Used Homogenizer for sale (229)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duxford

Duxford

436 km

Quattro Fluid SystemFlow 1000S quaternary diaphragm positive‑displacement pump

QuattroSystemFlow 1000S

Call

Condition: used, This listing is for 1 of 2 Quattro Fluid SystemFlow 1000S

These units is in full working condition and is ready for immediate use

Overview & Application

The Quattroflow 1000 S is a quaternary (four‑piston) diaphragm positive‑displacement pump—engineered for gentle, sterile handling of shear‑sensitive fluids such as proteins, vaccines, cell suspensions, and other biopharmaceutical or food-grade products. Its design features—like seal‑less operation, low shear, low pulsation, and dry‑run capability—make it ideal for critical applications including:

Filtration systems: Tangential‑flow filtration (TFF), recirculation pumps, filter cartridges

Chromatography: Gradient mixing and feed pumps

Centrifuge feeding and homogenization

Aseptic filling lines and other sensitive processing tasks

Commonly processed media include albumin, IgG antibodies, enzymes, vaccines, cell and virus suspensions, dairy products, and cosmetic or polymeric solutions.

Technical Specifications

Here’s what’s known about its performance and build:

Flow rate: Continuously variable between ~25 to 1000 L/h (at atmospheric pressure); around 750 L/h at 6 bar (depending on configuration)

Psdpexhfp Rsfx Afhogg

Max Pressure: Up to 6 bar, with high‑pressure variants available upon request

Drive mechanism: Four‑piston diaphragm setup actuated by an eccentric shaft; standard variant uses a 5° eccentric shaft reaching up to 1,800 rpm

Material & Construction:

Pump head: Stainless steel grades 1.4435 or 1.4539, optional alternatives (like PEEK) available

Membranes: Santoprene (diaphragm), EPDM (valve membranes)

Priming and Pumping Features:

Self‑priming, dry‑run capable

Four directional porting—pump orientation flexible

No shaft seals or wetted rotating parts, minimizing wear and product heating

Internal volume (filling volume): Approx 35 mL; designed to minimize dead volume and aid product recovery

Connections: Standard ¾″ TC (Tri‑Clamp) sanitary ferrule; other flange types available

Dimensions & Weight:

Pump: 523 × 155 × 212 mm, ~23 kg

Control unit (frequency inverter): 350 × 155 × 212 mm, ~6 kg

Electrical: 230 V AC (50 Hz) via a control box with 6.3 A fuse; motor IP54, control box IP53

Key Advantages

This model offers several standout benefits:

Gentle, high‑integrity fluid handling—ideal for fragile biologics due to low shear and pulsation

Contamination-free design—no mechanical seals, minimal abrasion

Robust operation—powerful 370 W motor, simplified maintenance with fewer parts

Aseptic and sterile process readiness—autoclavable, self‑draining, hygienic construction

Installation adaptability—four flow directions, small footprint, flexible hookups

Listing

Duxford

Duxford

436 km

Binder BF115 Incubator

BinderBF115

Call

Condition: used, This listing is for the Binder BF115 Incubator

The unit is in full working condition and is ready for immediate use

BINDER BF 115 – e Series Forced Convection Incubator

The BINDER BF 115 incubator from the e series is designed for precise and gentle incubation applications in laboratories where performance, uniformity, and reliability are critical.

Work particularly well under a full load and large batch throughputs. This incubator is extremely homogeneous and has quick recovery time.

Key Performance Features

Temperature Range: Ambient +8 °C to 100 °C – ideal for a wide variety of microbiological, bacteriological, and stability testing.

Excellent Uniformity & Stability:

±0.3 K uniformity at 37 °C

±0.1 K fluctuation at 37 °C

±1.6 K uniformity at 100 °C

Fast Heating & Recovery:

Heats to 37 °C in ~8 minutes

Recovers in ~3 minutes after a 30-second door opening

Design & Control Highlights

e™ Technology: Ensures uniform temperature distribution across all shelves – even with full chamber loads.

Forced Air Convection: Enables efficient heat transfer and consistent conditions throughout the chamber.

Disinfection Routine: Built-in 100 °C sterilization cycle for internal decontamination.

User Interface: Intuitive LCD controller with programmable timer, USB port for data logging, and electromechanical exhaust flap control.

Safety Thermostat: Class 3.1 safety (DIN 12880 compliant) with visual alarm for over-temperature protection.

Internal Viewing: Transparent inner glass door allows sample observation without disturbing internal environment.

Technical Specifications

Feature Details

Chamber Volume 114 liters

Temperature Range Ambient +8 °C to 100 °C

Internal Dimensions 550 × 550 × 380 mm (W×H×D)

External Dimensions 710 × 725 × 605 mm (W×H×D)

Power Supply 230 V, 0.4 kW, 6.3 A fuse (also available in 120 V)

Noise Level 43 dB(A) typical

Weight ~54 kg

Shelves 2 chrome-plated shelves (up to 5 possible)

Energy Consumption ~60 Wh/h @ 37 °C; ~235 Wh/h @ 100 °C

Applications & Benefits

Use Cases: Ideal for microbiology, bacteriology, tissue culture, stability testing, and pharmaceutical incubation.

Podpfsxhfz Tex Afhegg

Scalable Performance: Optimized for full load conditions and large batch throughput without compromising performance.

User-Friendly: Stackable, ergonomic handle design, easy-to-clean stainless steel chamber with no fixed fixtures.

Highly Reliable: Rapid recovery and precise temperature regulation for reproducible results, even with frequent door openings.

