Used Film Development for sale (2,245)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Kraków

Kraków

1,675 km

Image exposure unit

FujifilmLUXEL T-6500CTP S

Call

Condition: excellent (used), Year of construction: 2017, functionality: fully functional, Fuji Film LUXEL T-6500CTP S Thermal Platesetter (2017) – B2 Format

Technical Details and Equipment List:

A. CTP PLATESETTER – LUXEL T-6500CTP S

● Technology: Thermal CTP

● Year: 2017

● Laser Head: 32-channel (S Version)

● Productivity (B2): Up to 21 plates/hour at 2400 dpi

● Max Plate Size: 830 x 660 mm

● Min Plate Size: 324 x 330 mm

● Imaging Area: 830 x 636 mm

● Plate Thickness: 0.15 – 0.30 mm

● Resolutions: 2400, 2438, 2540 dpi

● Power Supply: 200/240 V, 47/63 Hz, Single-phase 35 A / 5 kW

● Weight: 830 kg

● Dimensions (L x W x H): 1985 x 1315 x 1300 mm

● Condition: Used, in daily production. Available for immediate inspection and testing.

Lhedexm Td Hspfx Ahzjb

B. RIP & SOFTWARE SYSTEM

● RIP Processor: FujiFilm XMF PROCESSOR V6 4UP BUNDLE

● Functionality: RIP for B2 format, standard screening, HR/LR output, ICC/DLP/CIP3 support

● License: XMF DONGLE ONLY security key included

● Computer: Dedicated PC for XMF Gateway

C. PLATE PROCESSOR

● Model: FLH-Z 85CD

● Max Plate Width: 850 mm

● Min Plate Length: 285 mm

● Plate Thickness: 0.15 – 0.40 mm

● Developing Speed: 15 seconds (dip to nip)

● Developer Tank: 30 L

● Weight: 364 kg (dry)

Commercial Information:

● Availability: Machine is active in production. Reason for sale is an upgrade to a larger format.

Listing

Valea Mare-Podgoria

Valea Mare-Podgoria

2,312 km

Imagesetter computer to plate

FujifilmCTP Luxel V8 + DEV FCF-125V

Call

Condition: excellent (used), Year of construction: 2014, Fuji Film CTP Luxel V8 & Developer FCF-125V | 2014

Overview:

Complete computer-to-plate package with autoloader and matching plate developer. Ideal for high-volume production.

CTP Unit – Luxel V8-MAL HD:

Maximum plate size (with punch): 1160 × 960 mm

Minimum plate size (with punch): 500 × 400 mm

Large and small plate capability

Autoloader with multiple cassettes (expandable)

Online processing

Dual laser system

Works with violet-sensitive aluminium plates

Compatible with violet-sensitive aluminium plates (405 nm) such as FUJIFILM Brillia LP-NV, HD LP-NV2, and Superia HD PRO-V

High plate output per hour

In excellent operating condition

Developer – Glunz & Jensen FCF-125V:

Plate width: 200 – 1250 mm

Plate length: 290 – 3000 mm

Supports violet chemfree plates

Adjustable plate width, length, and thickness ranges

Variable plate and brush speeds

Lo-Chem technology for reduced chemical usage

Large finisher tank capacity

Multiple voltage configurations available

Condition:

Fully functional and well maintained

Available for immediate inspection

Lhjdew Np Dcopfx Ahzsb

Price: On request

Listing

Rosmalen

Rosmalen

711 km

Moulder

ChambonProfilmax

Call

Condition: not inspected (used), Year of construction: 2002, Chambon (BMH) Profilmax moulder

Description

Infeed table 2000mm

Spindle sequense bottom-right-left-top

Ljdpfxjq Iir Nj Ahzehb

Motorpower 4/4/4/5,5 kW

Power (total) 26kW

Planing width: 230mm

Planing height: 120mm

Spindle diameter 40mm

2000 kg

Dimensions 3250 x 1600 x 1600mm

CE

(All changes, mistakes in technical data, info and prices reserved. Availability subject to prior sales. No guarantee on printed data!)

(Alle Änderungen und Irrtümer in den technischen Daten, Angaben und Preisen sowie Zwischenverkauf vorbehalten! Keine Garantie auf gedruckte Daten!)

Best woodworkingmachines from the Netherlands Holland

Die besten holzbearbeitungsmaschinen aus die Niederlande

De beste gebruikte machines uit Nederland

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Neukamperfehn

Neukamperfehn

747 km

High-bay warehouse

Link 51 Boltless XLFußplatte f. Rahmenprofil M,H,E und S

Call

Condition: new, Technical data for the base plate:

Manufacturer: Link 51

Type: Boltless XL

suitable for frame profile: M,H,E and S

Included in delivery:

01x base plate, new

Material color: sendzimir galvanized

Material thickness: 4 mm

Total width: 96 mm

Total depth: 137 mm

Number of drill holes: 3 pcs.

Drill hole Ø: 14 mm

Weight: approx. 0.480 kg | pcs.

