Used Yamaguchi Wb 12 H for sale (66,222)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Falkenberg

Falkenberg

1,345 km

Telescopic loader wheel loader with telescope

H&RTeleskopradlader 2512T

Call

Condition: new, functionality: fully functional, power: 18.8 kW (25.56 HP), gearing type: automatic, fuel type: diesel, color: red, overall weight: 2,740 kg, lifting height: 3,283 mm, tire size: 31x15,5x15 AS, tire condition: 100 %, drive condition: 100 %, axle configuration: 2 axles, number of seats: 1, emission class: euro5, Year of construction: 2025, fuel: diesel, Equipment: additional headlights, adjustable boom, all wheel drive, cabin, head guard, pallet forks, standard shovel, H&R Telehandler 2512T – The compact wheel loader for versatile applications with an enclosed cab for greater comfort.

Advantages of the H&R Wheel Loader 2512T

Powerful engine: The Yunnei DEF20CFF4 4-cylinder engine with 25 hp delivers high performance with low fuel consumption and complies with the Euro 5 emissions standard.

Easy operation: The 2-stage torque converter and all-wheel drive enable easy handling, even with heavy loads and difficult ground conditions.

Compact design, high maneuverability: Despite its weight and a lifting capacity of 1200 kg, the H&R wheel loader has a relatively small turning circle.

Hydraulic quick coupler: With the hydraulic quick coupler, you can quickly and easily switch between different attachments, such as the standard bucket or the manually adjustable pallet fork.

Expandable functions: Use the additional hydraulic control circuit to operate additional attachments such as mowers, bale grippers, snow plows, and much more.

Njdpfx Ajrhgn Sjacewc

H&R loaders are technically and visually optimized in-house and thoroughly tested. Additionally, each machine receives extensive rust protection treatment.

Our loaders are CE-compliant according to the EU Machinery Directive. Our machine has a TÜV Süd certificate for obtaining an individual operating permit in accordance with Section 21 of the German Road Traffic Licensing Regulations (StVZO) (road approval/operating permit as a self-propelled work machine).

Key Features of the H&R 2512T Telehandler

• Fully equipped

• Extensively optimized in Germany

• Telescopic boom for a greater reach

• Includes standard shovel (160 cm) and pallet fork

• Powerful and versatile - versatile

• Compact design ensures high maneuverability

• Comfortable cab with heating, ventilation, and radio (MP3 and USB) for extended working hours

• Joystick with electric gearshift for precise control

• Additional control circuit for attachments such as mowers, bale grabs, snow plows, etc.

• LED work lights and windshield wipers for clear visibility in all weather conditions

• MP3 radio and USB port for entertainment while working

• Rearview camera with display in the interior

• Trailer hitch for additional trailer use

• 220V cooling water preheater for reliable cold start capability and increased engine life

• Hour meter for monitoring operating times and ensuring optimal compliance with maintenance intervals

• Ideal for agriculture and construction and industry

• CE-compliant according to the EU Machinery Directive

• 1-year spare parts warranty

Price

Net: €21,845.00

VAT: €4,150.00

Gross: €25,995.00

Financing available!

Optional

Road registration / operating permit: €595

Extended warranty (2 years): €590

Transportation in Germany and Austria: Upon request

Technical details

Engine: 4-cylinder Yunnei DEF20CFF4

Engine power: 25 hp (18.8 kW)

Emissions class: Euro 5

Lifting capacity: 1200 kg

Lifting height: 3283 mm (bottom edge of standard pallet fork)

Unloading height: 2753 mm (standard bucket tipped)

Lifting capacity: 1200 kg

Wheelbase: 2.17 m

Tires: 31×15.5-15 AS

Dimensions: 3850 x 1610 x 2460 mm

Weight: 2740 kg

Accessories and spare parts are available from us.

Please provide your telephone number when making inquiries.

Listing

Falkenberg

Falkenberg

1,345 km

Farm loader Wheel loader Compact loader

H&RHoflader 2412

Call

Condition: new, functionality: fully functional, power: 18.39 kW (25.00 HP), gearing type: automatic, fuel type: diesel, color: red, overall weight: 2,470 kg, lifting power: 1,200 kg/m, lifting height: 2,489 mm, tire size: 31x 15,5 - 15 AS, tire condition: 100 %, drive condition: 100 %, axle configuration: 2 axles, number of seats: 1, first registration: 04/2025, emission class: euro5, digging bucket width: 1,600 mm, Year of construction: 2025, Equipment: additional headlights, all wheel drive, cabin, head guard, hydraulics, pallet forks, standard shovel, trailer coupling, H&R 2412 – The compact wheel loader for versatile applications with an open cab

Advantages of the H&R 2412 loader

Powerful engine: The Yunnei DEF20CFF4 4-cylinder engine with 25 hp delivers high performance with low fuel consumption and complies with the Euro 5 emissions standard.

Easy operation: The 2-stage torque converter and all-wheel drive enable easy handling, even with heavy loads and difficult ground conditions.

Compact design, high maneuverability: Despite its high weight and a lifting capacity of 1200 kg, the H&R wheel loader remains extremely maneuverable with a relatively small turning circle – ideal for tight construction sites and agricultural applications.

