Used Banding Machine for sale (64,704)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 260mm

CORMAKHBS320

Call

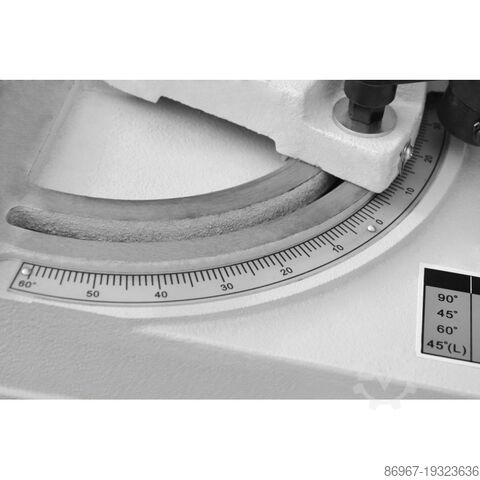

Condition: new, Year of construction: 2025, CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

Machine characteristics

CORMAK HBS320 band saw for metal provides cutting at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Band saw perfect for cutting tubes, profiles and other materials.

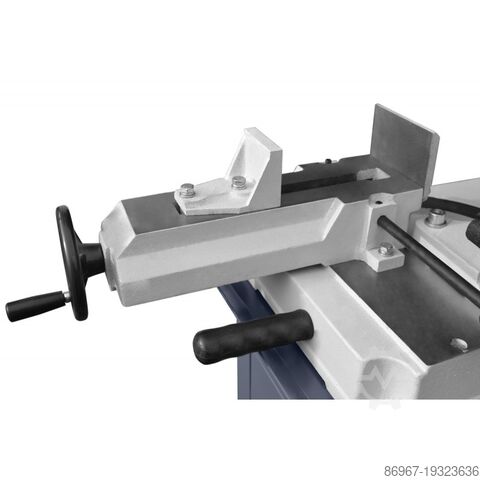

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. The band saw arm is made of massive, uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of structural steel, stainless steel and tools. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. It has a huge impact on the band guiding, its durability, accuracy and cutting quality. The carbide guiding drastically reduces the wear of both the machine and the blade.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a double-sided swivel arm and a control panel.

The feed speed is controlled by the control panel. There are 2 cutting band speeds: 44 and 88 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Ø max 260 mm /perpendicular cutting

H×B max 320×160 mm /perpendicular cutting

Power supply - 3–phase, 400V

Kledpei D Dgwofx Addjl

Total power - 1,5 kW

Arm lowering control - hydraulic cylinder

Band dimensions - 2740×27×0.9 mm

Band speed - 44 / 88 m/min

Vice base height - 920 mm

Dimensions - 1400×880×1550 mm

Weight - 280 kg

Cutting parameters

Angle

0º ---- ø260 320×160 255×255

45º R ø210 210×200 210×210

60º R ø135 135×130 130×130

45º L ø160 220×130 160×160

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine

CORMAKHBS260 + 2 piły M42 + 5L Emulgol

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

Kodsudi Uzspfx Addoll

Additionally

2 M42 saw blades

5L Emulsol

ZW580 magnetic chip collector

Listing

Siedlce

Siedlce

1,720 km

Semi-automatic band saw machine 250mm

CORMAKS-200RH przecinarka taśmowa do metalu

Call

Condition: new, Year of construction: 2025, Powerful, reliable and modern semi-automatic band saw for metal with automatic arm raising and lowering. The arm is rotational in both ways. The machine is fantastic for ironworking, e.g. cutting tubes and profiles.

Product features

CORMAK S-200RH band saw is by default equipped with automatic arm lowering and raising as well as with a precise arm height regulator. Due to an automatic hydraulic damper, the manual handling of the machine has been simplified to feed and clamping the cut material in a vice. The arm made of uniform iron casting, together with a refined, solid and stable construction, ensure S-200R's exceptional rigidity, resulting in failure-free handling and high cutting precision.

The innovativeness and production of semi-automatic and automatic series "CORMAK-PREMIUM LINE" band saws, compliant with the norms and standards consistent with ISO:910001 and ISO:140001 certificates, warrant safety, quality and reliability of the product. M3V motors from ABB, a renowned worldwide manufacturer, warrant long-term reliability. As an official and the only representative on the Polish market, we assure that the product is original and provide professional, customised warranty and post-warranty services.