Your contact at our company:

Mr.: Andre Evering

Mr.: Mario Klöver

Mr.: Falk Deutsch

General information about the article:

Lhjdpjrg D Awjfx Ahzeb

This item is only offered for collection. Any additional transportation or shipment of this item is subject to additional costs, which can be requested from us separately depending on the place of delivery or scope of delivery.

Listing

Częstochowa

Częstochowa

1,586 km

High-quality meltblown production line

ReifenhäuserReicofil MB 1600

Call

Condition: like new (used), High-Quality Meltblown Production Line for Nonwovens

A comprehensive machine inspection by the manufacturer's service department was carried out on 17 December 2025.

Report to follow

Operating hours: 80 hours (commissioning only)

Price for a new machine: EUR 7,500,000

• Manufacturer: Reifenhäuser GmbH & Co. KG Maschinenfabrik

• Model: Reicofil MB 1600

Ledpfx Aox Hx Rnohzehb

• Year of construction: 2021

• Last commissioning: 2022

Technical Specifications

• Working width: 1,600 mm

• Material: Polypropylene (PP), MFI 230 / 2.16 > 400 g/10 min

• Output: Up to 65 kg/h per metre width

• Product weight: 10–80 g/m²

• Production speed: 5–80 m/min

• Die head: MB 1600, 50 h/in

• Extruder: RT-1101-1-100, L/D 30

• Heating capacity of rotary beam: 65–172 kW

• Winding station: Contact winder with preset reel change

• Maximum winding diameter: 1,250 mm

• Web width: 1,700 mm

• Winding tension: 10–100 N/m

Additional Equipment and Accessories

• 3-component dosing system

• 80 mm seat changer

• Ultrasonic cleaning system

• Pyrolysis unit

• Ozone extraction

• Cutting knives

• Central control panel with touchscreen and data input

Listing

Hilzingen-Duchtlingen

Hilzingen-Duchtlingen

1,192 km

Four side Planer

ChambonProfil Max

Call

Condition: good (used), Planer moulder 230/120 mm, profiling capable, year 2006

Lodpfxexn Upto Ahzohb

Listing

Dinkelsbühl

Dinkelsbühl

1,170 km

Fully automatic circular saws for aluminium

Pressta-EiseleProfilma KS SW

Call

Condition: new, Suitable for a wide range of applications, especially in the photovoltaic and automotive industries.

We offer fully automatic circular saw machines and complete sawing centers from the "Profilma", "KS", and "SW" series with saw blade diameters up to 650 mm. Loading magazines and unloading systems are customized to your requirements. A high-performance extraction system with oil mist separator completes the comfort package.

Lhedex E U Dnepfx Ahzob

Contact us – together we will find the optimal solution for your production!

Listing

Dinkelsbühl

Dinkelsbühl

1,170 km

Circular saw automatic machine for aluminum profiles

Pressta-EiseleProfilma 510 E-SA

Call

Condition: excellent (used), Year of construction: 2007, Complete saw line consisting of loading unit, fully automatic circular saw, and unloading unit.

Suitable for a wide range of applications, especially in the photovoltaic and automotive industries.

Loading Unit:

- Horizontal loading magazine model HLM

- 4-strand timing belt conveyor

- 6 compartments, each 285mm wide, for profile feeding

- Maximum material height according to the saw cutting area; round material up to max. diameter 130mm

- 3 sliding strips between timing belts as additional support

- Profile length min. 2,700mm, max. 6,500mm

Saw:

- Fully automatic circular saw Pressta-Eisele model PROFILMA 510 E-SA

- Saw blade diameter max. 500mm

- Continuously variable speed adjustment

- Hydro-pneumatic saw blade feed, infinitely adjustable, from rear to front

- Siemens S7-300 control system with touchscreen

- Reversing device with five-fold stroke up to max. 5,000mm

- Electric material feed 3 – 1,000mm (single stroke)

Lsdsxvbvvopfx Ahzehb

- Cutting gap extension on both sides

- Pneumatic unloading slide

- Scrap flap after saw for offcuts / remains

- Cut length depending on profile, from 8mm

- Menzel minimum quantity lubrication system

- Clamping pressure regulation

- Two extraction nozzles for chip extraction

Unloading:

- Table size 1,500mm x 2,500mm

- Pneumatic cross pusher

Listing

Dinkelsbühl

Dinkelsbühl

1,170 km

Circular saw punching/drilling automats

Pressta-EiseleProfilma 502 ST und BG

Call

Condition: new, Fully automatic sawing and punching or drilling in a single machine!

Suitable for a wide range of applications, especially in the photovoltaic and automotive industries.

Compatible with Ø 500 or 550 mm saw blades, reversible mechanism for cut lengths up to a maximum of 4000 mm.

