Used Genome Sequencer for sale (347)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Weeze

Weeze

763 km

Planer

Rhino XL800XL800

Call

Condition: used, Year of construction: 2018, functionality: fully functional, planing height: 230 mm, planing width: 320 mm, FEM9-32XC / RHINO 800XL Feeler-series 9

FEELER series

A. Capacity:

(1) Working width: 18–320 mm

(2) Working thickness: 6–160/230 mm

(3) Minimum working length: 240 mm

(4) Feed speed: 7–36 m/min

B. Motor:

(1) 1st bottom horizontal spindle: 10/20 HP with outboard bearing

(2) 2nd right vertical spindle: 10/15 HP with outboard bearing

(3) 3rd left vertical spindle: 10/20 HP with outboard bearing

Klsdpfxjxrla Re Addjl

(4) 4th top horizontal spindle: 10/20 HP with outboard bearing

(5) 5th bottom horizontal spindle: 10/20 HP with outboard bearing

(6) 6th right vertical spindle: 10/15 HP with outboard bearing

(7) 7th left vertical horizontal spindle: 10/15 HP with outboard bearing

(8) 8th top horizontal spindle: 10/20 HP with outboard bearing

(9) 9th bottom horizontal spindle: 10/20 HP with outboard bearing

(10) Feed drive: 15 HP (Inverter)

(11) Elevation: 2 HP

C. Spindles:

(1) Spindle diameter: 50 mm for 1st, 2nd, 3rd, 4th, and 9th spindles; 40 mm for 5th, 6th, 7th, and 8th spindles

(2) Spindle cutting speed: 6200 rpm

(3) Adjustment range, vertical spindle: 80 mm

(4) Adjustment range, horizontal spindle: 35 mm

D. Cutting circles:

(1) 1st bottom horizontal spindle: 100–180 mm

(2) Right vertical spindle: 110–250 mm

(3) Left vertical spindle: 110–250 mm

(4) 1st top horizontal spindle: 110–250 mm

(5) 2nd bottom horizontal spindle: 110–250 mm

(6) Right vertical spindle: 110–250 mm

(7) Left vertical spindle: 110–250 mm

(8) Top horizontal spindle: 110–250 mm

(9) Bottom horizontal spindle: 110–250 mm

E. Miscellaneous:

(1) Dust extraction port diameter: 160 mm

(2) Infeed table: 2–2.5 m

(3) Feed roller diameter: 140 mm

(4) Includes 50 mm cutterhead

F. Standard Equipment:

(1) Digital feed speed display: DPRLF-40K

(2) Automatic table lubrication system

(3) Centralized point-to-point lubrication

(4) Pneumatic chip breakers on top spindles

(5) Pneumatic fence on left spindles

(6) CE marking

(7) Motor: IE3

(8) Sequence: Bottom, Right, Left, Top, Bottom, Right, Left, Top, Bottom

Options:

• OP014-15 Variable Feed Speed Controller, 15 HP inverter

• OP001 Pneumatic control for 1st and 2nd elevation infeed roller

• OP041 Outboard bearing for 2nd, 3rd, 6th, and 7th spindles

• OP017 Digital position controller for 3rd, 4th, 7th, and 8th spindles

• OP042C Enhanced sound enclosure

• OP023AE3-15 Feed motor, 15 HP (E3)

• OP023BE3-10-15 Motor for 10/15 HP spindle (Y/A, E3)

• OP008-5 Extension table, 2.5 m with stand and fence

• OP023BE3-10-20 Motor for 10/20 HP spindle (YiA, E3)

• OP002 Three-mode feed roller pneumatic elevation

• OP010-230 Extra working height 230 mm for 2nd, 3rd, 6th, and 7th spindles

• OP008A Air cushion table, 320–400 mm

This translation uses precise, industry-standard terminology suitable for specialized machinery listings.

Listing

Bitburg

Bitburg

902 km

Wide planer

MartinT45 - sofort verfügbar -

Call

Condition: new, Year of construction: 2024, Martin T 45 thickness planer with XPLANE cutterblock

The T45 thicknessing machine offers ideal conditions for modern production:

It delivers cleanly planed surfaces, is quick and easy to operate and works extremely quietly.

and works extremely quietly. The standard electronic control system makes

Thanks to 99 storable planing dimensions, setting the planing height is so easy that even the

the first workpiece fits perfectly. Of course, the

thicknessing table can also be moved at the simple press of a button, or can be incremented by 0.1 mm.

upwards. The switching elements of the feed control are also within easy reach.

Kledjqlck Nopfx Addsl

reach. The heavy, vibration-damping composite stand with the high-quality

the high-quality bearing-mounted planing shaft guarantees excellent surfaces. Thanks to the sound-insulating

construction, you can work quietly even in the standard version.

- Planing width: 630 mm

- Weight: approx. 1,200 - 1,400 kg

- Planing height: 2.8 - 300 mm

- Table length: 1,260 mm

- Workpiece length min.: 270 mm

- Speed: 5,000 rpm

- Operation: 1-axis control for planing dimension, max. 99 values can be stored, 49 of which can be used for a freely programmable planing sequence; button for manual quick and fine adjustment of planing thickness according to digital display, push button for cutterblock start and stop, integrated operating hours counter

- Cutterblock: Xplane solid steel cutterblock

Cutterblock with 3 spiral rows of knives (33 cambered hard metal knives per row), delivery includes full set of knives and a Torx T20 T-wrench; shaft speed 6,000 rpm included;

The emission sound pressure level LpA during processing is reduced by 10 dB(A)

- Thicknessing table: Electric thicknessing table adjustment with fine adjustment, travel speed 10 mm/s, mounted on 4 support spindles to prevent tilting, table surface precision-planed

- Feed: 2 speeds 6 / 12 m/min, can also be selected electrically during planing, large rubber feed rollers Ø 85 mm to compensate for different thicknesses of wood, rubber rollers are gentle on the material and self-cleaning, easy roller change; link pressure beam at the infeed

- Suction system: Swivel-up, split hood with chip extraction nozzle Ø 160 mm, can be connected optionally on the left / right (in special cases on both sides); minimum extraction air volume: 27 m³/min. at 20 m/s

- Maintenance device: Central lubrication strip for oil lubrication points; bearing / cutter shaft lubrication via nipple

- Accessories: 1 grease gun, filled with long-life grease

1 oil gun

1 open-end wrench

1 tool for blade change

1 pair of blind knives 640 mm

2 pairs of TERSA reversible knives 640 mm CV

- Emission values: Emission sound pressure level at the workplace LpA according to DIN EN ISO 11202 [dB(A)]

