Used Concentricity for sale (266)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

967 km

Cylindrical Grinding Machine

JUNKERQuickpoint 3000/20

Call

Condition: used, Year of construction: 2006, Technical details:

grinding diameter: 5-55 mm

grinding length: 500 mm

total power requirement: 44 kW

-- Intended use and general information --

Fully automated external and surface grinding of synchronous rings

Centre height: 200 mm

Grinding length: 500 mm

Grinding wheel arrangement: right, 30° angled Grinding wheel dimensions: 600 x 30 x 203.2 mm

Drive power: 7 kW X/Z axis drive: ball screw Travel speed: 0.01 - 10,000 mm/min. Resolution: 1 µm Concentricity of workpiece spindle: < 1 µm

Workpiece changing system: Fanuc robot Control: Siemens Sinumerik 840-D

Machine weight: 7,000 kg

Centre height: 200 mm

Grinding length: 500 mm

*

Pedpfovg Thiox Afhogg

Listing

Wald

Wald

1,198 km

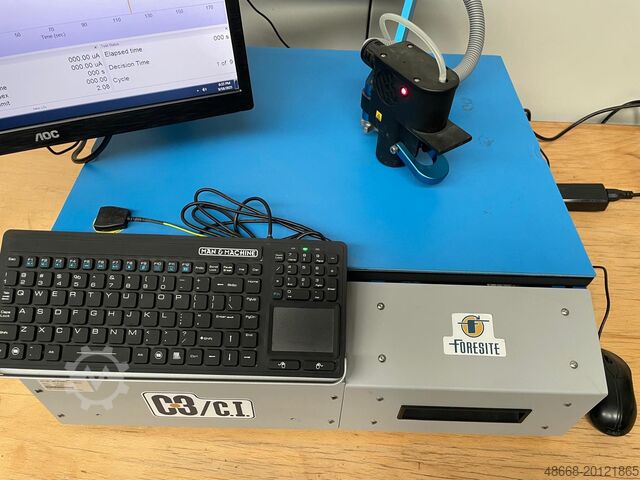

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

Pedexhcklopfx Afhogg

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Technical data deviations and errors in the description of the item may occur and are subject to change.

Listing

Germany

Germany

992 km

Swivel mill

Panhans245/200

Call

Condition: new, Year of construction: 2024, New machine

Year of construction 2024

Technical data

Table size 1100 x 760mm

Table height 905mm

Milling spindle 30mm with quick-release nut

Clamping height 140mm

Height adjustment 125mm

Suction nozzle 2 x Ø 120mm

Infinitely variable speed control 150010000 rpm

Motor power 7.5 kW (10 HP)

Net weight approx. 880kg

Technical description

7" touch control, can be used optionally, top and

bottom

7" capacitive touchscreen, can also be operated with gloves

can also be operated with gloves (e.g. with Maxi Flex)

Language switching German, English, French

(other languages on request)

Milling cutter zero point selectable in the program, 3

reference points

Simple menu structure thanks to innovative touch control

(max. 2 levels)

Display (work screen) for tool and program number

program number, height, angle, speed and

milling fence

Operating hours counter

Warning messages in the event of incorrect operation

Remote maintenance via Internet (VPN tunnel)

USB interface for data backup and importing

Tool, program and user

Tool database for 5 tools (20 programs possible per tool)

20 programs are possible per tool)

Heavy-duty bench router with double-sided swivel-mounted, fixed

built-in milling spindle for

swivel range of +/- 45.5°

2-axis positioning control for height and tilt adjustment

swivel adjustment

Electronic position and speed displays

Infinitely variable speed control 1500 10000 rpm

7.5 kW motor with 11 KW frequency converter

Push button with electronic soft start

Left and right rotation

Milling cutter quick clamping device

Finely planed gray cast iron table with rigid

frame support

Milling fence 301 Overall adjustment via 1

handwheel on the right-hand side,

Adjustment range approx. 140 mm, dimension display,

Total stop via touchscreen +/-0.1 mm,

Partial stop

adjustment, (chip removal) +5mm to -25mm is carried out

via a star knob screw on the left side

side, dimension display via one mm vernier, clamping on the machine table

the machine table manually via clamping

clamping screws, milling fence made of die-cast aluminum with 2

milled cast iron stop slats 500mm long

with aluminum splitter tongues, maximum possible tool diameter is

tool diameter is 250 mm

Machine socket

Lockable main switch

Electronic, wear-free motor brake

Milling protection and pressure device GAMMA V 1629

Arc milling fence 1639 Tapoa

Milling spindle 30mm with quick-release nut

CE-compliant

incl.

- Milling fence type 301

Podpfjx N Dhdex Afhogg

- Cast stop plates and aluminum splitter tongues

- Milling protection and pressure device GAMMA V 1629

Table pusher for table top 1100 x 760 mm

Coated surfaces, for quick, convenient and tool-free

tool-free adjustment to different tool diameters

tool diameters up to max. 240 mm, the table insert

Table insert with quick lock up to

tool diameter

155 mm instead of standard table insert rings (not in conjunction

connection with rotary table)

- Zeromaster reference measurement setting device

for exact 0-point height adjustment from the

milling tool to the table top

for 24 V DC

- HSK-80 quick-change arbor system with spindle lock and

spindle lock and milling arbor 30mm

instead of milling spindle 30mm

(higher concentricity and no sticking in the spindle as with the

spindle as with the

MK 5 system or steep taper)

- Console

to the

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Germany

Germany

1,137 km

Tool preheating equipment

BilzISG 3200-WK

Call

Year of construction: 2009, condition: used, Technical details:

tool taper: Ø 54

voltage: 3Ph AC 400V / 50-60 Hz V / Hz

Pgsdpjwp I S Hjfx Afheg

compressed air: Anschluß: 6 bar

total power requirement: 11 kW

Total weight, approx.: 120 kg

dimensions L x W x H: 0,7 x 0,65 x 1,7 m

Application: for secondary quick tool change through targeted inductive heating.

