Used machining centers with flat or grid table for sale (347)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Woodworking machinery CNC-processing machines Machining centers with flat or grid table

Listing

Netherlands

Netherlands

1,006 km

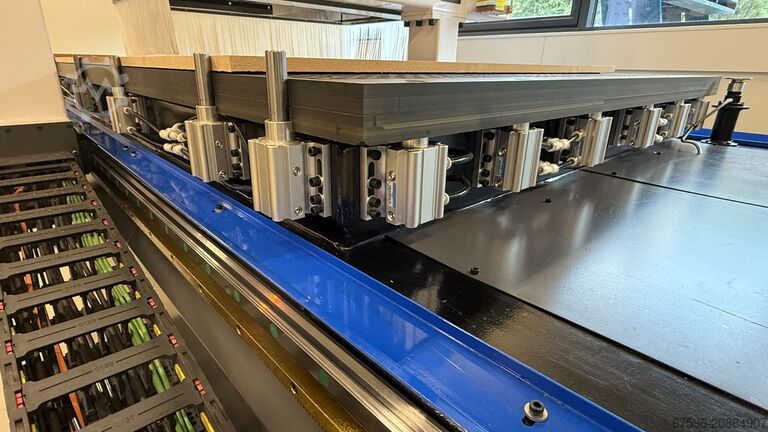

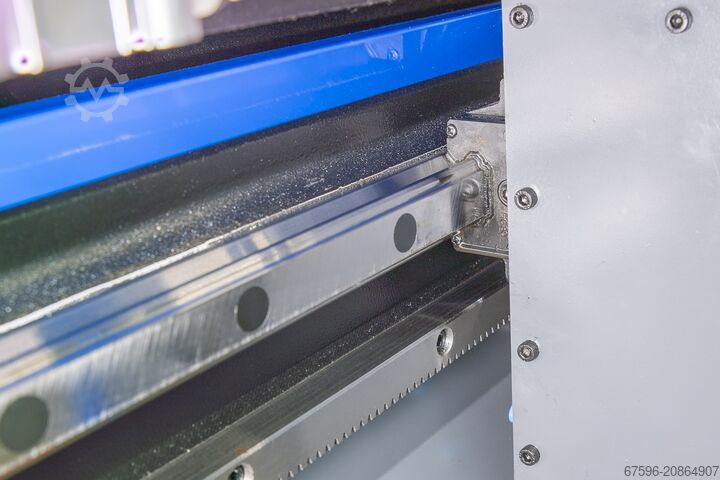

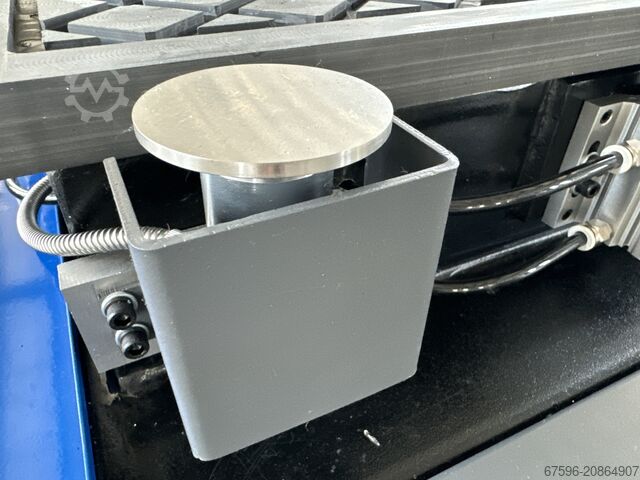

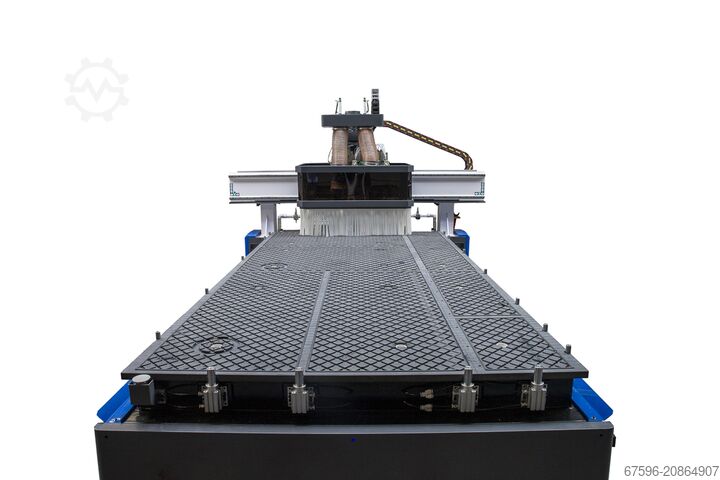

HOMAG WEEKE Profi BMG 611/60/15/F/AP

HOMAG WEEKEProfi BMG 611/60/15/F/AP

Call

Condition: ready for operation (used), Year of construction: 2012, travel distance X-axis: 6,175 mm, travel distance Y-axis: 1,900 mm, travel distance Z-axis: 300 mm, total height: 300 mm, spindle speed (max.): 24,000 rpm, spindle motor power: 15,000 W, number of axes: 3, This 3-axis HOMAG WEEKE Profi BMG 611/60/15/F/AP was manufactured in 2012. A CNC Wood Machining Centre designed for precision and efficiency in woodworking applications. Consider the opportunity to buy this HOMAG WEEKE Profi BMG 611/60/15/F/AP CNC Wood Machining Centre. Contact us for further details regarding this machine.