Hydraulic quick coupler: With the hydraulic quick coupler, you can quickly and easily switch between various attachments, such as the included standard bucket or the manually adjustable pallet fork.

Expandable functions: Use the 3rd and 4th hydraulic control circuits to operate additional attachments such as mowers, bale grippers, snow plows, and much more.

H&R loaders are technically and visually optimized in-house and thoroughly tested. Additionally, each machine receives extensive rust protection.

Our loaders are CE-compliant according to the EU Machinery Directive. Our machine has a TÜV Süd certificate for obtaining an individual operating permit in accordance with Section 21 of the German Road Traffic Licensing Regulations (StVZO) (road approval/operating permit as a self-propelled work machine).

Key Features of the H&R 2412

• Includes standard shovel (160 cm) and pallet fork

• Powerful and versatile - versatile

• Compact design ensures high maneuverability

• Joystick with electric gearshift for precise control

• Additional 3rd and 4th control circuits for attachments

• LED work lights

• Trailer hitch for additional trailer use

• 220V coolant preheater for reliable cold start capability

• Hour meter for monitoring operating times and ensuring optimal compliance with maintenance intervals

• CE compliant according to the EU Machinery Directive

• Extensively optimized in Germany

• Includes 1-year spare parts warranty

Price

Net: €18,680.00

VAT: €3,549.20

Gross: €22,229.20

Financing available!

Optional

Road registration / operating permit: €695

Extended warranty (2 years): €590

Transportation in Germany and Austria: Upon request

Nwedpfxswd I Epe Aacsc

Technical details

Engine: 4-cylinder Yunnei

Engine power: 25 hp (18.8 kW)

Emissions class: Euro 5

Lifting height: 2489 mm (bottom edge of standard pallet fork)

Unloading height: 2023 mm (standard bucket tipped out)

Lifting capacity: 1200 kg

Wheelbase: 2173 mm

Dimensions: 3740 x 1600 x 2460 mm

Weight: 2400 kg

Tires: 31×15.5-15

Accessories and spare parts are available from us.

Please provide your telephone number when making inquiries!

Listing

Falkenberg

Falkenberg

1,345 km

Farm loader wheel loader

H&RKompaktlader 2512

Call

Condition: new, functionality: fully functional, power: 18.8 kW (25.56 HP), gearing type: automatic, fuel type: diesel, color: red, overall weight: 2,470 kg, lifting power: 1,200 kg/m, lifting height: 2,489 mm, tire size: 31x15,5x15 AS, tire condition: 100 %, axle configuration: 2 axles, emission class: euro5, digging bucket width: 1,600 mm, Year of construction: 2025, fuel: diesel, load capacity: 1,200 kg, Equipment: additional headlights, all wheel drive, cabin, head guard, pallet forks, standard shovel, trailer coupling, The H&R 2512 farm loader offers you more fun at work for less money.

With a small turning circle, the H&R 2512 wheel loader is suitable even on small areas.

Thanks to the comfort cab, the H&R 2512 wheel loader is comfortable and also suitable for inclement weather.

Its 4-cylinder 25 hp engine is particularly economical and powerful.

With the 2-speed torque converter transmission and all-wheel drive, the loader is easy to drive even in difficult ground conditions.

The standard wide tires make it particularly stable and ensure high traction.

The hydraulic quick coupler allows for quick changes of the included attachments (standard bucket and pallet fork as standard).

An additional 3rd and 4th control circuit with float position is available.

H&R loaders are technically and visually optimized in-house and thoroughly tested. In addition, each machine receives extensive rust protection treatment.

Our loaders are CE-compliant according to the EU Machinery Directive. Our machine has a TÜV Süd certificate for obtaining an individual operating permit in accordance with Section 21 of the German Road Traffic Licensing Regulations (StVZO) (road approval/operating permit as a self-propelled work machine).

Key Features of the H&R 2512 Skid Steer Loader

• Fully equipped

• Extensively optimized in Germany

• Includes pallet forks

• Includes standard 160cm wide bucket

• Hydraulic quick coupler

• Auxiliary hydraulics for front attachments, 3+4 control circuits

• Auxiliary cooler for hydraulic oil

• Joystick with electric gearshift and float position

• Large cabin with good all-round visibility

• Heating + ventilation

• 220-volt electric heater for engine preheating

• Rotating beacon

• LED auxiliary lighting

• Radio with MP3 and USB

• Adjustable comfortable seat with armrest

• Adjustable steering column

• Hour meter and fuel gauge

• Trailer coupling for additional trailer use

• Rearview camera with display

• Wide tires 31x15.5-15 agricultural

• 1-year spare parts warranty

• CE compliant according to the EU Machinery Directive

Nwodpfxergn U Ej Aacoc

Price

Net: €19,975.00

VAT: €3,795.25

Gross: €23,770.25

Financing available.

Optional

Full warranty available for up to 48 months

Road registration/operating license €595

Transportation within Germany/Austria available for an additional charge.

-> Please provide us with your zip code for a non-binding, customized transport quote.

Technical Specifications

Lifting capacity: 1200 kg

Lifting height: 2489 mm (bottom edge of standard pallet fork)

Unloading height: 2023 mm (standard wheel bucket tipped out)

Engine: Yunnei 4-cylinder

Engine power: 18.8 kW / 25 HP

Emissions class: Euro 5

Drive: Torque converter

Speed: approx. 20 km/h

Dimensions (L x W x H): 3740 x 1600 x 2460 mm

Weight: 2470 kg

Tires: 31 x 15.5 - 15 AS

Accessories and spare parts are available from us.