Induction shrink fit unit with water cooling (tank 30 litres, built into the housing)

Cooling medium: emulsion

for Ø 3 - 50mm HM (carbide) and Ø 6 - 50 HSS tools

Tool holder Ø 54mm

Concentricity < 0,003mm

ThermoGrip chuck

Operation via control panel

*

Listing

Germany

Germany

1,137 km

Tool presetter

WMW

Call

Condition: used, Technical details:

x-travel: 130 mm

y-travel: - mm

z-travel: 140 mm

machine weight approx.: 107 kg

dimensions L x W x H: 0,72 x 0,33 x 0,63 m

Concentricity Gauge Device and Presetting Device (table device)

- application: measuring device for production components (helical tooth gears), testing and adjusting of milling tools

Characteristics:

- longitudinal axis approx. 100 mm, Ø 280 mm

- tool slides: turning range 360 °, tool holder Ø 30 x 80 mm, size LxW: 200x175 mm, with measuring device measuring rod Ø 8 x 400 mm adjustable

- vertical slide: pin gage Ø 20 x 80 mm

Pgjdpfx Aju N Apfefhsg

*

Listing

Babenhausen

Babenhausen

1,030 km

Paddle mixer

LochbihlerLa-Mix NEU

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2025, warranty duration: 12 months, overall weight: 49 kg, total length: 450 mm, total width: 620 mm, total height: 1,030 mm, space requirement height: 1,030 mm, space requirement length: 450 mm, space requirement width: 620 mm, NEW NEW Lye Mixing Device for Pretzel Lye NEW NEW

Includes hydrometer

Includes collection tray and dosing cap

Stainless steel cart with locking castors

Maximum safety for the desired lye concentration.

Optimally mixed, quantities dispensed precisely as needed.

Dimensions (WxDxH) in mm: 620 x 450 x 1030

NEW device + spare parts service

More bakery machines in stock!

Pgjdpfx Ajrkz E Ujfheg

Listing

Bad Honnef

Bad Honnef

891 km

Bench drill OPTIMUM D 23 Pro-Set OPTIdrill - Exhibition machine -

OPTIMUMTischbohrmaschine D 23 Pro-Set

Call

Condition: new, Bench drill OPTIMUM D 23 Pro-Set

OPTIdrill - Exhibition machine -

----- Technical data -----

Number of speeds: 12 steps,

Speed range: 200 - 2,440 rpm,

Spindle stroke: 80 mm,

throat depth: 180 mm,

Table size: 280 x 245 mm,

max. drilling capacity in steel: 25 mm,

Motor: 750 watts,

Columns Ø: 73 mm,

Dimensions (LxWxH): 615 x 330 x 1,015 mm,

Weight: 63.5 kg,

Spindle holder: MK 2

Bench drill with V-belt drive

- Industrial motor

- User-friendly safety switch in accordance with IP 54

- Digital drilling depth and speed display

integrated in the housing

- Separate emergency stop switch

- Precision spindle bore

- Safety electrics with 24 V DC voltage

- Guaranteed concentricity of less than

0.02 mm measured in the drill sleeve

- Drill spindle with precision ball bearings

- High-quality quick-action drill chuck

- Drilling depth stop

- Precisely machined, stable drill table with diagonal

T-slots running diagonally and

circumferential cooling water channel

- V-belt cover with safety switch

- One-piece cast aluminum

Die-cast quill lever with soft-grip handles

- Largely dimensioned, height-adjustable

safety screen with safety switch

- Heavy-duty design of the entire machine

- GATES quality belt

- Right/left rotation

-- Scope of delivery

Quick-action drill chuck 1 - 16 mm

Morse taper MK 2 / B16, T-nuts

Special offer set including machine vice BMS 100

Pjdsu R S Exspfx Afhegg

- new exhibition machine -

Listing

Bitburg

Bitburg

902 km

Carcase press

Ganner GannomatConcept 70

Call

Condition: refurbished (used), Year of construction: 2016, LAMELLA - CARCASE PRESS

GANNOMAT « CONCEPT 70 ECO »

Complete in standard configuration with:

- Sturdy, torsion-resistant frame made of steel in welded and bolted construction

Pgodpfoxvitijx Afhog

- Upper lamella pressing beam with 6 elements, side lamella pressing beam with 5 elements

- Lamella pressing beams with proven tolerance compensation system (Ganner system) for tightly pressed carcase joints

- Counterpressure surfaces (side pressure wall, base) made from 38 mm thick, coated, continuous support panels

- Continuous pressing surface with a height of 95 mm on the lower vertical pressing beam

- Electromotorical adjustment of both pressing beams via precision trapezoidal-thread spindles (with increased pitch and concentricity accuracy) and high-performance traveling nuts with grease reservoir

- Pressing is carried out electrically via 2 separate worm gear motors (2 x 0.75 kW)

- The pressing force of the beams is infinitely electronically adjustable via 2 potentiometers and regulated by a frequency inverter, resulting in absolutely wear-free pressing force control

- Pressing force for horizontal pressing beam: min. 500 daN (kg) up to steplessly max. 2200 daN (kg)