Saw-Punching Automation System Profilma 502 ST-V

• For aluminium and plastic profiles

Ljdjx Haftepfx Ahzohb

• For cutting to length and punching based on the Profilma 502 model

• Fully automatic operation

and

Saw-Drilling Automation System Profilma 502 BG

• For aluminium and plastic profiles

• Cutting to length, drilling, and thread cutting of up to 4 profiles simultaneously

• Fully automatic operation

Listing

Italy

Italy

1,900 km

Planers/Moulding Machines

CHAMBONPROFILMAX

Call

Condition: used, machine/vehicle number: 007243, Max. machinable height: 120 mm

Maximum machinable width: 230 mm

Max. forward feed speed: 12 m/min

Operator shafts number: 4

Lhjdpfx Ahjybavtozob

Listing

Gütersloh

Gütersloh

869 km

2004 Pressta Eisele Profilma 500

Pressta EiseleProfilma 500

Call

Year of construction: 2004, condition: used, Max. saw blade diameter: 500 mm

cutting range up to 80x 200 mm

Feed length: max. 800 mm with digital display

Saw blade speed: 2,000 - 3,800 rpm

Piece counter with automatic shutdown when setpoint is reached

Continuously adjustable pneumatic material feed

Hydropneumatic saw feed

Pneumatic material clamps

Spray device

Including instruction manual

Machine dimensions: 2100 x 1100 x 1500 mm (WxDxH)

1000 kg

Lodpsxn Iq Djfx Ahzehb

Listing

Gütersloh

Gütersloh

869 km

2011 Pressta Eisele Profilma 500 E

Pressta EiseleProfilma 500 E

Call

Year of construction: 2011, condition: used, Max. saw blade diameter: 500 mm

cutting range up to 80x 200 mm

Feed length: max. 800 mm with digital display

Saw blade speed: 2,000 - 3,800 rpm

Piece counter with automatic shutdown when setpoint is reached

Continuously adjustable pneumatic material feed

Hydropneumatic saw feed

Pneumatic material clamps

Spray device

Only 4400 operating hours

Including instruction manual

Ljdpfsxl Dz Tex Ahzshb

Machine dimensions: 2100 x 1100 x 1500 mm (WxDxH)

Listing

Gütersloh

Gütersloh

869 km

2006 Pressta Eisele Profilma 500 E

Pressta EiseleProfilma 500 E

Call

Year of construction: 2006, condition: used, Max. saw blade diameter: 500 mm

cutting range up to 80x 200 mm

Feed length: max. 800 mm with digital display

Saw blade speed: 2,000 - 3,800 rpm

Piece counter with automatic shutdown when setpoint is reached

Continuously adjustable pneumatic material feed

Hydropneumatic saw feed

Pneumatic material clamps

Lhodjvcmirspfx Ahzjb

Spray device

Only 2200 operating hours

Including instruction manual

Machine dimensions: 2100 x 1100 x 1500 mm (WxDxH)

Auction

Auction ended

Piemonte

Piemonte

1,432 km

Planing and moulding machine

CHAMBONPROFILMAX

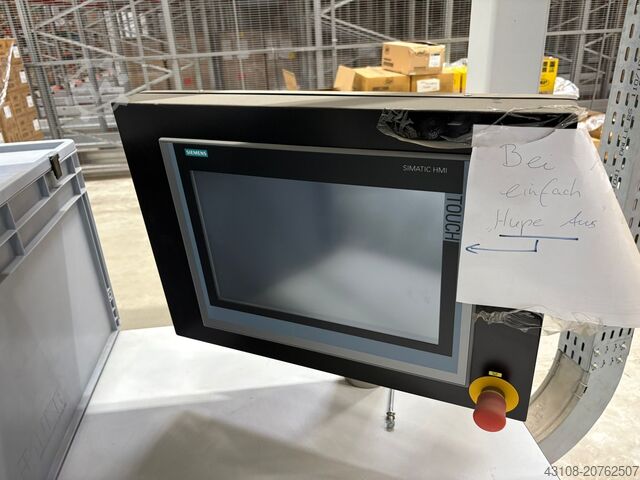

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, feed rate X-axis: 12 m/min, workpiece height (max.): 120 mm, workpiece width (max.): 230 mm, controller model: Siemens Simatic Panel Touch, workpiece length (max.): 8,483 mm, No reserve price – guaranteed sale to the highest bidder!

TECHNICAL DETAILS

Minimum processable height: 6 mm

Maximum processing height: 120 mm

Minimum processing length: 370 mm

Maximum processing length: 8,483 mm

Minimum processing width: 25 mm

Maximum processing width: 230 mm

Maximum feed speed: 12 m/min

Drive rollers

Number of rubber rollers: 1

Number of gear rollers: 4

Total number of rollers: 5

UNITS

Unit 1

Saw spindle: bottom

Spindle diameter: 40 mm

Spindle length: 240 mm

Motor power: 4 kW

Unit 2

Saw spindle: right

Spindle diameter: 40 mm

Lhsdpsxw U Syofx Ahzsb

Spindle length: 240 mm

Maximum tool diameter: 4 mm

Motor power: 4 kW

Unit 3

Saw spindle: left

Spindle diameter: 40 mm

Spindle length: 240 mm

Motor power: 4 kW

Unit 4

Saw spindle: top

Spindle diameter: 40 mm

Spindle length: 240 mm

Motor power: 5.5 kW

MACHINE DETAILS

Control type: Siemens Simatic Panel Touch

Installed total power: 24 kW

EQUIPMENT

CE marking

Auction

Auction ended

Sachsen-Anhalt

Sachsen-Anhalt

1,073 km

Profile grinding machine

Ziersch & BaltruschProfilmaster 40/100 CNC

Condition: ready for operation (used), Year of construction: 1993, functionality: fully functional, machine/vehicle number: 4110BC19, control type: CNC control, MACHINE DETAILS