Additional equipment

• Safety devices: Laser, bumper

• Torque support: Yes

• Grooving saw: 90° pivoting

• Vertical drilling spindles: 17

• Horizontal X drilling spindles: 2

• Horizontal Y drilling spindles: 2

• Liquid-cooled milling spindle: Yes

• Closed drag chain: Yes

• Handheld terminal: Yes

• HOMAG SaveScan: Yes

Machine Benefits

Technical Machine Benefits

• High spindle speed

Lrsdpeyap S Isfx Ahzeg

• Comprehensive safety features

• Independent z-axes: 2

• 4th axis: yes

• 5th axis: 5-axis spindle

• Workpiece support aids available

• Machine table: console table

• Number of consoles: 12

• Features: automatic table positioning, homag ap table, two stop rows

Extra Information

Conformity marking: CE mark

Dimensions

Machine Depth 6175 mm

Listing

Germany

Germany

1,006 km

HOMAG PROFI BOF 722/58/18/F/K

HOMAGPROFI BOF 722/58/18/F/K

Call

Condition: ready for operation (used), Year of construction: 2005, travel distance X-axis: 6,000 mm, travel distance Y-axis: 1,800 mm, travel distance Z-axis: 380 mm, number of axes: 5, This 5-axis HOMAG PROFI BOF 722/58/18/F/K was manufactured in 2005, featuring a machining range of X = 6000 mm, Y = 1800 mm, and Z = 380 mm. It includes a 5-axis fork head replaced in 2019 and two traveling plate changers with 18 slots each. Ideal for advanced woodworking, consider the opportunity to buy this HOMAG PROFI BOF 722/58/18/F/K CNC processing center. Contact us for more information about this machine.

• 5-axis fork head (replaced in 2019)

• Rear spindle with Flex5 unit

• 2 traveling plate changers, 18 slots each

Lredpfx Aox D Hxfshzeg

• Second vacuum pump, switchable individually

Additional equipment

• Computer with Windows 10 (new ~1.5 years ago)

• WoodWOP 8.1 software

Listing

United Kingdom

United Kingdom

1,006 km

SCM Record 125 N

SCMRecord 125 N

Call

Condition: ready for operation (used), Year of construction: 2007, travel distance X-axis: 3,400 mm, travel distance Y-axis: 1,720 mm, travel distance Z-axis: 400 mm, spindle speed (max.): 18,000 rpm, number of axes: 3, This 3-axis SCM Record 125 N CNC Wood Machining Centre was manufactured in 2007. It features a robust 7.5 kW electrospindle reaching up to 18,000 rpm, and an automatic tool changer with 8 positions. The working area extends to 3400 x 1720 x 400 mm, supported by a vacuum pump of 90 m³/h. If you are looking to get high-quality milling capabilities, consider the SCM Record 125 N machine we have for sale. Contact us for more information.

Additional equipment

• Vacuum Pump: 90 m³/h

Machine Benefits

Technical Machine Benefits

• Work table (between stops): 3100 mm

• Min/max spindle–work table nose distance: 96 / 496 mm

• Maximum piece width in "pendulum" mode: 1090 mm

• Real piece feed play (play): 335 mm (310 mm usable)

• Work table access in pendulum mode (right/left): 550 / 830 mm

• Tool socket: hsk 63

• Tool changeover: automatic, with 8 positions

Lodpfx Ahjyaixzjzsrg

Extra Information

Machine still under power

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Spain

Spain

1,006 km

BUSELLATO easyjet 5.12

BUSELLATOeasyjet 5.12

Call

Condition: ready for operation (used), Year of construction: 2013, travel distance X-axis: 3,686 mm, travel distance Y-axis: 1,555 mm, travel distance Z-axis: 100 mm, number of axes: 3, This 3-axis BUSELLATO easyjet 5.12 was manufactured in 2013, designed for high-accuracy operations in panel processing. It features a CNC-controlled spindle, optimized for drilling, milling, and nesting, with a travel range of 3686mm on the X-axis and 1555mm on the Y-axis. Ideal for wood, MDF, plywood, and composite panels. Consider the opportunity to buy this BUSELLATO easyjet 5.12 CNC Wood Machining Centre. Contact us for more information about this machine.