Pressing force for vertical pressing beam: min. 300 daN (kg) up to steplessly max. 2200 daN (kg)

Pressing and adjustment speed of the beams with fine positioning via 3-stage selector switch: 5 / 10 / 25 mm/second

Very easy operation

- Working height/loading height: 300 mm

- Working dimensions: length min: 150 mm, max: 2500 mm

height min: 150 mm, max: 1400 mm

depth: 700 mm

Machine No. 563.624

400V, 3Ph, 50Hz (3.2 kVA, 16 A)

Set of machine feet for 500 mm working height

Operating manual in German language

Completely overhauled by Ganner, 6 months parts warranty

Location: Ex stock 54634 Bitburg

- immediately available -

Listing

Germany

Germany

1,034 km

Circular Metal Saw

BERG & SCHMIDVKS 370 VA

Call

Year of construction: 2019, condition: ready for operation (used), Additional Equipment

Starter Kit 1 consisting of 2 circular saw blades and 10 liters of coolant concentrate.

Leveling element (1 set = 4 pieces) with stud bolt M 12x100.

Feed side – left.

Feed roller conveyor URB 290, Length 3000 mm.

Feed adapter for URB 290/400.

Outfeed roller conveyor URB 290, Length 2000 mm.

Removal adapter for URB 290/400.

Connecting piece for machine, attachment on the right.

LM 55 M/man. Length stop, Measuring length 2000 mm.

Pjdpfx Afex Nr Sqehogg

This BERG & SCHMID VKS 370 VA was manufactured in 2019. It features a fully automatic hydropneumatic vertical circular saw with CNC frequency conversion. The machine includes a roller conveyor on the feed side (3m) and discharge side (2m), enhancing material handling. Starter Kit 1 with circular saw blades and coolant concentrate is also included. Consider the opportunity to buy this BERG & SCHMID VKS 370 VA Circular Metal Saw. Contact us for more information.

Application Types

Sawing

Listing

Dortmund

Dortmund

842 km

Universal lathe

EPPLETD 4610 Digi

Call

Condition: new, Center height 230 mm

Center width 1000 mm

Turning diameter over bed 460 mm

Turning diameter without bridge 690 mm

Turning diameter over support 285 mm

Passage 58 mm

Spindle mount DIN 55029 1 - 6"

12 speeds 25 - 2000 rpm

Travel path - top slide 128 mm

Travel path - cross slide 285 mm

Feeds (longitudinal) 0.031 - 1.7 mm/rev

Feeds (transverse) 0.014 - 0.784 mm/rev

Thread (metric) 0.25 - 3.5 mm

Thread (inch) 2 - 112 Gg/1"

Thread (diametric) 8 - 144 D.P.

Thread (module) 0.25 - 3.5 mm

Motor power 400 V / 50 Hz / 5.5 kW

Tailstock MK 4

Dimensions L x W x H 2020 x 1080 x 1600 mm

Weight 1680 kg

Accessories / Special features:

• Lead and pull-spindle lathe in heavy-duty design with extensive standard equipment. Low vibration and smooth running. Including solid base and machine bed.

• 3-axis digital display

Psdok Dn Nwopfx Afhogg

• 3-jaw chuck Ø 250 mm

• 4-jaw chuck Ø 300 mm

• Fixed and rotating steady rest

• Quick-change tool holder system Multifix size B mounted, 5-part

• Strong and torsion-resistant construction of the machine base and bed, which is cast in one piece from vibration-absorbing gray cast iron.

• Hardened and ground bed guideways

• Generously dimensioned machine bed

• All guides are provided with adjustable wedge strips

• Central lubrication in the bed slide

• Right / left rotation can be switched on the bed slide

• Removable bed bridge for machining large workpieces

• Adjustable tailstock for turning cones

• Guaranteed concentricity < 0.015 mm measured in the spindle nose

• Closed feed gear, gears and shafts are hardened and ground

• Clear control element with solid selector levers for selecting the speeds

• Oil bath change gear with hardened and ground gears

• Handwheels with adjustable fine scaling

• Main spindle hardened and ground and running in an oil bath, as well as tapered roller bearings

• Longitudinal feed, can be switched off using 4 adjustable switching cams

• Mechanical foot spindle brake

• Lead screw cover

• Acceptance protocol

• Manufactured according to DIN 8606 toolmaker precision

• CE compliant

Delivery time: immediately, subject to prior sale

Year of manufacture: 2023 (unused exhibition machine)

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund - Wambel

Listing

Wymysłów

Wymysłów

1,472 km

GEWEFA SK40 drill chuck Ø2.5–16 mm – Made in Germany

Uchwyt wiertarski GEWEFA SK40 Ø2.5–16 mm – Made in GermanyUchwyt wiertarski GEWEFA SK40 Ø2.5–16 mm – Made in Germany

Call

Condition: excellent (used), Professional drill chuck from the renowned brand GEWEFA, made in Germany. Designed for clamping drills with a diameter from Ø2.5 to 16 mm in CNC machines, machining centers, and conventional milling machines. The high-quality construction ensures excellent concentricity, secure tool holding, and long service life even under intensive production work. Type: SK40 × Ø2.5–16. Catalogue number: 28.05.046.002. Taper: SK40 DIN 69871. Manufacturer: GEWEFA – Made in Germany. Year of manufacture: 2007. Condition: very good, used. An ideal choice for professional industrial applications and metalworking workshops specializing in precision machining. Price is per unit.

Pgedpfxoxizauj Afheg

Listing

Wymysłów

Wymysłów

1,472 km

Dividing head

Przyrzad kłowy do pomiaru osiowosci

Call

Condition: excellent (used), Professional measuring instrument with two sliding spindles terminated with cones.