Listing

Duxford

Duxford

436 km

Eppendorf Mixmate 5353 Mixer

EppendorfMixmate 5353

Call

Condition: used, This listing is for a nonoperational Eppendorf Mixmate 5353 Mixer.

This unit is supplied nonoperational and is ready for immediate release.

The Eppendorf MixMate 5353 is an advanced lab mixer designed for optimal precision and efficiency when handling small sample volumes, making it an essential tool for various applications in research and clinical settings.

Key Features:

Versatile Format Compatibility: The MixMate can accommodate a wide range of tube and plate formats, including 96 and 384 well plates, as well as 0.2ml PCR tubes, 0.5ml, 1.5ml, and 2.0ml tubes.

Integrated Vortexing Action: Its unique vortexing action is perfect for applications such as resuspending bacterial pellets, DNA samples, cell cultures, conducting immunoassays, and performing solubility tests. For instance, it can quickly re-suspend DNA pellets after ethanol precipitation, ensuring thorough mixing without sample loss.

Podpfx Aoxv A Tcsfhegg

Speed and Flexibility:

Mixing Frequency: Ranges from 300 to 3,000 RPM in 50 RPM increments.

Touch Vortexing Frequency: Reaches up to 3,500 RPM for rapid, on-demand mixing.

2D Mix Action: The innovative 2D mixing action ensures uniform mixing across all wells, which is critical for experiments requiring consistent sample homogeneity, such as high-throughput screening assays.

Adjustable Mixing Time: Users can set mixing times between 15 seconds and 99.5 hours or choose continuous operation, providing flexibility for both quick mixing tasks and longer protocols.

Programmable Features: The user-friendly digital control panel can store up to 5 predefined programs, allowing for quick access to frequently used mixing parameters.

Specifications:

Plate Dimensions: Accommodates plates sized 5 x 3 inches.

Power Requirements: Operates on 115 – 230V; 50-60 Hz.

Dimensions: Compact size of 9 x 7 x 7 inches.

Weight: Weighs 10 lbs, making it portable yet sturdy.

Applications:

The Eppendorf MixMate 5353 is ideal for:

Molecular Biology: Resuspending nucleic acid samples and cell cultures.

Immunology: Preparing samples for immunoassays with consistent mixing.

Pharmacology: Conducting solubility tests for drug compounds in different solvents.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Duxford

Duxford

436 km

Thermo Scientific B·R·A·H·M·S Kryptor Gold Immunoanalyzer

Thermo Fisher ScientificB·R·A·H·M·S Kryptor Gold

Call

Condition: used, This listing is for a Thermo Scientific B·R·A·H·M·S Kryptor Gold Immunoanalyzer.

The unit is in full working condition and is ready for immediate release.

Revolutionize your laboratory testing with the Thermo Scientific B·R·A·H·M·S Kryptor Gold Immunoanalyzer. This fully automated, random-access bench top immunoanalyzer is engineered to enhance user autonomy, maximize throughput, and optimize cost efficiency, making it an essential tool for modern clinical laboratories.

Key Features:

High Throughput: Achieve up to 115 tests with an 80-sample capacity, ensuring rapid processing for high-demand environments.

Nobel Prize-Winning TRACE Technology: Benefit from the TRACE (Time Resolved Amplified Cryptate Emission) technology, delivering fast and reliable results across a variety of essential medical indications.

Comprehensive Immunoassay Menu: Access a broad range of homogeneous immunoassays for critical applications, including prenatal screening, oncology, endocrinology, infectiology, and acute care.

Benefits:

The Kryptor Gold Immunoanalyzer significantly enhances laboratory productivity and workflow. With its fully automated operations, it minimizes manual handling, thereby reducing the likelihood of errors and improving overall efficiency. Laboratories can also enjoy cost savings through reduced reagent consumption and waste.

Technical Specifications:

Technology: TRACE (Time Resolved Amplified Cryptate Emission)

Throughput: Up to 115 tests

Pgsdpoxx Af Refx Afhjg

Sample Capacity: 80 samples

Applications: Prenatal screening, oncology, endocrinology, infectiology, acute care

Listing

Duxford

Duxford

436 km

Hanna HI 180 Speedsafe Magnetic Stirrer

HannaHI 180 Speedsafe

Call

Condition: used, This listing is for 1 of 2 Hanna HI 180 Speedsafe Magnetic Stirrer.

Psdoxxz U Ropfx Afhogg

The unit is in full working condition and is ready for immediate release.

The Hanna HI 180 Speedsafe Magnetic Stirrer is an excellent choice for laboratories seeking a compact and efficient mixing solution. Here’s a detailed overview of its features and applications:

Key Features:

Compact and Lightweight Design: Its small footprint makes it perfect for laboratories with limited bench space.

Attractive Colour Options: Available in various colours, it allows easy identification of different samples, enhancing workflow efficiency.

Electronic Speed Control: Users can easily regulate stirring speed through electronic controls, ensuring precise mixing.

Speedsafe Mechanism: This safety feature limits the maximum stirring speed to 1000 rpm, even if the load is suddenly removed. This helps prevent accidents and ensures consistent performance.

Durable ABS Housing: The stirrer's housing is constructed from ABS, making it resistant to most harmful chemicals typically found in laboratory environments.

Maximum Stirring Capacity: Capable of stirring up to 1 litre, making it suitable for small-scale applications.

Performance and Applications:

The Hanna HI 180 Speedsafe Magnetic Stirrer is ideal for various light-duty laboratory stirring tasks, such as:

Mixing Small Volumes of Liquids: Perfect for preparing solutions in microcentrifuge tubes or small beakers.