Please provide your telephone number for inquiries.

Listing

Wymysłów

Wymysłów

1,472 km

GARANT SK40-12-50 holders with VHM milling cutters · Ø12 mm · G2.5 · 25,000 rpm

Oprawki GARANT SK40-12-50 z frezami VHM · Ø12 mm · G2.5 · 25 000 rpmOprawki GARANT SK40-12-50 z frezami VHM · Ø12 mm · G2.5 · 25 000 rpm

Call

Condition: excellent (used), Collet chuck from the renowned brand GARANT (Hoffmann Group) – guaranteed top quality and reliability in CNC machining. Model SK40-12-50, catalogue number 300100 12. • SK40 taper – industry standard for machining centres • Clamping diameter Ø12 mm • Chuck length 50 mm • Max. RPM 25,000 • High precision and dynamic balancing • Supplied with a mounted end mill. Very good condition, ready for immediate use. Professional tool for CNC milling machines, ideal for workshops that value quality and reliability.

-- PRICE LISTED IS FOR 1 PIECE --

Njdpow Sy Anofx Aacswc

Listing

Wekerom

Wekerom

703 km

WAM WBHX1200M/0CK mixer

WAMWBHX1200M/0CK

Call

Condition: good (used), WAM mixer, paddle mixer

Manufacturer: WAM

Type: WBHX1200M/0CK

Completely constructed from stainless steel

Motor power: 15 kW

Njdpfexnkghex Aacjwc

Mixing shaft speed: 111 rpm

Equipped with a completely new drive system (electric motor, gearbox, belt drive, shaft coupling, stainless steel motor base)

Fitted with a new pneumatic actuator for discharge flap opening

Various electrical components present (excluding control cabinet)

Mixing capacity: liters

See our other listings

VMA Wekerom

Listing

Erwitte

Erwitte

883 km

Profile Laser Cutting Machine

Tube, H, I,Profile Laser Cutting Machine10050HS 12000w - 20000w

Call

Condition: new, functionality: fully functional, Year of construction: 2025, laser type: fiber laser, laser power: 12,000 W, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, nozzle changer, safety light barrier, Supports 12m steel pipe cutting

Equipped with fully automatic combined loading and unloading system

One-stop intelligent loading, cutting and unloading, increasing production efficiency by 200%

Supports multiple processes such as beveling, locking, cutting, punching, opening welding holes, cutting bolt holes, marking and marking

Laser power 12,000 W – 20,000 W

X-axis travel 1,600 mm

Y-axis travel 1,900 mm

Z-axis travel 900 mm

A-axis rotation ±90°

C-axis rotation ±90°

U-axis travel 30 mm

V-axis travel 13,000 mm

Positioning accuracy ±0.1 mm

Max. workpiece section 1,000 × 400 mm

Max. supported weight 5 T

Nwjdpfxow A H T Aj Aacsc

Supported profiles H-beam, channel steel, I-beam

Listing

Brzesko

Brzesko

1,721 km

Hako Hakomatic B90 TB750 NEW BATTERY

HakoHakomatic B90 TB750 1299h NEW BATTERIES

Call

Condition: reconditioned (used), operating hours: 1,299 h, functionality: fully functional, working width: 750 mm, area performance: 3,700 m²/h, overall weight: 480 kg, warranty duration: 12 months, water tank capacity: 90 l, HAKO HAKOMATIC B90 TB750 SCRUBBER

NEW 6V 175Ah SIAP GEL BATTERIES (4x)

Nsdpfxsx Tg Emj Aacowc

The 750mm cleaning head (TB750) is equipped with two new medium-hard disc brushes for use on any surface.

New polyurethane squeegee rubbers are resistant to oil, grease, and petroleum products. The built-in battery charger and wheel drive simplify daily operation.

A new protective rubber around the brush head prevents water from splashing outside the machine's outline.

The device is equipped with a new, durable drain hose and a new suction hose.

A new suction turbine ensures high water suction power from the squeegee.

Each device we offer is individually photographed; you buy exactly what you see.

TECHNICAL DATA:

Power supply voltage (V): 24

Brush working width (mm): 750

Suction nozzle working width (mm): 1100

Theoretical capacity (m²): 3700

Working speed (km/h): 5

Tank capacity (l): 85/85

Weight (kg): ~480

Power (kW): 2.6

INCLUDED:

NEW GEL BATTERIES 6V 175Ah SIAP (4x)

NEW 24V 500W suction turbine

NEW 380mm PPL 0.5 disc brushes (2x)

NEW suction hose

NEW drain hose

NEW head guard rubber

Squeegee blade with new oil-resistant rubbers

Built-in battery charger

5 liters of Tenzi Normal solution - FREE

KEY FEATURES:

The 85 liter tank allows for a large volume of cleaning solution, eliminating the need to frequently stop for refills.

The machine's design makes it highly maneuverable. The small turning radius allows for operation even in narrow passages and alleys. The parabolic squeegee beam ensures precise suction of the solution from the cleaned surface.