Idle noise (without extraction) P1 65

Idle noise (w. extraction) P1 77

Operating noise (without extraction) P2 65

Operating noise (with extraction) P2 78

Sound power level LWA according to DIN EN ISO 3746 [dB(A)]

Idle noise (without extraction) 84

Operating noise (with extraction) 90

Dust emission Low dust emission according to DGUV 209-044 / BGI 739-1

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

902 km

Wide planer

MartinT45 - sofort verfügbar -

Call

Condition: new, Year of construction: 2024, Martin T 45 thickness planer with Tersa cutterblock

The T45 thicknessing machine offers ideal conditions for modern production:

It delivers cleanly planed surfaces, is quick and easy to operate and works extremely quietly.

and works extremely quietly. The standard electronic control system makes

Thanks to 99 storable planing dimensions, setting the planing height is so easy that even the

the first workpiece fits perfectly. Of course, the

thicknessing table can also be moved at the simple press of a button, or can be incremented by 0.1 mm.

upwards. The switching elements of the feed control are also within easy reach.

reach. The heavy, vibration-damping composite stand with the high-quality

the high-quality bearing-mounted planing shaft guarantees excellent surfaces. Thanks to the sound-insulating

construction, you can work quietly even in the standard version.

Ksdpfsqlckpox Addsll

- Planing width: 630 mm

- Weight: approx. 1,200 - 1,400 kg

- Planing height: 2.8 - 300 mm

- Table length: 1,260 mm

- Workpiece length min.: 270 mm

- Speed: 5,000 rpm

- Operation: 1-axis control for planing dimension, max. 99 values can be stored, 49 of which can be used for a freely programmable planing sequence; button for manual quick and fine adjustment of planing thickness according to digital display, push button for cutterblock start and stop, integrated operating hours counter

- Cutterblock: TERSA solid steel cutterblock Z4 Ø 125 mm; incl. blocking for easy cutter change

- Thicknessing table: Electric thicknessing table adjustment with fine adjustment, travel speed 10 mm/s, mounted on 4 support spindles to prevent tilting, finely planed table surface

- Feed: 2 speeds 6 / 12 m/min, can also be selected electrically during planing, large rubber feed rollers Ø 85 mm to compensate for different thicknesses of wood, rubber rollers are gentle on the material and self-cleaning, easy roller change; link pressure beam at infeed

- Suction system: Swivel-up, split hood with chip extraction nozzle Ø 160 mm, can be connected optionally on the left / right (in special cases on both sides); minimum extraction air volume: 27 m³/min. at 20 m/s

- Maintenance device: Central lubrication strip for oil lubrication points; bearing / cutter shaft lubrication via nipple

- Accessories: 1 grease gun, filled with long-life grease

1 oil gun

1 open-end wrench

1 tool for blade change

1 pair of blind knives 640 mm

2 pairs of TERSA reversible knives 640 mm CV

- Emission values: Emission sound pressure level at the workplace LpA according to DIN EN ISO 11202 [dB(A)]

Idle noise (without extraction) P1 65

Idle noise (w. extraction) P1 77

Operating noise (without extraction) P2 65

Operating noise (with extraction) P2 78

Sound power level LWA according to DIN EN ISO 3746 [dB(A)]

Idle noise (without extraction) 84

Operating noise (with extraction) 90

Dust emission Low dust emission according to DGUV 209-044 / BGI 739-1

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HebrockF4 - Kurzfristig verfügbar -

Call

Condition: new, Year of construction: 2025, Hebrock F 4

For complete processing of your panels

For all those who don't want to do things by halves. With the F 4, we offer you a model with which you can produce fully processed edges on a machine length of just 4 m. The F 4 is not only space-saving, but also extremely attractive in terms of price-performance ratio.

Max. Edge thickness 3 mm

Min/Max. Workpiece thickness 8 - 50 mm

Min. workpiece length approx. 160 mm

Feed speed approx. 7 m/min.

Ready for operation approx. 3.5 min.

Max. Power consumption Ø approx. 7.4 kW

Electrical connection 400 V - 3 Ph - 50 Hz

Work table height approx. 900 mm

Machine dimensions approx. 4050 x 1300 x 1400 mm (LxWxH)

Weight approx. 820 kg

Suction nozzle Ø 1 x 140 mm

PLC control 10″ touchscreen

Top-mounted rapid-heat adhesive container (maintenance-free)

Support plate for edging material

Automatic central lubrication (cross-cut saw, corner router)

Visual display for workpiece sequence

Extension arm (can be pulled out to the front)

Interchangeable basin pre-equipment incl. adhesive changing device for PUR processing

Surface scraper with dual tracing

Pneumatic roller capping (scissor cut design, Hebrock system)

Double roller top pressure (ball bearing)

Transport chain with bolted special chain plates

Jointing cutter

Milling unit

cross-cut saw

Corner cutter

Accessories:

F4/09 Radius scraper (incl. pneumatic lift)

F4/09/4 Multi radius scraper (R1/R2)

F4/30 Pneumatic 3-point adjustment

Location: From stock 54634 Bitburg

- available at short notice -

Ksdjhqadcspfx Addell

Listing

Bitburg

Bitburg

902 km

Carcase press

GannomatConcept 70 Easy

Call

Condition: new, Year of construction: 2026, FLAT PANEL CASE CLAMP

GANNOMAT "CONCEPT 70 EASY 170"

Fully equipped in standard configuration with:

Kljdsw Sgnkopfx Addel

- Sturdy, torsion-resistant steel frame made with welded and bolted construction

- Lateral pressing beam with continuous pressure surface, equipped with a 25 mm thick coated support plate

- Counter-pressure surfaces (side pressure wall, base) are continuous, 25 mm thick coated support plates

- Electromotoric adjustment of the pressing beam via precision trapezoidal threaded spindles (with increased pitch and concentric accuracy) and high-performance carriage nuts with grease reservoir

- Pressing is performed by electromotor via worm gear motor (0.75 kW)

- The pressing force of the pressing beam is infinitely variable and electronically set via potentiometer, regulated by frequency converter, allowing completely wear-free pressure force control

- Pressing force for vertical pressing beam: min. 300 daN (kg) up to stepless max. 2200 daN (kg)

- Pressing and adjustment speed of the pressing beams with fine positioning, via 3-stage selector switch: 5 / 10 / 25 mm per second

- Jog mode for precise positioning of the pressing beam, e.g. for low pressing forces such as drawers, etc.

