Used Packer for sale (303)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Kirchenlamitz

Kirchenlamitz

1,184 km

Rash rust, unpacker

Call

Condition: good (used), Rash rust, unpacker with two vibration motors, good condition, ready for immediate use, wooden supports have to be replaced

Ihedped Tx Absfx Addjt

Listing

Newton Aycliffe

Newton Aycliffe

147 km

Framax Glass Bottle Filling Line with Capacity 2900 Bottles / Hour

FRAMAXVarious

Call

Condition: used, Used Framax glass bottle filling line with capacity approximately 2900 bottles / hour made in 2017 and used for approximately 2500 hours.

Equipment includes isobaric bottling machine model Modulblock RFC1-16/16/1-DPS/C and also depalletiser, packer (box former, 24 bottles/box).

Iedpfx Adjw U A Ifjdoht

Previously used for craft beer and RTD (Ready To Drink) carbonated pre-mixed alcoholic drinks.

Equipment list and additional photos available on request.

Listing

Janville

Janville

878 km

Encaisseuse latérale semi automatique

OLI210

Call

Condition: used, Year of construction: 1988, Manufacturer : OLI

Model: 210

Year : 1988

Type : Semi-automatic side loading case packer

Application : To insert grouped cartons of regular shapes into shipping cartons

Carton infeed and grouping : automatic

Empty box loading: manual

Infeed conveyor

Outfeed roller conveyor

Ijdpfxex R Dhgs Addoht

Factory voltage: 220 / 380 V

Control voltage: 24 V

Max. pressure: 6 bar

Current format: see illustration, adaptation can be quoted separately.

Listing

Marxen

Marxen

901 km

Agricultural machine

Optimer XL600 DEMO

Call

Condition: used, Year of construction: 2025, working width: 6 mm, Equipment: lighting, OPTIMER XL6000 / 47M notched disc / 1 set double-U roller OPT.L/XL6000 / 1 set without front tools / 1 set leveling harrow in front of packer OP XL6000 / 1 set front support wheels / 1

Iodpfxoyahgqe Addoht

Listing

Thisted

Thisted

772 km

Trepko 9104-2 Form–Fill–Seal Cup Packaging

TrepkoFSS 9104-2

Call

Year of construction: 2016, condition: used, Trepko 9104-2 FFS Line + Freemantle S09 (2016)

Trepko 9104-2 Form–Fill–Seal Cup Packaging Line (2016) with T. Freemantle S09 Wrapper

This complete Form–Fill–Seal (FFS) production line from 2016 is engineered for high-capacity manufacturing of thermoformed cup products. The main unit, Trepko 9104-2, forms cups from roll-fed plastic material, fills them with viscous food products, seals with PET/EVOH lids, cuts multipacks, and discharges them for further downstream handling.

Included with the line is a T. Freemantle S09 wrap-around packer from 2016 for grouping and wrapping finished multipacks.

The line is ideal for yoghurt, dairy desserts, processed cheese, margarine/spreads, pâté, and other pumpable or semi-solid food products.

Key Features

- Complete FFS system: forming, filling, sealing, cutting, and discharge

- Designed for 125 g cups (available formats: 4-pack and 8-pack)

- Fully automatic, continuous operation

- Hygienic, stainless-steel construction

Ihsdox Eldxepfx Addet

- Suitable for chilled and ambient food products

- Includes T. Freemantle S09 wrapper/packer for downstream grouping

- Supplied with documentation and manuals

TREPKO 9104-2 – Technical Highlights

Cup Forming

- Thermoforming from PS/EVOH/PE roll material

- Max film width: 740 mm

- Max roll diameter: 1000 mm

- Heavy-duty forming tools for 125 g round cups

- Multi-cavity arrangement for high throughput

Filling System

- Stainless steel volumetric dosing block

- Multi-nozzle configuration for accurate filling

- Suitable for viscous food products

- CIP-compatible design

Sealing

- Lidding material: PET/EVOH, width 240 mm

- Heated sealing station for hermetic seals

- Precise lid positioning and temperature control

Cutting & Discharge

- Automatic multipack cutting

- Supports 4-cup and 8-cup retail pack formats

- Smooth discharge conveyor for integration with wrapping or case packing

T. Freemantle S09 Wrapping Unit (2016)

- For grouping and wrapping cup multipacks or blocks

- Film-fed automatic folder/wrapper

- Adjustable for various package dimensions

- Stainless-steel construction, CE marked

- Compact, reliable downstream solution

Applications

- Stirred yoghurt

- Sour cream / dairy desserts

- Processed cheese spreads

- Margarine, butter portions, vegetable fat spreads

- Dips, pâté, paste-type products

- Any pumpable or semi-viscous food requiring thermoformed cups

Technical Information

- Trepko Model: 9104-2

- Machine No.: 3859

- Year: 2016

- Voltage: 415 V / 50 Hz

- Freemantle S09 Year: 2016

- Voltage: 240 V

- Full documentation available.