The large working width (750mm) ensures high surface coverage.

The control panel is very clear and intuitive.

Listing

Stettfeld

Stettfeld

1,127 km

Bottle Filler for PET-bottles

H&KVVF112/14SV

Call

Year of construction: 1985, condition: not inspected (used), PET-Filler, with 112 Filling valves, with 120 mm pitch, with 14-head screw capper make Alcoa für PCO 28 caps, already dismantled ex location for sale.

Njdpfx Aeh Nq Tkoacswc

Listing

Radeberg

Radeberg

1,243 km

Filter system with pocket filter, stainless steel

Aerob 50m² 6700m³/hAAS 2.12

Call

Condition: excellent (used), Year of construction: 1998, A stainless steel filter system with compressed air cleaning in very good condition.

Filter area 50 m².

Material: V4A (1.4571) 316TI

Installed stainless steel radial fan drive power 22kW; volume flow: 6700m³/h; pressure: 8000Pa

Nwsdpfefg Iphex Aacoc

Compressed air valves: ASCO 24Volt

Number of filter pockets: 48

Filter medium: no longer available

Insulation: Yes

with differential pressure measurement

Size L/W/H: 3000mm/ 1700mm/ 2100mm (up to outlet)

The filter consists of 2 modules that are divided in the middle.

Also available stainless steel cooling screw Ø400mm; length 4100mm

Listing

Radeberg

Radeberg

1,243 km

Refrigerated compressed air dryer / compressed air dryer

FST 12000m³/hDFLO 1200 W

Call

Condition: as good as new (ex-display), Year of construction: 2016, operating hours: 10 h, functionality: fully functional, type of input current: AC, volume flow: 12,000 m³/h, total width: 3,000 mm, total length: 3,700 mm, total height: 3,650 mm, overall weight: 5,600 kg, operating pressure: 16 bar, pressure dew point: 2 °C, ambient temperature (max.): 45 °C, ambient temperature (min.): 2 °C, type of cooling: water, A compressed air refrigeration dryer consisting of 2 DFLO 1200 W units.

The dryer has only been operated for a few hours on a test bench. Afterwards, it was repacked in its original packaging and stored in dry conditions.

Volume flow rate: 12,000 m³/hour

Min. / max. operating pressure: 2 - 16 bar

Test bench operating pressure during last application: 1.4 to 2.3 bar

Inlet diameter: 1x DN 200

Outlet diameter: 1x DN 200

Nsdpew Dppvsfx Aacjwc

The dryer features a second overpressure outlet DN 100 with Samson pressure regulator.

Min. / max. compressed air temperature: +2°C to +55°C

Min. / max. ambient temperature: +2°C to +45°C

Cooling water requirement: 14.3 m³/h

Cooling water connection: 2"

Refrigerant: R407C

Refrigerant charge: 24 kg

Installed electrical power: 29 kW

Power consumption: 18 kW

Wooden crate dimensions:

Length: 3700 mm

Width: 3000 mm

Height: 3650 mm

Weight: 5600 kg

Listing

Vuren

Vuren

685 km

Refrigerated/frozen transport

IVECO120E19 EUROCARGO 120-190 WB 310

Call

Condition: good (used), mileage: 306,393 km, power: 137 kW (186.27 HP), first registration: 03/2017, fuel type: diesel, tire size: 245/70R17,5, axle configuration: 4x2, wheelbase: 3,100 mm, fuel: diesel, color: white, driver cabin: day cab, gearing type: automatic, number of gears: 6, emission class: euro6, suspension: steel-air, total length: 5,920 mm, total width: 2,400 mm, total height: 3,360 mm, loading space length: 3,930 mm, loading space width: 2,260 mm, loading space height: 2,100 mm, Year of construction: 2017, Equipment: ABS, central locking, cruise control, electric window regulation, power mirror, traction control, = Additional Options and Equipment =

- Digital tachograph

- Tachograph (recording device)

- Fixed fifth wheel

- Short cab

= Notes =

Number of axles: 2, Configuration: 4x2, Unladen weight: 5,805 kg, Gross weight: 11,990 kg, Total fuel tank capacity: 100 liters, Fifth wheel: fixed, Cab type: short cab, Cruise control, Tachograph (recording device), Digital tachograph, Electric windows, Electric mirrors, Radio/cassette, Color: white, Heated mirrors, Reverse camera, Lighting type: halogen lamp, Lane departure warning, Bluetooth, Engine power: 137 kW (184 hp), Fuel type: diesel, Emissions standard: Euro 6, Transmission type: AS-Tronic, Gearbox manufacturer: ZF, Gears: 6, Power steering, ABS, ASR, Starter battery, System type: central locking, Seat configuration: 1+2, Seat upholstery: fabric, Seat adjustment: manual, Refrigeration unit manufacturer: Thermoking, Refrigeration unit model: V-500, Refrigeration unit: electric, ATP condition: ., Wall thickness: 40 mm, Cooling type: refrigerated, Day/night cooling function: day/night cooling

= Further Information =

Transmission

Transmission: ZF, 6 gears, automatic

Axle configuration

Tyre size: 245/70R17.5

Brakes: disc brakes

Axle 1: steering; left tyre tread: 11 mm; right tyre tread: 2 mm; suspension: leaf springs