Dissolving Solids in Solvents: Efficiently mixes solids into liquids, ensuring thorough dissolution.

Preparing Samples for Analysis: Excellent for creating homogenous mixtures needed for accurate laboratory testing.

Discover more used machines

Listing

Duxford

Duxford

436 km

IKA RCT CL S2 Heating Magnetic Stirrer

IKARCT CL S2

Call

Condition: used, This listing is for a IKA RCT CL S2 Heating Magnetic Stirrer.

The unit is in full working condition and is ready for immediate release.

The IKA RCT CL S2 Heating Magnetic Stirrer is a reliable laboratory device designed for efficient stirring and heating of various substances. Part of the IKA RCT series, it combines precision, safety, and durability to meet the demands of modern laboratories.

Key Features:

Precise Temperature Control:

Offers a temperature setting range of 0 - 310°C with a resolution of 1 K, ensuring faster and accurate heating of the medium.

Wide Speed Range:

Adjustable speed from 50 to 1500 rpm, with a setting accuracy of 10 rpm, making it versatile for different stirring needs.

Safety Features:

Equipped with a hot top indicator, digital error code display, and an adjustable safety circuit for heating plate temperatures (50 - 360°C) to prevent overheating and ensure safe operation.

Efficient Magnetic Stirring:

Utilizes a strong motor, capable of stirring volumes up to 20 L (H₂O), suitable for large-scale or intensive laboratory tasks.

Durable Heating Plate:

Constructed from aluminum alloy, the heating plate delivers optimal and homogeneous heat transfer for consistent results.

Advanced Connectivity:

Includes USB and RS232 interfaces for easy control and documentation of test parameters using a PC, and compatibility with labworldsoft laboratory software.

Technical Specifications:

Dimensions: 160 x 85 x 270 mm (W x H x D)

Weight: 7.29 pounds

Podoxxz Udjpfx Afhegg

Wattage: 600 watts

Material: Aluminum alloy

Brand: IKA

Manufacturer: IKA WORKS, INC

Listing

Duxford

Duxford

436 km

Binder BF115 UL Incubator

BinderBF115 UL

Call

Condition: used, This listing is for the Binder BF115 UL Incubator / Oven

The unit is in full working condition and is ready for immediate use

BINDER BF 115 UL – Forced Convection Incubator

The BINDER BF 115 incubator from the e series is designed for precise and gentle incubation applications in laboratories where performance, uniformity, and reliability are critical.

Work particularly well under a full load and large batch throughputs. This incubator is extremely homogeneous and has quick recovery time.

Key Performance Features

Temperature Range: Ambient +8 °C to 100 °C – ideal for a wide variety of microbiological, bacteriological, and stability testing.

Excellent Uniformity & Stability:

±0.3 K uniformity at 37 °C

±0.1 K fluctuation at 37 °C

±1.6 K uniformity at 100 °C

Fast Heating & Recovery:

Heats to 37 °C in ~8 minutes

Recovers in ~3 minutes after a 30-second door opening

Design & Control Highlights

e™ Technology: Ensures uniform temperature distribution across all shelves – even with full chamber loads.

Forced Air Convection: Enables efficient heat transfer and consistent conditions throughout the chamber.

Podpjxhfz Hofx Afhjgg

Disinfection Routine: Built-in 100 °C sterilization cycle for internal decontamination.

User Interface: Intuitive LCD controller with programmable timer, USB port for data logging, and electromechanical exhaust flap control.

Safety Thermostat: Class 3.1 safety (DIN 12880 compliant) with visual alarm for over-temperature protection.

Internal Viewing: Transparent inner glass door allows sample observation without disturbing internal environment.

Technical Specifications

Feature Details

Chamber Volume 114 liters

Temperature Range Ambient +8 °C to 100 °C

Power Supply 120 V, 12.5 A fuse (NB At this time we also have in stock 230 V See BF115)

Noise Level 43 dB(A) typical

Weight ~54 kg

Shelves 2 chrome-plated shelves (up to 5 possible)

Applications & Benefits

Use Cases: Ideal for microbiology, bacteriology, tissue culture, stability testing, and pharmaceutical incubation.

Scalable Performance: Optimized for full load conditions and large batch throughput without compromising performance.

User-Friendly: Stackable, ergonomic handle design, easy-to-clean stainless steel chamber with no fixed fixtures.

Highly Reliable: Rapid recovery and precise temperature regulation for reproducible results, even with frequent door openings.

Listing

Duxford

Duxford

436 km

Pall Allegro 200 L Single‑Use Mixer System

PallAllegro 200 L

Call

Condition: used, This listing is for a Pall Allegro 200 L Single‑Use Mixer System.

The unit is in full working condition and is ready for immediate release.

The Pall Allegro 200 L single‑use mixer (model LGRMXTTE200L230B) is engineered for scalable, robust mixing in biopharmaceutical operations. It is part of Pall’s Allegro single‑use technology portfolio and is designed for applications from media and buffer preparation through final formulation.

Built with proven engineering principles and compatibility with Pall’s Allegro biocontainer film formats, it offers ease-of-use, reproducible performance, and minimal validation burden.

Key Features

4‑Pitch Blade Impeller – Effective, low-shear mixing over a broad range of conditions.

Bidirectional Flow Capability – Able to run clockwise (up‑flow) or counterclockwise (down‑flow), accommodating different density fluids and solids.

Bag Inflation System – Mixer bag inflation provides a controlled mixing envelope, allowing consistent performance across 50–200 L volumes, and supports gas blanketing.

Flush Drain Valve – Helps avoid dead legs by removing settled materials that might otherwise be left unagitated.