Condition

The line is in very good used condition, complete with all major forming, filling, and sealing components, stainless-steel safety enclosures, and electrical cabinets. Well maintained and previously used for yoghurt production in a European dairy facility.

Discover more used machines

Listing

Brakel

Brakel

926 km

BTS-Tyre Packing Machine Gen.2

Beckmann Technik & Service KGBTS-Reifenpackmaschine Gen.2

Call

Year of construction: 2026, condition: as good as new (ex-display), The BTS-Tyre Packing Machine Gen.2 is ideal for used tyre companies with large tyre volumes. The triple machine is the perfect solution for cost-effective disposal or resale of second-hand tyres.

By doubling or tripling the tyres you achieve an enormous volume reduction, the available storage and loading capacity, as well as the permissible transport weight can be used much more efficiently.

Pressing cylinder: Pneumatic

Pressing force: 1.23 kN, adjustable

Machine size: 1250 H x 1930 W x 660 D mm

Machine weight: 93 kg

Transport size: 1250 H x 1200 W x 800 D mm

Working height: 800 - 1020 mm, adjustable

Power supply: Air, up to 10 bar / 145 Psi

Working pressure: 6 - 8 bar

User-friendly and safe two hand control

Strong and long-life design

High-performance pneumatic cylinder

Ball bearing roller guides

Adjustable working height

Low noise level by silencer

Air quick connector

A quality product “Made in Germany”

Suitable for doubling and tripling

Second-hand tyres

Optional extras

Machine colour RAL

BTS-MF550HD Scrap Tyre Baler

Demo-Video shows BTS-Tyre Packing Machine Gen.1, the BTS-Tyre Packing Machine Gen.2 operates on same way.

Tyre packing machine, Tyre triple machine, Tyre double machine, Tyre doubler, Tyre tripler, Tyre packer, Tire packing pachine, Tire tripling machine, Tyre doubling machine, Tire doubling machine

Ihedpfx Aeb Rz R Usddjt

Listing

Germany

Germany

1,034 km

Stone Production Plant

OmagTronic S22 140-90

Call

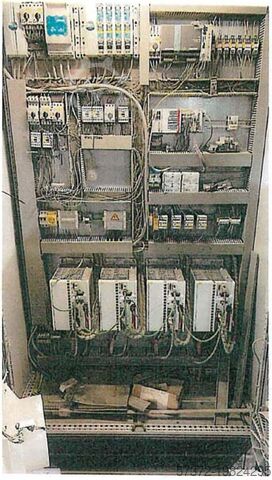

Year of construction: 2001, condition: ready for operation (used), A paving stone production line Omag, which has been continuously optimized and upgraded to the latest technical standards, is available. Overhauls: 1) Conversion for an additional hydraulic unit for additional load in 2020. 2) Conversion to servo-vibration with Siemens S7 control in 2016. 3) Conversion to digital path measurement of mould and ram in 2017. 4) New core filling carriages in 2017. Plant components: 1) Board destacker and board stacker including roller conveyor. 2) Board feeder (advance) and board conveyor (scraper) to the lifting frame. 3) Board turner. 4) Horizontal and vertical bundling units Ridder & Signode, years of manufacture: 1994 and 1983. 5) Trafo lifting platform including motors and without control, year of manufacture: 1983. 6) Doppler including hydraulic unit, year of manufacture: 2004. 7) Stone packer Omag K1400 including hydraulic unit, year of manufacture: 1997. The line has no base boards. 8) Stone finisher Omag S22 140-90, year of manufacture: 2001. Documentation available. An on-site inspection is possible.