- Extremely simple operation via two separate pushbuttons; two motion sequences (open/close) can be selected via controller

- Freely adjustable pressing time preselection 0–30 min (switchable to seconds or hours), with individually programmable opening dimensions for both pressing beams

- Re-pressing function to increase or decrease the pressing force during the pressing process

- Working height/loading height: 200 mm

- Working dimensions:

Length min: 150 mm, max: 1300 mm

Height min: 150 mm, max: 1700 mm

Depth: 700 mm

Electrical connection: 400 Volt, 50 Hz, 16 A

Available: at short notice

Discover more used machines

Listing

Bitburg

Bitburg

902 km

Welding fume extraction

SchweisskraftSRF Master XL

Call

Condition: as good as new (ex-display), Year of construction: 2026, SRF Maxi. (Picture on the right)

Klodpfxodqzcve Addel

3 m suction arm

Scope of application

Medium smoke and dust

Regular usage

Use

Little run the extractor hood

required

Contamination free filter change

Safe operation due to phase sequence detection

High efficiency due to long

Service life of the filter

Properties

Safe operation through filter monitoring

Extractor hood 360 degree rotating and swivelling

Automatic start/stop system (optional)

Workplace lighting (optional)

Technical data

Procedure 2-speed

Filter type disposable filter

Filter surface approx. 20 m ²

ᐳ 99% filtration efficiency

Filter material of non-woven polyester

Welding smoke off vagina class W3

Additional filter pre-filter (ALU knitted fabric)

Basic data suction capacity Max 1,100 m³/h

Extraction arm diameter Ø 150 mm

Extraction arm, length 3 m

Diameter suction connection Ø 150 mm -.

Power supply 3 x 400 V / 50 Hz

Motor 1,1 kW

Noise level 70 dB(A)

Dimensions (W x D x H) 790 x 815 x 1080 mm

Weight 71 kg approx. 120 kg

Listing

Bitburg

Bitburg

902 km

Edge banding machine

HEBROCKK36 Neumaschine sofort verfügbar -

Call

Condition: new, Year of construction: 2025, The Hebrock K 36 Top equipment with motorized adjustment - Exhibition piece - New machine -

- immediately available -

This Hebrock endurance racer offers unimagined possibilities. Developed for the highest demands, the K 36 stands for absolute reliability and productivity in daily use. With the option of equipping the machine with a step cutter and a multi-radius scraper, Hebrock is setting new standards in the field of perfect edge processing of various edge thicknesses.

max. edge thickness: 3 mm

max. workpiece thickness: 60 mm

Ready for operation in 6 min.

Max. Edge thickness 3 mm

Min/Max. Workpiece thickness 8 - 60 mm

Min. workpiece length approx. 140 mm

Feed speed approx. 15 m/min.

Ready for operation approx. 6 min.

Max. Power consumption Ø approx. 7.4 kW

Electrical connection 400 V - 3 Ph - 50 Hz

Work table height approx. 900 mm

Machine dimensions approx. 5250 x 1230 x 1430 mm (LxWxH)

Weight 1750 kg

Equipment:

Hebrock K 36 - 15 m/min

Kodei Am Ukepfx Addsll

Edge banding machine K36

With PLC control (incl. 15'' touch screen), hot melt adhesive application to the workpiece

workpiece for edgebanding material up to 3 mm; jointing cutter (incl. slide tool)

up to 3 mm routing depth, maintenance-free, coated glue tray with

HF double-motor cross-cut saw station (approx. 12000 rpm), HF trimming station (approx. 12000 rpm) with pneumatic trimming adjustment and interchangeable panel trimmer (combi version), corner rounding trimmer, radius scraper, surface scraper (incl. cleaning station, robust chain drive, ball-bearing mounted double roller top pressure, unit viewing window from the rear of the machine and operator side, signal lamp for workpiece sequence, extendable workpiece support, feed approx. 15 m.

support, feed rate approx. 15 m/min, gluing up to 60 mm workpiece thickness

36/08/1 Quick-change equipment for corner router

36/08/2/1 additional exchangeable motor corner router R=1

36/09/1 Multi-radius scraper

36/24/1 Release agent spraying device

36/24/2 Cleaning agent spraying device

36/25 Protective spraying edge

36/27 Nesting (1x milling station + 1 x radius scraper)

36/30 Pneumatic 3-point adjustment

36/30/1 Multitool for HF milling station (R2/R1/bevel)

36/45 Axis package Motorized adjustment of panel, edge thickness and joint milling depth

jointing depth adjustment

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

902 km

Thickness Planers

MartinT45 - sofort verfügbar -

Call

Condition: new, Year of construction: 2025, Martin T 45 thickness planer with Tersa cutterblock

Accessories: 7,5 KW

The T45 thickness planer offers ideal conditions for modern production:

It delivers cleanly planed surfaces, is quick and easy to operate and works extremely quietly.

and works extremely quietly. The standard electronic control system makes

Thanks to 99 storable planing dimensions, setting the planing height is so easy that even the

the first workpiece fits perfectly. Of course, the

thicknessing table can also be moved at the simple press of a button, or can be incremented by 0.1 mm.

upwards. The switching elements of the feed control are also within easy reach.

reach. The heavy, vibration-damping composite stand with the high-quality

the high-quality bearing-mounted planing shaft guarantees excellent surfaces. Thanks to the sound-insulating

construction, you can work quietly even in the standard version.

- Planing width: 630 mm

- Weight: approx. 1,200 - 1,400 kg

- Planing height: 2.8 - 300 mm

- Table length: 1,260 mm

- Workpiece length min.: 270 mm

- Speed: 5,000 rpm

- Operation: 1-axis control for planing dimension, max. 99 values can be stored, 49 of which can be used for a freely programmable planing sequence; button for manual quick and fine adjustment of planing thickness according to digital display, push button for cutterblock start and stop, integrated operating hours counter

- Cutterblock: TERSA solid steel cutterblock Z4 Ø 125 mm; incl. blocking for easy cutter change

- Thicknessing table: Electric thicknessing table adjustment with fine adjustment, travel speed 10 mm/s, mounted on 4 support spindles to prevent tilting, finely planed table surface

- Feed: 2 speeds 6 / 12 m/min, can also be selected electrically during planing, large rubber feed rollers Ø 85 mm to compensate for different thicknesses of wood, rubber rollers are gentle on the material and self-cleaning, easy roller change; link pressure beam at infeed