Technical data

Type - semi-automatic

Arm raising and lowering - hydraulic with smooth arm lowering control

Band speed - 36/70 mm/min

Angled cutting - left to 45°, right to 60°

Vice - hydraulic

Minimum cutting diameter - Ø 5 mm

Minimum material length in vice - 30 mm

Vice base height - 780 mm

Cutting band dimensions - 27×0.9×2910 mm

Total power - 2.1 kW

Dimensions (LxWxH) - 1600×800×1400 mm

Weight - 530 kg

Angle

0º -----ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

Kledpfx Aoi D D A Sjddol

Default equipment

Control panel on separate component

Built-in hydraulic unit

Hydraulic control of arm motion (up – down) with possibility of smooth lowering speed control

Arm position memory function (arm returns to a defined height after cutting)

Cutting at angles of L/R 45° - 0° - 45° - 60°

Brush for cleaning band

Cooling system

Bi-metal band saw

EC Declaration of Conformity

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 230mm

CORMAKHBS260

Call

Condition: new, Year of construction: 2025, The CORMAK HBS260 band saw for cutting pipes, profiles and bars is widely used in all locksmith workshops where precision, quality and cutting speed are important. The model is equipped with a 0-60° swiveling arm. The frame design ensures accurate and quiet operation. It has a removable filing tray for easy cleaning!

Machine characteristics

A horizontal metal band cutter with a swiveling arm allows cutting in a plane perpendicular to the axis of the material being cut and at any angle ranging from 0 to 60°. The material to be cut can be fed manually or with any mechanical device, and the tool feed is automatic. The tape guides are equipped with special carbide plates and bearings. This has a huge impact on the belt guidance, its life, straightness, accuracy and cutting quality. Carbide guidance greatly reduces wear of the machine and saw blade. The machine is equipped with an efficient cooling pump with a closed coolant circuit.

The cutter's arm made of uniform cast iron together with the 27 mm wide cutting band used in this cutter allows it to fully perform multi-series cuts of both profiles and solid materials. The vice is located in an adjustable bed and is equipped with a quick clamp. The saw blade guides are equipped with hard metal plates - sintered carbides and a rolling bearing system. It is the CENTRED CARBIDE GUIDES that are responsible for the precision and straightness of the cut.

The shape of the upper part of the base constitutes a bathtub for draining coolant and catching chips generated while cutting the material. A cast iron work table with a swivel arm and a control panel on a separate arm is attached to the base. In the cutting process, the main cutting movement is the movement of the cutting band and the falling feed of the arm. The arm lowering speed (cutting speed) is regulated by a hydraulic actuator.

The feed speed is regulated on the cutter's control panel. We can choose from two cutting band speeds: 35 and 70 m/min. In the lower position of the arm (after cutting the material), the cutting belt drive is turned off automatically. Safety is ensured by the cutting band covers and micro switches that stop the engine after the cutting cycle is completed or any of the covers are opened. Additional protection consists in automatic shutdown of the cutter in the event of the cutting band breaking.

Cutting band size [mm] 2520 x 27 x 0.9

Tape tension mechanical (manual)

Belt speeds [m/min] 35, 70

Adjustable arm drop stepless - hydraulic actuator

Vice base height [mm] 860

Saw wheel diameter [mm] 300

Saw frame tilt [°] 0-60

Power supply 3 phases 400V

Main engine power [kW] 1.1/1.5

Cooling pump motor power [kW] 0.05

Kljdpfxemrnk Ee Addol

Dimensions with base [cm] 150x80x140

Weight [kg] gross/net - 210 / 180 kg

*Please note that machine is sold without CEE connector by default, since there are many different types of it. If you would like to receive it with the machine, please write it to the seller before making a purchase/during order proceeding.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 250mm

CORMAKS-200R manual

Call

Condition: new, Year of construction: 2025, Cormak S200R Manual band saw for cutting in large industrial facilities.

Features high accuracy metal cutting, even at 45º/60º.

Machine features

CORMAK S-200R MANUAL band saw with EC declaration, provides cutting metal at any angle from -45° to + 60°. The element cut can be fed manually or by any feeding device. The feed during cutting is gravitational on the principle of oil flow in a two-chamber hydraulic cylinder. Appropriate arm lowering speed is ensured by a valve controlling oil flow between the chambers.

Operator starts the machine by pressing the START button and sets cutting speed. After the cycle is finished the machine automatically stops and the operator lifts the arm to the starting position. Material is fed manually. This model is used in both low and high quantity production, and due to its solid construction allows for cutting various materials, including stainless steel, tool steel and profiles. The machine provides cutting at an angle due to rotary arm. The band saw arm is made of uniform cast iron, and together with 27 mm wide cutting band enables high quantity cutting of various materials. The vice is located in an adjustable bed and equipped with a quick clamp. Blade guides are equipped with a ball bearings system and cemented carbides, ensuring excellent cutting precision and straight cut. The arm is equipped with an automatic blade tension sensor, at a 25° angle, thus increasing blade's durability.

There is a blade cleaning brush attached to the bottom of the arm. Machine drive is transmitted through a worm drive filled with gear oil. The machine is equipped with a three-phase motor with double winding and two cutting speeds. The motor is thermally protected.