Retention of Allegro Film Materials – Uses the same film as standard Allegro 2D/3D biocontainers for material consistency, reducing requalification effort.

Optional Baffle Kit – To mitigate air entrapment at higher rotational speeds for shear-sensitive processes.

Technical Specifications

Parameter Value

Psdpfexl Dxlsx Afhsgg

Model / Part Number LGRMXTTE200L230B

Operating Volume Range 50 – 200 L

Voltage / Frequency 230 V AC, 50 Hz

Current Draw ~5.1 A

Motor Power 0.37 kW

Rotation Speed Range 50 – 200 rpm

Materials of Construction Mixer tote in 304 stainless steel; film, manifolds, ports in LDPE / PS / silicone etc.

Weight (empty system) ~120 kg

Footprint (W × D) 1,054 mm × 748 mm

Height 1,378 mm

Gas Supply Requirements 4 – 6 barg (for bag inflation / blanket)

Operating Temperature Range 4 – 40 °C

Connections / Ports Inlet, gas inflation, exhaust, flush drain, powder addition ports etc.

Applications

Upstream Media Preparation – Efficient mixing of culture media and supplements.

Downstream Buffer Preparation – Rapid homogenization of buffers or reagents.

Final Formulation / Filling – Gentle mixing for drug products.

Powder Addition / Reconstitution – Capable of handling solid-liquid mixing (e.g. powders) with repeatability.

Shear-Sensitive Biologics – Low shear impeller design suitable for sensitive proteins or biologics.

Benefits & Validation

High Performance Mixing across Conditions – Demonstrated capability to mix a wide range of systems including liquid-liquid, solid-liquid, and viscous solutions with good speed and uniformity.

Validated Materials & Safety – Components meet USP /, USP , , endotoxin limits, gamma-irradiation compatibility (up to 50 kGy), and leak-tested containers.

Reduced Validation Overhead – Using the same film materials as existing Allegro biocontainers helps streamline requalification and process transfer.

Minimal Dead Volume / Entrapment – Flush drain valve and optional baffles help prevent accumulation of settled solids.

Scalable & Flexible – Supports operations from 50 L to 200 L with consistent mixing performance.

Listing

Janville

Janville

878 km

Laboratory mixer

IKAT 65 D Ultra turrax

Call

Condition: used, Manufacturer : IKA

Model : T 65 D

Year : -

Type: Agitator / Disperser / Homogenizer

Capacity (water): 2 - 50 l

Max. viscosity 5000 mPas

Speed range 1000 - 9500 rpm

Motor power: 2.2 KW

Digital version

Support / Telescopic stand: T 653

Psdpfx Aox R D E Eofhogg

Listing

Janville

Janville

878 km

Vacuum mixer

Fryma KorumaDinex Lab

Call

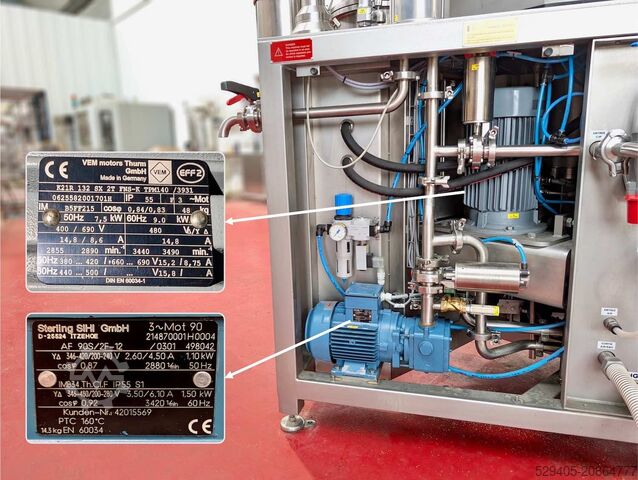

Condition: used, Year of construction: 2009, Manufacturer: Romaco - Frymakoruma

Model: Dinex Lab

Year: 2009

Type: Vacuum mixer for R&D or small-scale production

Application: liquid and/or viscous (semi-liquid) products = dispersion, homogenization, emulsion, grinding, and pumping of the product

Tank:

Pressure: -1 / 0 bar

Volume: 18 L

Temperature: 130°C

Jacket:

Pressure: 6 bar

Volume: 2 L

Temperature: 180°C

Homogenizer: high-speed agitation

2 modes = Pumping with discharge / Dispersion with high shear force

Tool size: 100 mm

Rotor: 20 x 4 mm

Stator: 30 x 4 mm

VEM motor 7.5 kW / 2890 RPM

Scraper mixer: slow agitation

SEW 0.37 KW motor

Sterling SIHI LEMA 25 liquid ring vacuum pump

Power 1.1 KW - Max. 16 m³/h.

CIP (clean in place)

2 x feed hoppers, 1 of which is connected to the jacket with its piping

Air pressure: 6 bar

Water pressure: 6 bar

Pgjdpfx Afsx R D Elehog

Temperature control regulator

Single-acting seal: reconditioned by Burgmann

Paper documentation

Weight: 750 kg

Listing

Janville

Janville

878 km

Mélangeur sous vide

OlsaSpeedycream 750

Call

Condition: used, Year of construction: 1986, Manufacturer : OLSA

Model : Speedycream 750

Year : 1986

Type: vacuum mixer

Capacity: 750 Liters

Total capacity: 880 Liters

Minimum working capacity: 280 Liters

Jacketed : 3 bars

Inside tank pressure: 1 bar

Slow stirring: 5.5 KW

Planetary: 15-78 rpm

Blade with Teflon scrapers: 5-26 rpm

Satellite rapid mixer (located on the lid): 7.5 KW

Homogenizing disperser: 1400 - 2800 rpm

Pgodpox R Dmiofx Afheg

Movement speed: 5-26 rpm

Temperature controller

Planetary mixer speed indicator

Internal vacuum indicator

Planetary mixer power consumption indicator

Fast stirrer power consumption indicator

Planetary speed indicator

Satellite speed selector

Tilting axis

Vacuum pump : 1,45 KW

Drain valve Ø 65 mm

Exterior dimensions: 2658 mm x 1420 mm x 2510 mm (3870 mm - lid open)