Enables precise positioning of a component for checking runout, straightness, or concentricity.

Specification (approximate):

Podpfx Afsw Rkqtohegg

Working length between centers: about 300 mm

Base length: about 380 mm

Spindles with sliding and locking capability

High-precision industrial construction

Universal application for measurement or workshop use

Condition: Very good technical and visual condition

The instrument is ready for operation

Listing

Dinkelsbühl

Dinkelsbühl

1,170 km

Cold saws

Behringer EiseleVMS 350

Call

Condition: new, Available from stock / short-term delivery!

Speed: 17 / 34 rpm.

For saw blades up to 350 mm diameter.

Equipped with a pole-changing three-phase motor, 1.4/1.9 kW.

Stationary base frame with built-in coolant system and chip drawer.

Cutting capacity:

Flat 90°: 170 x 100 mm

Flat 45°: 120 x 100 mm

Flat 30°: 85 x 100 mm (right side only)

Square 90°: 100 mm

Square 45°: 95 mm

Square 30°: 85 mm (right side only)

Pedjllvpwopfx Afhjgg

Round 90°: 120 mm

Round 45°: 120 mm

Round 30°: 100 mm (right side only)

Technical Data:

Length: 895 mm

Width: 665 mm

Height: 1750 mm

Weight: 300 kg

Support height: 900 mm

Options:

Roller conveyors and length measuring systems (image is for illustration purposes only, available in manual and automated versions upon request)

We recommend our proven coolant concentrate for 'Eisele' saws, our micro-spray oil (for machines with micro-spray equipment), as well as high-quality circular saw blades and band saw blades tailored to your specific needs.

Contact us for a non-binding enquiry!

Listing

Zdziechowice

Zdziechowice

1,523 km

Mobile welding fume extraction

KEMPERMaxiFil CLEAN

Call

Condition: excellent (used), Year of construction: 2018, suction capacity: 1,100 m³/h, negative pressure: 3,200 Pa, Welding fume extractor, dust extraction unit, Kemper self-cleaning, pneumatic, vacuum filter.

Suitable for welding, grinding, and all types of dry dust.

Self-cleaning welding fume filter with contamination-free dust collection.

The mobile Kemper MaxiFil Clean cartridge filter is designed for continuous operation to filter welding fumes and high-concentration dusts.

Suitable for use with all welding methods for carbon steel, low-alloy and high-alloy steels, as well as aluminum.

Cost-effective in operation due to the long service life of the filter cartridge.

With IFA-W3 certification, the standard version of the filter may be used for welding high-alloy steels.

Specifications:

Airflow capacity – 1,100 m³/h

Maximum negative pressure – 3,200 Pa

Three-phase fan motor – 1.5 kW

Pgodpfx Afjtq E Siehog

Filtration area – 15 m²

Year of manufacture – 2018

PTFE-membrane cartridge filter

Filtration efficiency – >99.97%

Integrated start/stop delay timer.

When connected to an optional start/stop sensor, the extraction delay time after completing the welding process can be set between 5-60 seconds.

Stock no. – 1091

Listing

Jesewitz

Jesewitz

1,146 km

Screw compressor for biogas

adicompUVG30-20.5WG-INV

Call

Year of construction: 2023, condition: new, functionality: fully functional, Screw compressor model: UVG30-20.5WG-INV (WP-SF-BV-CM-BY2-PL-PB) Ex

Medium: Biogas

Electrical power: 37 kW

Operating pressure: 20 bar g

Inlet pressure: 0.003–0.15 mbar (g)

Volume flow: 104 Nm³/h

max. H2S concentration:

Pjdpfx Aox R Tucjfhjgg

Listing

Berlin

Berlin

1,153 km

Fire engine with water tank TLF 3000

RenaultD14 4x4 Allrad Single-Bereifung Staffel

Call

Condition: new, functionality: fully functional, power: 209.62 kW (285.00 HP), fuel type: diesel, axle configuration: 4x4, Year of construction: 2025, Equipment: additional headlights, air conditioning, all wheel drive, differential lock, parking heater, trailer coupling, Are you looking for a reliable and affordable emergency vehicle for your fire department? Then you’ve come to the right place!

From our immediately available new vehicle stock, we offer:

TLF 3000 AWD on off-road capable Renault D14 chassis

Outstanding for small and medium-sized fire departments in rural areas that want to handle a wide variety of tasks with a compact vehicle while still requiring a large water supply. Ample weight and space reserves are available for custom additional equipment.

Also ideal due to its off-road capability and comprehensive firefighting equipment for vegetation and forest fire operations.

Chassis:

• Renault D14 4x4 EURO 6 with 286 hp (210 kW) and manual transmission

• Single tires with matching track for high off-road mobility

Cab:

• Standard crew cabin (1:5) in RAL 3000 (fire red)

• Air conditioning and auxiliary heater included

• 4 standard SCBA holders in the crew compartment

Body:

• High-quality body in frame construction using rust- and corrosion-free materials

• Folding steps for each side compartment

• Stainless steel storage systems individually tailored to your requirements

• Walkable, anti-slip roof with large, LED-illuminated roof box

Fire pump / extinguisher tank:

• Maintenance-free combined normal/high-pressure pump FPN 2000-10, pump & roll capable

• 2,000 l/min at 10 bar and 400 l/min at 40 bar

• Integrated, infinitely variable foam proportioning system

• 3,000 l water tank with integrated 300 l foam concentrate tank

Firefighting Equipment:

• High-pressure rapid attack system with 50 m form-stable hose

• Foam/water monitor 2,000 l/min on the vehicle roof

• Self-protection system with 4 spray nozzles in front of the wheels

Safety and Lighting:

• LED mini lightbar on the vehicle roof / 2 LED front flashers

Pjdpexiwb Isfx Afhsgg

• Pneumatic special signalling system

• 100 W speaker system with announcement unit

• Rear view camera

• Comprehensive LED lighting in crew and all equipment compartments

• LED perimeter lighting on the body and auxiliary spotlights

• Pneumatic LED light mast with remote control

We would be happy to provide you with a detailed offer and to present the vehicle to you at our Berlin location.

