HiTec Steam Cooker, are versatile, custom-built cookers are designed to Steamcook & pasteurize, a wide range of production needs such as gyoza, dumplins etc. Engineered with food safety,EHEDGE, efficiency, and footprint in mind. Year of construction 2021 and not used much since that!

Kjdpfoxl Tnpsx Addell

Listing

Bitterfeld-Wolfen

Bitterfeld-Wolfen

1,114 km

Baler

StrautmannPP1208

Call

Condition: good (used), Year of construction: 2007, Baler STRAUTMANN PP1208, year of manufacture 2007

Kljdpjxwc Nyofx Addel

Listing

Bitterfeld-Wolfen

Bitterfeld-Wolfen

1,120 km

Baler

StrautmannBale Trainer

Call

Condition: good (used), Year of construction: 2015, Year of manufacture 2015, serial number 413.00.032, pressing force 600 kN

Ksdpfx Adexwc Najdjll

Listing

Zutphen

Zutphen

727 km

Baler

PaalDOKON 500 H/S

Call

Condition: used, Year of construction: 2014, pressing force: 122 t, overall weight: 40,000 kg, pressure: 315 bar, Machine has been used but is surplus and therefore for sale!

Ksdpfx Adswa N U Dsdell

Listing

Almelo

Almelo

741 km

Baler

BOAImpress D90

Call

Condition: reconditioned (used), Year of construction: 2005, functionality: fully functional, pressing force: 90 t, filling opening width: 1,620 mm, filling opening length: 972 mm, bale width: 720 mm, bale height: 1,100 mm, bale weight: 600 kg, overall weight: 32,000 kg, pressure: 300 bar, power: 110 kW (149.56 HP), BOA baler with double pre-press flaps available in fully refurbished condition. The machine is located at our workshop in Almelo and can be inspected by appointment. If required, a matching (new) conveyor belt can be produced. The machine is perfectly suited for baling various materials such as cardboard, paper, plastics, car tires, and RDF.

Ksdpfx Adsxbc U Dedell

The machine is equipped with a so-called refu-ram. This is ideal for baling materials such as plastic bottles and/or shredded RDF.

Technical specifications:

Drive: 2x 55 kW

Pressing force: 90 tons

Bale dimensions: 1100 x 720 mm

Bale weight: approx. 600 kg (depending on material)

Number of tying wires: 5 vertical

Listing

Hessisch Lichtenau

Hessisch Lichtenau

989 km

High performance baler, hydraulic press for packaging waste, press for recyclable waste

MACFAB - BEMA650A

Call

Condition: used, High-performance baler MACFAB - BEMA type 650A

Hydraulic press for packaging waste, recyclable renewable raw materials, secondary raw materials

Manufacturer no. MF J0162 Year of manufacture 2021

Kledpfsvq Rtkex Addsl

Pressing force 50 tons.

Press plate stroke approx. 1000 mm

Cycle time per stroke approx. 40 sec.

Pressing chamber floor area 1500 x 1100 mm

Pressing chamber height 1650 mm

Filling opening 1500 x 870 mm

Filling height approx. 1250 mm

Bale format 1500 x 1100 mm

Bale height max. 1100 mm

Hydraulic operating pressure 200 bar

Motor power 5.5 kW

Mains connection 400 volts, 50 Hz, 12 amps.

- with two hydraulic cylinders

- Door locking via threaded spindle with handwheel

- Pressing operation only with the pressing chamber door closed

- 2-hand operation for hydraulic tipping of the finished pressed bale

- Free space for manual strapping

- Standard industrial bales of 1500 x 1100 x 1100 mm are produced

- the highly compressed bale is automatically tipped onto a pallet

- only 62 operating hours

Space requirement L x W x H 2120 x 1350 x 3220 mm

Height for transport with lowered hydraulic cylinders approx. 260 cm

Weight 1.8 ton.

The machine is in very good condition, as good as new.

The press has a new price of EUR 22,200 net at BEMA

The BEMA company also buys the packaging waste that you press into bales with this press.