Spare parts available (see photos)

Original paper documentation available

Video available in running condition

Listing

Janville

Janville

878 km

Vacuum mixer

Dumek-

Call

Condition: used, Year of construction: 1985, Manufacturer : Dumek

Model: –

Year : 1985

Type: Vacuum mixer / Homogenizer

Total volume: 80 L

Useful volume: approx. 50 L

Slow agitation : Stirring / counter-stirring

Pgedpfex R Awasx Afheg

Rapid agitation : rotor / stator 3.3 KW

Up/down: mechanical

Tilting: manual

Jacketed with integrated heating unit

Immersion heaters (new): 2 x 3000 W

Regulation: mechanical

Tank bottom sample

Vacuum pump

New scrapers are required; these items can be quoted separately.

Listing

Lopik

Lopik

670 km

Direct UHT Unit

GEATDS-6600-160INJ

Call

Condition: excellent (used), Year of construction: 2023, operating hours: 400 h, Skid-mounted UHT system, direct steam injection, 16,000 L/h, 2023.

A complete UHT line, suitable for milk, cream and ice cream mixes.

The system is delivered turnkey and is ready for both pilot and production operations.

GEA TDS-6600-160INJ – 16,000 liters per hour

Process Configuration

Direct steam injection into the product with culinary steam filter

Holding tube/flash tank

Plate heat exchangers:

PHE1: regeneration + steam heating

PHE2: regeneration + chilled water cooling

Heater: 137–142 °C / 6 seconds

Final product temperature fully controllable via plate cooler

Skid Layouts

The UHT line is constructed on multiple skids, including the UHT section, homogenizer, and aseptic systems:

SKID A: Balance tank for product, Fristam product pumps, Grundfos water pumps, process and steam valves, piping, ROI-box with recorder

SKID B: Steam injector, holding heater, flash tank, pumps, valves, and auxiliary systems:

PHE1: Plate heat exchanger for regeneration + steam heating

PHE2: Plate heat exchanger for regeneration + chilled water cooling

Aseptic Homogenizer: Soavi Ariete 5200, 250 bar, 5 pistons, 2-stage, installed downstream

Sterile Water Skid: Auxiliary system for homogenizer

Control Panels & MCC: including PLC and frequency converters

SKID A: Aseptic valve manifolds (inlet and outlet cluster for tank)

SKID B: Sterile air system for aseptic tank

SKID C: Jacketed water circulation

Excluding: 60 m³ aseptic tank

Control System

Siemens PLC

Danfoss variable frequency drives (VFDs)

SCADA-controlled (SCADA system needs adaptation; not included in this offer)

Central control panel and MCC included

Condition

Year of Manufacture: 2023

Pgodpfx Ajx R Uk Sefhog

Less than 400 operating hours

Excellent condition

Documentation and P&ID drawings available

Listing

Bitburg

Bitburg

902 km

Glue spreader

OsamaS4R/P-1400 sofort verfügbar

Call

Condition: new, Year of construction: 2024, Osama Automatic 4-Roller Glue Application Machine

Model: S4R/P-1400

Automatic gluing machine with 2 motors

Working width: 1,400 mm

Max. pass-through height: 0 - 100 mm

Speed: 22 m/min

Working height: 900 mm

Diameter of application rollers: 250 mm

Motor power: 3 kW

Electrical: 400 V / 50 Hz / 3 phase

Automatic gluing machine with 4 rollers for polyvinyl acetate (PVAC), urea-formaldehyde (UF), and polyurethane adhesives, suitable for various materials such as MDF, multi-layer boards, particle boards, composites, and gypsum plasterboard.

This type of gluing machine allows for precise and homogeneous dosing of adhesive, taking into account the corrugation of the rollers, which must be suitable for the respective production requirements. The heavy-duty structure and the roller cores, manufactured with greater thickness compared to earlier models, enable a high production rate without issues and bonding of materials up to 2200 mm in width. Roller removal for maintenance is straightforward, as the supports can be split in two via a simple bayonet coupling.

The gluing machine can also be equipped with different accessories, such as an electronic speed controller, automatic roller washing device, and an automatic upper roller lifting mechanism with position display on the control panel.

The S4R/P gluing machine is used in various production sectors, including construction and the manufacturing of foam panels and mattresses.

Equipment:

Podpfx Asu I R Utsfhjgg

- Automatic roller cleaning

- Infeed roller

- Outfeed roller

- Working height: 900 mm

- Infeed table TRF 1400x3000 mm with PVC rollers, 60 mm diameter, 200 mm spacing

- Outfeed table TDF 1400x3000 mm with disc rollers, D: 122 mm, stainless steel

Location: in stock at 54634 Bitburg

- Available immediately -

Listing

Borken

Borken

785 km

Climatic chamber

Heraeus VötschVC³ 0100

Call

Condition: excellent (used), Heraeus Vötsch climatic test chamber

Here we offer Heraeus Vötsch climatic test chamber.