All information provided to the best of our knowledge, without guarantee for completeness or accuracy. This advertisement does not constitute a binding offer, but is for information purposes only. Subject to prior sale!

Listing

Burgoberbach

Burgoberbach

1,171 km

Water treatment plant distillation

EnvoTech Spalt- Seperations Anlage0320 mit Reaktionsbehälter Ölabscheider

Call

Year of construction: 1999, condition: good (used), For sale is a water treatment plant of make ENVOTECH and type 0320 from 1999.

Pgodpfxepl Tqts Afhsg

In 2016 a new reaction tank of the brand Leiblein, made of stainless steel, with the dimensions of 500*500*400 mm was added.

The plant is fully functional and the contact details of the competent service technician are available and can be forwarded at the time of purchase.

Technical data & information:

- Executed in stainless steel

- Including oil separation by coalescence principle

- Including automatic cleaning

- Built-in pump for waste water, concentrate and distillate

- Frequency control of the compressor motor

- Type: 0320

- Rated capacity l/h: 320

Energy consumption

- In operation: 25 kW

- Maximum power: 35 kW

Supply voltage: 3*400 V - 50 Hz

Dimensions lxwxh: 245x155x265

Face: ca 2600 kg

Sound pressure level: 75 dB

All data refer to operation with water

On request, loading and shipping can be organized throughout Europe.

Prices plus VAT

Viewing by appointment possible. Contact us, our team is happy to help you.

Ch3mj0l3eg

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES ETC.

Do you need a high quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For more information or to contact us please visit our website

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Syrup Room

ALFA LAVAL

Call

Condition: used, Used syrup room with pasteurizer Alfa Laval

This second hand Syrup Room is a complete processing section designed for the preparation of concentrated base syrups and finished syrups for beverage production. Engineered for integration upstream of a premix and an isobaric filler, it supports efficient industrial packaging workflows in a used bottling line. It is ideal for beverage production environments that require reliable sugar dissolving, thermal treatment, and hygienic storage prior to mixing, carbonation, and filling.

The system covers the full syrup preparation sequence: simple syrup creation from treated water and sugar, finished syrup blending with concentrates, acids, colors, and flavors, and hygienic storage in stainless steel tanks. A dedicated pasteurizer helps ensure product stability, while mixers and pumps support consistent, repeatable processing. This Syrup Room is well suited for soft drink formulations such as cola, tonic, and other flavored carbonated beverages, and it integrates seamlessly with premix units that add CO2 just before the filling machine. The plant layout and component selection make it a practical solution for upgrading or expanding a used bottling line in the beverage production sector.

Technical Specifications & Performance Data

Sugar dissolver: AICMA

Pasteurizer: Alfa Laval

Storage tanks (finished/simple syrup): 4 x 4,000 L Cavalzani

Storage tanks (finished/simple syrup): 3 x 2,000 L Bertuzzi

Mixers and pumps: Included for circulation, transfer, and blending

Process materials: Treated water, sugar/sweeteners, fruit concentrates, flavors, additives

Construction: Stainless steel AISI 304/316 process equipment

Cleaning: CIP-ready design for sanitary cleaning in place

Advanced Automation & Control Systems

Pgedpfxsxywg So Afhjg

The Syrup Room features a centralized control panel with analog/digital selectors for process management, enabling operators to supervise dissolving, thermal treatment, storage, and transfer operations. Dosing can be achieved using precision pumping and flow control to maintain recipe accuracy. Hygienic design, sanitary valves, and instrument connections support repeatability and quality. The configuration is suitable for integration with plant-level automation and recipe control, with clear operator interfaces that simplify changeovers and routine adjustments while supporting safe and reliable operation.

Production Line Integration Capabilities

This processing plant is designed to feed finished syrup to a premix unit, where it is blended with treated water and CO2 immediately before the isobaric filler. It can be integrated inline with existing beverage production and industrial packaging equipment and is compatible with used bottling line layouts handling both PET and glass bottling downstream. Recipe-based operation supports multi-flavor portfolios, and transfer connections allow straightforward tie-in to upstream water treatment and downstream premix and filling systems.

Listing

München

München

1,298 km

Lead/traction spindle lathe

BoleyKonventionelle Drehmaschine

Call

Condition: good (used), functionality: fully functional, turning diameter: 240 mm, turning length: 600 mm, For sale is a Boley lathe

The guides and the concentricity are still very good (see pictures)

center distance 600mm

turning diameter 240 mm

spindle bore: 20 mm

Pjdpfordf A Dsx Afhsgg

Many accessories (cabinet incl.)

IDEAL COLLECTION DATE 06.02.2024

On request, for an extra charge, loading and transport (Europe-wide) can be organized.

Prices plus VAT

Viewing possible by appointment. Contact us, our team will be happy to help you.

Trade-in or exchange possible!

Machines purchase / sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MUCH MORE.

Do you need a high-quality but inexpensive metalworking machine for your production? Or do you want to sell yours?