Two cutting band speeds: 35 and 70 m/min. The construction: the arm, the vice and the rotating table are iron castings. Closed cooling system. The machine is equipped with a bumper with a ruler for setting the length of material cut. The base of the machine is a rigid cuboid made of steel sheets in which a fluid container with a flood coolant pump is located. Safety during cutting ensures an electrical system that meets all EC requirements. The machine is equipped with a limit switch which stops the machine after a cutting process is finished, an emergency button, and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened

Technical data

Type gravitational

Arm raising and lowering gravitational with stepless arm lowering adjustment

Band speed 36/70 m/min

Cutting at an angle from 45° left up to 60° right

Vice manual

Minimum cutting diameter Ø 5 mm

Minimum material length in vice 30 mm

Vice base height 890 mm

Cutting band dimensions 27×0.9×2910 mm

Total power 2.1 kW

Dimensions (LxWxH) 1600×800×1400 mm

Weight 500 kg

Max. cutting range [mm]

Kljdpfxjfy Ttij Addsl

Angle

0º ø250 320×240 240×240

45º L ø200 220×120 190×190

45º P ø220 235×120 210×210

60º P ø110 155×110 100×100

For more information please visit our web page or contact us

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

Kodpfx Aswq A Dyjddell

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 250mm

CORMAKG5025

Call

Condition: new, Year of construction: 2025, A strong, big band saw for metals with a swivel arm, enabling cutting in the plane perpendicular to the axis of the cut material and at any angle from -45° (left) to + 60° (right). Band saws are perfect for cutting tubes, profiles and other materials.

Product features

Material cut can be fed manually or by any feeding device, with automatic tool feed. Appropriate cutting speed (band speed) is obtained through a change on a control panel. Rigid construction arm is made of profiled cast iron.

The drive from the electric motor directed to the cutting band driving wheel is transmitted by a motor with worm drive. The cutting band is tensioned on two cast iron wheels with a manual tightener and guided by adjustable rolling and linear carbide guides.

The base is enclosed, constituting a rigid welded body of steel sheets. A separate flood coolant container with an electropump is inside. The shape of the base upper part constitutes a tank for flood coolant draining and chips produced during cutting. Cast iron workbench is attached to the base, with a -45° to + 60° swivel arm and control panel on separate arm.

The main cutting move in the cutting process is moving the cutting band. The arm lowering speed (the cutting speed) is adjusted with the hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds: 36 and 72 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Klsdpji D Ddijfx Addol

Cutting band size - 2720×27×0.9 mm

Band tension - mechanical (manual)

Band speed - 36, 72 m/min

Arm lowering control - stepless – hydraulic cylinder

Vice base height - 765 mm

Minimum material length in vice - 100 mm

Power supply - 3-phase, 400 V

Total power - S1 100%: 1.5; S6 40%: 2.1

Cooling pump motor power - 0.025 kW

Weight - 370 kg

Warranty - 12 months

User manual - yes

CE declaration - yes

Angle

0° --- ø250 310×210 240×240

45° R ø200 200×140 180×180

45° L ø165 185×145 160×160

60° R ø120 120×95 100×100

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine 125mm

CORMAKBS-128HDRC 230V

Call

Condition: new, Year of construction: 2025, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Kjdpfx Aomrp Tleddoll

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine

CORMAKBS260G

Call

Condition: new, Year of construction: 2025, The CORMAK BS 260G band saws, due to being equipped with a hydraulic cylinder, a cooling and an arm swivelling up to 60°, together with blades from renowned German Röntgen company, are used commonly in ironworking where precision, quality and cutting speed are important.

Horizontal band saw with a swivelling arm for cutting metals, allows for cutting in plane perpendicular to the axis of material cut and at any angle from 0 to 60º. Material for cutting can be fed manually or by any mechanical feeding device, with automatic tool feed. Band guides are equipped with dedicated carbide plates and bearings. This has a huge impact on band guiding, its durability, cut straightness, cutting accuracy and quality.

Machine's arm is made of profiled CAST IRON. Control panel is located by the arm. The drive from the electric motor directed to the cutting band driving wheel is transmitted by a motor with worm drive. The cutting band is tensioned on two cast iron wheels with a manual tightener and guided by adjustable rolling and linear set of carbide guides. A separate flood coolant container with an electropump is inside. The arm lowering speed (the cutting speed) is adjusted with a hydraulic cylinder. The feed speed is controlled by the control panel. There are 2 cutting band speeds to choose from: 36 and 72 m/min. In rest arm position (after the cutting process) the cutting band drive is switched off automatically. Safety is ensured with cutting band guards and microswitches stopping the motor after cutting cycle is finished or after any of the guards are opened; additional protection consists of automatic switch-off of the band saw in case the cutting band breaks.

