Used Cnc Center for sale (18,555)

Alblasserdam

Alblasserdam CNC turning and milling center

Mori SeikiZT1000Y

Düsseldorf

Düsseldorf CNC turning-drilling-milling center

KlaaßenSDM15-5

Velbert

Velbert CNC turning and milling center

DMG MORICLX 450 TC

Wijchen

Wijchen CNC Horizontal Machine centers SCM Tech Z5 2014 5 Axis

SCMTech Z5

Rodgau

Rodgau CNC machining center

MasterwoodProject TF 100

Discover more used machines

Germany

Germany CNC Turning- and Milling Center

NAKAMURA TOMESuper NTJ

Bremen

Bremen CNC turning and milling center

TRAUBTNX 65/42 DGY

Bremen

Bremen CNC turning and milling center

TRAUBTNA 480

Luckenwalde

Luckenwalde Vertical CNC machining center

HAASVF-4 BHE

Hattingen

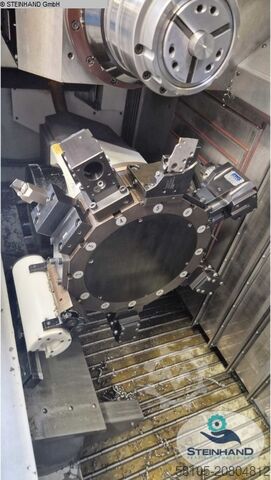

Hattingen CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Bayern

Bayern CNC turn-mill center

DMG MORINTX 2500/1500

Dieburg

Dieburg CNC machining center

ALZMETALLBAZ 15

Dieburg

Dieburg CNC machining center

POSMILLE 2050

Dieburg

Dieburg CNC horizontal machining center

DECKEL MAHODMC 60 H

Dieburg

Dieburg CNC machining center

OKUMAMB-46 VAE

Dieburg

Dieburg CNC turning and milling center

MTRENTMTCUT T20MC

Dieburg

Dieburg CNC machining center

MORI SEIKINH 5000/40

Dieburg

Dieburg CNC turning and milling center

MAZAKSQT 200 MS

Dieburg

Dieburg CNC machining center

SAEILOCONTUR TV 1000

Dieburg

Dieburg CNC machining center

OKUMAEuro Center V50

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERCTX 200 E

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERCTX 420

Dieburg

Dieburg CNC turn-mill center

GILDEMEISTERTwin 500 GMX

Uhingen

Uhingen CNC machining center

DECKEL-MAHODMU100T

Uhingen

Uhingen CNC machining center

Deckel MahoDMU100P DuoBLOCK

Used Cnc Center (18,555)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you