For further information or contact options, please visit our website

Listing

Bienne

Bienne

1,178 km

NC TURNING CENTER

SpinnerTM

Call

Condition: excellent (used), Year of construction: 2001, operating hours: 4,500 h, functionality: unexamined, machine/vehicle number: 090119, Manufacturing origin CE - Germany

Voltage 400V

Netweight 7500 kg

Custom position 8458.91 20

Dimensions 2,9 x 2,3 x 2,3 m.

29731 hrs - work 4500h rs

TECHNICAL DATA

AXES

Maximum travel X-axis 400 mm

Maximum travel Y-axis 300 mm

Maximum travel Z1-axis 475 mm

Maximum travel Z2-axis 475 mm

Pgodpoht Hg Djfx Afheg

Relative positions B-axis 0,0001 – 360°

Relative Position C1/C2-axis 0,0001 – 360°

WORKPIECE

Maximum cubic dimensions 80x80x80 mm

Maximum weight 5 kg

TURRET

Number of stations 24

Number of controlled stations 18

Number of steady stations 6

Maximum tool attachment (round) Ø 20 mm

Maximum tool attachment (square) 16x16 mm (20x20)

Maximum trajectory of turret above tool’s point 500 mm

Rotation speed of live tools 1-9000 min-1

SPINDLE

Maximum rotation speed 6000 min-1

Maximum bars diameter Ø 42 mm

Maximum forced chuck clamping 140 mm

BARS MACHINING

Maximum bar length for bar’s feed 1000 mm

Maximum piece size for the bar taker Ø42 x Long.100 mm

Maximum diameter of taker’s collets 42 mm

Pulling and pressure force of clamping cylinder 20000N

FEEDS

X-axis advance force abt.895 daN

Y-axis advance force abt.895 daN

Z1-axis advance force abt.895 daN

Z2-axis advance force abt.895 daN

Fast moves axes X/Y/Z 20 m/min

Motor’s torque of tool control 2,4 Nm

Spindle S1 / Spindle S2 70Nm

COOLING (values only as indication)

Capacity of pump submerged inside chips conveyor 10 l/min for abt. 4,5 bar

80 l/min 3,2 bar

150 l/min 0,7 bar

Capacity of overpressure pump inside conveyor 10 l/min 13,2 bar

50 l/min 9 bar

90 l/min 1 bar

Lubricating coolant volume inside conveyor abt.134 L.

Coolant volume inside cooling aggregate 45 L.

NUMERIC CONTROL Siemens 840D

MACHINING PRECISION

Resolution axes X/Y/Z 0,1 µm

Resolution axe B 0,0001°

Resolution axe C 0,0001°

Positioning precision 5 µm

Repeatability 0,6 µm

Maximum error on workpiece’s concentricity 0,5 µm

ELECTRIC

Spindle 1 / Spindle 2 (at 100%) 11 kW

Spindle 1 / Spindle 2 (at 40 %) 15 kW

Advance motors axes X/Y/Z1/Z2 1,3 kW

Axis B 1,3 kW

Tool control 2,3 kW

Hydraulic pump 7,5 kW

Hydraulic back movement 0,75 kW

Cooling aggregate fan 1 / 2 0,18 kW

Circulation pump of cooling aggregate 1,1 kW

Compressor of cooling aggregate 2,2 kW

Chips ejector 0,25 kW

Emulsion pump 1 1,1 kW

Emulsion pump 2 2,2 kW

Operation tension 400 V

Network frequency 50Hz (60option)

Control tension 24V DC

Absorbed power 35 kW

Nominal current 63A

Connecting réseau TM / TT / IT

PNEUMATIC

Maximum operation pressure 10 bar

Normal operation pressure 6 bar

Minimal operation pressure 5 bar

Air output env. 150 L/min

Valves tension 24V DC

Oil-mist lubrication tank capacity 12 L

Quality level 2 selon Pneurop6611

NOISE LEVEL

Normal use 78—80 dB

errors and omissions excepted-data given without obligation

Inventory no.2321018, machine equipped with :

Chip conveyor

Preparation for bar feeder

Tool holders :

6 fixed drills ER32

8 turning tool holders

5 live tool holders ER32

4 live tool holders ER25

6 live tool holders ER20

Listing

Siedlce

Siedlce

1,720 km

Self-centring 3-jaw chuck

CORMAKUchwyt samocentrujący do rur WP200

Call

Condition: new, Year of construction: 2026, The WP200 self-centring 3-jaw chuck is a professional accessory designed for use with welding positioners and welding rotators such as models PS310 and PS320. Its precise clamping mechanism allows quick, stable, and concentric fastening of pipes and cylindrical or hexagonal parts, significantly improving the efficiency and safety of circumferential welding.

Main advantages of the WP200 chuck

Self-centring 3-jaw mechanism – ensures even and stable clamping of workpieces regardless of their shape.

Versatility – compatible with most welding rotators and welding positioners, including CORMAK PS310 and PS320.

Psdoycqnvspfx Afhogg

Clamping precision – perfect alignment of workpieces translates into better weld quality and smooth rotation.

Durable construction – robust body made from high-strength materials resistant to heavy mechanical and thermal loads.

Compact size and easy installation – low weight and precisely positioned mounting holes ensure quick integration with welding equipment.

Design and technology

The WP200 chuck features three high-quality jaws designed to automatically centre the workpiece on the rotational axis. Its outer diameter of 200 mm and inner diameter of 80 mm allow clamping of workpieces up to 170 mm in diameter. The body is made of high-grade steel, providing excellent resistance to deformation during long-term use.