Iodpsw R Uziefx Addeht

Listing

Hénanbihen

Hénanbihen

764 km

Egg packing machine

STAALKATFP292

Call

Condition: excellent (used), Year of construction: 2010, Staalkat FP292 egg packer

Year 2010

Iedpsvf Rv Uefx Addoht

72,000 eggs per hour

In very good working order

Listing

Helmstedt

Helmstedt

1,008 km

Book binding machine

WohlenbergQuickbinder

Condition: excellent (used), Year of construction: 2008, functionality: fully functional, type of input current: AC, throughput speed: 2,000 mm/s, Equipment: documentation/manual, Built in 2008

Size max 320 x 430 x 70 mm

min 105 x 140 x 2 mm

Book block thickness max 70 mm

min 2 mm

Cover size max 435 x 650 mm

min 140 x 208 mm

Speed max 2.000 c/h

Length 3.700 mm

Width 1.400 mm

Height 1.300 mm

Equipment milling station

• dust extraction

• PUR gluing unit

• premelter for PUR glue

• gauzing/- back stripping station

• pile cover feeder

• cover pressing station

• belt delivery

• packer stack delivery

standards

• 1 set of operator manuals

• 1 set of standard tools

• information:

Ihodpeuyx Avofx Addjt

• condition: cleaned in very good working condition

• location: Germany Helmstedt

Listing

Milano

Milano

1,417 km

KHS can filling line for CSD and beer

KHSCAN FILLING LINE FOR CSD AND BEER

Call

Condition: like new (used), Year of construction: 2012, functionality: fully functional, KHS CAN FILLING LINE FOR CSD AND BEER

Technical Data

Capacity: 25,000 bph (0.5L)

Product: Carbonated soft drinks and beer

Can Formats: 500ml 211/202

Lid Formats: 211/202

Packaging: Tray with shrink film

Application: CSD and beer

Condition: Good technical condition, dismantled

Scope of Supply

- Bulk can depalletizer | LINKER | DPG-500 | Year: 2012

- Can inspection system | TransTech | Hysek CanCheck | Year: 2012

- Can conveyors | LINKER / KHS | Conveyor RC | Year: 2012

- Can rinser | LINKER / KHS | Triplex Rinser TR | Year: 2012

- Flash pasteurizer | KHS | Innopro 140/14/85 | Year: 2012

- Can filler | KHS | Innofill Can DVD | Year: 2017

- Can seamer | Ferrum | F08 | Year: 2012

Ihedjx U Snpopfx Addot

- Lid feeder | NSM | Lidserver A30 | Year: 2017

- Conveyor | KHS | Innoline BTR | Year: 2012

- Fill level inspection | KHS | Innocheck CUB | Year: 2012

- Can blowing unit | Europool | –

- Tray packer | KHS Kisters | SP0502 | Year: 2012

- Pack conveyor | KHS | Innoline GTR | Year: 2012

- Handle applicator | KHS | CSM 050-2 | Year: 2012

- Packing machine | KHS | Innopack 035 B2 + FS A-L | Year: 2012/2017

- Palletizer | KHS | Innopal PBL1N1 | Year: 2012

- Stretch wrapper | SIAT | MFP | Year: 2017

- Pallet conveyor | KHS | Innoline PTR

This line is suitable for bottling carbonated soft drinks and beer in 500ml cans, with a maximum output of 25,000 cans per hour. It comes dismantled, in good technical condition, and ready for reinstallation.

Listing

Thisted

Thisted

772 km

CARDBOARD MULTIPACK SLEEVER

SMI Flexi (NEW PRICE)MP 150 TR

Call

Year of construction: 2011, condition: excellent (used), The MP series includes automatic machines for the packaging of plastic, metal, cardboard and glass containers in overwrapping cardboard sleeves.

MP series packers can achieve an output up to 150 packs per minute, depending on the product to be packaged. Low or medium capacity containers can be packed in OTT (Over The Top) or NT (Neck Through) style.

For shaped products, the pack can be strengthened by adding a top/bottom retaining flap which keeps the containers steadier inside the cardboard sleeve; furthermore.

The pack collations can vary according to the containers shape and dimensions; in general, the most requested collations are: 1x3, 1x4, 2x2, 2x3 and 2x4. All MP models feature an electronic grouping system; the changeover is manual.

Cardboard sleeves with flap

Stacked packs

Pack with handle

Iodpofvcu Eofx Addoht

Cardboard sleeves - Over The Top (OTT)

Cardboard sleeves - Neck Through (NT)

Machine has been used only 250 hours!

Listing

Brakel

Brakel

926 km

BTS-Tyre Packing Machine Gen.2

BTS-Reifenpackmaschine Tyre Packing Machine

Call

Condition: as good as new (ex-display), Year of construction: 2026, The BTS-Tyre Packing Machine Gen.2 is ideal for used tyre companies with large tyre volumes. The triple machine is the perfect solution for cost-effective disposal or resale of second-hand tyres.

By doubling or tripling the tyres you achieve an enormous volume reduction, the available storage and loading capacity, as well as the permissible transport weight can be used much more efficiently.