Technical data

Cutting band saw dimensions

2455×27×0.9 mm

Band tension

mechanical (manual)

Band speed

36, 72 m/min

Feed speed

0–50 m/min (stepless feed)

Arm lowering control

stepless – hydraulic cylinder

Vice base height

900 mm

Power supply

3-phase 400V

Motor power

1.1 kW

Weight

216 kg

Warranty

12 months

Manual

yes

CE declaration

yes

Angle

0º

ø230

260×150

Klodevuf S Nepfx Addol

225×225

45º

ø165

180×130

165×165

60º

ø105

100×90

110×110

*Please note that machine is sold without CEE connector by default, since there are many different types of it. If you would like to receive it with the machine, please write it to the seller before making a purchase/during order proceeding.

Listing

Siedlce

Siedlce

1,720 km

Band saw machine

CORMAKBS-530

Call

Condition: new, Year of construction: 2025, Powerful Band Saw equipped with a movable arm that can rotate from -45° to +60°, a portable vice with quick-locking mechanism, a strain gauge for band tension, and a hydraulically adjustable arm with smooth regulation. Additionally, it features an ergonomically designed control panel, ensuring safety and comfort during operation. The maximum cutting width is 490 mm.

Key Features of the Band Saw:

The band tensioning wheel is equipped with a dial strain gauge that indicates the proper band tension, ensuring optimal results and blade durability.

The saw frame is rigid, made of cast iron, and resistant to twisting. High-quality drive wheels are mounted inside, on which the cutting band is mounted.

The control panel is ergonomic, with clearly placed buttons such as the main switch, start, stop, cooling, and band speed control buttons (slow/fast). Additionally, the panel features an emergency stop button that complies with the latest EU safety standards.

The panel column contains hydraulic actuator controls, enabling precise regulation of the arm's descent speed and turning it on/off.

The drive is stable, thanks to high-quality hardened and ground gears. The powerful motor is appropriately matched to the sizes of the materials being cut.

The band’s guidance is reliable due to bearings in the guides that can be adjusted according to the width of the material being cut.

The saw is equipped with a mechanism for automatic shut-off when the arm is lowered.

The vice is solid and securely holds workpieces. A limiter for cutting workpieces is included in the set.

The hydraulic actuator is reinforced, allowing precise adjustment of the arm's lowering speed using a potentiometer. The saw arm can rotate from -45° to +60°, with the lifting force adjusted using a spring.

An efficient cooling system is built into the base of the saw.

Workpieces can be quickly clamped in the vice. The vice can be adjusted on both sides, enabling cutting at different angles.

The set includes a coolant tank with a pump.

The saw’s solid body is made of cast iron, ensuring stability during cutting.

The band saw's arm can be locked.

The base is rigid, allowing operation at a height of approximately 95 cm, which is standard with the saw.

Additional Advantages of the Band Saw:

Other features include band speed regulation (35/70 m/min), quick-lock vice, movable saw arm from -45° to +60° with a scale reading, a fully functional device with an excellent price-to-quality ratio, a solid construction ensuring precise, quiet, and vibration-free operation, infinitely adjustable hydraulic arm lowering, durable carbide roller guides, reinforced worm gear with bronze components, automatic end switch, and a liquid cooling system as standard equipment.

Technical Specifications:

Working height: 870 mm

Cutting speed: 35/70 m/min

Kedpfov R Tgtox Addell

Band saw dimensions: 3770 x 34 x 1.1 mm

Band saw width: 34 mm

Cooling system pump power: 0.1 kW

Total power: 2.8 kW

Voltage: 400V

Dimensions (width x depth x height): 2200 x 1400 x 1500 mm

Weight: 630 kg

Listing

Hüllhorst

Hüllhorst

866 km

Edge banding machine

HEBROCKAKV 3003 DK - F

Call

Condition: used, Year of construction: 2007, machine/vehicle number: Werksüberarbeitungsnummer: WÜA1363DK-F7560, Used Machine GM020.0068

AKV 3003 DK - F

Year of manufacture: 2007

Kjdpsw Nih Ijfx Addoll

Specification: 3 mm

1st milling station: Combination

Surface pull scraper with extraction

Chassis

Pneumatic milling adjustment

Limit switch lever, 7.5° inclination

Listing

Hüllhorst

Hüllhorst

866 km

Edge banding machine

HEBROCKAKV 3005 DK-F

Call

Condition: used, Year of construction: 2005, machine/vehicle number: Werksüberarbeitungsnummer: WÜA920DK-F12960, Used machine GM020.0029