Performance Data

Connection: 380 V

Frequency: 50 Hz

Rated power: 35 kVA

Fusing: 63 A

EQUIPMENT

Lhedpfx Aexxklxehzsb

CNC control

Listing

Germany

Germany

1,034 km

High-performance automatic sawing m/c

PRESSTA-EISELEProfilma 510

Call

Condition: ready for operation (used), Year of construction: 2008, functionality: fully functional, High-performance automatic sawing machine / Brand: PRESSTA-EISELE

Type: Profilma 510 / Year of construction: 09/2008

Description:

* High-performance automatic sawing machine with fully automatic operation,

* Very high cutting accuracy, * Low cycle times,

* Burdere-free sawing, * High reliability, * Low maintenance

Suitable for aluminum and plastic, for cutting large quantities of small parts,

length tolerance 1/10 mm.

The automatic sawing machine can be inspected and tested by appointment.

Previous use: Used for cutting corner connectors.

Condition: Very well maintained, used, ready to use.

Technical specifications:

- Saw motor: 7,5 kW, S6

- Speed: 2.000 - 3.500 rpm

- Cutting speed: up to 92 m/s

- Material feed length: up to 1.000 mm / 5-fold reversal possible

- Section length: from 8 mm depending on profile

- Remaining piece length: from 90 mm depending on section length

- Working pressure: 6 - 8 bar

- Power supply: Standard: 400 V, 50 Hz

- Weight: 1.750 kg

- Dimensions Length/Depth/Height: 2.700 x 1.400 x 2.300 mm

Equipment:

- Control via Siemens S7 panel

- Fully automatic bar feed

- Roller conveyors

- Extraction

- Chip bunker

- Various accessories

- CE marking

Ljdpfx Ahow D T Uiszehb

There is no guarantee for correctness and completeness of the technical details

and accessories.

Listing

Zamość

Zamość

1,847 km

CUTTING MACHINE

PRESSTA EISELEPROFILMA 450

Call

Condition: excellent (used), Year of construction: 2001, functionality: fully functional, machine/vehicle number: 1015, profiles with dimensions (HxB) up to 100x195mm, 80x200 mm

automatic work cycle

driven by a 3 kW/400 V, 2850 rpm motor

Ledpfx Ahjwgmv Sozohb

cutting disc d=450x3.8x40mm, z=110

horizontal and vertical material clamping on the feed side

dosing spray system

horizontal material clamping in the feeder

moving both clamping jaws when retracting (prevents scratching of the profile)

infinitely adjustable hydropneumatic cutting disc feed

cutting disc exiting from the rear

length of cut sections adjustable in the range of 0-300mm (with reversing device 0-600 mm)

setting the cutting length by a handwheel with a mechanical counter

maximum width of the cut profile 200 mm

cutting range (height x width) 100x195mm, 80x200mm

automatic shutdown when material runs out

possibility of connecting a dust extractor

Listing

Germany

Germany

1,034 km

Banding Machine

MeurerFILMline CMB 600

Call

Condition: ready for operation (used), Year of construction: 2015, operating hours: 5,842 h, A film banding machine with shrink wrapper Meurer packaging machines is available. Banding capacity: 35 products/min, bundle capacity range: 1x5/1x10, product dimensions X/Y/Z min./max.: 120mm x 120mm x 70mm / 265mm x 125mm x 38mm, bundle dimensions X/Y/Z min./max.: 228mm x 265mm x 125mm / 350mm x 120mm x 120mm. Machine dimensions X/Y: approx. 3300mm/3020mm, operating hours: approx. 5842h. Documentation available. On-site inspection is possible.

Ljdevmq Tpspfx Ahzohb

Listing

Duxford

Duxford

436 km

Edwards Rv12 Rotary Vane Pump

EdwardsRv12

Call

Condition: used, This listing is for a Edwards Rv12 Rotary Vane Pump.

The unit is in full working condition and is ready for immediate release.

The Edwards RV12 is a versatile and efficient rotary vane pump designed for high performance, making it an ideal choice for various applications requiring reliable vacuum solutions.

Key Features:

Ultimate Vacuum Pressure: Achieves an excellent ultimate vacuum pressure of 2.0 x 10^-3 mbar, enabling effective vacuum applications.

High Pumping Speeds: Facilitates rapid evacuation, which is crucial for time-sensitive processes.

