Used Mash for sale (117)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Peskojai

Peskojai

1,539 km

Belt Press for Juice

ProFruit MachineryPOWERPRESS 300

Call

Year of construction: 2026, condition: new, functionality: fully functional, Belt press POWERPRESS 300 is designed for pressing fruit, berry and vegetable mash. Fruit mash is supplied on the belt which presses it against shafts.

The obtained juice flows into a small collection tank under the press with filtration sieve on top. Then the external pump or juice collection tank with pump transfers the juice from the press to a desired storage tank or straight to ROCKET pasteurizer for further processing. The pressing process is continuous.

Capacity: 300 kg/h

The most cost-efficient belt press in the market!

The most evolutionary feature of our Belt press POWERPRESS 300 is one huge pressing shaft, which lets the machine to maintain the longer pressing time (belt length is 4900 mm) and huge shaft dimensions squeezes the juice efficiently by saving the costs and space.

The juice yield of apples using our belt press is ~65-75 %. The yield highly depends on freshness and variety of fruits.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 300 filtrates the juice even during the pressing stage providing cleaner and purer product.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves service costs.

Adjustable fruit inlet lever lets fruit mash supply onto the shaft easily.

Crushed fruit mash can be supplied from MAXIMILL or straight from a bucket or basket.

Hnedpfx Ajt Rft Ujadjh

After work, belt press should be manually washed with a water stream. A full washing process takes around 15 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

The machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

1,539 km

Belt press

ProFruit MachineryPOWERPRESS 3000

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 3000 kg/h.

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

-The juice yield of apples using our belt press 3000 is ~75 %.

-There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Hnedpoq Nl Aqefx Aadoh

-The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

-The belt press 3000 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

-Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

-After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

-Belt tension is adjustable.

-Machine is made entirely of stainless steel and has adjustable feet for more convenient use.

-Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Peskojai

Peskojai

1,539 km

The Mobile Juice Production Line

ProFruit MachineryMobile Line

Call

Condition: new, Year of construction: 2026, The Mobile Fruit Processing Line is designed to conveniently accommodate all the machines necessary for juice production and a smooth work process. It contains:

-Fruit and vegetable washer elevator mill MAXIMILL 3000

-Belt press POWERPRESS 1500

-Transporter for leftover mash

-Stainless steel tanks

-Diesel pasteurizer

-Semi-automatic Bag in Box filler

-Juice filters

-Sink with a stainless steel table

Capacity: 1500 kg/h.

Other available capacities: 400 kg/h, 800 kg/h, 1200 kg/h.

Hnodpfeq Nl Afjx Aadjh

Features:

-The mobile juice line conveniently contains all the machines required for fruit processing & juice production.

-Requires only 1 person to operate the whole line.

-Mobility is the biggest advantage which eliminates costs for premises and provides the ability to change location.

-The juice yield from apples is ~75 % .

-All machines are interconnected and controlled automatically.

-The mobile juice production unit includes a Bag in Box filler which fills the juice into both Bag in Box and Stand up Pouch packages.

-The mobile juice line can be customized on client’s request.

-The line is easy to operate and maintain.

-The mobile fruit processing line is installed in a specially made trailer which can be easily opened for work and shut when needed.

-The biggest advantage of our Mobile Fruit Processing Line is the ability to produce juice anywhere you like. This way the client avoids additional expenses for premises and gets the ability to change work location.

Mobility is the key aspect here which provides the client with more possibilities, such as developing a juice pressing service business at various apple farms or different towns.

Listing

Great Britain

Great Britain

0 km

Brewery tanks

Moeschle

Call

Condition: not inspected (used), Brewery tanks comprising:

Moeschle mash tun, 9,000 litre

Hnjdpfx Aaswifdtsdeh

Moeschle stainless steel copper kettle, 12,350 litre

Moeschle cold liquor tank, 18,000 litre

2 - Moeschle square fermentation vessels, each 11,700 litre

STB Engineering fermentation vessel, 11,800 litre, 2400mm square

Eastfield Process stainless steel tank, advised circa 5,000 litre

4 - Moeschle racking / conditioning vessels, 8,850 litre / 8,950 litre

Listing

Gargždai

Gargždai

1,555 km

Screw conveyor

ProFruit MachineryScrew conveyor

Call

Year of construction: 2026, condition: new, The leftover fruit, berry or vegetable mash enters the loading hopper of the screw conveyor. The screw inside the machine is continuously turning and this way transports the mash from the loading hopper to the exit outlet at the top of the machine. The mash exits the machine.