Designation VC³ 0100

Test chamber dimensions: H x W x D, approx. 950 x 1100 x 950 mm

TEMPERATURE TESTS:

Minimum temperature -0°C

Maximum temperature +90°C

Temperature change rate cooling 0.2 K/min

Temperature change rate heating 0.5 K/min

Temperature deviation in time ± 0.1 to ± 0.5 K

Temperature homogeneity in space ± 0.5 to ± 1.0 K

Pedpfx Asn Ard Sofhsgg

Heat compensation at +20 °C 350W

CLIMATIC TESTS:

Minimum temperature +10°C

Maximum temperature +90°C

Dew point temperature range +4°C to +89.5°C

Humidity range 10 to 98% r. h.

Humidity deviation over time ± 1 to ± 3% r. h.

Temperature deviation temporal ± 0.1 to ± 0.3K

Temperature homogeneity in space ± 0.5 to ± 1.0K

Voltage: 1/N/PE AC 230V±10% 50Hz

Rated power: 2.6 kW

Nominal current: 12 A

Refrigerant: R 404A

Weight approx. 1400 kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. refilling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Type: VC³ 0100 / year of construction 2013

Condition: second-hand / used

Scope of delivery: (see picture)

(Subject to changes and errors in the technical data and specifications!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Climate cabinet 138 liters

CLIMATSEXCAL 1413-HA -40 bis 180°C

Call

Condition: excellent (used), Climats

Type: EXCAL 1413-HA

Air-cooled climate control cabinet

Pgedpfx Ajv Dt T Tefhog

EXCAL is equipped with a 15-inch capacitive multi-touch panel PC, SSD

memory, Windows 7 and 2 USB ports.

This means it is state-of-the-art.

Technical data:

Test room dimensions: width 550 mm x depth 500 mm x height 500 mm

Housing dimensions: width 820 mm x depth 1375 mm x height 1730 mm

Window 350 x 380

Volume: 138 liters

Flow-through installed in basic equipment

R1: 80 mm ∅

L1: 80 mm ∅

Data for temperature tests:

Temperature range: -40°C to +180°C

Temperature deviation over time ± 0.1 to ± 0.3 K

Temperature homogeneity in space ± 0.5 to ± 1.8 K

Temperature change rate

Heating 15 K/min

Cooling 10 K/min

Data for climate tests:

Temperature range + 10 to +90 °C

Humidity range 10 to 98 %r.h.

Data for operation:

3/N/Ph+T 400V±10% 50 Hz

Rated power 9.8 KVA

Refrigerant R-404A / R-23

Weight: 430 kg

For your safety as a buyer, the following information!

The following points are carried out in advance on the chambers we offer:

1. Functional check and replacement of necessary components

2. If necessary, new filling with legally compliant refrigerant

3. Leak test with certificate

4. After successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (See image)

(Changes and errors in the technical data, information is subject to change!)

We are happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

785 km

Climatic chamber

VötschVC³ 4100

Call

Condition: excellent (used), Vötsch climatic test chamber

Here we offer a Vötsch climatic test chamber.

Designation VC³ 4100 Air-cooled

Pgsdpfxeqmn A Ne Afhog

With temperature change rate of 3 K/min

Test chamber dimensions: Height 950 mm x width 1100 mm x depth 950 mm

Unit dimensions: Height 2000 mm x width 1300 mm x depth 1916 mm

Volume: 990 liters

Feed-through: Ø 125 mm Ø 50 mm

Data for temperature tests:

Temperature range -42°C to +180°C

Temperature deviation temporal ± 0.1 to ± 0.5 K

Temperature homogeneity in space ± 0.5 to ± 1.5 K

Temperature change rate:

Heating 4.0 K/min

Cooling 3.0 K/min

Max. heat compensation at +20°C 4500 watts

Data for climate tests

Temperature range +10°C to +95°C

Dew point range -3°C to +94°C

Humidity range 10 to 98% r. h.

Temperature deviation temporal ± 0.1 to ± 0.3 K

Temperature homogeneity in space ± 0.5 to ± 1.0 K

Humidity deviation temporal ± 1 to ± 3% r. h.

Heat compensation max. 500 W

Voltage: 3/N/PE AC 400V ± 10% 50Hz

Rated power: 11.5 kW

Nominal current: 22.0 A

Refrigerant: R-404 A

Weight approx. 840 kg

Type: VC³ 4100

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, refilling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Climate test chamber with humidity

VötschVC³ 4100 990 Liter -42°C bis +180°C

Call

Condition: excellent (used), Here we offer a Vötsch climatic test chamber.

Designation VC³ 4100 Air-cooled

With temperature change rate of 3 K/min

Test chamber dimensions: Height 950 mm x width 1100 mm x depth 950 mm

Unit dimensions: Height 2000 mm x width 1300 mm x depth 1916 mm

Volume: 990 liters

Feed-through: Ø 125 mm Ø 50 mm

Data for temperature tests:

Temperature range -42°C to +180°C

Temperature deviation temporal ± 0.1 to ± 0.5 K

Temperature homogeneity in space ± 0.5 to ± 1.5 K

Temperature change rate:

Heating 4.0 K/min

Cooling 3.0 K/min

Max. heat compensation at +20°C 4500 watts

Data for climate tests

Temperature range +10°C to +95°C

Dew point range -3°C to +94°C

Humidity range 10 to 98% r. h.

Temperature deviation temporal ± 0.1 to ± 0.3 K

Temperature homogeneity in space ± 0.5 to ± 1.0 K

Humidity deviation temporal ± 1 to ± 3% r. h.