Precision and efficiency

The WP200 self-centring 3-jaw mechanism significantly reduces setup time for welding operations. The elimination of backlash and positioning errors directly improves the quality of circumferential welds. Stable clamping of workpieces also enhances operator safety during welding.

Applications

The WP200 chuck is designed for use with welding rotators, welding positioners, and welding manipulators in operations involving pipes, flanges, rings, and cylindrical components. It is ideal for welding workshops, manufacturing plants, and the steel construction industry.

Technical parameters

Max pipe diameter: 170 mm

Outer diameter: 200 mm

Inner diameter: 80 mm

Mounting hole spacing: 85 mm

Mounting hole diameter: 9 mm

For welding positioner: PS310, PS320

Weight: 10 kg

Trust Seal

Dealers certified through Machineseeker

Listing

Sittard

Sittard

789 km

Telehandler

MagniHTH 25.11 | 2013

Call

Condition: good (used), functionality: fully functional, power: 175 kW (237.93 HP), gearing type: hydrostat, fuel type: diesel, fuel tank capacity: 200 l, color: blue, overall weight: 29,700 kg, empty load weight: 29,700 kg, maximum load weight: 25,000 kg, lifting power: 25,000 kg/m, lifting height: 10,500 mm, tire size: 18.00 R25, tire condition: 85 %, axle configuration: 4x4, number of seats: 1, emission class: euro3, mast type: telescopic, Year of construction: 2013, operating hours: 700 h, Equipment: CE marking, air conditioning, all wheel drive, === KEY SPECIFICATIONS ===

Year: 2013

Operating hours: 700

Max lifting capacity: 25,000 kg

Max lifting height: 10.50 m

Max outreach: 5.80 m

Drive: Diesel

Transmission: Hydrostatic, 2-speed forward/reverse

Drive type: 4x4

Steering modes: Frontal / Concentric / Crab

Stabilisers: No

Cab: Closed cab with A/C and heating

Heated cab: Yes

Fork length: 2,400 mm (pallet forks included)

Tyres: 18.00 R25 – Off-road

Engine manufacturer: Volvo / Deutz

Emission class: Stage IIIA

Weight: 29,700 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from trusted sources with verifiable history

CE-certified and complete documentation included

Hydrostatic transmission with 2 forward/reverse speeds

Three steering modes for maximum manoeuvrability (Frontal, Concentric, Crab)

Ideal for mining, quarrying, and industrial logistics

Available immediately from stock in Sittard

Pgedpoxct N Iefx Afhog

=== CONDITION ===

Very good condition — fully inspected, serviced, and ready for operation.

=== LOCATION & DELIVERY ===

Located in Sittard, the Netherlands

Worldwide delivery available

Price: €235,000 (EXW / excluding VAT)

The Magni HTH 25.11 is a robust heavy-duty telehandler designed for the most demanding lifting operations.

With a 25-ton capacity and 10.5 m lift height, it’s ideal for industrial, mining, and logistics sectors.

Equipped with a 175 kW diesel engine, hydrostatic transmission, and electro-proportional joystick.

Fully CE-certified and ready for immediate use.

=== DELIVERY ===

Crane loading available upon request.

Flexible worldwide shipping handled by Collé Rental & Sales logistics team.

Listing

Sittard

Sittard

789 km

Telehandler

MagniHTH 16.10 | 2023

Call

Condition: new, functionality: fully functional, power: 160 kW (217.54 HP), gearing type: hydrostat, fuel type: diesel, fuel consumption per hour: 14 l/h, fuel tank capacity: 200 l, color: red, overall weight: 20,500 kg, empty load weight: 20,500 kg, operation weight: 20,500 kg, maximum load weight: 16,000 kg, lifting power: 16,000 kg/m, lifting height: 9,700 mm, tire size: 16.00-R25, tire condition: 100 %, drive condition: 100 %, axle configuration: 4x4, number of seats: 1, emission class: euro5, mast type: telescopic, Year of construction: 2023, operating hours: 1 h, Equipment: CE marking, air conditioning, all wheel drive, cabin, === KEY SPECIFICATIONS ===

Year: 2023

Operating hours: 0 (new)

Max lifting capacity: 16,000 kg

Max lifting height: 9.70 m

Max outreach: 5.00 m

Drive type: Diesel

Transmission: Automatic (hydrostatic, 2-speed forward/reverse)

Drive: 4WD

Stabilisers: No

Cab type: Enclosed cabin with air conditioning and heating

Heated cabin: Yes

Fork length: 2,400 mm (standard)

Tyres: Rough terrain (16.00 R25)

Engine manufacturer: Volvo TAD582 VE – 160 kW / 218 hp

Emission class: Stage V / Tier IV Final

Weight: 20,500 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from reliable sources with verifiable history

CE certified and supplied with full documentation

Heavy-duty telehandler with 16-ton lifting capacity

Psdpfx Ajxdar Sofhsgg

Equipped with Volvo Stage V engine and hydrostatic transmission

Comfortable FOPS/ROPS cabin with air conditioning and joystick control

Three steering modes: front, concentric, and crab steering

Available directly from stock in Sittard

=== CONDITION ===

Brand-new machine – fully inspected, tested, and ready for work.

Inspection available on request.

=== LOCATION & DELIVERY ===

Located in Sittard, the Netherlands. Worldwide delivery available.

Price on request (EXW / excluding VAT).

The Magni HTH 16.10 is a powerful heavy-duty telehandler designed for demanding industrial and construction applications.