Year of manufacture: 2005

AKV 3005 DK-F

8 mm version

1st milling station: Combination

Cleaning station

Klodpfx Adsw In R Eedsl

Corner rounding cutter

Jointing cutter

Surface scraper with extraction

Profile scraper

Chassis

Pneumatic milling adjustment

SPS control

Preparation for interchangeable tanks

Listing

Aschersleben

Aschersleben

1,058 km

Cross-band grinding machine

VitrododiBELTEX 111

Call

Condition: excellent (used), Stainless steel version,

Length: 1400mm

Width: 1200mm

Height: 1900mm

Ksdpfx Adohvyzwedoll

Weight: about 250kg

Listing

Gorzów Wielkopolski

Gorzów Wielkopolski

1,252 km

Band saw machine

Viber-SystemS275

Call

Condition: new, Year of construction: 2025, S275 Metal Cutting Machine

Motor

Type - 3-phase induction motor

Electrical connection - 400V 50/60Hz

Power supply: 400V (three-phase)

Protection - IP54

Power - 1.5 HP 1.1 kW

Rated current - 400V - 3.6 Amp

Speed (RPM) - 50Hz - 2840/1420

Gearbox

Transmission ratio - 50Hz - 1:30

Band saw

Saw blade dimensions - 2480x27x0.9x6-10mm

Blade guide wheel diameter - 293mm

Saw blade speed - 50Hz - 45/90mm (m/min)

Cooling System Pump

Type – 230V 100W Pump

Rated Current – 0.3 (Amp)

Speed – 50Hz-2840 (rpm)

Kledpfexdbzbjx Addsl

Tank Capacity – 10 liters

Mechanical Data

Dimensions with base – 1560x990x1665 (mm)

Dimensions without base – 1320x510x755 (mm)

Shipping Dimensions – 1380x570x890 (mm)

Weight – Net – 185 (kg) | Gross – 200 (kg)

Noise Level – 70 (dB)

Fuse – max. 16 (Amps)

Ambient Temperature – 5-35 (°C)

Ambient Humidity – 25-80%

General:

Cutting Angle Adjustment: Via Swivel Arm

Saw Blade Guides: Ball Bearing Guide Rollers

Saw Arm Lift: Manual

Feed: Continuously Adjustable

Saw Blade Tension: Manually via Handwheel

Band Guides with Bearings and Carbide Tiles

Height from Floor to Vice: 910 mm

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

OTTPacific V12 F

Call

Condition: excellent (used), Year of construction: 2002, edge seize 0,2 - 12 mm

work piece dimension

width min. 70 mm

height min. / max. 8 / 42 mm

length min 160 mm (strips)

length min 60 mm from roll

Durchlaufgeschwindigkeit: 12 m/ min

glue coating with roller

working height : 880 mm

compressed air 6 bar,1/4 Zoll

suction connection, DM 160 mm

dimensions: L x W x H = 5600 x 950 x 1300 mm

weight: ca. 2200 kg

total conection: ca. 11,5 kW, 400 V, 50 Hz

Kjdpfxshy Tlre Addjll

machine equipped with:

- double top roll pressure with electric height adjustment

- autom. roll magazine for rolls up to 800 mm DM, pneumatic cutting up to 3 mm

- autom. infeed fence - no adjustment of edge seize

premilling aggregate

with 2 HF-motors 1,5 kW, 12000 n

double end trim unit

- 2 HF-motors 0,2 kW, 12.000 n

2 autom. positions = 0 + 3 deg.

flush trimming aggregate

with 2 HF-motors 0,7 kW, 12.000 n

radius trimming unit

- with2 HF-motors 0, 3 kW, 12.000 n,

radius scraping unit, autom. set in

flat scraping unit

Advise used machines:

• Technical data without obligation, mistake and intermediate sale reserve.

• Price is considered ex-location price

• All articles or machines are bought as seen without any entitlement on warranty.

• It is left to the choice of the buyer to view the machines before at its location.

• Special arrangements are possible but only valid in written form.

(We answer your inquiries only with stated address + telephone number!)

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

SCM MiniMaxME 40TR

Call

Condition: new, The model ME 40TR is SCM’s ‘bestseller and in this category offering unrivaled price / performance ratio.

We can offer the following new machine

SCM me 40tr, CE

Volt 400 EU, frequency 50 Hz

edge thickness coils 0,4 - 3 mm

max. edge thickness strips 5 mm

min. – max. work piece thickness 8 - 50 mm

feed speed 9 m/ min

glue pot unit 0,18 kW, capacity 0,8 kg

premiling aggregate 2,2 kW, 9000 U/ min

end-cutting unit with "Radius" allows you to make a radius on the corners of the edged panel

trimming unit 2 x 0,35 kW, 12.000 U/ min

Kodpfjc S Di Rex Addsll

OPTIONAL

device for panel preheating

edge scraping unit

flat scraping unit

grooving unit 1,1 kW, 12.000 U/ min, notch width 4 mm

brushing unit with 2 independent motors

magazine for strip edges

kid for quick exchange of glue unit

...

