Used Biesse Rover 35 for sale (334)

Pollenzo

Pollenzo SUCTION CUP 131.5X75X74 WITH BASE

BIESSE

Pollenzo

Pollenzo Sharpener

BIESSEH0102DE323A0

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSEH0102DE222A0

+44 20 806 810 84

Pollenzo

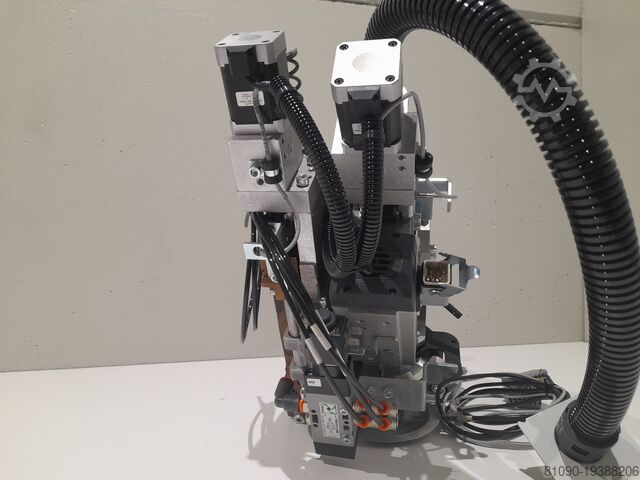

Pollenzo 3-POINT HEAD MC

BIESSE6714A1734

Pollenzo

Pollenzo TEST.SPECIAL 7 SPINDLES, 4 MOUNTINGS, PITCH 57

BIESSE

Discover more used machines

Pollenzo

Pollenzo TEST. SPECIAL MANDREL. CENTRAL THROUGH ATTACHMENT 57

BIESSE

Pollenzo

Pollenzo TEST.SPEC.4 MANDREL ATTACHMENT, 2ND LINE, STEP 57

BIESSE

Pollenzo

Pollenzo Lower edge rounding unit

BIESSE

Pollenzo

Pollenzo Upper stripping group

BIESSE

Pollenzo

Pollenzo LEFT HEAD 7 POINTS

BIESSE

Pollenzo

Pollenzo PLIERS 130X130 H=85

BIESSE

Pollenzo

Pollenzo BIESSE 6 SPINDLE DRILLING HEAD

BIESSE

Pollenzo

Pollenzo TEST. SPECIAL4 SPINDLES MOUNT 2 PITCH 57

BIESSE

Pollenzo

Pollenzo HSD PE 106 MODULE

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

Pollenzo COMPLETE HEAD 4 SPINDLES

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 OUT

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 OUT

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

Pollenzo 3-POINT HEAD MC

BIESSE

Pollenzo

Pollenzo MOD.PE323A

BIESSE

Pollenzo

Pollenzo MOT. SM137 R=1:8

BIESSE

Pollenzo

Pollenzo Suction cup SAG. 131.5X75X48

BIESSE

Pollenzo

Pollenzo TEST.SPECIAL 6 SPINDLES WITH 3 HOLDERS, PITCH 57

BIESSE

Pollenzo

Pollenzo Edgebander

BIESSE

Used Biesse Rover 35 (334)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84