Pressing cylinder: Pneumatic

Pressing force: 1.23 kN, adjustable

Machine size: 1250 H x 1930 W x 660 D mm

Machine weight: 93 kg

Ihjde Ry Huspfx Addot

Transport size: 1250 H x 1200 W x 800 D mm

Working height: 800 - 1020 mm, adjustable

Power supply: Air, up to 10 bar / 145 Psi

Working pressure: 6 - 8 bar

User-friendly and safe two hand control

Strong and long-life design

High-performance pneumatic cylinder

Ball bearing roller guides

Adjustable working height

Low noise level by silencer

Air quick connector

A quality product “Made in Germany”

Suitable for doubling and tripling

Second-hand tyres

Optional extras

Machine colour RAL

BTS-MF550HD Scrap Tyre Baler

Demo-Video shows BTS-Tyre Packing Machine Gen.1, the BTS-Tyre Packing Machine Gen.2 operates on same way.

Tyre packing machine, Tyre triple machine, Tyre double machine, Tyre doubler, Tyre tripler, Tyre packer, Tire packing pachine, Tire tripling machine, Tyre doubling machine, Tire doubling machine

Listing

Germany

Germany

1,034 km

Fully automatic side sealing machine

SchlichterSCV 400 Pro + SCT 400U

Call

Condition: used, Year of construction: 2020, Packaging Machine

Fully Automatic Side Sealing Machine Profi Packer

Manufacturer: Schlichter

Model: SCV 400 Pro

Year of Manufacture: 2020

Longitudinal Sealing: Continuous

Photoelectric Sensors: Horizontal and vertical (standard)

Compressed Air: 6 bar

Conveyor Speed per Minute: min. 5 meters, max. 30 meters

Film Core Ø: 76 mm

Max. Film Roll Ø: 350 mm, with optional folding device up to 700 mm!

Ihodoxuglmjpfx Addot

Max. Film Roll Width: 650 mm

Sealing Bar Width: 300 mm

Product Width (min./max.): 50 mm to 410 mm

Product Height (min./max.): 1 mm to 250 mm

Product Length (min.): 50 mm, (max.): unlimited

Film Thickness: 7 to 80 μm

Film Material: Polyolefin fine shrink film, Polyethylene, PVC; PLA and other bio films

Cycles per Minute: up to approx. 85 cycles

Machine Dimensions (L x W x H): 2,200 x 1,680 x 1,800 mm

Weight: 800 kg

Shrink Tunnel:

Model: SCT 400U

Year of Manufacture: 2020

Passage Width: 450 mm

Passage Height: 280 mm

Heating Power: 14 kW

Dimensions (L x W x H): 2,065 x 1,065 x 1,340 mm

Listing

Buseck

Buseck

976 km

Packaging machine

WebomaticVAKUUMGERÄT E-15 BASIC

Call

Year of construction: 2019, condition: used, functionality: fully functional, machine/vehicle number: 077-Z2A-2147, This is a manual packaging machine E 15 Basic from the premium manufacturer Webomatic, built in 2019. These small vacuum table-top machines offer high packaging performance. If you need to pack large products at high capacity but have limited space for a vacuum packaging machine, the compact yet powerful E 15 Basic or C 15-HL packaging machines are the perfect choice!

You will receive an invoice with VAT shown separately.

Our used equipment service for you:

• 6-month warranty on all electrical parts

• High-quality brand-name equipment at fair prices

• Professional refurbishment, inspection & expert cleaning

• Tested and fully functional – or your money back

• Flexible shipping or collection options

• Competent advice – before and after purchase

• Provision of operating manuals, connection diagrams & spare parts

• Safety check according to DGUV V3

Technical data:

MAP (E 15 Basic)

Soft-Air (E 15 Basic)

Undercarriage

Angled insert

GreenVAC

Machine dimensions: 490 x 610 x 470 mm (W x D x H)

Iodpox Drl Djfx Addjht

Chamber dimensions: 430 x 500 x 180 mm (W x D x H)

Weight: net/gross approx. 83 kg / 91 kg

Pump: 21 m3/h high-performance pump, built-in

Cycle performance: 2-3 cycles/min., depending on product size and desired vacuum

Chamber made of high-quality stainless steel

Easy operation

MAP (C15, optional for E 15 Basic)

Soft-Air (C15, optional for E 15 Basic)

Serial number: 077-Z2A-2147

Year of manufacture: 2019

Additional information:

The vacuum packer for any application.

The E 15 Basic and C 15 HL packaging machines are perfectly suited for vacuum packing and packaging in kitchens, at weekly markets, branch operations, or for meat packaging in hunting and game processing. They are also ideal for packaging sterile and sensitive medical products or items from the electronics sector, as well as for packaging banknotes.