Axle 2: twin tyres; left inner tread: 5 mm; left outer tread: 5 mm; right inner tread: 5 mm; right outer tread: 6 mm; suspension: air suspension

Weights

Curb weight: 5,805 kg

Payload: 6,185 kg

Gross vehicle weight: 11,990 kg

Functional

Loading platform height: 104 cm

Refrigeration unit: electric

Wall thickness: 40 mm

Condition

Technical condition: good

Visual condition: good

Damage: none

Number of keys: 1

Identification

Nwsdpfxoxxrywo Aacjc

Registration number: KLEYN1

= Company Information =

Kleyn Trucks is one of the world’s largest independent dealers in used vehicles. Here you can choose from a constantly changing stock of 1,200 used trucks, tractors, and trailers. Our inventory includes all European brands, model years, and price ranges.

Why buy from Kleyn Trucks? Simple!

• Large, rapidly changing stock

• Recognized quality

• Competitive pricing

• Proper business conduct

• We speak many languages

• We understand our customers

• Assistance with import and transport

• (Export) license plates quickly arranged

• Expert technical services

• Assurance of 'recognized quality'

• And more...

Visit our website for special offers and the complete stock:

Leasing via Kleyn Trucks is possible in most European countries!

Quickly calculate your lease rate and submit an enquiry via our website.

Ask directly about our European warranty package.

Listing

Vuren

Vuren

685 km

Container transportation

RENDERSRPCC 12 27 HIGH CUBE all connec

Call

Condition: used, axle configuration: 3 axles, first registration: 06/1993, total length: 13,100 mm, total width: 2,450 mm, total height: 1,350 mm, suspension: air, tire size: 385/65R22,5, color: other, Year of construction: 1993, Number of axles: 3, Unladen weight: 6,760 kg, Gross weight: 39,000 kg, Chassis type: Full chassis, Chassis material: Steel, Kingpin size: 2 inch, Suspension type: Full air, Year of body: 1993, Container dimensions: all connections, Axle type: BPW, HIGH CUBE ALL CONNECTIONS

= More Information =

General Information

Cab: Day cab

Registration number: KLEYN1

Drivetrain

Fuel type: Diesel

Transmission

Gearbox: Manual transmission

Axle configuration

Tyre size: 385/65R22.5

Brakes: Drum brakes

Suspension: Air suspension

Axle 1: Tyre tread left: 13 mm; Tyre tread right: 14 mm

Axle 2: Tyre tread left: 11 mm; Tyre tread right: 10 mm

Axle 3: Tyre tread left: 9 mm; Tyre tread right: 11 mm

Weights

Empty weight: 6,760 kg

Payload: 32,240 kg

GVW: 39,000 kg

Environment

Emission class: Euro 0

Condition

General condition: moderate

Technical condition: moderate

Optical condition: moderate

Damages: none

Nwsdpfoym Nniex Aacec

= Company Information =

Kleyn Trucks is one of the world's largest independent dealers of used vehicles. Here you can choose from a constantly changing stock of 1200 used trucks, tractor units, and trailers. Our offer includes all European makes, model years, and price ranges.

Why buy at Kleyn Trucks? It's easy!

• Large, fast-rotating stock

• Recognisable quality

• Fair prices

• Reliable business practices

• Multilingual staff

• We understand our customers

• Assistance with import and transport

• (Export) license plates arranged quickly

• Expert technical services

• The security of 'recognisable quality'

• And more....

Please visit our website for special offers and our complete inventory:

Leasing via Kleyn Trucks is possible in most European countries!

Quickly calculate your leasing rate and send a request via our website.

Ask us directly about our European warranty package.

Listing

Vuren

Vuren

685 km

Suitcase

MAN12.290 TGM AIRCO LIFT WB 513

Call

Condition: good (used), mileage: 597,364 km, power: 213 kW (289.60 HP), first registration: 07/2015, fuel type: diesel, tire size: 305/70R19,5, axle configuration: 4x2, wheelbase: 5,130 mm, fuel: diesel, color: other, driver cabin: day cab, gearing type: automatic, number of gears: 12, emission class: euro6, suspension: steel-air, number of seats: 2, total length: 9,160 mm, total width: 2,550 mm, total height: 3,300 mm, loading space length: 7,110 mm, loading space width: 2,470 mm, loading space height: 2,080 mm, Year of construction: 2015, Equipment: ABS, air conditioning, cruise control, electric window regulation, navigation system, power mirror, tail-lift, traction control, trailer coupling, = Additional Options and Equipment =

- Digital tachograph

- Tachograph (control device)

- Fixed

Nodew Uc Sqspfx Aacewc

- Short cab

- Tail lift

= Remarks =

Number of axles: 2, Configuration: 4x2, Twin tyres, Payload: 4,195 kg, Unladen weight: 7,795 kg, Gross weight: 11,990 kg, Total tank capacity: 300 litres, Towing hitch, Kingpin diameter: 40 DIN, Fifth wheel: Fixed, Suspension type: Air suspension, Cab type: Short cab, Cruise control, Tachograph (control device), Digital tachograph, Air conditioning, Electric windows, Electric mirrors, Radio/Cassette, GPS navigation, Colour: Multicolour, Heated mirrors, Reversing camera, Lighting type: Halogen lamp, Speed limiter, Bluetooth, Engine output: 213 kW (286 Hp), Fuel: Diesel, Euro: 6, Transmission type: Automatic, Gearbox: ZF, Speed limiter, Gears: 12, Power steering, ABS, ASR, Starter battery, Rotation: 1x20, System type: .., Seats: 2, Seat configuration: 1+1, Seat upholstery: Fabric, Seat adjustment: Manual, Tail lift, Tail lift design: Rear flap, Tail lift capacity: 2,500 kg, Tail lift manufacturer: Dhollandia, Tail lift material: Steel, Tail lift size: 216 x 252