Additional equipment

• Material Handling: Optimized for wood, MDF, plywood, and composite panels

• Software Integration: Nesting software integration for optimized cutting patterns

• Safety Features: Safety enclosures and interlocks

Machine Benefits

Technical Machine Benefits

• Precision: high-accuracy operations for drilling, milling, and nesting

• Control system: cnc interface (busellato proprietary or compatible)

• Control system: cnc interface (busellato proprietary or compatible)

• Clamping: vacuum or mechanical clamping for panels

• Spindle: cnc-controlled, suitable for drilling, milling, and nesting

• Tool changer: automatic tool changer (depending on configuration)

Lodpfxeyaipte Ahzjrg

Extra Information

Machine still under power

Listing

Romania

Romania

1,006 km

SCM Morbidelli M100

SCMMorbidelli M100

Call

Condition: ready for operation (used), Year of construction: 2019, operating hours: 1,500 h, This 5-axis SCM Morbidelli M100 was manufactured in 2019. It features a large working area of 3110 × 1620 mm, 21 vertical and 12 horizontal spindles, and a maximum rotation speed of 8,000 rpm. The machine includes vacuum suction cups and has been used for approximately 1,500 hours. Consider the opportunity to buy this SCM Morbidelli M100 CNC Wood Machining Centre. Contact us for more information about this machine.

• Machine Condition: Excellent, very little use

• Configuration: 5-axis CNC machining centre

Ledpfoyab Axex Ahzerg

• Working Area (X × Y): 3110 × 1620 mm

• Vertical Spindles: 21

• Horizontal Spindles: 12

• Maximum Rotation Speed: 8000 rpm

• Vacuum System: Including vacuum suction cups

Listing

Germany

Germany

1,006 km

VITAP K3

VITAPK3

Call

Condition: ready for operation (used), Year of construction: 2023, spindle speed (max.): 3,600 rpm, spindle motor power: 5,000 W, number of axes: 3, This 3-axis VITAP K3 CNC Wood Machining Centre was manufactured in 2023. Consider the opportunity to buy this VITAP K3 CNC Wood Machining Centre. Contact us for more information.

Additional equipment

• 20" LCD TFT monitor

• Industrial PC

• WSC user interface with Lister, parametric tools, and parametric setup

• Graphical CAD programming TPA EDI32, basic version

• USB port

• Storage of all files

• Macro programming

• Import of DXF files

• CE compliant

Machine Benefits

Qualitative Machine Benefits

• A showroom machine never used

Technical Machine Benefits

• Feed speed: 25 m/min

• Automatic 4-position tool changer

• Max. Horizontal tool Ø: 12 mm

• Max. Vertical tool Ø: 35 mm

• Motor: 1. 7 kw

• Number of independent vertical spindles: 12 // number of independent horizontal spindles on the x-axis: (2+2)

• Max. Horizontal drilling depth on x and y axes: 35 mm // max. Vertical drilling depth: 43 mm // number of horizontal drilling spindles on the y-axis: (2+2)

• Electro spindle: 5 kw with iso30 taper (rpm 12000–24000)

• Max. Workpiece dimensions: y 1250 mm, z 50 mm

• Min. Workpiece dimensions: x 270 mm, y 150 mm, z 3 mm

Extra Information

Axes: 3 controlled axes (X, Y, Z)

X-Axis: DDT feed system

Y-Axis: Drilling head travel path

Z-Axis: Drilling operations

Optional Upgrades (at Additional Cost):

Tool set for production startup

Tool holder ISO 30 / ER 32

Lubricant cartridges

Lredpfxjx U Ub Sj Ahzsg

PC with a more powerful processor

Additional pneumatic upper pressure

Free Nesting System

Barcode scanner

Post-processor for MPR files

Office software license TPA

Front and rear roller support

Narrow part guides

Optional clamp opening for 60 mm thickness

Angle gear options

CAD design software for furniture construction

Listing

Germany

Germany

1,006 km

OMAKSAN Mastercraft 2137

OMAKSANMastercraft 2137

Call

Condition: ready for operation (used), Year of construction: 2021, travel distance X-axis: 3,700 mm, travel distance Y-axis: 2,100 mm, travel distance Z-axis: 200 mm, spindle motor power: 9,000 W, number of axes: 3, This 3-axis Omaksan Mastercraft 2137 was manufactured in 2021. It features a robust aluminum processing table, a 9 kW IOX spindle, and a 12-fold linear traveling tool changer. The machine includes a Beckhoff control system and drive motors, enhancing its precision and efficiency in wood machining. If you are looking to get high-quality milling capabilities, consider the Omaksan Mastercraft 217 machine we have for sale. Contact us for more information about this machine.