As the C 15 HL version, the table-top machine is equipped with the sensor-controlled WEBOMATIC C 3000 S computer and comes standard with Soft-Air and MAP gas flushing for gentle gassing and vacuum packaging of delicate products. These functions are also optionally available for the E 15 Basic table-top machine. Food-safe PE chamber inserts for reducing chamber volume are included with the vacuum packer.

Shipping:

Delivery or collection by arrangement

Worldwide shipping available on request

Shipping to islands or mountain stations only by arrangement

Listing

Söding

Söding

1,595 km

Wide belt sander

JetDDS-237

Call

Condition: excellent (used), !!!DEMONSTRATION MACHINE!!!

For sale is an as-new JET DDS-237 sanding machine with a maximum sanding width of 940 mm.

The machine is in excellent condition and has been refurbished and inspected by our specialist staff. (Fully functional)

Technical data:

- Double drum sander JET DDS-237

- Motor: 400 V / 7.5 HP

- Sanding drum speed: 1,400 rpm

- Feed speed: 3 m/min

- Max. sanding width: 940 mm

- Sanding thickness: 0.8 to 133 mm

- Minimum workpiece length: 230 mm

- Sanding drum dimensions: 152 x 940 mm each

- Sanding belt width: 75 mm or 100 mm

- Extraction port: 2 x diameter 100 mm

Ijdpfx Asx Sqzvoddeht

- Dimensions (LxWxH): 1,090 x 1,420 x 1,090 mm

- Weight: 440 kg

The machine is located in A-8561 Söding and can be inspected and collected at any time during our opening hours. Subject to prior sale!

Related terms: column drill, pillar drill, drilling machine

Reference: R-D1618

Listing

Oosterhout

Oosterhout

684 km

Bag forming, filling and sealing machine

ROVEMAVPX 250 for powder

Call

Condition: refurbished (used), DL Packaging – Complete Powder Packaging Lines

We build and install cost-efficient, hygienic, and accurate powder packaging lines.

Our Second Life Machines offer the performance of new equipment at a fraction of the cost and with fast delivery.

Why choose our powder solutions?

• High automation for maximum output and minimal labor

• High filling accuracy with sensors that adapt to product and environment

• Easy access & fast cleaning for minimal downtime

• Strong technical support and durable wear parts

Complete lines include:

• SDX dosing system with custom auger screw

Isdpjx Dbq Asfx Addsht

• VFFS machine (pillow, block-bottom, doypack, stabilo bags)

• Discharge conveyor, Turntables,

• Cartoning/ Case packer solutions

Suitable for powders from 5–30 kg (milk, coffee, spices, sugar, chemicals) with speeds up to 100 bags/min.

DL Packaging – Reliable, hygienic and affordable powder packaging from A to Z.

Listing

Thisted

Thisted

772 km

Filling Machine Elopak

Elopak (New Discount Price)P-M30D

Call

Condition: good (used), Item: M-8040-Elopak-P-M30D

Filling machine: Elopak Type P-M30D

Pure-Pak Classic Type P-M30D with Screw caps!

Capacity 3.000 pieces/hour

Filling 0,2 - 0,33 - 0,5 L

Complete with Tetra Pak Cardboard Packer 70!

Carton conveyor

Spare part kit

The machine has been in production to 2019 and was dismantled q3 2019

Machine speed: Maximum 3000 cartons per hour (mechanical capability) Selectable speeds.

Standard Carton sizes: 200 - 330 - 500 ml

More technical details can be provided upon request

Ijdpfjd Ec I Nox Addjht

Listing

Newton Aycliffe

Newton Aycliffe

147 km

Kosme PET Bottling Line with Capacity 3000 Bottles/hour

KOSMEVarious

Call

Condition: used, Used Kosme edible oil PET bottle filling line with capacity 3000 bottles / hour and including blow moulding equipment. Made in 2012 and with only approximately 72 hours of use.

Last used on sunflower oil and suitable for bottles sized 1l (3000 BPH, press cap, hot melt label), 2l (2800 BPH, press cap, hot melt label), 5l (2000 BPH, screw cap, adhesive label) and 10l (1000 BPH, screw cap, adhesive label).

Line includes the following equipment:

- Kosme KSB 2XL/4F blow moulder. Preform neck dimensions: smallest neck 28mm, largest neck 48mm, neck ring diameter 53mm, neck height 22mm, max length (under neck ring) 200mm. Preform bottle dimensions: max diameter 235mm, max height 430mm, base height 55mm.