With a lifting capacity of 16 tonnes, a robust Volvo Stage V engine, and hydrostatic drive, this machine delivers outstanding performance, precision, and safety.

Thanks to its 4-wheel drive and three steering modes, it remains stable and highly manoeuvrable on any terrain.

=== DELIVERY ===

Crane loading available on request for smooth dispatch.

Flexible delivery options tailored to your destination and logistics preferences.

All transport handled professionally by the Collé Rental & Sales logistics team.

Listing

Sittard

Sittard

789 km

Telehandler

MagniRTH 5.18 | 2024

Call

Condition: new, functionality: fully functional, power: 55 kW (74.78 HP), gearing type: hydrostat, fuel type: diesel, fuel tank capacity: 175 l, color: red, overall weight: 14,400 kg, empty load weight: 14,400 kg, lifting power: 4,999 kg/m, lifting height: 17,400 mm, tire size: 445/65 R19.5, tire condition: 100 %, axle configuration: 4x4, emission class: euro5, mast type: telescopic, Year of construction: 2024, operating hours: 1 h, Equipment: air conditioning, all wheel drive, pallet forks, parking heater, === KEY SPECIFICATIONS ===

Year of manufacture: 2024

Operating hours: 1

Maximum lifting capacity: 4,999 kg

Maximum lifting height: 17.40 m

Maximum outreach: 14.50 m

Drive: Diesel

Transmission: Automatic (hydrostatic)

Four-wheel drive: Yes

Stabilisers: Yes (pivoting type)

Cab: Enclosed cab with air conditioning

Heated cab: Yes

Fork length: 1,200 mm (pallet forks)

Tyres: Rough terrain (445/65 R19.5)

Engine manufacturer: Deutz – 55.4 kW (75.3 hp)

Emission class: Stage V

Weight: 14,400 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from reliable sources with verifiable history

CE certified and supplied with full documentation

Compact rotating telehandler with 360° continuous rotation

Equipped with Deutz Stage V engine and hydrostatic transmission

Podpfx Asxdatisfhogg

Comfortable cab with air conditioning and heating

Three steering modes: 4x4, concentric, and crab steering

Includes pallet forks, pivoting stabilisers and high-performance hydraulic system

Immediately available from stock

=== CONDITION ===

Excellent working condition – fully inspected, maintained and tested by certified technicians.

Inspection available upon request.

=== LOCATION & DELIVERY ===

Located in Sittard, the Netherlands.

Worldwide delivery possible.

Price on request (EXW / excluding VAT).

The Magni RTH 5.17 is a compact and versatile rotating telehandler designed for precision handling and maximum efficiency.

With 360° continuous rotation and a lifting capacity of 5 tonnes, this model is ideal for construction, industrial and installation work.

Equipped with a Deutz Stage V engine, hydrostatic drive and pivoting stabilisers, it offers excellent stability and control on all terrains.

=== DELIVERY ===

Crane loading available on request for smooth and safe transport.

Flexible shipping options adapted to your destination and logistics needs.

All transports are professionally managed by the logistics team

Listing

Sittard

Sittard

789 km

Telehandler

MagniHTH 24.11 | 2023

Call

Condition: new, functionality: fully functional, power: 175 kW (237.93 HP), gearing type: hydrostat, color: red, overall weight: 29,700 kg, lifting power: 24,000 kg/m, lifting height: 10,500 mm, tire size: 18.00 R25, tire condition: 100 %, axle configuration: 4x4, Year of construction: 2023, operating hours: 1 h, Equipment: air conditioning, all wheel drive, cabin, T=== KEY SPECIFICATIONS ===

Year of manufacture: 2023

Operating hours: 0 (new)

Maximum lifting capacity: 24,000 kg

Maximum lifting height: 10.50 m

Maximum outreach: 5.70 m

Drive: Diesel

Transmission: Automatic (hydrostatic, 2-speed forward/reverse)

Four-wheel drive: Yes

Stabilisers: No

Cab: Enclosed cab with air conditioning and heating

Heated cab: Yes

Fork length: 2,400 mm (standard)

Tyres: Rough terrain (18.00 R25)

Engine manufacturer: Volvo TAD583VE – 175 kW (238 hp)

Pgedsxdatcopfx Afhjg

Emission class: Stage V

Weight: 29,700 kg

CE certification: Yes

=== HIGHLIGHTS ===

Carefully selected from reliable sources with verifiable history

CE certified and supplied with complete documentation

Heavy-duty telehandler with 24-ton lifting capacity

Equipped with Volvo Stage V engine and hydrostatic transmission

Comfortable FOPS/ROPS cab with air conditioning and overpressure system

Three steering modes: front, concentric, and crab steering

Sideshift, fork positioner, and high-quality hydraulic components

Immediately available from stock

=== CONDITION ===

New machine – fully inspected, tested, and ready for operation.

Inspection available upon request.

=== LOCATION & DELIVERY ===

Located in Sittard, the Netherlands.

Worldwide delivery possible.

Price on request (EXW / excluding VAT).

The Magni HTH 24.11 is a heavy-duty telehandler designed for safe and efficient handling of large and heavy loads.

With a lifting capacity of 24 tons, Volvo engine, and advanced hydraulic system, this machine is ideal for industrial, mining, and heavy construction applications.

Thanks to four-wheel drive, three steering modes, and high ground clearance, it remains stable and manoeuvrable on all terrains.

=== DELIVERY ===

Crane loading available on request for smooth transport handling.

Flexible shipping options tailored to your destination and logistics preferences.

All transport is professionally managed by the logistics team

We make it easier for you to find: "concentricity"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Concentricity (266)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month