Additional equipment

• Software: Pegasus CAD software with Office license

Machine Benefits

Technical Machine Benefits

• Control system: beckhoff

• Table: aluminum processing table

• Stop rail: aluminum stop rail in x and y direction

• Tool changer: 12-fold linear traveling tool changer

• Drilling spindles: 9 vertical drilling spindles, scm gearbox

• Vacuum pump: 2 x 250m³ becker vacuum pump

Extra Information

Ljdpfx Ahox U T Tmezerg

Machine still under power

Listing

Germany

Germany

1,006 km

INTOREX TKC-1500

INTOREXTKC-1500

Call

Condition: ready for operation (used), Year of construction: 2025, number of axes: 5, This 5-axis INTOREX TKC-1500 CNC Wood Machining Centre was manufactured in 2025. It features a high-performance electrospindle with a 7.5 kW motor, achieving speeds up to 22,000 rpm. The machine includes a rotary tool magazine with 8 slots and an automatic feed unit for workpieces up to 1500 mm in length. Fully enclosed safety guards ensure compliance with EU standards. If you are looking to get high-quality woodworking capabilities, consider the INTOREX TKC-1500 machine we have for sale. Contact us for more information.

Additional equipment

• Unloading unit and part removal via conveyor belt

• Fully enclosed safety guards with pneumatically operated front door

• "Anti-shock" pneumatic cylinders for part damage prevention during unloading

• Headstock support for interchangeable centers

• Abrasive belts, grit 150, dimensions: 170x1500 mm

Machine Benefits

Qualitative Machine Benefits

• Electrospindle (axis b): electric motor with 7. 5 kw power and rotational speed from 0 to 22000 rpm, controlled by the cnc

• Headstock (axis a): 15. 3 kw motor with interpolation and positioning over 360°, continuous rotation speed from 0 to 1500 rpm, cnc-controlled

• Turning or milling head with saw blade (axis y, unit y2): equipped with a 9 kw motor, variable speed from 1000 to 4500 rpm

• Milling head with milling tool (axis y, unit y3): equipped with a 9 kw motor, variable speed from 1000 to 5000 rpm

• Sanding head (axis y, unit y4): with a 2. 2 kw motor and 3000 rpm rotation speed

• Rotary tool magazine with 8 tool slots (axis q): includes 6 tool holders with hsk f63 cone type

• Maintenance tools, hydraulic oil, and operating manual included

Technical Machine Benefits

• Digital osai open 6-axis control system with ethercat interface

• Industrial panel pc 15. 6" ip65 front

• Fanless 15. 6" resistive touchscreen, 1366x768 resolution

• Intel celeron j1900 quad-core 2. 0ghz processor

Lrjdox U T H Hopfx Ahzsg

• 60gb solid state drive (ssd)

• 4gb ram

• Communication ports: 1 x usb front + 3 x usb, 2 x ethernet, 1 x rs-232/422/485, 1 x vga

• Audio – input/output

• Os: windows 10 iot enterprise – embedded

• Intoredit 3d – cad-cam software developed for designing parts and post-processing machining programs

Extra Information

Machine still under power

Listing

Germany

Germany

1,006 km

IMA BIMA CUT 120/240

IMABIMA CUT 120/240

Call

Condition: ready for operation (used), Year of construction: 2003, travel distance X-axis: 4,200 mm, travel distance Y-axis: 1,200 mm, overall weight: 7,200 kg, spindle speed (max.): 15,000 rpm, This IMA BIMA CUT 120/240 was manufactured in 2003. A CNC Wood Machining Centre featuring a processing range of X: 4200 mm, Y: 1200 mm, and a maximum clamping height of 100 mm. It includes a main spindle with a tool holder HSK F63 and a drive power of 7.5 KW. The machine also boasts a tool change magazine with 18 places and a variety of drilling and milling capabilities. Contact us for more information about this machine.

Machine Benefits

Qualitative Machine Benefits

• Drive power: 7. 5 kw in s-1 mode

• Spindle lubrication: one-time factory grease lubrication

• Spindle cooling: water cooling

• An automatic tool/adapter change magazine features a disk changer design with 18 place-coded magazine slots and moves with the support in the x-direction.

• The adapter units include a saw unit (max. 15,000 rpm, 200 mm blade), a horizontal drilling and milling head with 4 spindles (max. 15,000 rpm), a drilling unit for lock case/rung holes (max. 12,000 rpm), a vertical drilling unit s21 (6,000–9,000 rpm, max. 35 mm drill diameter), and a horizontal drilling-sawing unit (4,500–6,000 rpm, max. 125 mm grooving saw, swivel range 0 or 90 degrees).