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

HEBROCKF2 next

Call

Condition: new, Hebrock

Model F 2 next

Klsdpfjl D Rp Eex Addol

Offer type: New machine, SALE ONLY IN AUSTRIA! Immediately available new machine with special offer price and full manufacturer warranty.

The 3.3 m long F 2 is not only inexpensive and space-saving. It also has the equipment you need to process perfect edges right from the start: diamond-tipped jointing cutters guarantee excellently prepared workpieces for edging. The equipment includes a jointing unit (up to 2 mm milling depth), the top-mounted fast heating glue container, cross-cut saw and combination router. Optionally, the F 2 can also be equipped with a surface scraper.

max. edge thickness: 3 mm

max. workpiece thickness: 50 mm

Ready for operation in 3.5 min

Feed rate approx. 10 m/min

Equipment:

Edge banding machine F2 next

With PLC control (incl. touch screen)

Hot melt glue application to the workpiece for edgebanding material up to 3 mm

jointing cutter (incl. slide - tool) up to 2 mm milling depth

maintenance-free glue basin with change basin pre-equipment incl. glue discharge device

HF crosscut saw station (approx. 12000 rpm)

HF milling station (approx. 12000 rpm) with separate pneumatic milling adjustment and interchangeable plate milling cutter (combination version)

robust chain drive

ball bearing mounted double roller top pressure

viewing window from rear side of machine

extractable workpiece support

Including special equipment:

F2/12 surface scraper (incl. pneum. lift)

F2/30 pneumatic 3-point adjustment (radius- ,chamfer-, flush milling)

F2/27 Nesting for milling stations

Listing

Schwanberg

Schwanberg

1,610 km

Edge banding machine

OTTTornado

Call

Condition: excellent (used), Year of construction: 2007, Edge thickness 0.2 - 12 mm

Workpiece thickness 8 - 52 mm

Workpiece width min. 70 mm

Workpiece length min. 150 mm

Automatic edge magazine

Ksdpfxjlc Ewis Addsll

milling unit 2 x 1.5 kW, application-controlled

Cut-off unit 2 x 0.3 kW

Flush trimming unit 2 x 0.7 kW, scanning on one side

Fine trimming unit 2 x 0.35 kW, tiltable 15/ 30/ 45 degrees

Fine trimming unit 2 x 0.3 kW, R=2, scanning on both sides

Corner copying unit 2 x 0.3 kW

Scraper unit, autom. in/ out

Flat scraper unit

Buffing unit 2 x 0.2 kW, oscillating

5 x spray device (2 x release agent, 1 x lubricant, 2 x cleaning agent)

Color touch screen control OTT C3

Motorized height adjustment

Feed 10 - 14 m/min

COMBI MELT gluing part for EVA/ PUR, volume 1.5 l

CE mark

Total connection 12.6 kW

Dimensions L x W x H approx. = 6120 x 840 x 1500 mm

Weight approx. 2,900 kg

Listing

San Giovanni Al Natisone

San Giovanni Al Natisone

1,577 km

BAND RE-SAWING MACHINE

MeberSR900

Call

Condition: used, Year of construction: 2000, functionality: fully functional, table width: 975 mm, table length: 810 mm, SECOND-HAND BAND RE-SAWING MACHINE MEBER MOD. SR900

Kljdpfx Asx Rt Aaeddjl

- Table dimensions mm. 975x810

- Motor Kw 11

- Year 2000 (CE)

Listing

Sankt Peter im Sulmtal

Sankt Peter im Sulmtal

1,613 km

Edge banding machine

OTTUNIKANT 202

Call

Condition: excellent (used), Year of construction: 1993, max. edge thickness coils 0.2 - 3 mm

max. edge thickness solid strips15 mm

feed speed 12/ 18 m/min

glue plot heating time approx. 6 min

autom. strip magazine

Kledpfx Adsfbr S Rjdel

coil magazine

granulate heating pot

flush trimming unit

radius trimming unit

operating panel

extendable work piece support

noice cancelation hood

machine length 3800 mm

Advise used machines:

• Technical data without obligation, mistake and intermediate sale reserve.

• Price is considered ex-location price

• All articles or machines are bought as seen without any entitlement on warranty.

• It is left to the choice of the buyer to view the machines before at its location.

• Special arrangements are possible but only valid in written form.

(We answer your inquiries only with stated address + telephone number!)