Superior Vapor Handling: Excellent at managing vapors, making it suitable for applications with volatile substances.

Quiet Operation: Operates at a low noise level of 48 dB, ensuring a quieter work environment.

Fast Acting Inlet Valve: Features an automatic inlet valve for superior anti-suck back protection, preventing backflow and maintaining system integrity.

Mode Selector Switch: This unique feature allows users to easily switch between high vacuum and high throughput modes, adapting to various operational needs.

Lhsdpfx Asxv Dkijhzob

Gas Ballast: The two-position gas ballast is configurable, optimizing the pump’s performance to match specific vacuum requirements.

Easy Maintenance: Designed for user-friendly maintenance, minimizing downtime and enhancing reliability.

Universal Motor: Covers a wide voltage and frequency range (115 to 230V) from a single model, simplifying integration into diverse setups.

Applications:

The RV12 is suited for a wide range of applications, including:

Mass Spectrometry: Ideal for sample analysis requiring stable vacuum conditions.

Electron Microscopy: Provides the necessary vacuum for high-resolution imaging.

Sample Preparation: Essential for preparing samples in various scientific processes.

Research and Development: Supports innovative projects with versatile vacuum needs.

High Energy Physics: Facilitates experiments requiring precise vacuum conditions.

Industrial Processes: Suitable for a range of manufacturing applications.

Chemical Processing: Enables efficient handling of chemical reactions under vacuum.

Freeze Drying: Optimizes the freeze-drying process for sensitive materials.

Filtration and Extraction: Enhances efficiency in laboratory extractions and filtration processes.

Coating Systems: Provides necessary vacuum for thin film deposition.

Laser Evacuation: Supports laser systems by maintaining optimal vacuum levels.

Degassing/Curing: Efficiently debubbles and cures materials like oil and epoxy resin.

Specifications:

Voltage: Operates between 115 to 230V.

Weight: 29 kg, ensuring sturdy construction for stability.

Temperature Range: Effective between 12°C to 40°C.

Noise Level: Maintains a low operational noise of 48 dB.

Oil Capacity: Holds 1 L of pump oil for effective lubrication.

Motor Speed: Operates at 1800 rpm, ensuring consistent performance.

Listing

Borken

Borken

785 km

X-ray diffractometer (XRD)

PANalyticalX’Pert PRO MPD

Call

Condition: used, PANalytical

PANalytical X’Pert PRO MPD X-ray Diffractometer (XRD)

Excerpt from the service report:

Device: PANalytical X’Pert PRO MPD

Report date: 07.07.2021

Work performed:

- Reinstallation and commissioning of the system

- Connection of external supply lines

- Warm-up phase

- Complete alignment of goniometer and additional components

- Maintenance carried out, including replacement of defective parts

Spare parts used:

L 3.6V NC/U3 R15.0X52.0 BATTERY. NI-CD

FAN FOR X-CELERATOR UNIT

FILTER, WATER

Motor PW3050

("Device was not tested in-house")

The X’Pert PRO MPD is a highly versatile and powerful X-ray diffractometer (XRD) designed for structural characterization of crystalline materials. It is ideal for pure research as well as routine applications in industry and academia. Thanks to its modular design, fast detection, and control of temperature and atmosphere, it is excellently suited for both routine analyses and complex in-situ experiments.

Key features:

- Multiple measurement geometries possible:

- Reflection measurements in Bragg-Brentano (θ–2θ) mode

- Transmission geometry for powders in capillaries

- Optional SAXS (Small-Angle X-ray Scattering) for nanostructure analysis

- Radiation source and detectors:

- Typically copper anode (Cu-Kα, λ ≈ 1.54 Å)

- X’Celerator detector (1D, ultra-fast) for parallel data acquisition

- Modular system with PreFIX technology:

Lhsdpfx Aewycatshzjb

- Rapid change of optics and sample stages without recalibration

- In-situ measurements at high temperatures:

- Measurements up to approx. 1200°C possible

- Controlled atmosphere: air, nitrogen, oxygen (limited for reducing atmospheres)

Typical applications:

- Phase analysis and quantitative Rietveld refinement

- Determination of crystallite size, microstrain, residual stress

- In-situ investigation of phase transitions, oxidation, crystallization, etc.

- SAXS measurements for analysis of nanoparticles and pore structures

- Broad range of sample types: powders, thin films, ceramics, pharmaceuticals, catalysts, and more

Technical data (typical)

Property & Specification

Angle range (2θ): approx. 0.5° to 150°

Step size: up to 0.002° or finer

Goniometer: vertical, 0–0, radius approx. 240 mm

Temperature range: room temperature up to approx. 1200°C

Atmosphere: air, N₂, O₂ (limited for reducing atmospheres)

Detectors: X’Celerator (1D), proportional counter

Distribution & application areas:

The X’Pert PRO MPD is in use worldwide at, for example:

- Universities (ETH Zurich, TU Dresden, University of Vienna)

- Research institutes (e.g., Max Planck Institutes, ICN2, IS2M)

- Industry (e.g., materials development, pharmaceuticals, chemistry)

Condition: used

Scope of delivery: (See image)

(Specifications and technical data subject to change and error!)