• Graphical user interface: imawop for pc computer

• Bima cut editor office

• Bima cut editor import interface

• Control for label printers

• Label printer

Technical Machine Benefits

• Max. Clamping height from upper edge of suction plate z1: 100 mm

• Workpiece thickness z2: 14 - 38 mm

• Work table height: approx. 1000 mm

• Alternating field range without pendulum machining x: 2 x 2000 mm

• Free space in the middle x without pendulum processing: 200 mm

Lrodpjx U T Hmsfx Ahzog

• With pendulum processing x: 2 x 1500 mm

• Free space in the middle x with pendulum processing: 1200 mm

• Tool infeed: automatic

• Pull-in force: 11000 n

• Direction of rotation: programmable, clockwise/anticlockwise

Extra Information

Machine still under power

Listing

Austria

Austria

1,006 km

GANNOMAT ProTec 571

GANNOMATProTec 571

Call

Condition: ready for operation (used), Year of construction: 2017, number of axes: 6, This 6-axis GANNOMAT ProTec 571 was manufactured in 2017, featuring a precise steel worktable and a working stroke length of 1000 mm on the X-axis. It includes a drilling unit with 13 vertical and 6 horizontal spindles, a milling unit with a power range of 3000-18000 rpm, and a grooving unit in Y. If you are looking to get high-quality woodworking capabilities, consider the GANNOMAT ProTec 571 machine we have for sale. Contact us for more information.

Machine Benefits

Lodpsx U Thwofx Ahzorg

Technical Machine Benefits

• Working stroke length (x-axis): 1000 mm

• Working height: 905 mm

• Size on x-axis: min. 85 mm / max. 1000 mm

• Size on y-axis: min. 285 mm / max. Unlimited (max. 70 kg)

• Size on z-axis: min. 6 mm / max. 60 mm

• Precise steel worktable

• Drilling unit bk6: 1. 5 kw motor, 3200 rpm

• Vertical spindles: 13 pcs. // horizontal spindles: (3+3) on y-axis, (1+1) on x-axis

• Milling unit: 4. 5 kw, 3000 - 18000 rpm

• Grooving unit on y

Extra Information

Machine still under power

Listing

Misterton

Misterton

274 km

CNC Machine

Infotec1008 Rotary

Call

Condition: good (used), Infotec 1008 Rotary CNC machine

Ledpfx Ahjx Ai T Nszerg

adjustable RPM, manual or auto, 3Ph

Listing

Germany

Germany

1,006 km

HOLZHER Pro Master 7123-320K

HOLZHERPro Master 7123-320K

Call

Condition: ready for operation (used), Year of construction: 2009, This 4-axis HOLZHER Pro Master 7123-320K was manufactured in 2009. It features a large working area with X stroke of 3200 mm, Y stroke of 1445 mm, and Z stroke max of 325 mm. Equipped with six workpiece supports and automatic table setup in X and Y directions, it enhances productivity in complex woodworking tasks. If you are looking to get high-quality milling capabilities consider the HOLZHER Pro Master 7123-320K machine we have for sale. Contact us for more information.

• Axes: 4

• X Stroke: 3200 mm

Lrodpfx Ahox Ut Idezsg

• Y Stroke: 1445 mm

• Z Stroke: max 325 mm

• Traversing Height with 2-Stage Milling Spindle: 428 mm

• 6 workpiece supports, pneumatically clamped

• 4 pcs. suction consoles each

• Each suction console equipped with 2 vacuum cups

• Table automatically set up in X and Y direction

• Stop rows in X-direction, in front and behind

Auction

Auction ended

Gelderland

Gelderland

724 km

CNC horizontal machining center

BiesseRover A 1536 G FR

Condition: ready for operation (used), Year of construction: 2012, functionality: fully functional, machine/vehicle number: 81399, travel distance X-axis: 3,765 mm, travel distance Y-axis: 1,585 mm, travel distance Z-axis: 170 mm, swivel angle C-axis (max.): 360 °, TECHNICAL DETAILS

X-axis travel: 3,765 mm

Y-axis travel: 1,585 mm

Z-axis travel: 170 mm

C-axis: 360°

Worktable zones: 9

MACHINE DETAILS

Dimensions & Weight

Dimensions (L x W x H): 13,500 mm x 2,450 mm x 2,400 mm (l x w x h)

Transport weight: 2,500 kg

Transport packages: 4

EQUIPMENT

Central lubrication

12 kW electrospindle, ISO 30, air-cooled

Ledpfx Ahsx Rbpbjzerg

Biesse WORKS

Biesse NEST MODULE

Air conditioning

16-position rotary magazine

2x vacuum pump 250 m³/h

BH 17 L drilling unit

Loading and unloading system

Listing

Germany

Germany

992 km

CNC Reichenbacher Vision 1 MNR 1476

ReichenbacherVision 1 MNR 1476

Call

Condition: used, Year of construction: 1999, Used machine

Year of manufacture: 1999

Retrofit: 2018

Machine body constructed as a one-piece, compact honeycomb welded design.

X-axis: 3,740 mm longitudinal travel

Y-axis: 1,630 mm transverse travel

Z-axis: 340 mm vertical travel

C-axis: ±360-degree rotary movement

Continuously programmable working speed up to max. 60 m/min in the X/Y plane. Rapid traverse up to max. 85 m/min. Vertical travel up to max. 20 m/min. Rotary movement up to max. 90°/s.