- Suction system: Swivel-up, split hood with chip extraction nozzle Ø 160 mm, can be connected optionally on the left / right (in special cases on both sides); minimum extraction air volume: 27 m³/min. at 20 m/s

- Maintenance device: Central lubrication strip for oil lubrication points; bearing / cutter shaft lubrication via nipple

- Accessories: 1 grease gun, filled with long-life grease

1 oil gun

1 open-end wrench

1 tool for blade change

1 pair of blind knives 640 mm

2 pairs of TERSA reversible knives 640 mm CV

- Emission values: Emission sound pressure level at the workplace LpA according to DIN EN ISO 11202 [dB(A)]

Idle noise (without extraction) P1 65

Idle noise (w. extraction) P1 77

Operating noise (without extraction) P2 65

Kjdoqlclbopfx Addsll

Operating noise (with extraction) P2 78

Sound power level LWA according to DIN EN ISO 3746 [dB(A)]

Idle noise (without extraction) 84

Operating noise (with extraction) 90

Dust emission Low dust emission according to DGUV 209-044 / BGI 739-1

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Sierakowska Huta

Sierakowska Huta

1,368 km

Turning machine

HamechDF-140

Call

Condition: excellent (used), CATALOG NUMBER 7714

TECHNICAL DATA

- Machined diameter range: 40-140mm

- Minimum input material length: 750mm

- Allowance for machining (on diameter): max 50mm

- Cutter head drive motor: 22kW

- Infinitely variable feed speed + forward/reverse

- Feed motor: 2.2kW

- Pneumatic cylinders: 6 pcs

Sequence:

- Infeed roller

- 3 toothed feed rollers

- 3-knife cutter head

- 3 smooth outfeed rollers

- Outfeed roller

- Extraction port diameter: 200mm

- Brake

- Dimensions (L/W/H): 3300x1450x1750mm

- Weight: 2100kg

ADVANTAGES

Kledpfx Adsw Ipccedsl

– Manufactured in Poland

– DTR documentation

– Used rounding machine

– Excellent condition

Net price: 78,900 PLN

Net price: 18,780 EUR depending on the rate of 4.2 EUR

(Prices may change with significant fluctuations)

Listing

Borken

Borken

785 km

Resonance testing machine

SincoTecPOWER SWING 20 kN Mot Big Table

Call

Condition: used, Type: POWER SWING 20 kN

Sincotec Resonance Testing System Power Swing 20 kN

Manufacturer Service Performed

General Information:

For sale is a used resonance testing system Power Swing 20 kN from Sincotec Test Systems GmbH. The test bench was operated in single-shift use, with all maintenance carried out regularly by the manufacturer.

Key Features:

- Robust design for continuous operation

Klodpfx Aoxrffaeddsl

- Precise resonance testing up to 20 kN

- Manufacturer maintenance included

- Ideal for research, testing, and development applications

Technical Data – Test Bench

Feature / Value

- Overall height of test bench: 1215 mm (without clamping device)

- Width of test bench: 2005 mm

- Depth of test bench: 1205 mm

- Maximum force amplitude: 10 kN

- Maximum total force: ±20 kN

- Measurement transducer accuracy: min. Class 1 (according to DIN EN 10002-3)

Technical Data – Control Cabinet

Feature / Value

- Overall height of control cabinet: approx. 1800 mm

- Table top height: 1080 mm

- Width of control cabinet: 650 mm (narrow table top) / 1450 mm (wide table top)

- Depth of control cabinet: 700 mm (narrow table top) / 800 mm (wide table top)

- Weight: 152 kg (small table top)

187 kg (large table top); with granite plate: 247 kg

Site Requirements

Feature / Value

- Required space: 4.3 × 3.0 m

- Required ceiling height: 2.5 m

- Floor load capacity: 234 N/cm²

Power Requirements

Feature / Value

- Voltage: 400 V three-phase AC with neutral and protective earth

- Phase rotation: clockwise sequence

- Voltage fluctuation: ≤ ±10 %

- Short voltage dips: < 20 ms

- Limits for continuous interference: interference class A according to VDE 0871

- Frequency: 50 Hz ± 1 %

- Protective earth / ground resistance: < 0.3 Ω

Connection and Fusing

Feature / Value

- Power supply: 400 V / 50 Hz (clockwise phase sequence)

- Connector: CEE plug, 5-pin, 16 A

- Fuse rating: 16 A

Test bench weight: approx. 3.6 t

Max. weight of clamping device: 250 kg

Condition: used

Scope of delivery: (see image)

(Subject to changes and errors in technical specifications!)

Further questions can be answered by phone.

Listing

Borken

Borken

785 km

Hardness tester

KB Prüftechnik GmbHKB 750 BVRZ

Call

Condition: used, KB Prüftechnik hardness tester type: KB 750 BVRZ

Machine type: KB 750 1 kg - 750 kg

UNIVERSAL

DIGITAL

KB universal hardness testing machines for automatic and standard-compliant hardness testing.

Suitable for all hardness testing methods in the load level range HV 0.2 1 - 3000 kgf, Vickers, Brinell, Rockwell,

Super-Rockwell, Knoop (HK 1 only), ball indentation hardness (plastics) and depth measurement according to Vickers and Brinell.

Fully automatic test sequence, evaluation of the impressions on the built-in LCD monitor using a built-in video camera

and zoom lens guarantee maximum evaluation accuracy in accordance with the standard. All hardness values are immediately displayed digitally.

User-friendly and powerful control panel with color LCD monitor, high-contrast and glare-free.

The indentation is measured without parallax.

The test forces are electronically controlled and applied with maximum precision.

The video image can optionally be output as a BMP file.

All KB hardness testing machines are supplied with basic equipment that enables immediate commissioning with the indenters ordered.

A selection of fixtures, test tables, indenters, lenses, hardness reference blocks etc. are available.

Connection to a PC or central computer is possible with all KB hardness testing machines.

In conjunction with the fully automatic software and motorized cross table, the machine can be operated as a fully automatic machine.