Listing

Hamburg

Hamburg

891 km

Machining center with edge banding

IMABIMA 400 V

Call

Condition: excellent (used), Year of construction: 2009, functionality: fully functional, 4-axis CNC machining center with console table and edge banding unit

Klodpfx Ajxrltkoddsl

Manufacturer: IMA

Model: BIMA 400 V

Year of manufacture: 2009

8 manually adjustable supports in X-axis,

3 vacuum pods per console,

Vacuum pump 100 m³/h -2*

Vacuum connection for templates

LED display for pod position indication

Working area X: 200 – 6150 mm

Working area Y: 0 – 1600 mm (milling/drilling), with edge banding 1525 mm

Working area Z: 12 – 125 mm (clearance 150 mm)

14 vertical drilling spindles

Horizontal drilling and grooving saw unit, swiveling 90°

Milling spindle 11 kW / 7.5 kW up to 24,000 rpm

With C-axis, 360° interpolation, liquid circulation cooling

– 18-position tool changer, traveling with y-support

Edge banding unit VT 100, 4-sided/all-round – rotation range 740 degrees

With dual roller magazine, automatic granulate feeding

Adapter units:

– Saw, fixed at 90°

– 5-axis saw/drill/milling unit Vario NC

– Horizontal cutter (corner notching)

– Flush trimming and profile scraping blade with extension for flat scraper

ICOS open control system with 17" TFT

ImaWop 6.0 incl. MDE and production list software

Chip conveyor

Side safety fencing and front safety mats;

Rear: requires wall placement or separate safeguarding

Trust Seal

Dealers certified through Machineseeker

Listing

Wittlich

Wittlich

922 km

Edge banding machine

OttPROFImatic M 258-FÜ

Call

Condition: excellent (used), Year of construction: 2000, functionality: fully functional, machine/vehicle number: M/53056, total length: 9,800 mm, overall weight: 4,500 kg, compressed air connection: 6 bar, input voltage: 400 V, input frequency: 50 Hz, Single-sided edge banding machine in right-hand configuration

- with jointing unit

- gluing unit

- double end cutting unit

- flush trimming, chamfering, and radius milling unit

- corner rounding unit

- scraper and edge buffing unit with high-performance automation

- pressure zone with one driven roller and six follow-up rollers

- automatic edge thickness adjustment for all units

- automated chamfer thickness adjustment of the top pressure to panel thickness

- pneumatic engagement/disengagement of all processing units with monitoring

- Machine in CE-compliant design with complete encapsulation of processing zones by high-quality noise protection hoods.

Machine length: 9,800 mm

Machine weight: 4,500 kg

Gluing unit

- for hot-melt adhesive granules

- with quick heating tank, preheating time: 6 minutes

Ksdpsxy Sizjfx Addsll

- electronic temperature control

- adhesive application roller (no adjustment required for different material heights)

- operates in both co- and counter-rotation, automatically activated via program control

Edge thickness: 0.2 - 20 mm

Workpiece dimensions:

Minimum width: 60 mm

Minimum height: 8 mm

Maximum height: 60 mm

Minimum length: 160 mm for strip edges / 60 mm for continuous roll edges / 150 mm with double end cutting unit

Workpiece transport

- heavy-duty chain conveyor with precision sliding guides for chain support plates with flat and round guide rails to ensure positive workpiece transport

- feed speed: 12 - 20 m/min, adjustable via electronic frequency inverter from the central control panel, values can be saved in work programs

- motor power: 5.5 kW

Panel thickness adjustment

Motorized adjustment of double roller top pressure, preselection via the central control panel, values can be saved in work programs

Edge thickness adjustment

- automatic positioning of all edge thickness-related units including the pressure zone, preselection via the central control panel, values can be saved in work programs

Machine control

- central control panel

- PLC and line control for contactless control of the processing units

Central control panel

- for flexible and easy operation of the edge banding machine, with a specifically developed user interface for clear and rapid access to all important machine and unit statuses

- intuitive menu navigation via two-line text display, supported by clearly arranged symbols with two-color LED status indicators

PLC

- high-performance PLC to industrial standards for fast and efficient interaction with the machine and for controlling all functional groups and line control

Line control

- high-resolution line control of all processing units with +/- 1mm accuracy over the full machine length

- complete access via the control panel for all program-controlled processing units

- values can be saved in various work programs

EFU

- electronic frequency inverter

Connections

Electrical: 3 x 400 V, 50 Hz, rated current 42 A, protection: 50 ampere, supply: 5-core, 5 x 10 mm², control voltage: 24 V

Extraction: 1 x 120 mm, 1 x 160 mm, 1 x 120 mm, extraction air velocity: min. 20 m/sec, required capacity: approx. 65 m³/min

Compressed air: 6 bar, 1/4" - consumption approx. 300 l/min, required minimum pressure: 4.5 bar, all workpiece blow-off lines are line-controlled.

Auction

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

782 km

Edge banding machine

Format4Tempora 60.06 Gluebox

Condition: ready for operation (used), Year of construction: 2022, functionality: fully functional, machine/vehicle number: 220.01.016.22, feed rate X-axis: 18 m/min, workpiece height (max.): 60 mm, rotary table diameter: 750 mm, rotational speed (max.): 12,000 rpm, The machine is being auctioned due to a business closure! Further details on the machine’s equipment can be found in the attached order confirmation.