Listing

Tata

Tata

1,725 km

Horizontal bale press

BORG B.B.C.S-15KK 15 ton

Call

Condition: excellent (used), Year of construction: 2002, functionality: fully functional, pressing force: 15 t, bale width: 700 mm, bale height: 700 mm, bale weight: 220 kg, input voltage: 400 V, power: 4 kW (5.44 HP), empty load weight: 2,700 kg, Manufacturer: Borg Baling Company

Type: S-15KK

Year of production: 2002

Kledpfx Adeh Dy Rfodel

3x400V, 4kW, 14.5A

Compression force: 15t

Net weight: 2.7 t

Bale max. sizes

700x700x1000 mm

weight of a bale: ca 120 – 220kg

Wide Range of Used Machinery, Industrial Equipment

Listing

Tata

Tata

1,725 km

Channel Bailing Press

PAAL PACOMAT V50ton 500kg bale

Call

Condition: not inspected (used), Year of construction: 1985, functionality: fully functional, pressing force: 50 t, bale length: 1,000 mm, bale width: 750 mm, bale height: 750,750,750 mm, bale weight: 500 kg, input voltage: 400 V, overall weight: 7,500 kg, oil tank capacity: 500 l, power: 30 kW (40.79 HP), empty load weight: 7,500 kg, input frequency: 50 Hz, Manufacturer: Paal

Typ: Pacomat V

Year of construction: 1985

Press power main press: 50 t

Specific press capacity: 5 kg/cm²

Feed channel: 1.000 x 720mm (l x w)

Theoretic throughput rate: 200 cbm/h

Bale size: 700 x 1.000 mm (w x h) length adjustable

Driving motor: 30 kW

Ksdpfx Adsic Rl Djdoll

Bale weight: approx. 500 kg

Machine weight: approx. 8t

The hydraulic unit is functional, the drive motor is in the removed state.

Trust Seal

Dealers certified through Machineseeker

Listing

Kosorowice

Kosorowice

1,531 km

Bale press

HSM500.2 VL, 500.3 VL

Call

Condition: ready for operation (used), Year of construction: 2003, Baling press HSM 500.2 VL

Fourfold wire bale tying

Bale dimensions (L x W x H, mm): 1200 x 800 x 1000–1200

Kjdpfx Adera Ak Eodsll

Bale weight (kg): approx. 500 kg

Technical data (L x W x H, mm): 1213 x 1824 x 2987

Feed opening (mm): 1200 x 565

Cycle time (sec): 35

Pressing force (T): 54

Power supply (V): 400 (three-phase)

Year of manufacture: 2002–2005, price: 3,400 EUR

Baler HSM V Press 500.2 VL

Year: 2006–2008, price: 3,600 EUR

Transport height: 2600 mm

Listing

Kosorowice

Kosorowice

1,531 km

Bale press

HSMV press 1160 plus , v press 1160 max

Call

Condition: ready for operation (used), Model: HSM V-Press 1160 Plus Baler

Pressing force (kN): 532

Output (bales/h): 1–2

Max. bale size (mm): 1200x1100x1000–1200

Dimensions (L x W x H) (mm): 1780x1150x2985

Power (kW): 7.5

Year 2007–2008 price €5,500

year 2009–2010 price €5,800

year 2011–2013 price €6,300

We also offer HSM V-Press 1160 Max balers, year 2014–2015

Weight (kg): 2,300

ALSO AVAILABLE: 2017–2018 models – €7,500

Kledjra Nyuspfx Addol

Listing

Vilnius

Vilnius

1,820 km

Bale press

HSM45 VL

Call

Condition: used, Year of construction: 1995, power: 2 kW (2.72 HP), Vertical baler HSM 45 VL for SALE/RENT!

Kodox H Skbjpfx Addsll

Manufacturer: HSM

Model: 45 VL

Year of manufacture: 1995

Total available: 8 units.

Sale price: €1,200 per unit (ex works Lithuania)

Listing

Alsfeld

Alsfeld

991 km

Baler

BalemasterCMG 268

Call

Condition: excellent (used), Year of construction: 2006, Balemaster

Koderdwlkopfx Addjll

Year: 2006

Type: CMG 268

Waste compactor

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used bale presses (199)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month