Kledpfxou Hy Ime Addel

Fully automatic test sequence

Optical evaluation via integrated video evaluation

Extremely user-friendly and powerful

large LCD color display

industrially designed membrane keyboard

Variable software customization

zoom lens 1:7

parallax-free measurement

load cells, controlled load application, LED illumination

Rockwell resolution 0.025 HRC

Extremely powerful

200 freely definable test programs

Calibration machine accuracy (option)

Innovative LED ring light (option)

Automatic image evaluation (option)

2 interfaces parallel + serial, as well as

keyboard connection

extended load range XL (option)

freely switchable language selection

German, English, French, Italian

KB750 BVRZ:

Test load 3-750 kgf

Brinell ISO 6506

HB depth measurement

Vickers ISO 6507

HV Depth measurement

Rockwell ISO 6508

Rockwell ISO 6508 Superrockwell

Test table ∅80 mm

Motor zoom 1:7

Objective 4x for HV10-HB5/750

NOT suitable for HV5

Operating function:

Programmable digital panel with the following functions:

Measurement of the hardness impression on the LCD display, with movable measuring marks, parallax-free

Logically structured, simple operator guidance

Creation and storage of any of 200 test programs

Automatic force selection by selecting the test method

Freely selectable test force application times

Freely selectable holding times of the test forces

Online help

Automatic correction for curved surfaces in accordance with DIN EN ISO

Control of the fully automatic test sequence

Direct, digital hardness value display

Tolerance display

Conversions according to DIN 50150 table B1

Report generation in DIN A4 format with standard printer via parallel interface

Serial interface for data output to PC

Optional network

4 languages German-English-French-Italian

Statistics functions, such as

Number of tests

Min / Max

Mean value

Range

Standard deviation

cp / cpk

Histogram

(Subject to changes and errors in the technical data!)

Listing

Borken

Borken

785 km

Laser and punching machine

TRUMPFTruMatic TC 6000 L 1300

Call

Condition: excellent (used), Trumpf

Here we offer a laser and punching machine.

Technical data:

Network: 400V/50 Hz

Kjdpfx Asm Ak Huoddoll

Fuse: 3 x 100 A

Connection power 65 kVA

Working area X x Y without repositioning

Combined operation 2585 x 1280 mm

Punching operation 2585 x 1370 mm

Laser operation 2585 x 1280 mm

Power:

Laser 2000 W

Maximum sheet thickness 8mm

Maximum punching force (including 20 kN hold-down device) 220 kN

Active hold-down device (programmable in stages) 4.5-20 kN

Maximum workpiece weight 200 kg

Maximum clearance height

In punching operation 35mm

1m laser operation 22mm

Speeds:

X-axis 90 m/min

Y-axis 60 m/min

Simultaneous Stroke sequence

Punching 900 min

Signing 2800 min

C-axis

Punching 60 revolutions/min

Thread forming 330 revolutions/min

Tools

Tool positions on the linear magazine 19 with 2 clamps

Number of tools when using multitool 19 to 190 tools

Rotation of all tools 360°

Tool change time 1.5-5 s

Maximum punching diameter

Single stroke 76.2 mm on all tool positions

Standard multicut 200mm

Maximum bending height 25mm

Maximum part size 500 x 500 mm

Accuracy:

Position deviation ± 0.1 mm

Average position spread ±0.03 mm

TRUMPF CNC control: Basis: Siemens SINUMERIK 840D

Type: TC 6000 L 1300

Loading and dismantling must be carried out by the buyer!

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, information are subject to change!)

We will be happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

785 km

Optical emission spectrometer

Horiba Jobin YvonULTIMA 2 ICP-OES

Call

Condition: excellent (used), Optical emission spectrometer

Ultima 2 benchtop device, sequence spectrometer with a 1m monochromator,

2400 g/mm grating in first and second order 160-800 nm without image

Quick overview analysis

IMAGE:

Kledpfxjur Rmvs Addol

Quick overview analysis IMAGE NAVIGATOR for JY 2000-2,

JY Ultima 2 or JY Ultima 2C

External closed cooling circuit for cooling the Ultima 2's HF coil

Argon humidifier - for analyzing solutions with a high salt content.

ULTIMA 2 ICP-OES - Optical Emission Spectrometer

reliable high-efficiency 40.68 MHz semiconductor generator

complete and precise wavelength scan from 160 to 800 nm as standard

highest practical resolution

Listing

Borken

Borken

785 km

Laboratory dissolver tripod

GRIESERGFD 11 LST

Call

Condition: excellent (used), Here we offer a GRIESER tripod dissolver laboratory.

Product: Grieser laboratory tripod dissolver

Type: GFD 11 LST

Purpose:

The machine is designed for mixing of powdery solids, liquids and pastes

as well as to the work of fillers. The viscosity range can be from

low viscosity to Pasty range.

Machine design:

Klodpfx Aded Edm Sodsl

The laboratory stand dissolver consists of machine frame, the

Lifting device, the drive for mixing tool, the telescopic hood with

Spring contact pressure, the Collet and the control panel (non-ex) with control

and compact controller.

The container (customer) and the telescopic hood form one in working position

closed mixing room. The hood is intended, a hose connection

It is used according to the purpose.

The drive of the mixing tool with a speed adjustment is by means of

Frequency converter fitted. The arrangement, performance and speed of the

Motors are indicated in the enclosed drawing of the project.

On the display of the compact controller can the speed of the mixing tool, the

Mixing time / mixing time, mixing sequences, as well as other functions are displayed

be.

Operation

Switching on and off is done via corresponding buttons in the control cabinet

Lifting of the mixing tool drive

Lifting is carried out of the hub motor is switched on. This runs only as long as the

Push button (2-hand safety circuit on-on) is pressed. After releasing

the button

Listing

Borken

Borken

785 km

Digital scanning electron microscope

ZeissDSM 962

Call

Condition: excellent (used), ZEISS

Type: DSM 962

Kedpofcwwnsfx Addjll

The digitized scanning electron microscope DSM 962 is equipped with an integrated 4 MB image memory, a 40 MB hard disk for internal image storage and drives for external storage of data and images.

hard disk for internal image storage and drives for external storage of data and images.

This makes it possible to quickly and easily gain insights into the composition and morphology of

morphology of specimen surfaces far into the sub-micrometer range. With

magnification range from 5x to 300,000x, both macrostructures and microstructures can be examined.

as well as microstructures is possible.

The range of applications can be extended considerably by adding special accessories, allowing, for example

analytical investigations in micro areas of the surface are possible.

The device can be operated both via conventional switching elements and via the keyboard or mouse (add-on).

or mouse (add-on). Electron optics and vacuum control are conventional. Functions of the

Image memory functions are operated using the keyboard or mouse (add-on). A separate information screen is located centrally on the

separate information screen for displaying the menus.

These operating instructions are intended as a guide to help the user achieve the best possible results with the device.

results with the appliance. The explanations have been kept as simple as possible so that even a less experienced user

less experienced users the necessary tools.