= Further Information =

Transmission

Gearbox: ZF, 12 gears, automatic

Axle Configuration

Brakes: Disc brakes

Axle 1: Tyre size: 305/70R19.5; Steering; Left tyre tread: 1 mm; Right tyre tread: 1 mm; Suspension: Leaf spring

Axle 2: Tyre size: 285/70R19.5; Twin tyres; Left inner tread: 9 mm; Left outer tread: 12 mm; Right inner tread: 7 mm; Right outer tread: 13 mm; Suspension: Air suspension

Weights

Unladen weight: 7,795 kg

Payload: 4,195 kg

Gross Vehicle Weight (GVW): 11,990 kg

Functional

Tail lift: Dhollandia, rear flap, 2,500 kg

Loading platform height: 104 cm

Condition

Technical condition: good

Visual condition: good

Damages: none

Number of keys: 3

Identification

Registration number: 61-BGF-1

= Company Information =

Kleyn Trucks is one of the world's largest independent dealers of used vehicles. Here you can choose from a constantly changing stock of 1,200 used trucks, tractor units, and trailers. Our range covers all European makes, years of manufacture, and price categories.

Why buy from Kleyn Trucks? Simple!

• Large, fast-changing stock

• Recognisable quality

• Good prices

• Reliable trading

• We speak many languages

• We understand our customers

• Assistance with import and transport

• (Export) registrations are quickly arranged

• Expert technical services

• The security of “recognisable quality”

• And much more....

Please visit our website for special offers and our complete stock:

Leasing through Kleyn Trucks is possible in most European countries! Calculate your leasing rate quickly and send an inquiry through our website.

Ask us directly about our European warranty package.

Listing

Groenlo

Groenlo

758 km

Scissor lift

HaulotteCompact 12 Electric, 12m Working Height, 300kg Cap

Call

Condition: used, Year of construction: 2008, operating hours: 1,188 h, machine/vehicle number: CE140920, Empty weight: 2.630 kg

Lifting capacity: 300 kg

Nwjdpfsydhqkjx Aacsc

Working height: 1.200 cm

Front tyres / undercarriage remaining: 60

Rear tyres remaining : 60

Tyre brand: -

Transport dimensions (LxWxH): 2.45x1.2x1.53

Please contact PFEIFER GROUP for more information

Listing

Deinze

Deinze

675 km

Vertical turning machines conventional & CNC

TosSK16 Ø 1700 x H 1250 mm

Call

Condition: ready for operation (used), chuck outer diameter: 1,620 mm, total height: 4,650 mm, empty load weight: 20,000 kg, + zijsteun Elektrisch vernieuwd in 2007!!!

Max turningdia -- passage: 1700 mm

Power on the spindle: 37 kW

Max hight of workpiece Z-axis: 1290 mm

Digital screen: Heidenhain 2 axes

Number of speeds: 3,5 - 150 rpm

Nedpfsyl A Hpjx Aacowc

Long: 4550 mm

Wide: 2670 mm

Listing

Deinze

Deinze

675 km

Coiler straightening machines

Hammerle / GFpart straightener 750 x 12 mm

Call

Condition: ready for operation (used), (Merk is oorspronkelijk Georg Fischer, overgenomen door Hämmerle AG)

Compacte machine van Zwitserse makelij die gebruikmaakt van een automatisch nivelleringsdruksysteem om onderdelen recht te zetten en spanningsvrij te maken.

Toepassingen: fijngestanste onderdelen - koppelingsplaten - remschijven - zaagbladen - vliegtuigonderdelen - laser- en plasmagesneden onderdelen - vlakmaken van onderdelen vooraf aan robotlassen/-slijpen.

Nwjdpfsv Rwcrox Aacec

- voorkomen doorbuiging met 19 teruglopende rollen

- 11 tegenrollen in onderste positie

- 10 tegenrollen in overwegend positie

- boven- en onderrollen zijn voorzien van hydraulische motoraandrijvingen

- overbelastingsventielen voorkomen schade aan de machinedeur, overbelasting of verkeerde instelling

- snelle insteltijd, vereist invoer van 3 parameters (ingangsspleet - uitgangsspleet - invoersnelheid)

- snelheid van de machine: 2-20 m/min

maximale breedte: 750 mm

maximale dikte: 12 mm

min. onderdeellengte: 100 mm

vermogen: 31kW

totaalgewicht: 10 ton

Listing

Bury St Edmunds

Bury St Edmunds

442 km

Rotary filler for plastic tubs

Hema / BWMRH 9/12

Call

Condition: good (used), This filling machine was filling 3 litre tubs of honey. It can be supplied at extra cost with two GlobeTech tub lidding machines which worked in line with it.