Milling spindle: 10.0 kW (repaired in 2025)

Tool holder: steep taper SK 40

Tool changer: Disc-type changer for 12 tools.

Drilling head: 21 drilling spindles

Central lubrication

Extraction: 250 mm

Vacuum table: The fixed machine table has a smooth tabletop made of a 30 mm thick solid wood plate.

Table size: 3,800 x 1,150 mm

Working area size: 3,740 x 1,430 mm

Table divided into 2 x 1 clamping zones for alternating operation.

Safety system: bumper

Footprint: approx. 7,300 x 3,000 mm

Lsdpfx Ahox Tkgnjzjrg

Retrofit 2018

New control cabinet with Siemens Solution-Line, DriveQlic drive package with new servo motors and cables.

Software for Sinumerik 840Dsl including WIN7 operating system.

Stops: All 11 stops renewed. One additional stop field installed.

Valve terminal converted to Festo Profibus valve terminal.

Bumpers: All bumpers replaced.

Total investment: €93,810 net (documentation available)

Price applies for sale ex-location, for collection no later than calendar week 6/2026

Availability: Immediate

Location: Hesse

Listing

Leipzig

Leipzig

1,139 km

Cnc-processing center

WINTERROUTERMAX 1325 SIM 4SP

Call

Condition: new, Year of construction: 2025, Dimensions (L/W/H) 3300x2100x2100 mm

Ledpfx Asv A Ha Dehzjrg

Weight 1500 kg

Total power requirement 17,5 kw

Listing

Leipzig

Leipzig

1,139 km

Cnc-processing center

WINTERROUTERMAX ATC 2130 ECO

Call

Condition: new, Year of construction: 2025, Dimensions (L/W/H) 4000x2900x2100 mm

Weight 2500 kg

Lsdev A E Uajpfx Ahzorg

Total power requirement 24 kw

Listing

Norway

Norway

936 km

Machining center

SCM Accord25 fxm

Call

Condition: like new (used), Year of construction: 2023, functionality: fully functional, travel distance X-axis: 4,970 mm, travel distance Y-axis: 2,120 mm, travel distance Z-axis: 250 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 30 m/min, feed rate X-axis: 60 m/min, feed rate Y-axis: 60 m/min, feed rate Z-axis: 30 m/min, spindle speed (min.): 600 rpm, spindle speed (max.): 20,000 rpm, spindle motor power: 12,000 W, number of slots in tool magazine: 24, mount diameter: 350 mm, tool weight: 8 g, input voltage: 400 V, type of input current: AC, Equipment: documentation/manual, Complete machine, with Coral filter system and SCM lifter for sale.

The equipment has very little use.

Numeric control machining centre, with mobile gantry and fixed worktable for the processing of solid wood and various types of materials: glued laminated timber, plywood, chipboard, MDF, Aluminium etc.

Designed using the best three-dimensional solid modelling systems, the structure is composed

Lrjdpfx Ahjwd Nrdezjg

of a machine bed and a mobile gantry made of electro-welded steel. Component's milling of machine bed are performed on high quality CNC machining centres, with one single positioning operation, in order to guarantee the very best planarity, perpendicularity and precise tolerances.

The control unit is a numeric control interfaced with an industrial PC.

The CNC solution with PC combines all of the qualities of numeric controls with the user-friendliness typical of personal computers.

The PC allows to use the operator interface Maestro cnc, developed by SCM to make machine programming fast and simple even for the less skilled operator.

Technical specifications:

- drilled and tapped holes spaced 120x120 mm for vacuum connection of jigs and equipment fitting - groove scheme spaced 40 mm for suction cups or rubber gaskets - n. 2 working areas - max. dimension to work in Y direction = 2170 mm

TELESOLVE teleservice via internet

Mobile console with "eye-M PRO" integrated PC

TECPAD - Remote machine control

Mobile console with 7" touch-screen color monitor for control and management.

PRISMA KT Machining Head

The machining head with 5 interpolating axes, fixed directly to the mobile gantry, guarantees maximum strength during routing operations and provides top finishing quality also with high stock removal.

Technical specifications:

Routing unit with 5 interpolating axes

− electro-spindle with HSK 63F quick release tool-holder

− Rotation speed 600-20000 rpm

− right and left rotation

− max power (S1/S6) 11/12 kW (15/16.5 HP) from 9000 rpm

− Inverter

− C-axis rotation = 640°

− B-axis rotation = 270°

− C-axis equipped with TTS locking system (Total Torque System – SCM Patent)

− "For Life" grease lubrication

− liquid cooling with heat exchanger

- Automatic dust extraction hood with four positions and ON-OFF by workpiece program.

Two 250 (300) m3/h - 50 (60) Hz vacuum pumps

Vacuum pump for each half-table. Independent vacuum circuit for each half-table.