Magnification range: 20x to 300,000x at 7 mm working distance

Stages in a sequence of 1-2-3-5-10

Minimum magnification: 5x at 50 mm working distance

Resolution:

4 nm - guaranteed with tungsten cathode at 30 kV, 6 mm working distance, untipped specimen

25 nm - guaranteed with tungsten cathode at 1kV, 6 mm working distance, untipped specimen

3.5 nm - guaranteed with optimal LaB6 cathode at 30 kV, 6 mm working distance, untilted specimen

Scope of delivery: (DSM 962 with accessories as shown)

Condition: used

(Subject to changes and errors in technical data and specifications)

Please ask about transportation options before purchasing.

We will be happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

785 km

Tipper semi-trailer

ATMOpal 460

Call

Condition: used, Opal

Type: Opal 460

Opal 460 from ATM

The Opal 460 is a fully hydraulic, water-cooled hot mounting press for mounting micrograph samples.

The process sequence is carried out automatically.

The fully automatic sliding shutter enables trouble-free opening and closing of the mounting area.

Kedpevd Dlgjfx Addjll

and closing of the embedding area.

Manufacturer ATM Q Ness GmbH

Model OPAL 460

Functional principle:

The Opal 460 is a fully hydraulic, water-cooled hot mounting press for mounting micrograph specimens.

During hot mounting, the specimen is embedded in a mounting press under temperature and pressure with a plastic granulate.

The advantages of the process are the high hardness of the embedding material (e.g. glass fiber reinforced) and the good freedom from splitting.

Hot embedding agents are available based on epoxy resin, acrylic resin, phenolic resin and graphite resin.

Main area of application:

Mounting of samples for better sample preparation for further metallographic examinations.

Technical data:

Press mold Ø 30 mm, Ø 50 mm

Temperature range 20 ... 200 °C

Max. Pressure 310 bar

Weight ~ 40 kg

Condition: used

Scope of delivery: (see picture)

(We reserve the right to make changes and errors in the technical data)

We will be happy to answer any further questions you may have on the phone.

Clickout

Duisburg

Duisburg

805 km

Production line

BattenfeldBEX - 2 - 65 - 18 V- -DURUMAX

Condition: used, Production line consisting of:

(1) Twin-screw extruder

Technical details:

Screw diameter 65 mm, weight 2.8 t /// Drive: Thyssen Henschel TPM 3-65-DOS-25, serial number 6333547/13, weight 710 kg

(1) Calibration table

Technical details:

Table length approx. 6 m

(1) Haul-off unit

Technical details:

Contact length approx. 1,500 mm

(1) Film application unit

(1) Saw unit

Technical details:

Upward stroke, saw blade diameter 250–400 mm, profile gap WxH 340 x 20 mm / diameter 115 mm, sequence max. 40 cuts/min

(1) Tilting table

Kljdpjx I Itbofx Addjl

Technical details:

Length approx. 6,000 mm

Listing

Babenhausen

Babenhausen

1,030 km

Dishwasher

MilbrandtR-Line NEU

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2025, warranty duration: 12 months, input voltage: 400 V, DGUV certified until: 12/2026, total length: 700 mm, total width: 600 mm, total height: 850 mm, input frequency: 50 Hz, type of input current: three-phase, power: 6.7 kW (9.11 HP), electrical fuse: 16 A, Dishwasher

Model: R-Line 1500

Quick-ready system

Euronorm 500

2.4 liters of fresh water consumption

Klsdofffhwopfx Addjl

7 washing programs with 3 easy

Rinse aid and detergent dosing pump

extra deep interior for sheets / tubs 600 x 400 mm

DGUV V3 checked

Sequence / drain pump

Connection: 400 V, 6.7 kW, 16A-CEE plug

Dimensions: 600 x 700 x 850 mm, WxDxH

with warranty

Included accessories:

1 plate basket

1 universal basket

1 cutlery basket

Inlet and outlet hoses

Listing

Hüllhorst

Hüllhorst

867 km

Edge banding machine

LangeB 90 KFE mit Fügen + Eckenkopieren

Call

Condition: as good as new (ex-display), Year of construction: 2025, One-sided automatic edge banding machine with pre-milling unit, direct glue application to straight workpieces (EVA-PUR Glue pot with run-out function/optional), HF-cut-off saw station, HF-top and bottom milling unit, corner rounding unit, chain feed, double roller top pressure, extendable work piece support, signal lamp for work piece sequence and synchronisation of working units by encoder. For ABS, PVC, melamine and

strong wood veneer roll material as well as fixed lengths from 0.4 – 3.0/6.0 mm and of 8 – 60 mm work piece thickness.

Speed: 10,0 m/min.; 8,0 m/min. with corner rounding • 3 spaces for finishing units • 10“ Colour Touch screen

Klsdpfx Adsd R U Agodjl

→Automatic edge feeding for roller material over turntable D = 800 mm

→Longer infeed lineal (650 mm)

→Two reverse, operating-controlled pre-milling units with diamond charged helical joining millers provide a neat and tear-free premilling of the work pieces before the gluing of the edge material

→Glue application directly to workpieces: Teflon-coated glue pot with a capacity of 1,5 kg, leak proof with glue supply from below (excess glue automatically flows back into the glue pot). Glue roller allows exact dosage of glue. Separate glue roller temperature adjustment. Electronic temperature control with automatic stand-by function (reduces probability that the glue burns if the machine is not used for a longer periods and is still turned on).

Optional: EVA/PUR gluepot with run out / cleaning function for quick change of glue

→Pneumatically operated cut-off knife from roll material up to 3mm edge thickness

→Automatic feeding magazin (70mm magazin capacity) with spiked roller for solid wood

→Pressure unit consisting of one driven pressure roller synchronized with glue spreading roller and two of smaller diameter, conical, one positive and one negative pressure roller with spring tension for a nearly invisible joint of the edge material with the work piece , adjustment of the pressure unit with digital readout.

→High-frequency cut-off saw equipped with HF motor 0.35 kW, 12,000 rpm, 2 saw blades and high-precision linear guides ensure a clean and precise saw cut, with extraction hood.

→High-frequency top and buttom milling station, 2 powerful 0.55 kW high-frequency motors with HM-WPL special millers; suitable for radius, bevel and flush milling, horizontal and vertical scanning of the work piece; aggregate adjustment equipped with digital readouts for setting to various edge types; 2 extraction hoods for shavings with central extraction nozzle 2 x Ø 100 mm; height adjustment of the upper aggregate with the top roll pressure

→Corner rounding unit : Automatic processing of corner edges up to 2 mm edge thickness. Equipped with one high frequency motor 0, 27 kW, selectable on operating panel.