TECHNICAL DETAILS

Workpiece height: 8–60 mm

Rotary table edge magazine diameter: 750 mm

Edge banding material (coil): 0.4–3 mm

Rotary table diameter for coil edge material: 740 mm

Support surface (workpiece infeed): 600 mm

Spindle speed of diamond pre-milling unit: 12,000 rpm

Feed speed, chain feed: 10 and 18 m/min

Spindle speed, cross-cut saw unit: 12,000 rpm

Upper multifunctional milling unit speed: 12,000 rpm

Lower multifunctional milling unit speed: 12,000 rpm

Cutter assembly: 64 mm

MACHINE DETAILS

Electrical data

Voltage: 400.0 V

Phases: 3

Frequency: 50/60 Hz

Current: 28.0 A

Power: 15.0 kW

EQUIPMENT

Kodpfjxwt Nqex Addjll

Ball bearing rotary table for edge banding coil material

Workpiece infeed and feed fence with manual adjustment

Chain feed with two speeds

Edge feeding for coil and strip material in single feed

Upper and lower multifunctional milling unit x-motion PLUS via smartouch

Upper and lower radius scraper blade x-motion PLUS

Corner rounding unit with motorized adjustment for postforming and softforming profiles

Upper and lower polishing units

Pneumatic-mechanical infeed stop for workpiece gap monitoring

glueBox application unit

Listing

Nürtingen

Nürtingen

1,151 km

Edge banding machine

HOLZ-HERACCURA 1556 Premium

Call

Condition: used, Year of construction: 2015, functionality: fully functional, total length: 7,920 mm, workpiece height (max.): 60 mm, warranty duration: 3 months, HOLZ-HER Edgebander ACCURA 1556 premium with intelligent equipment package for edge thicknesses up to 15mm. Simple program changeover and tool adjustment via the 18.5" touch control panel.

Short heating time for the GlueJet adhesive system of approx. 2 to 3 minutes, depending on adhesive type and ambient temperature. Always fresh glue thanks to the GlueJet application system and glue cartridges. Changing PUR adhesive and cleaning the system is quick and easy within a few minutes.

Axis adjustment via high-precision, repeatable servo motors.

Special configuration for materials with protective film, such as high-gloss and supermatt surfaces!

One of the true highlights of this machine is the multifunction package, which shows its strengths in companies processing a wide variety of edges. The DIA tools are constructed in multiple stages and can switch between radii and bevels as needed – from the longitudinal milling unit to corner copying and the profile scraper.

The pull-out workpiece support and the extended infeed area facilitate processing of large workpieces, and a guide system assists in feeding small parts into the machine.

Kedpfx Ajx Emf Djddell

Edging thickness (coil material): 0.4 – 3 mm (depending on material)

Edging thickness (strips): 0.4 – 15 mm

Workpiece thickness: 8 – 60 mm

Workpiece width: min. 65 mm

Feed speed: 10 – 25 m/min

Glue application with GlueJet in EVA and PUR, with minimal effort required.

All common edge types, including high-gloss, supermatt, and solid wood edges up to 15mm.

iTronic – pressure and glue quantity control

Prepared for connection to a RETURN system

Motorized pressure bridge with upper belt drive

Multifunction units for rapid changeover between radius, flush, and bevel processing

Vertical & horizontal spray systems

and much more.

Listing

Sulęcin

Sulęcin

1,255 km

Band slicing machine

noname

Call

Year of construction: 1997, condition: used, Band Slicing Machine

Klodpfx Adsx Hvcuodsl

This conveyor slicer with an extended infeed belt is specifically designed for slicing vegetables and fruit. Thanks to a wide range of interchangeable cutting tools, the machine is capable of producing slices, strips, and cubes. Special knives are also available for shredding pulled meat.

It is highly versatile and suitable for slicing salad, leafy and non-leafy vegetables, fruit, herbs, meat, fish, sausage, bread, cheese, nuts, and more. It is ideal for commercial kitchens, catering operations, fresh produce retailers, and industrial food processing applications. Numerous cutting accessories are available, allowing adaptation to a broad spectrum of uses. The user-friendly control panel enables fast and easy product changeovers.

Both the conveyor belt speed and blade rotation speed are continuously adjustable (frequency-controlled), ensuring precise and gentle cutting even of sensitive products. The machine is constructed entirely from stainless steel for maximum hygiene and durability.

We make it easier for you to find: "banding machine"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Banding Machine (64,704)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Baking Machine

- Band

- Band Feed

- Band Saw Machine

- Band Saw Sharpening Machine

- Banding

- Bandsaw Machine

- Belt Grinding Machine

- Belt Saw Machine

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month