PRO-SPACE Safety system

– full protection of the machining head with anti-ejection strips curtains and bumpers with emergency sensors

- Emenency cable in the operator area

- rear and side protection along the perimeter

Enclosed cable-holder chain

MAESTRO ACTIVE Human-Machine interface software (HMI)

Maestro active is the new interface software (HMI) which has been unified across all SCM technologies. A single operator can easily and confidently run multiple SCM machines, reducing operator training times and facilitating entry into production.

Windows 10 embedded 64 bit operating system

Maestro cnc programming software

MAESTRO CNC SOFTWARE SUITE – USER INTERFACE AND PROGRAMMING

Advanced nesting free-form + Label module for Maestro cnc

Rapid 24 - Rear Tool store

Circular tool store anchored to the mobile gantry.

Max load 96 kg

Listing

Almelo

Almelo

738 km

Machining center

CNC-ROUTER DMA-BudgeCraftNesting Professional

Call

Condition: ready for operation (used), Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 50 m/min, rapid traverse Y-axis: 50 m/min, rapid traverse Z-axis: 15 m/min, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, - BudgeCraft CNC ROUTER

- Best Price-Quality CNC

- CNC Router: Wood, Plastic & Aluminum Processing

- High Precision (0.01mm) Milling

- No Annual License Fees

Descriptions:

The most complete CNC machine for wood, plastic, and aluminum. Fully servo-driven for the most complex operations. Starting at €34,500.

- Take advantage of a fixed price for CadCam software and starter kit.

- Assembled in the Netherlands according to the strictest CE standards.

- Powerful 9KW ATC spindle and speeds up to 50m/min.

- Equipped with automatic tool change magazine for up to 16 tools.

- From standard milling jobs to complex projects.

- BudgeCraft offers the highest precision and lowest purchase price for professionals.

Featured Highlights:

* No hidden license fees

* CadCam Professional - translates; Image BMP, JPG, TIF, GIF, PNG vector files

* Formats: Adobe Illustrator, DXF (AutoCAD), EPS, PLT, TXT

* 9kW ATC spindle, air-cooled

* Ready to use

CNC ROUTER:

Precision CNC ROUTER Specifications: Review the technical details of our 0.01mm precision machines.

Work Area & Options: From 1300x2600 - 1600x3200 - 2100x3200mm.

CE Safety: Why our machines are the safest choice for your workshop. Compliant with the New Machine Guidelines 2026.

Full technical specifications available on the Danmar Machines Bv website:

X-Axis work area : 2600, 3200mm

Y-Axis work area : 1300-1600-2100mm

Z-Axis stroke : 200mm

Gantry construction : Yes, servomotors

Spindle motor : 9Kw Servomotor (ATC spindle)

Speed : 1,000-24,000 RPM

X-Axis travel : 50m/min

Y-Axis travel : 50m/min

Z-Axis travel : 15m/min

Holder : ISO30-ER32-ER40

Software : Pegasus PWoodMilling

Ljdpfx Asx Sx Rfehzerg

Vacuum pump : included

Contact us for more information.

Listing

Almelo

Almelo

738 km

Machining center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

Lsdpfx Ajx R D Rnjhzorg

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

Listing

Almelo

Almelo

738 km

Machining center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 20 m/min, controller manufacturer: syntec, workpiece length (max.): 6,000 mm, workpiece width (max.): 2,100 mm, workpiece height (max.): 350 mm, total height: 2,200 mm, total length: 4,200 mm, total width: 2,100 mm, table load: 1,500 kg, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,800 kg, spindle mount: MK 3, number of slots in tool magazine: 10, input voltage: 400 V, type of input current: three-phase, Equipment: documentation/manual, rotational speed infinitely variable, Cost savings for the end customer: €80,000 instead of €40,000

DMA delivers high-quality CNC machines at unbeatable prices by eliminating expensive service contracts and installation visits. Ideal for professionals who want to maintain full control.

Included in the purchase price:

- CNC controller "SYNTEC"

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, after diagnosis (photo/video), spare parts will be supplied free of charge. • Labor costs not included: You can replace the part yourself or commission an external service provider.

• Low-maintenance designs.

• Digital commissioning: Via app or TeamViewer, direct online service. This means technician visits can be avoided, saving both time and costs.

• 24/7 online support.

Digital support as an alternative

• Video tutorials: Clips for calibration or parts replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3,200 x 1,600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9 kW router spindle.

Up to 26 spindle positions.

Row drilling unit optional. Grooving unit optional.

CadCam nesting software.

Pressure rollers (for uneven materials) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-duty CNC milling machine

Type "NESTING"

Working area: 1,300 x 2,600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW router spindle

Lrodpfx Asx Rz Auehzog

Drilling unit optional

Grooving unit optional

CadCam nesting software

Pressure rollers (for uneven materials) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Listing

Almelo

Almelo

738 km

Machining center

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Call

Condition: new, Year of construction: 2026, functionality: fully functional, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at bottom prices by eliminating expensive service contracts and on-site installation visits. Ideal for professionals who prefer to remain in control themselves.