One side (front or back edge) or both side corner rounding unit.

→Rotatable control panel with 10“ color touch screen controls glue temperature settings, automatic temperature reduction for stand-by function of the machine, switching on and off of aggregates and error diagnosis, incl. digital Meter counter

Additional finish aggregates :

→Radius scraper unit : With a slight draw cut eventual radius milling traces are removed to provide a perfect finish. The fine adjustment is made by digital readouts.

→Glue scraper unit : Removes eventual glue rests with a slight draw cut from the glue joint of the work piece surf

Listing

Hövelhof

Hövelhof

893 km

Horizontal broaching machine Broaching machine

Arthur KlinkRIW 10 x 1600

Call

Year of construction: 1999, condition: like new (used), functionality: fully functional, Manufacturer: Arthur Klink

Keder A Hcbjpfx Addoll

Year of construction: 1999

Type: horizontal broaching machine

Model: RIW 10x1600x400

Weight: 2.700 KG

General / technical data:

horizontal hydraulic internal broaching machine in mint condition with tool holding system ideal for the use of flat broaching tools.

Broaching stroke: 1.600mm

Tractive force: 10,000 kg (100kN)

Mounting in the drawbridge: Ø 85mm Cylindrical

Through-hole in the clamping table: Ø 100mm

Workpiece diameter: max. 400mm (due to the machine body of the tool trough)

Cutting speed: hydraulically infinitely variable from 1.0 m/min to 9 m/min

Return speed: hydraulically infinitely variable from 1 m/min to 24 m/min

Space requirement of the machine: (w x d x h) approx. 6,400 mm x 1,450 mm x 1,600 mm (without working area)

Power supply: 400Volt 50 HZ

Connected load: 9kw

Equipment:

- the machine has an electric control for the clearing stroke movement with manual operation and automatic sequence

- the machine has an integrated coolant system

- the machine has a tool holding system for flat broaching tools (no feed)

- The broaching carriage with the pulling head holder is equipped with a flat guide on both sides

Accessories

- 1 universal pulling head for flat shanks from 3mm to max. 25mm wide and a maximum pulling force of 10kN (10,000kg)

- Complete machine documentation and CE declaration of conformity

Remarks:

The machine is ideal for the production of keyways.

Due to the connection with the stable machine bed of the machine and the broaching tool holding system, the machine is particularly suitable for quick and easy use of flat broaching tools.

The machine has been used very little and is in mint condition. The machine is available for inspection in our warehouse and is ready for demonstration under power.

Our direct contact details and further information about the machine can be found in the attached PDF document

Listing

Wald

Wald

1,198 km

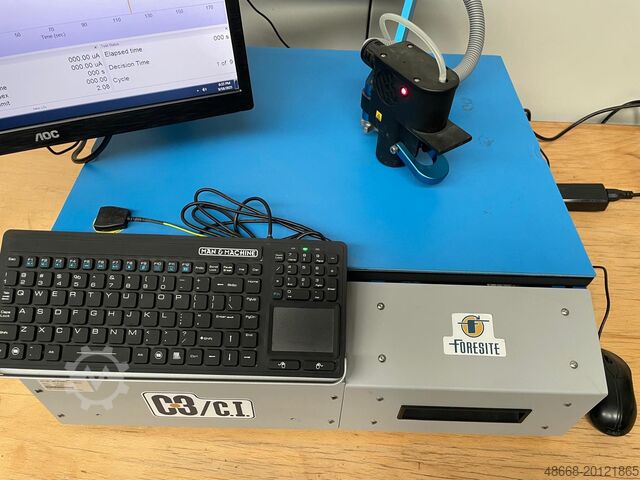

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Klsdpfx Aexhckljddol

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Technical data deviations and errors in the description of the item may occur and are subject to change.

Trust Seal

Dealers certified through Machineseeker

Listing

Limburg an der Lahn

Limburg an der Lahn

948 km

Tube bending, mandrel bending machine

Jutec Biegesysteme GmbH & Co. KGBiegesystem 5000

Call

Condition: new, Year of construction: 2025, THE ECONOMICAL BENDING MACHINE FOR TIGHT BENDING RADII:

The bending machine with free-standing bending head can be easily converted to right and left bending for difficult geometries. The plug-in bending tools allow quick conversion to other tube sizes. Fast hydraulics to shorten non-productive times is an important factor for series production.

The clamping pressure for tube clamping can be optimally adjusted. The PLC control (arbitrarily expandable via USB stick) with data memory and latest X2X interface, can accommodate an almost unlimited number of programs for bending angle, linear dimension and twisting angle for max. 50 bending sequences on one tube length. A freely programmable database for up to 200 materials is available for monitoring springback values.

The machine has 2 operating modes: In "Simple Bending", the length and twist of the bends relative to each other are automatically displayed. In the "Controlled bending" mode, the data is stored beforehand and a permanent target/actual comparison is performed during bending.

This excludes incorrect positioning within a tolerance window and thus minimizes the user-related error rate. General error messages are displayed on the large screen with full text. The mandrel retraction is programmable and can be retracted automatically ahead of time when the bending angle is reached.

The compact drive unit with the detachable mandrel carrier offers advantages for use at the assembly site as well as for special designs with a very large tube feed and is also available as a stationary variant with a tidy system for tools and mandrel bars. The low-cost alternative to the fully controlled CNC machine.

POSSIBLE APPLICATIONS:

Hydraulic piping

Pipeline construction

Plant construction, e.g. chemical industry

Metal construction

Sample construction

Technical data:

Bending capacity Ø 6 to 50 x 4 mm depending on material

bending radius min/max: 10 mm/140 mm

Bending radius min: 1,5 x Ø (standard 2 x Ø)

Multifunctional machine control Bending angle adjustment (0.1°)

Mandrel beam lengths 1500/3000/4500/6000 mm (special version also longer)

Maximum 180º bending result

Weight 600-700 kg (depending on version)

Ergonomic operation via safety foot switch

OPTIONAL ACCESSORIES:

Automatic mandrel lubrication (minimum quantity)

Kledpfendn Agex Addsl

Pneumatic or hydraulic quick-action chuck

Positioning of length and torsion via automatic brake function or via manual stops by foot switch

Semi-automatic positioning of length and rotation via servo motors

Pneumatic rotation stop

Pipe calculation software

Laser-supported tool monitoring for monitoring the tool tension

10 inch touch screen with integrated tube calculation

Bending radius up to 250 mm

Data transfer via cable (LAN), wireless (WLAN) or USB

OUR SERVICE:

- Welcome to the test production in our house in the demo room

- Consultation and information meeting at your site

- Consultation and handling as leasing/financing-purchase via

the company JUTEC

- Service contracts, maintenance at your site

Listing

Limburg an der Lahn

Limburg an der Lahn

948 km

Tube bending, mandrel bending maschine

Jutec Biegesysteme GmbH & Co. KGDornbiegemaschine Biegesystem 5000S

Call

Condition: new, Year of construction: 2026, THE ECONOMICAL BENDING MACHINE FOR TIGHT BENDING RADII:

The bending machine with free-standing bending head can be easily converted to right and left bending for difficult geometries. The plug-in bending tools allow quick conversion to other tube sizes. Fast hydraulics to shorten non-productive times is an important factor for series production.