- Filler / capper model Weighblock 16/1440 6/540 P.

- Labeller model Extra HM 4/720 Sa1 E1.

- Packer model Acepack 2/4T.

- Carton erector model Formapack H.

- Carton sealing unit model Sealpack H.

- Palletiser and stretch film wrapper.

Iedpfx Adow U A Ilodjht

- Coders, handle applicators, elevators and conveyors.

- (8) 25000 litre oil tanks, compressor, dryer, air tank, spare parts, auxiliary equipment and approximately 100,000 PET preforms.

Listing

Birmingham

Birmingham

339 km

C Frame Hydraulic

WMWC FRAME

Call

Year of construction: 1990, condition: like new (used), Quality WMW 250ton C frame hydraulic press for sale

Ijdpfoig Hzkox Addsht

The machine bed size is approximately 630mm x 850mm with an Opening/Daylight dimension of 300mm.

The machine is fitted with a 150mm Packer plate which could be removed to allow for 450mm opening.

Listing

Greven

Greven

815 km

High-barrier film, cardboard packaging, PET cans

Kaiser, Obeck

Call

Condition: new, Year of construction: 2023, functionality: fully functional, High-Barrier Film:

Premium film from a German quality manufacturer – no imported goods! Ideal for producers, co-packers, and fillers with the highest demands for aroma protection and machinability.

Product Details:

Product type: High-barrier flat film featuring EVOH aroma protection

Aroma barrier: Extremely strong – suitable even for citrus aromas

Colour: Transparent

Roll width: 260 mm

Film thickness: 62 µm

Core diameter: 76 mm

Roll length: 1,000 linear meters

Manufacturer: Kaiser Verpackung GmbH

Applications: For food products (e.g. spices, tea, snacks, coffee pads); for cosmetics & non-food items; compatible with virtually all form, fill and seal machines; suitable for aroma-sensitive products.

Availability & Tiered Pricing (1,000 linear meters/roll):

Price per 1,000 lfm (1 roll):

5 rolls – €140/roll

10 rolls – €135/roll

30 rolls – €130/roll

60 rolls – €125/roll

120 rolls – €120/roll

Stock: 120,000 lfm

Location: Greven

Shipping via freight forwarding or collection by arrangement

Quick and cost-effective – below current market price. Perfect for your ongoing production!

-----

Cardboard Boxes – Remaining Stock

Dimensions: 374x374x166 mm 3C450g/m2 (super sturdy!) 5,000 units

Price: €0.30 per box when purchasing 5,000 units, smaller quantities available upon request

We also offer matching jars for sale; each carton fits 32 pieces of 400 ml jars:

-----

PET Jars from German brand manufacturer OBECK:

Material: PET (Polyethylene terephthalate)

Colour: White

Volume: 400 ml

Diameter: 93 mm (SP400)

Height: 81 mm

Weight: 36 g

Suitable for food & recyclable

Matching PP Lids:

Type: Screw cap (Smooth 89SP400)

Material: PP (Polypropylene)

Colour: Black

Height: 14 mm

Applications: Food packaging (spices, nuts, protein powder); cosmetic products (creams, lotions, masks); dietary supplements (capsules, powders); industrial use (chemicals, paints, adhesives)

Prices (per jar and lid set):

2,880 pcs – €0.35

each 5,760 pcs – €0.32

Ihedpfx Adex A S A Hedet

each 11,520 pcs – €0.30

each 20,160 pcs – €0.26

each 48,960 pcs – €0.22

each 100,800 pcs – €0.20

each 400,320 pcs – €0.18 each

Minimum order: 2,880 pcs (2 pallets)

Stock location: Greven

Shipping: Freight forwarding or collection (by arrangement)

Quick sale – We need storage space and are significantly cheaper than the manufacturer. Secure below-market deals now!

If interested or if you have any questions, please get in touch!

Listing

Mala Vranjska

Mala Vranjska

2,023 km

Vacuum machine

RöschermaticV 21 2

Call

Condition: like new (used), Vacuum machine

Ijdpoxru H Hsfx Addsht

Manufacturer: Röschermatic

Double-chamber vacuum packer

Dimensions: 470x450x180mm

Seal bar lenght: 450mm

Pump capacity: 63 m³/h

Voltage: 380V / 50Hz

Trust Seal

Dealers certified through Machineseeker

Listing

Oosterhout

Oosterhout

684 km

Bag forming, filling and sealing machine

ROVEMAVPL 260 Doypack

Call

Condition: refurbished (used), Introducing the Rovema VPL 260 Doypack + Reclose (Adhesive Strip) (VFFS)!