For further questions, we are happy to assist you by phone.

Listing

Braunschweig

Braunschweig

978 km

Packaging machine for e-commerce

BVM BrunnerCOMTEX 4G

Call

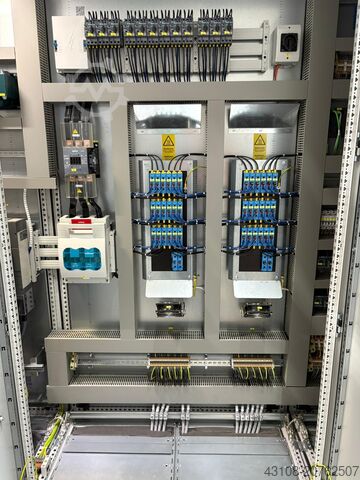

Condition: refurbished (used), Year of construction: 2017, functionality: fully functional, machine/vehicle number: 20170259471, total length: 22,000 mm, total height: 2,000 mm, total width: 2,000 mm, control cabinet length: 2,400 mm, control cabinet width: 400 mm, warranty duration: 12 months, control cabinet height: 2,200 mm, year of last overhaul: 2025, Side Sealing Machine

- Manufacturer: BVM Brunner GmbH & Co. KG

- Machine type: Comtex 4G

- Machine No.: 20170259471

- Year of manufacture: 2017

- BVM reference no.: 5947

- Voltage, Frequency: 3N 400V, 50Hz

- Power specifications: P=18kW, I=26A, F=32AT

- Condition: Fully refurbished with warranty

Comtex 4G Shipping System:

The BVM shipping system ‘Comtex 4G Shipping’ is the complete solution for mailing various items directly to customers, including labeling. Delivery notes, invoices, and goods are packed together in a tightly sealed PE film bag, labeled with the address sticker, and handed directly over to the respective logistics partner.

Technical data:

- Seal width: 750 mm (transverse), 800 mm (longitudinal)

- Product height: up to 250 mm

- Capacity: Up to 25 cycles/min*

(Special) features:

- Special color

- Signal control light with three colors to indicate error messages

- Pneumatically operated buffer plate and presence control for the film waste tray, enabling tray change during automatic operation (no machine stoppage required). Note: At this station, the Comtex working height is limited to 850 +/- 10 mm.

- Electronically controlled sealing bar drive (servo-driven, stepless speed adjustment)

- Film end detection by ultrasonic sensor, incl. analog input card (one per film carrier)

- Mechanical distribution device for film scrap strips in combination with a large film scrap storage

- Individual wire numbering in the control cabinet of the packaging machine for Comtex 3G and 4G

- Grooved aluminum profile covered with plastic profile

- Bypass conveyor as folding belt integrated in the Comtex downstream of the side sealing station for transferring products out of the machine

- Film folding device (no separate control) for converting flat film into center-folded film

- Film sealing device for flat films

Lhedpjw Ryt Djfx Ahzob

- PN/PN coupler (Profinet coupler) for establishing a Profinet connection

- Software development for PN/PN coupling including release connection, interlock and combined fault message

- Film end detection at the film mount and film level detection at the film unwinder, detected by photoelectric sensors, including three-color signal lamp and acoustic signal

- Mounting preparation for labeler, suitable models on request, installed at the infeed including electrical and pneumatic connections

- Sealing bar for producing a wide seal seam with separate cold knife cut, suitable for Comtex 3G, 4G and Compacta with EGS

- Manual labeling device with linear motion (Model: Caljan Type: FPS BVM L113 L)

- Reclosable film bag by means of double-sided adhesive tape in the film bag, incl. tear-off perforation wheel

- Additional tear-off perforation wheel, allowing complete removal of the bag’s edge area

- Stand-alone control cabinet for Comtex with 5 meter cable

- Two sequentially mounted indexing belts (600 x 900 mm/600 x 14,000 mm) for Comtex 4G (total length 14,950 mm) with space for installation of a scanner or camera incl. trigger light curtain for scanner

- Height adjustment of cross seal for pass-through height 220-250 mm

- Cognex scanner system, consisting of:

-- Scanner below the infeed for delivery notes

-- 2 overhead scanners

-- 1 overhead scanner for control

+++ Fully refurbished equipment with 12-month warranty according to our attached warranty conditions +++

Trust Seal

Dealers certified through Machineseeker

Listing

Sunderland

Sunderland

142 km

Laminating sleeking machine

GMPQTopic380

Call

Condition: excellent (used), Now in stock at Glendale we have this GMP QTopic 380 Laminator with Foiling/Sleeking rewinder. Having been within a small digital implant, this laminator has had little use. The laminator is in perfect working order and includes the air compressor and foiling unit.

Raising ordinary print work to 'extra-ordinary'.GMP QTopic 380 has been developed to meet specific print finishing requirements and built to exacting technical standards – with fully controllable pressure and heat processes, devised to deliver optimum results with today's digital print output.