Heat compensation max. 500 W

Voltage: 3/N/PE AC 400V ± 10% 50Hz

Rated power: 11.5 kW

Nominal current: 22.0 A

Refrigerant: R-404 A

Weight approx. 840 kg

Type: VC³ 4100

The following information is for your safety as a buyer!

Pgodpoqwim Eefx Afheg

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, refilling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Climate test chamber with humidity 34 liters

VötschVCL 7003 -70°C bis +180°C

Call

Condition: excellent (used), Vötsch

Type: VCL 7003

Air-cooled climatic test chamber

Test chamber capacity approx. 34 liters

Psdpsv Tnd Ssfx Afhjgg

Capacity for temperature tests:

Temperature range -70 to +180°C

Temperature deviation over time ±0.3 to ±1.0 K

Temperature homogeneity over space ±0.5 to ±2.0 K

Heating rate of change 4.0 K/min

Cooling rate of change 3.0 K/min

Heat compensation max. 550 W

Temperature calibration value +23°C and +80°C

Capacity for climatic tests:

Temperature range +10 to +95°C

Humidity range 10 to 98%

Humidity deviation over time ±1 to ±3%

Temperature deviation over time ±0.3 to ±0.5 K

Spatial temperature homogeneity ±0.5 to ±1.5 K

Climate calibration values +23 °C / 50% RH and +95 °C / 50% RH

Test room dimensions: Width 350 mm, Depth 300 mm, Height 310 mm

External dimensions: Width 640 mm, Depth 750 mm, Height 1730 mm

Electrical connection:

1/N/PE AC 230 V ±10%, 50 Hz

Rated current 11.0 A

Rated power, max. 2.5 kW

Sound pressure level 59 dB(A)

Refrigerant: R-404 A / R23

Weight approx. 130 kg

For your safety, please note the following information as a buyer!

The following steps are performed on our chambers in advance:

1. Functional testing and replacement of necessary components

2. Refilling with legally compliant refrigerant, if necessary

3. Leak testing with a certificate

4. After successful testing, the chambers are subjected to a documented test run.

Condition: Used

Scope of delivery: (See image)

(Subject to change and errors in the technical data, information is subject to change!)

We are happy to answer any further questions you may have over the phone.

Listing

Borken

Borken

785 km

Xenon Weather-Ometer/ Fade-Ometer

AtlasCI3000+ Bewitterungsprüfung

Call

Condition: excellent (used), Atlas

Type: CI3000+

Ci3000+ Weather-Ometer/ Fade-Ometer

Model: CI3000W

Year of manufacture: 06/2022

Operating time: Device 816.5 hrs.

Light duration device 647.4 hrs.

Total lamp operation 88.9 hrs.

Atlas CI3000+ Xenon Weather-Ometer with calibration case

The Ci3000+ Weather-Ometer and the Fade-Ometer with its advanced digital control systems,

represent monumental achievements in the application of digital and optical technologies in easy-to-use laboratory weathering instruments.

The 3000 series is recognized by many OEMs in the textile, paint, coatings and plastics industries as the exclusive platform for precise, reproducible and repeatable results,

reproducible and repeatable life prediction results. The 3000 series is CE, UL, CSA, ISO and EN certified.

Key features of this device include: a rotating sample basket to maximize the homogeneity of all samples;

Pjdpfxetq Em Eo Afhogg

customized nozzles for uniform sample front and back spraying;

ASTM black plate thermometer or ISO/DIN black standard thermometer for control and monitoring,

temperature at sample level to ensure test repeatability.

4500 W water-cooled xenon lamp

Total exposure area 2188 cm2 (339 in2)

12-inch TFT full-color touchscreen control panel - display of all test parameters

Direct setting and control of black panel (BPT, non-insulated) or black standard (BST, insulated) temperature

Direct setting and control of relative humidity

Direct setting and control of the air temperature of the sample chamber

Display of diagnostic messages

14 factory pre-programmed test methods (Weather-Ometer); 6 factory pre-programmed test methods (Fade-Ometer)

Features:

Climate type

Test type Sunlight simulation

Light source with xenon arc lamp

Applications:

Additives and colorants

Adhesives and sealants

Architecture and construction

Automotive industry

Food and beverages

Graphics

Packaging

Paints and coatings

Photovoltaics

Plastics

Textiles

Wind and solar

Consumer electronics

Voltage: 340-415V 43A 50/60Hz

〜3/N/PE 8kW

410 kg

Condition: gebraucht / used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Temperature cabinet -72°C to +180°C

WeissTempEvent T/800/70/10 800 Liter

Call

Year of construction: 2022, condition: excellent (used), White

Type: T/800/70/10

Water-cooled

External dimensions (HxWxD): 2085 x 1415 x 2810mm

Test room dimensions (HxWxD): 950 x 1100x 800 mm

Volume: 800 liters

Minimum temperature: -72 °C

Maximum temperature: +180 °C

Temperature change rate, cooling: 12.0 K/min

Temperature change rate, heating: 12.0 K/min

Temperature deviation over time: ±0.1 to ±0.5 K

Temperature homogeneity spatially: ±0.5 to ±2.0 K

Temperature gradient: ≤2.0 K

Heat compensation, at +20 °C: 8000 W

Power connection 3/N/PE AC 400 V ±10% 50 Hz or 3/N/PE AC 440 V ±10% 60 Hz

Rated power: 30 KW

Rated current: 57 A

Operating hours: approx. 10 (never used)

Condition: used

Weight 1600 kg

Scope of delivery: (See picture)

Sold ex location!

Pgsdpfovxrwgex Afheg

(Changes and errors in the technical data, information are reserved!)

We will be happy to answer any further questions you may have over the phone.