Designed for flexibility and performance, the Rovema VPL 260 Doypack offers top-tier packaging solutions for a wide variety of products. With its sturdy construction and efficient design, this machine handles everything from pasta and cereals to sweets, pet food, and more.

The VPL 260 delivers an impressive output of up to 70 bags per minute, offering a range of packaging options, including block bottom bags, and Ro pack bags with a zip. With the added reclose (adhesive strip) feature, it ensures maximum convenience for both the producer and end consumer.

Key Features:

• Brand: Rovema

• Model: VPL 260

• Capacity: Up to 70 bags/min

• Applications: Granules, pasta, cereals, grains, seeds, granola, muesli, sweets, candy, nuts, dried fruits, pet food, crackers, cookies, tea, dry pasta, and more

Iodox Ag Nuepfx Addoht

• Packaging types: Block bottom bags, Ro pack bags with zip, Stabilo bags

• Construction: Robust design for durability

• Control system: User-friendly interface

• Warranty: 3 months

• Delivery time: On request

Optional extras: Stabilo/Doy packaging, resealing strip (adhesive), and more – fully customizable for your specific needs.

DL Packaging specializes in modernizing dosing systems, vertical form-fill-seal machines, cartoners, and end-of-line packers. Our "Second Life Packaging Solutions" are rebuilt to like-new standards and can be integrated into fully automated lines, all from a single source.

With over 30 years of experience, in-house dosing expertise, and tailored advice, we ensure your machine or line is perfectly suited to your needs. We also offer remote support, maintenance contracts, and a warehouse with 20,000+ parts for seamless production.

DL Packaging – your global partner for retrofitted packaging solutions, based in Oosterhout and a proud partner of the Rovema Group.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Filling Monoblock

CimecLD 16-16-3E/PK-1RF-1V

Call

Condition: used, Year of construction: 2010, Technical Specifications & Performance Data

This Pentablock Filling Monoblock combines rinsing, filling, corking, and wire-hooding in a single compact rotary frame for glass bottle handling. Manufactured by Mondial, the LD 16-16-3E/PK-1RF-1V configuration delivers robust mechanical design with precise bottle control across the rinsing, filling, capping, and wire-hooding turrets. It is suitable for second hand installations and integration into a used bottling line focused on beverage production and industrial packaging.

Model: LD 16-16-3E/PK-1RF-1V

Bottle materials: Glass

Bottle formats: Compatible with 0.33L and 0.75L bottle formats

Rinser turret: 16 grippers (rotary)

Filler turret: 16 valves, gravity/light depression technology

Closures supported: Crown cap, champagne-style mushroom cork

Wire hooding: Integrated wire-hood applicator for champagne-style closures

HMI: Siemens OP73 Micro

Typical applications: Wine, sparkling wine, and specialty beverages in glass

Advanced Automation & Control Systems

The monoblock features an integrated automation architecture with a user-friendly HMI for setup, format recipes, and diagnostics. Line operators benefit from clear alarm messaging and guided procedures that reduce downtime and facilitate changeovers between formats and closure types. The control system supports coordinated motion across turrets to maintain stable product handling and consistent fill accuracy.

Siemens OP73 Micro HMI for monitoring and control

Programmable format parameters for different bottle sizes

Interlocked guards and safety logic for operator protection

Quick adjustments for height and starwheel changeovers

Production Line Integration Capabilities

Engineered to operate as a standalone monoblock or integrated within a complete used bottling line, this machine accepts infeed conveyors and outfeed conveyors for seamless connection to upstream and downstream equipment such as labelers, inspectors, and packers. Its rotary architecture accommodates format parts for multiple glass bottle sizes and closure types while maintaining consistent throughput and gentle handling.

Inline integration with standard conveyor systems

Multi-format capability: 0.33L and 0.75L glass bottles

Closure flexibility: crown cap and champagne-style cork with wire-hood

Ijdpfxox Ivq Ie Addoht

Suitable for production environments of refermented beer and classically prepared sparkling wine

Machine Condition & Maintenance History

The machine is presented as ready for operation with a commercial focus on reliable second hand bottling equipment. Standard preventive maintenance points are accessible, with clear procedures for scheduled inspections and sanitation to maintain consistent quality.

Operational status: ready for operation

Routine access for inspection and cleaning

Supports sanitization of product-contact parts

Operational Performance & Versatility

This monoblock is designed for glass beverage applications requiring high-quality rinsing, accurate gravity/light depression filling, robust closure application, and secure wire-hooding for champagne-style finishes.