Lhsdpfx Ahowi T Tvszob

The GMP QTopic 380 offers pneumatic pressure which is required to get a great finishing when laminating and/or foiling is required. The pneumatic pressure is supplied by the integrated silent air compressor housed in the Qtopic 380 stand. This semi-automatic system is hand feed with automatic sheet separation. Capable of working at speeds up to 10 metres per minute the QTopic 380 can laminator over 1300 SRA3 per hour.

Turnaround times and waste are further minimised with the unique 'burst separation' system. The laminating film is micro-perforated on the edge by the robust marking device and then separated by the pneumatic burst roller. This easily separates the laminated sheets prior to the actual edge of the media, leaving clean and square datum edges from which to measure, cut, fold or guillotine.

Faultless lamination. Class-leading lamination for the commercial and digital printer. Using state-of-the-art technology, combined with integrated pneumatic pressure, the QTopic 380 delivers superior bonding and faster production times – compared to standard systems. In addition, the fully adjustable heat and pressure combinations enable a wider range of laminates to be used with litho or digital printed media.

Stunning foiling. For today's printers who demand stunning results with that extra ‘wow’ factor – the GMP QTopic 380 delivers more than just class-leading lamination. Metallic, coloured, patterned or holographic style foils can be added to digitally printed materials in either spot or flood treatments. This decorative effect traditionally would involve costly custom die production to create these effects. However, the QTopic can deliver instant and affordable results - and with upgraded pneumatic pressure, an even wider choice of media is now suitable for great results!

Specifications

Manufacturer GMP

Model QTopic 380

Year 2021

Condition Refurbished

Stock Number 114941

Laminating speed 1.5m to 10m/min

Paper weight 110-400gsm

Warm up time 5 minutes

Laminating temperature up to 150°

Temperature control Touch screen

Speed control Touch screen

Roller pressure Pneumatic

Film core (mm / inches) 77mm 3"

Electrical requirements 220/240v 50/60Hz

Machine weight 187kg

Dimensions L2010mm x W710mm x H1475 - all when in use

Listing

Nürnberg

Nürnberg

1,181 km

Screen printing machine

ESC, M&R, SchulzeESC

Call

Condition: good (used), Year of construction: 2016, functionality: fully functional, ESC screen printing machine model 600 H/E, semi-automatic, print format max. 400 x 550 mm

Precision printing machine with vertical frame lifting designed for high-quality, precise screen printing on foils, scales, circuits, panels, glass, etc.

Standard equipment:

- vertical frame lifting with pressure in the longitudinal direction from right to left

- pneumatic drive, infinitely adjustable

- hardened and ground guide shafts with ball guides

- pneumatic maintenance unit

- pneumatic squeegee head with fine adjustment and automatic, vertical lifting for screen changing and cleaning

- flood squeegee device

- individual function control for setup operation

- individual cycle with operation via foot switch

- automatic cycle via timer

- modern, synchronized screen frame lifting

- print path adjustment infinitely via limit switch

- metal vacuum base plate with micrometric fine adjustment in x-y axis

- central height adjustment of the Printing unit via trapezoidal thread spindles

- stepless squeegee angle adjustment readable via scale

- squeegee quick release fasteners

- printing and flood squeegee separately adjustable via pressure regulator and readable via pressure gauge

Technical data model 600 H/E:

Vacuum plate: 500 x 700 mm

max. printing format: 400 x 550 mm

max. printing material height: 8 mm

max. frame format: 600 x 850 mm

micrometric fine adjustment: ± 10 mm

air consumption: 11.3 I

electrical connection: 110V/5A 230V/3.5A

max. cycle performance: 1200 p/h

Dimensions:

Width: 1000 mm

Depth: 800 mm

Height: 1700 mm

Packaging dimensions: 1000 x 880 x 1860 mm Net weight: 250 kg

Gross weight: 375 kg

• two printing squeegees - length according to customer specifications

• two flood squeegees - length according to customer specifications

Powder Machine 4050

Lsdpfx Ahovvwbfszohb

The Powder Machine was specially developed for the easy powdering of DTF transfers. The continuously adjustable film holders allow films up to 40 x 50 cm to be processed. The thermal powder is evenly distributed on the film with one hand. Thanks to the vibration, the excess thermal powder is removed from the film. The thermal powder only sticks to the printed areas. With the Powder Machine you always achieve the optimal application of thermal powder for your transfers.

Technical data:

Dimensions: 79 x 42 x 64 cm

Operating voltage: 230 VAC

Power: 35 W

Max. format: 40 x 50 cm

Time setting: 0 - 3 seconds

Volume: less than 70 dB (A)

Net weight: 27.5 kg

Shipping weight: 44 kg

M&R Economax II small dryer

Listing

Bad Driburg

Bad Driburg

921 km

Sofa packaging line

ARTEMIS

Call

Condition: new, Year of construction: 2025, functionality: fully functional, total height: 2,808 mm, total width: 4,850 mm, warranty duration: 12 months, total length: 14,875 mm, Artemis

Upholstered Furniture Packaging Line

Efficiency Meets Protection – The Modern Solution for the Furniture Industry

Whether sofa, armchair, or entire living room sets: The "Artemis" sofa packaging line brings speed, precision, and security to your packaging processes. Say goodbye to time-consuming manual packaging and unnecessary material consumption – with Artemis, you secure your furniture swiftly, economically, and reliably for transport and storage.