Trust Seal

Dealers certified through Machineseeker

Listing

Borken

Borken

785 km

Climate chamber

WEISSWK1-1000/70

Call

Condition: good (used), White

Type: WK1-1000/70

Weiss climatic test chamber water-cooled

(refrigerant converted to R-452A)

Psdsrvx Ezopfx Afhegg

Touch panel" control unit

All control and operating commands can be triggered by simply touching the function icons on the

all control and operating commands by simply touching the function icons.

Feedthroughs

The test chamber is equipped with feed-throughs on the right and left side.

Measurement cables and test equipment can be routed into the test chamber through these.

Feed-throughs:

1 feed-through ∅ 125 mm installed on the right

1 feed-through ∅ 50 mm installed on the left

Volume 990 liters

Test chamber dimensions:

Test chamber: width 1100 mm, depth 950 mm, height 950 mm

Housing: width 1385 mm, depth 1850 mm, 1980 mm

Data for temperature tests:

Minimum temperature -70 °C

Maximum temperature +180 °C

Temperature deviation, temporal ± 0.1 to ± 0.5 K

Temperature homogeneity, spatial ± 0.5 to ± 2 K

Temperature change rate, heating 4 K/min

Temperature change rate, cooling 2.5 K/min

Max. heat compensation 2750 W

Data for climate tests:

Temperature range +10°C to +95°C

Humidity range 10 to 98% r.h.

Temperature deviation, temporal ± 0.1 to ± 0.3 K

Temperature homogeneity, spatial ± 0.5 to ± 1 K

Humidity deviation, temporal ± 1 to ± 3% r.h.

Data for operation:

Rated voltage: 3/N/PE AC 400V ±10% 50Hz

Nominal current: 29A Nominal power 19.8 kW

Refrigerant: R-452A/ R23

Weight approx. 910kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, new filling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Temperature test chamber 270 liters

VötschVTS³ 7027-25 -72°C bis +180°C

Call

Condition: excellent (used), Vötsch

Type: VTS³ 7027-25

Heraeus Vötsch temperature test chamber, water-cooled

Performance data:

With temperature change rate of 25 K/min

Test chamber dimensions Height 750 mm Width 580 mm Depth 615 mm

External dimensions Height 1775 mm Width 780 mm Depth 1895 mm

Temperature range -72°C to + 180°C

Temperature deviation temporal ± 0.1 to ± 0.5

Temperature homogeneity in space ± 0.5 to ± 2.0

Pedpfxotz Rqms Afhjgg

Temperature change rate cooling 25 K/min

Temperature change rate heating 25 K/min

Heat compensation at -20 °C 8000 W

Heat compensation at +20 °C 8000 W

Test volume: 270 liters

2x lateral feed-through ∅ 125 cm

1x side feed-through ∅ 50 cm

Cabinet is water-cooled

Test room lighting:

LED strip 24 V, 6.8 W / 2x halogen bulb 24 V, 50 W

Electrical connection:

Nominal voltage: 3/N/PE AC 400V ±10% 50Hz

Nominal power: 26 KW

Rated current: 44 A

Refrigerant: R-452A and R-23

Weight: approx. 980 kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, new filling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Climate test chamber with humidity

VötschVC³ 0100 0°C bis + 90°C

Call

Condition: excellent (used), Vötsch

Type: VC³ 0100

Vötsch climatic test chamber, air-cooled

Test chamber dimensions: Height 950 mm x width 1100 mm x depth 950 mm

Device dimensions: Height 2000 mm x width 1300 mm x depth 1916 mm

Test chamber 990 liters

Temperature tests:

Minimum temperature -0°C

Maximum temperature +90°C

Temperature change rate cooling 0.2 K/min

Temperature change rate heating 0.5 K/min

Temperature deviation in time ± 0.1 to ± 0.5 K

Temperature homogeneity in space ± 0.5 to ± 1.0 K

Heat compensation at +20 °C 350W

Climatic tests:

Minimum temperature +10°C

Maximum temperature +90°C

Dew point temperature range +4°C to +89.5°C

Pgedpfxstz T D As Afheg

Humidity range 10 to 98% r. h.

Humidity deviation over time ± 1 to ± 3% r. h.

Temperature deviation temporal ± 0.1 to ± 0.3K

Temperature homogeneity in space ± 0.5 to ± 1.0K

Voltage: 1/N/PE AC 230V±10% 50Hz

Rated power: 2.3 kW

Rated current: 10 A

Refrigerant: R-404A

Weight approx. 1400 kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, new filling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Borken

Borken

785 km

Laser Sinter SLS Printer

EosEOSINT P 380

Call

Condition: excellent (used), Eos EOSINT plastic laser-sintering system

Here we offer an Eos EOSINT plastic laser-sintering system.

Eos EOSINT Plastic Laser-Sintering-System P380

The EOS P380 system includes the following

Installation space container

Powder container

Overflow tank

Cooler: Termo TEK Termochiller Type: 802-18644-3

Unpacking stamp

Removal trolley

3DM 8 zone process chamber heating 250°C

Each zone individually adjustable, homogeneous temperature field ± 1°C Kelvin

350mm x 350mm x 610mm

Voltage 3/N/PE/ 400V AC

Frequency 50 Hz

Connected load 8 kW

Fuse 32 A

MAX. Laser power 100 W

Laser class open 4

Laser class Closed 1

Weight 850 kg

Type: EOSINT P 380

condition: used / used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

Pjdsft R Swspfx Afhegg

We can answer further questions for you on the phone.

We make it easier for you to find: "homogenizer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Homogenizer (229)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month