Listing

Oosterhout

Oosterhout

684 km

Bag forming, filling and sealing machine

DLPACKDLPACK 260 Servo

Call

Condition: like new (used), functionality: fully functional, warranty duration: 12 months, filling weight (min.): 5 g, filling weight (max.): 5,000 g, Introducing the brand-new DLPACK 260 Servo! Built with stainless steel and equipped with Siemens controls, this machine delivers exceptional performance for a wide range of applications, from powders and granules to food and non-food products.

The first 20 machines have already been built and commissioned, achieving an output of up to 105 bags per minute. With a dosing range of 5g to 5000g and bag sizes from 60–260 mm (W) × 80–500 mm (L), it is designed to handle almost any packaging requirement.

Key Features:

Brand: DLPACK

Model: DLPACK 260 Servo

Capacity: Up to 105 bags/min

Dosing range: 5g – 5000g (via separate dosing)

Bag format: 60–260 × 80–500 mm

Construction: Stainless steel

Control system: Siemens

Warranty: 12 months

Delivery time: 10 weeks

Optional extras: Printer, labeler, weigher, screw dosing, and more – fully customizable for your application. Suitable for pillow bags and almost any product type.

About DL Packaging

DL Packaging specializes in modernizing and installing dosing systems, vertical form-fill-seal machines, cartoners, and end-of-line packers. Our “Second Life Packaging Solutions” are rebuilt to near-new standards and can be combined into fully automated lines – all from a single source.

With over 30 years of experience, in-house dosing capabilities, comprehensive warranties, and tailored advice, our experts design the perfect machine or packaging line for your needs. Remote support, maintenance contracts, and a warehouse stocked with over 20,000 parts ensure your production keeps running smoothly.

DL Packaging – your worldwide partner in retrofitted packaging solutions, based in Oosterhout and proud retrofit partner of the Rovema Group.

Iodpfx Asx Ag Ikoddeht

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, operating hours: 30,000 h, Used CFT can filling line for soft drinks – 12,000 cans per hour

Introduction and Production Capacity

The Used CFT can filling line for soft drinks – 12,000 cans per hour delivers a complete solution for filling carbonated beverages in aluminum cans. CFT designed the line in 2017 and configured it to handle two Slim formats, which are commonly used in the soft drink industry. Specifically, the system processes up to 12,000 cans per hour, meeting the output requirements of medium-scale industrial facilities. As of 30/06/2025, the owner will release the line for sale. Therefore, this represents a valuable opportunity for facilities seeking to expand their production capacity.

Depalletizing and Initial Inspection

Initially, the CFT depalletizer automatically separates empty cans and feeds them into the production flow. Then, a HEUFT inspection unit checks each container for visual defects and dimensional non-conformities. As a result, the system ensures that only clean, undamaged cans move forward for rinsing. In addition, this early inspection step reduces the risk of line stoppages later in the process.

Ijdpfxox H Tilj Addsht

Can Conveyance and Rinsing

Next, CFT cable conveyors transport the accepted cans to a dual-channel rinser. The CFT rinser cleans the interior of each can using pressurized water jets or sterile air. Consequently, the machine maintains hygiene standards in line with food and beverage regulations. Moreover, the dual-channel configuration improves throughput while reducing contamination risks. Notably, this section plays a key role in maintaining microbiological safety.

Filling

After rinsing, a CFT monoblock handles the filling and seaming stages with 12 filling valves and 4 seaming heads. The machine processes cans of 150 ml and 330 ml efficiently. It also controls pressure and temperature precisely to prevent CO₂ loss during the filling of carbonated soft drinks. Furthermore, this phase supports both performance and product integrity. In effect, it ensures consistent quality in high-speed conditions.

Full Can Inspection and Rejection

Following the filling stage, another HEUFT unit inspects the filled cans to verify fill levels, seal integrity, and the absence of leaks. When it detects non-compliant cans, an automated HEUFT rejection module removes them from the line. As such, this step protects the quality of downstream operations. Additionally, it avoids the unnecessary packaging of defective units. Overall, the system minimizes waste and downtime.

Conveyance and Packaging

Subsequently, CFT conveyors move the approved cans to an SMI shrink wrap packer. The packer forms bundles in several formats: 4×3 (12 cans), 6×4 (24 cans), and 2x2x3 (12 cans). In this way, the flexible configuration supports various packaging and distribution strategies. Besides improving logistics, this packaging versatility allows rapid changeovers between product sizes.

We make it easier for you to find: "packer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Packer (303)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you