Technical Description

The Artemis sofa packaging line has been specifically developed for the requirements of modern upholstered furniture manufacturers. It enables fast, material-saving, and secure packaging of sofas, armchairs, and other bulky furniture items.

Automatic Packaging Process: Combination of stretch film and protective material application for optimal transport protection

Flexible Application: Suitable for various sofa and armchair dimensions, rapid changeover without long downtimes

Robust Construction: Industry-grade steel frame, durable drive technology, designed for multi-shift operation

User-Friendly Control: Intuitive touch panel with recipe management, easy operation, and minimal training requirements

Energy and Material Efficiency: Optimized film dispensing reduces consumption and lowers ongoing costs

Safety Standards: CE-compliant, equipped with modern safety systems and emergency stop features

Key Advantages

Cost Savings: Significantly lower material consumption compared to manual packaging

Process Optimization: Automated processes reduce staffing requirements and throughput times

High Product Quality: Consistent, tight, and secure packaging reliably protects furniture from dust, moisture, and transport damage

Scalability: Designed for growing production volumes—from medium-sized to large-scale furniture manufacturers

Lhedpfxsw Rybuj Ahzeb

Sustainability: Resource-efficient packaging system with reduced film thickness and optional recyclable materials

Typical Areas of Application

Furniture manufacturers

Logistics centers for upholstered furniture

Packaging service providers for bulky goods

Mattress manufacturers

Listing

Borken

Borken

777 km

Fully automatic pallet wrapping machine

CousinsLPSWA-CE („The Switch Semi2Auto“)

Call

Condition: excellent (used), Year of construction: 2021, Semi & fully automatic pallet wrapping machine

Manufacturer: Cousins

Model: LPSWA-CE (“The Switch Semi2Auto”)

Operating mode: Semi-automatic & fully automatic

Year of manufacture: 2021/2022

Functions and specifications of the LP-SWA-SERIES

Production speed: Up to 35 loads per hour.

Load capacity: Maximum load weight: 4,500 lbs dynamic - 10,000 lbs static

Maximum load size to safely pass the tower: 67“ x 67” (96“ load diagonal) x 80” H

Maximum load size to stay inside the turntable: 46“ W x 46” L (65“ load diagonal) x 80” H

Low profile turntable: 65” diameter, laser-cut steel top with all-around deck protection.

Maintenance free

54-roller bearing support system.

Turntable height 2.813 inches from floor.

ANSI No. 50 direct chain drive with chain tensioner.

Speed between 3 and 12 rpm with smooth start acceleration

Film carriage elevator: 1/2 HP DC motor with variable speed

ANSI No. 40, direct chain drive with shock absorber and fall protection

Automation functions: Fully electric - no pneumatics required

Cousins Smart Engineering has developed the A-Arm, an advanced cutting and holding device. It offers significant productivity gains and safety benefits. This technology is only available on Cousins machines.

This unique method of applying and cutting stretch film offers you the following benefits:

- Selectable banding function at the top

- Stabilizes the load early in the wrapping cycle

- Places the film end at the top of the load instead of the bottom

- There is no film clamp on the turntable that can be damaged by dirt or operator error - and

Also, no slip rings are required to power the turntable, reducing maintenance requirements

- Load placement on the turntable is not critical

- No air connections or noisy compressors

- New automatic load detection safety feature on first rotation detects unevenly

or partially stacked top layers and automatically adjusts the A-arm height to avoid obstructions

- A-arm fall protection

Control functions:

Electronic control with LED user interface

Wireless start/stop remote control with one transmitter (additional transmitters available)

Power off - power on - reset switch and operation indicator

Automatic wrapping cycle start/pause with just one button

Cycle pause for applying the cover sheets

Reinforce the wrapping control for the wrapping center

Emergency stop button

Turntable jog button

Buttons for lowering and raising the film carriage

Film tension control (force-to-load)

Lhodpfowb A N Rsx Ahzjb

Separate speed controls for raising and lowering the film carriage

Variable speed control of the turntable

Three-beam automatic load height detection sensor for dark or shiny loads

Separate control for 1 to 12 turns top and bottom wrapping

Selectable parameters for reduced film tension to wrap the top and/or bottom of the load

Non-proprietary UL/CSA approved components

A - B - C wrapping program selector with the option of entering and saving individual wrapping parameters for each program

Product video 1

Product video 2

Product video 3

You can find more items - new and used - in our store!

International shipping costs on request!

We make it easier for you to find: "film development"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Film Development (2,245)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month