Njdpjpfdhpsfx Aacswc

Listing

Wijchen

Wijchen

724 km

Construction lift

BöckerAgilo HL 27 Furniture Lift, 12-2024, 62 hours!

Call

Year of construction: 2024, condition: used, General information

Field of application: Freight transport

Drivetrain

Make of engine: Mitsubishi

Weights

Njdpfjyly Rxsx Aacowc

Empty weight: 3.500 kg

Functional

Lifting capacity: 4 kg

History

Number of owners: 1

Condition

General condition: very good

Technical condition: very good

Visual appearance: very good

Other information

Hydraulic outreach: 2700 cm

Remote control: Cable

Latest inspection: 2025-02-03

Production country: DE

Additional information

Please contact Michael Overmeer for more information

Böcker HL 27 Agilo Furniture lift mounted on a Mitsubishi Fuso 3515 construction year 12-2024 (first in use 02-2025) with only 62 hours and 2.865 kilometers. The lift is like new and has a capacity of 400 kg and is equipped with a XXL basket, hydraulically operated support legs, remote control and a storage box. Changes and typographical errors reserved.

Listing

Meerkerk

Meerkerk

676 km

Loading platform

FloorFLO 12 30H2

Call

Condition: used, axle configuration: 3 axles, first registration: 04/1998, loading space length: 13,580 mm, loading space width: 2,500 mm, total length: 13,580 mm, total width: 2,500 mm, suspension: air, tire size: 425/65R22,5, wheelbase: 10,020 mm, color: red, Year of construction: 1998, Equipment: ABS, = Additional options and accessories =

- EBS

- Toolbox

Njdpfxexwxvpo Aacowc

= Further information =

Axle configuration

Tyre size: 425/65R22.5

Brakes: Drum brakes

Suspension: Air suspension

Maximum front axle load: 10,000 kg

Center axle: max. axle load: 10,000 kg; Steerable

Rear axle: max. axle load: 10,000 kg; Steerable

Weights

Unladen weight: 8,180 kg

Payload: 33,820 kg

Gross vehicle weight: 42,000 kg

Identification

Registration number: OF-13-NG

Listing

Hedel

Hedel

701 km

Box body

MANTGL 12/250 DHolandia LBW LAADKLEP!!EURO6!!

Call

Condition: good (used), mileage: 520,051 km, power: 184 kW (250.17 HP), first registration: 07/2014, fuel type: diesel, axle configuration: 4x2, wheelbase: 4,550 mm, fuel: diesel, color: other, driver cabin: sleeper cab, gearing type: automatic, emission class: euro6, number of seats: 2, total length: 8,500 mm, total width: 2,550 mm, loading space length: 6,100 mm, loading space width: 2,500 mm, loading space height: 3,080 mm, Year of construction: 2014, = Additional options and accessories =

- Sun visor

= Remarks =

Tail lift: Dhollandia 1000 kg achtersluiter, 1000 kg

= More information =

Technical information

Number of cylinders: 6

Engine capacity: 6.871 cc

Max. front axle load: 4400 kg

Max. rear axle load: 8400 kg

Weights

Empty weight: 6.880 kg

Carrying capacity: 5.210 kg

GVW: 11.990 kg

Condition

Technical condition: good

Visual appearance: good

Identification

Registration number: 07-BST-4

= Dealer information =

We do not charge delivery costs.

All trade-ins and financing are possible.Although we take great care in preparing our advertisements, it is possible that some of the options described may or may not be present on the car.

Please check before purchasing that all the options described that are important to you are actually present.We are RDW certified.

You can opt for an extended warranty; see our website for the packages.

All our cars have a clear maintenance history and mileage registration.Our opening hours are:

Monday to Friday from 9:00 a.m. to 5:00 p.m. and evenings by appointment.

Saturday from 9:00 a.m. to 3:00 p.m.You can find us at:Middelingenseweg 22

5321 JH Hedel

The NetherlandsAnd reach us at:Trucks:

Passenger cars: Website:

Nwsdpfxeydctmj Aacoc

Email:

Listing

Nieuwerkerk a/d IJssel

Nieuwerkerk a/d IJssel

652 km

Tanker truck

IvecoT-Way AD380T43H AT Water Tank Truck (12 units)

Call

Condition: new, power: 316 kW (429.64 HP), fuel type: diesel, tire size: 315/80R22.5, axle configuration: 6x4, wheelbase: 4,500 mm, fuel: diesel, color: white, driver cabin: day cab, gearing type: automatic, emission class: euro3, suspension: steel, Year of construction: 2024, Equipment: air conditioning, = Additional Options and Accessories =

- Leaf spring suspension

Nwedpoymnzzefx Aacsc

= Notes =

Fuel tank: 290 liters

Air conditioning

Equipped with 10,500 liter water tank

Container frame for water tank on 20 ft twistlocks

Tank production year: 1999

Side-mounted engine enclosed in a box

Dual manhole covers on the top for easy access

Two rear ladders: one chassis-mounted and one container-mounted

Support legs for free-standing water tank container

= Further Information =

Transmission: ZF16TX2240TO, automatic

Year of manufacture: 2024

Tire size: 315/80R22.5

Suspension: leaf spring suspension

Front axle: steered

Gross vehicle weight: 33,500 kg

Trust Seal

Dealers certified through Machineseeker

Listing

Wiefelstede

Wiefelstede

785 km

CNC press brake 3200 mm x 125 to

NOVAKRAFTPBS-H 125-3200

Call

Condition: good (used), Year of construction: 2010, Press brake, bending machine, bending machine, swing bending machine, die bending machine