Screw conveyor is made of stainless steel.

Machine has a closed tunnel.

Hnedpfx Aajizbffjdsh

Conveniently transports leftover pressed mash from press.

Discover more used machines

Listing

Gargždai

Gargždai

1,555 km

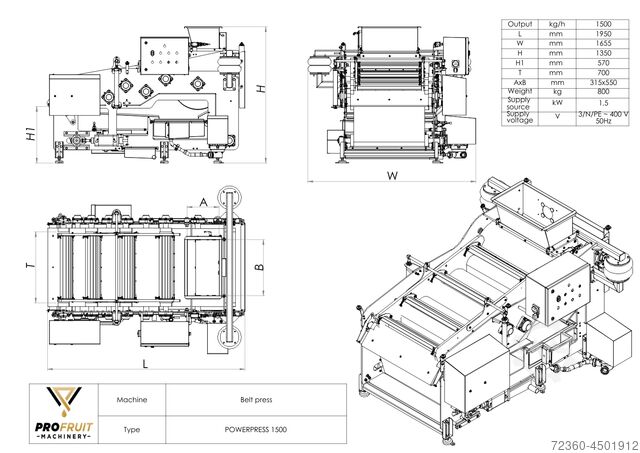

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1500

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1500 kg/h.

- The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

- The juice yield of apples using our belt press 1500 is ~75 %.

- There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

- The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

- The belt press 1500 includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

- Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

Hedpfx Ajflpp Eeadjnh

- After work, belt press should be manually washed with a water stream. - A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

- Belt tension is adjustable.

- Machine is made entirely of stainless steel and has adjustable feet.

- Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Listing

Gargždai

Gargždai

1,555 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 3000

Call

Year of construction: 2026, condition: new, The fruit washer elevator mill is made from stainless steel. Firstly, the operator of the machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 3000 kg/h.

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

- Machine has additional table in front of the basin for putting fruits or boxes on it.

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

- Belt conveyor has a water drainage and speed regulation system.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

Hnsdpfx Aaoflpmksdoh

- The mill does not damage the fruit seed.

- Powerful 4 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

- Machine is entirely made of stainless steel and easy to clean after using.

Listing

Gargždai

Gargždai

1,555 km

Fruit Washer Elevator Mill

ProFruit MachineryMAXIMILL 1000

Call

Year of construction: 2026, condition: new, The fruit washer mill is made from stainless steel. Firstly, the operator of machine pours fruits and vegetables into the washing tub with clean water. Conveyor lifts the products up to the mill. During the lifting process, water nozzles spray the fruits and vegetables with clean water. The mill crushes the products after they reach the top of the conveyor. Finally, the fruit and vegetable mash comes out of mill.

Capacity – 1000 kg/h.

- The crushing head of the machine is round, so all the crushed mash goes directly out for further processing. This feature significantly helps when washing the head as there are no corners.

- Our round shape technology is superior to other producers’, because a lot of fruit mash gets stuck in the corners of square-shaped heads for hours and can cause juice fermentation!

- Machine has additional table in front of the basin for putting fruits or boxes on it. It facilitates the process of pouring the products into the basin.

- V form washing basin helps fruits and vegetables move directly to the conveyor, therefore less fruit stay in the basin.

Integrated water-spraying system provides additional washing when lifting the fruits up the conveyor.

Hodpeflpfbsfx Aadsnh

- Belt conveyor has a water drainage and speed regulation system.

- The speed of the belt conveyor is adjustable in the control panel.

- Optional replaceable cutting graters/sieves are available for different fruits and berries.

- The mill does not damage the fruit seed.

- Machine is easy to clean after using.

- Powerful 2.2 kW crushing engine can crush various fruits, berries and vegetables – from soft raspberries to hard apples, beets, etc.

- Machine is entirely made of stainless steel.

Listing

Gargždai

Gargždai

1,555 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 1200

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous.

Capacity: 1200 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our machine is ~75 %.

There is a filtration sieve integrated into the juice collection tank. It filtrates the juice providing clearer and purer product.

Machine works automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

Hsdpfoflpplex Aadenh

Pneumatic lifting of the security cover of the press ensures easier access when cleaning.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

The washing is simple, and all machinery parts are easily removable.

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 400, POWERPRESS 800, POWERPRESS 1500.