The purchase price includes:

- CNC control “SYNTEC”

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools for sheet metal machining CNC machining centers.

• Parts supply: In the event of a defect within 12 months, components will be shipped free of charge after diagnosis (photo/video).

• Excluding labor costs: Replacement of the part is done by you or outsourced at your discretion.

• Designed with minimal maintenance requirements

• Digital preparation: via app or TeamViewer for direct online service. This makes technician visits unnecessary, resulting in significant cost and time savings.

• Online service: 24/7

Digital Support as an Alternative

• Video manuals: Clips covering calibration or part replacement

• Exploded view diagrams: Instantly identify the necessary component

Focus on functionality: Your machine, your management, our lowest price.

You can call or WhatsApp us for more information and/or to make an appointment.

WhatsApp:

Lrjdpfx Ahoxx Uc Ujzeg

Trust Seal

Dealers certified through Machineseeker

Listing

Neustadt am Rübenberge

Neustadt am Rübenberge

898 km

Machining center

SCMRecord 110

Call

Condition: good (used), Year of construction: 2003, functionality: fully functional, travel distance X-axis: 2,970 mm, travel distance Y-axis: 1,480 mm, travel distance Z-axis: 330 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 25 m/min, controller model: XILOG Plus, table width: 960 mm, table length: 2,970 mm, spindle motor power: 11 W, Machining centre SCM, model RECORD 110 with solid table. Working area 2970 x 1480 x 3302 mm. Milling spindle 11 kW, tool holder HSK F63, tool magazine with 8 positions, vacuum pump with cooling. The detailed technical specification is provided in the attached PDF file.

Ledpfxox Ttlme Ahzjrg

Listing

Shrewsbury

Shrewsbury

301 km

CNC Machining Center

SCMRecord RD 110NTTVN

Call

Condition: excellent (used), Year of construction: 2008, functionality: not functional, machine/vehicle number: AA2/0001518, travel distance X-axis: 6,000 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 300 mm, nominal power (apparent): 10 kVA, controller manufacturer: SCM, workpiece length (max.): 6,000 mm, workpiece width (max.): 1,200 mm, number of spindles: 2, number of slots in tool magazine: 12, input voltage: 400 V, Equipment: chip conveyor, rotational speed infinitely variable, SCM Record RD 110NTTVN CNC Machining Centre, Series: AA2/000518 Year 2008.

In very good condition.

X=6m, Y=1.2m, Z=300m/m.

Currently running software for staircase production.

12 Position Tool Changer with 1 Extra Head.

Rail & Pod machine with 8 Rails.

Can work in 2 Fields.

Front Safety Mats, and Overhead Laser System.

Fully tooled up with complete documentation.

Overall size: 8m. x 2.4m. x 1850m/m (H) Weight : 5000kg.

Can be viewed at: The Old Basket Works, Lyng Road, Burrowbridge, Somerset TA7 0SG

Video and Photos available on WhatsApp

Lredpex Ek Rkofx Ahzjg

Listing

Shrewsbury

Shrewsbury

301 km

CNC Machining Center

SCMRecord 132 TVN

Call

Condition: excellent (used), Year of construction: 2004, functionality: not functional, machine/vehicle number: AA1/013950, travel distance X-axis: 6,000 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 300 mm, nominal power (apparent): 10 kVA, controller manufacturer: SCM, workpiece length (max.): 6,000 mm, workpiece width (max.): 1,200 mm, number of spindles: 3, number of slots in tool magazine: 10, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, SCM Record 132 TVN CNC Machine Centre in very good condition.

Lsdpfx Ahox Ekxzezjrg

Fully tooled up and currently running software for staircase production.

Rail and Pod Machine with 8 Rails.

10 Position Tool Changer with secondary head and Saw Unit.

Can work in 2 fields, Front Safety Mats, Overhead Laser system.

Full documentation available.

Over all dimensions: 8m. x 2.4m. x 1850m/m (H) Weight About 6000kg.

Ready packed for shipment.

Can be viewed at The Old Basket Works, Lyng Road, Burrowbridge, Somerset TA7 0SG

Photos and Video available on WhatsApp

Listing

France

France

1,093 km

CNC Machine Centres With Flat Tables

SCMACCORD 20

Call

Condition: used, machine/vehicle number: 008356, X axis working area: 3650 mm

Y axis working area: 1560 mm

Working Table: Flat table

Main Electrospindle power: 13 KW

Number of controlled axes: 4 axes

Total number of drilling spindles: 18

Lrjdpfx Ahsx Swf Ijzog

Total number of tool changer positions: 26

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used machining centers with flat or grid table (347)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Bed Type Milling

- Bed Type Milling Machine

- Center Lathe

- Cnc Turning And Milling Center

- Flat Bed Cnc Lathe

- Flat Bed Grinding Machine

- Gear Griding Machine

- Machine Table

- Machining Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month