-Machine: can be viewed while powered on

-CNC press brake: with 3 axes and laser safety system

-Working width: 3200 mm

-Pressure force: 125 tons

-Max. stroke of the bending beam: 160 mm

-Distance between the stands: 2700 mm

-Backgauge travel: 590 mm

-Backgauge: 2 axes electronically movable, 1 axis manually movable

Nwsdpfx Ajxxz E Njacsc

Accessories: see pictures

-Installation dimensions: 2140/5195/H2530 mm

-Transport dimensions: 1680/5195/H2530 mm

-Weight: 9300 kg

Listing

TILBURG

TILBURG

700 km

Flatbed

NooteboomOVB-90-05 / 5 axle 12 Ton Hydraulic / BPW Drum ...

Call

Condition: used, axle configuration: > 3 axles, first registration: 09/2004, total length: 16,800 mm, total width: 2,530 mm, total height: 1,750 mm, suspension: hydraulics, tire size: 295 / 80 / R22.5, color: red, Year of construction: 2004, General information

Model code: ###

Axle configuration

Tyre size: 295 / 80 / R22.5

Make axles: BPW ECoPlus

Brakes: drum brakes

Suspension: hydraulic suspension

Rear axle 1: Double wheels; Lift axle; Max. axle load: 12000 kg; Tyre profile left inner: 50%; Tyre profile left outer: 50%; Tyre profile right outer: 50%; Tyre profile right outer: 50%

Rear axle 2: Double wheels; Max. axle load: 12000 kg; Tyre profile left inner: 30%; Tyre profile left outer: 30%; Tyre profile right outer: 30%; Tyre profile right outer: 30%

Rear axle 3: Double wheels; Max. axle load: 12000 kg; Steering; Tyre profile left inner: 70%; Tyre profile left outer: 70%; Tyre profile right outer: 70%; Tyre profile right outer: 70%

Rear axle 4: Double wheels; Max. axle load: 12000 kg; Steering; Tyre profile left inner: 50%; Tyre profile left outer: 50%; Tyre profile right outer: 50%; Tyre profile right outer: 50%

Rear axle 5: Double wheels; Max. axle load: 12000 kg; Steering; Tyre profile left inner: 50%; Tyre profile left outer: 50%; Tyre profile right outer: 50%; Tyre profile right outer: 50%

Weights

Empty weight: 21.680 kg

Condition

General condition: average

Technical condition: average

Visual appearance: average

Nwjdpfx Ajymxu Ssacsc

Product safety

Manufacturer: Kuijpers Trading BV Minosstraat 8 5048CK TILBURG, NL

Listing

Ahaus

Ahaus

779 km

Thread-Cutting Machine

HUVEMAHU Tap AT-12 / II

Call

Condition: new, thread dia. 12 M max.

turning speeds 400 U/min

thread M 3 - M 12 M

working area 1600 R max.

working range 500 Rmin.

weight 16.0 kg

Description:

The AT II models have a radius of up to 1600 mm and thanks

to their construction a flexible workspace.

For professional use. Easy to mount on a worktop.

Nsdpfx Aexabbmeacjwc

Furnishing:

- Tool holder with 6 cutter holders

• M3 20111812 DIN 371 19

• M4 20111814 DIN 371 19

• M6 20111816 DIN 371 19

• M8 20111817 DIN 371 19

• M10 20111818 DIN 376 19

• M12 20111820 DIN 376 19

- with slip clutch

- Control valve with lubrication

- Including compressed air motor / maintenance unit

- Adapter connection size 1

Clickout

Langenfeld (Rheinland)

Langenfeld (Rheinland)

837 km

Balancing machine

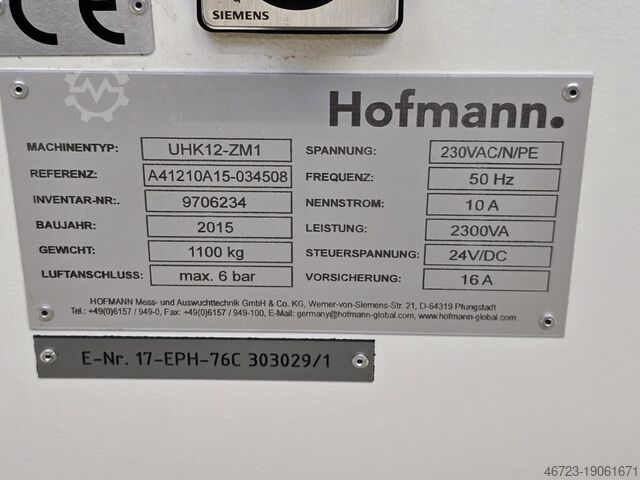

HofmannUHK 12 - ZM1

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Nsdpfx Aaowg A Siecswc

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

We make it easier for you to find: "yamaguchi wb 12 h"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Yamaguchi Wb 12 H (66,222)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you