The clamping pressure for tube clamping can be optimally adjusted. The PLC control (arbitrarily expandable via USB stick) with data memory and latest X2X interface, can accommodate an almost unlimited number of programs for bending angle, linear dimension and twisting angle for max. 50 bending sequences on one tube length. A freely programmable database for up to 200 materials is available for monitoring springback values.

The machine has 2 operating modes: In "Simple Bending", the length and twist of the bends relative to each other are automatically displayed. In the "Controlled bending" mode, the data is stored beforehand and a permanent target/actual comparison is performed during bending.

This excludes incorrect positioning within a tolerance window and thus minimizes the user-related error rate. General error messages are displayed on the large screen with full text. The mandrel retraction is programmable and can be retracted automatically ahead of time when the bending angle is reached.

The compact drive unit with the detachable mandrel carrier offers advantages for use at the assembly site as well as for special designs with a very large tube feed and is also available as a stationary variant with a tidy system for tools and mandrel bars. The low-cost alternative to the fully controlled CNC machine.

POSSIBLE APPLICATIONS:

Hydraulic piping

Pipeline construction

Plant construction, e.g. chemical industry

Metal construction

Sample construction

Technical data:

Bending capacity Ø 6 to 50 x 4 mm depending on material

Klsdpfx Adeng Exaedjl

bending radius min/max: 10 mm/140 mm

Bending radius min: 1,5 x Ø (standard 2 x Ø)

Multifunctional machine control Bending angle adjustment (0.1°)

Mandrel beam lengths 1500/3000/4500/6000 mm (special version also longer)

Maximum 180º bending result

Weight 800-900 kg (depending on version)

Ergonomic operation via safety foot switch

OPTIONAL ACCESSORIES:

Automatic mandrel lubrication (minimum quantity)

Pneumatic or hydraulic quick-action chuck

Positioning of length and torsion via automatic brake function or via manual stops by foot switch

Semi-automatic positioning of length and rotation via servo motors

Pneumatic rotation stop

Pipe calculation software

Laser-supported tool monitoring for monitoring the tool tension

10 inch touch screen with integrated tube calculation

Bending radius up to 250 mm

Data transfer via cable (LAN), wireless (WLAN) or USB

OUR SERVICE:

- Welcome to the test production in our house in the demo room

- Consultation and information meeting at your site

- Consultation and handling as leasing/financing-purchase via

the company JUTEC

- Service contracts, maintenance at your site

Listing

Sierakowska Huta

Sierakowska Huta

1,368 km

Turning machine

SERMIAC MBR 165 siłowniki pneumatyczneSAFO WEMA PROBST HAMECH

Call

Condition: excellent (used), CATALOGUE NUMBER 7660

Klsdex U Ackopfx Addel

TECHNICAL DATA

- maximum diameter of machined material: 160mm

- minimum input material length: 750mm

- machining allowance (on diameter): max 30mm

- knife head drive motor: 33kW

- stepless feed speed control via frequency inverter

- feed motor: approx. 2.2kW

- pneumatic actuators: 7 pcs

Sequence:

- 4 toothed feed rollers

- 3-knife head

- 3 smooth outfeed rollers

- dimensions (L/W/H): 3800x1100x2800mm

- weight: approx. 4000kg

ADVANTAGES

– French manufacture

– Robust construction

– Pneumatic actuators (hold-downs)

– Used peeling lathe

– Very good condition

Net price: 85,900 PLN

Net price: 20,450 EUR (exchange rate 4.2 EUR)

(Prices may change with higher fluctuations)

Listing

Hilden

Hilden

833 km

Measuring Machine

KLINGELNBERG-OERLIKONCS 200

Call

Year of construction: 2004, condition: used, z-travel 200 mm

clamping diameter of cutter heads max. 550 mm

max. permissible cutter head weight 150 kg

mounting plaute diameter for cutter heads 360 mm

taper for cutter heads, nominal diameter 500 mm

weight of the machine ca. 2,3 t

dimensions of the machine ca. 2 x 1,5 x 2,03 m

Cutter Head Set-Up- and -Measuring Machine

In the manufacturing process for spiral-toothed bevel gears, the quality of

the gear cutting gear cutting tools used plays a decisive role.

Particularly in dry milling, high gear cutting quality and a long service

life can only be achieved with precisely adjusted cutterheads.

Kodpfx Adevq Sd Rodsll

The Oerlikon cutterhead setting and testing device CS 200 enables quick and

easy setting of the individual knives and simple adjustment of the individual

knives, it checks the position and documents the measurement results. The

measuring sequence on the CNC-controlled testing device is partially automated:

The individual actions for carrying out the actions for carrying out the

sequence are displayed on the screen via the operator guidance. The positioning

of the individual knives in the cutter head and the height of the knife tips is

largely automatic thanks to a special sequence and is simultaneously documented

by means of a run-out diagram. A subsequent measuring sequence checks the

radial position of the inner and outer cutting edges of all knives in the

cutterhead. If individual test parameters on the knives do not correspond to the

the tolerance specifications, this can be individually repositioned. The

combination of semi-automated setting sequence, operator-guided set-up actions

and automatic operator-guided set-up actions and automatic measuring sequence,

cutterheads can be can be set conveniently, quickly and with high precision.

Operator-guided setting and test sequence

- Graphic display of the cutter head design and the measurement results with

tolerance check

- Instructions for the operator in plain text Instructions for the operator in

plain text (without coded information)

- Simple assignment of the measurement results to the knives

- Documentation of the setting and measurement results via printer- Setting and

test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types

- Interface for neutral data

We make it easier for you to find: "genome sequencer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Genome Sequencer (347)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you