Listing

Gargždai

Gargždai

1,555 km

Belt Press for Juice Production

ProFruit MachineryPOWERPRESS 400

Call

Year of construction: 2026, condition: new, The obtained juice flows into integrated collection tank under the press. Then the pump transfers the juice from the press to a desired tank for further processing. The pressing process is continuous

Capacity: 400 kg/h

The most evolutionary feature of our Belt press POWERPRESS line is that belt presses come with integrated pump and juice collection tank. This means you save money and do not need additional juice collection tank and pump which otherwise would use much space and cause additional costs.

The juice yield of apples using our belt press is ~75 %.

There is a filtration sieve integrated into the juice collection tank. Because of that the belt press 400 filtrates the juice even during the pressing stage providing cleaner and more pure product.

The belt presses work automatically: when the mash inlet tank is full, all other machines, which come before belt press, turn off automatically. When the juice tank is full, the pump automatically pumps the juice into the tanks.

The belt press includes a high-pressure washer, which continuously washes the belt of the machine. Our belt washing system is simple, does not contain any engines or reducers, so it prolongs the use time and saves the service costs.

After work, belt press should be manually washed with a water stream. A full washing process takes around 15-20 minutes. Washing is simple and all the parts of the belt press are easily removable without any tools.

Belt tension is adjustable.

Machine is made entirely of stainless steel and has adjustable feet.

Easy to clean with no closed or inaccessible spaces, all parts are easy to assemble.

Hnodpjflpnyefx Aadsh

Interested in belt press only with different efficiency? Check out our other belt presses: POWERPRESS 800, POWERPRESS 1200, POWERPRESS 1500.

Listing

Forst

Forst

1,069 km

15 m³ stainless steel agitator tank

Call

Condition: good (used), Agitator bowl made of stainless steel (V2A), horizontal

Technical data / dimensions

Available quantity: 2

Volume: approx. 15,000 liters

Tank type: Agitator tank

Condition: used

Suitable for food: yes

Design: horizontal above ground

Internal diameter: approx. 2,000 mm

Cylindrical length: approx. 4,500 mm

Total length: approx. 5,300 mm

Specific weight of the medium: 1.05 to/m³

Operating pressure: unpressurized

Wall thickness of bottom: approx. 2.3 mm

Wall thickness shell / cylinder: approx. 2 mm

Hodoty Np Hopfx Aadenh

Remarks: Mash tun

Material / composition

Material inner jacket: V2A (1.4301)

Feet material: V2A (1.4301)

External surface: Front base

Features

Base shape: Profile feet

Number: 6

Fastening: fixed

Base type: dished base

Front shelf:

1 x oval manhole (approx. 430 x 330 mm)

1 x residual drain DN 80

1 x bearing for agitator shaft

Jacket:

1 x manhole with hinged cover and DN 50 vent nozzle

Rear base:

1 x agitator motor

Notes: An optional catwalk is available for the two containers

available for the two containers, with which the two containers can be walked on

(surcharge: 450 €).

Agitator

Agitator available

Type of agitator: Beam agitator

Classification: Slow speed

Quantity: 1

Installation: lateral

Speed: 1,450 rpm

Agitator power: 4.8 kW

Bottom bearing for agitator shaft available

Manufacturer: Leroy Somer

Notes: Agitator shaft passes horizontally through the center of the tank

Listing

Estavayer

Estavayer

1,189 km

Red wine fermenter Tanks unit

DEFRANCESCHI100 000 Liter

Call

Condition: good (used), Consisting of :

- 3 tanks of 18000 litres

- 3 tanks of 15300 litres

- With walkways

- Material: AISI 316

- Square discharge door (bottom)

- Motorised mash discharge

- Round manhole DN 400 (cylindrical part)

- Total emptying: ball valve Ø 40 Friedrich no 2

- Partial drain: ball valve Ø 40 Friedrich no 2

- Taster

- Recirculation with ball valve Ø 40 Friedrich no 2

- Dome Ø 400 mm, eccentric

- Central dome DN 400, with a cylinder-grid fixed inside

(to keep the mash cake wet)

Dimensions :

Hnodpfxjib H Dds Aadeh

- 3 tanks 18000 litres: Ø 2000 mm, height 5600 mm

- 3 tanks 15300 litres: Ø 2000 mm, height 4800 mm

- Ground clearance: approx. 550 mm

Listing

Stuttgart

Stuttgart

1,127 km

Brew house, fermentation cellar, storage cellar

20hl Brauerei komplett2019

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2019, Complete brewery with a brew length of 20 hl – 25 hl and an annual capacity between 2,000 hl and 3,000 hl. The manufacturer is BREW TEK TM from Hong Kong. The system was installed in 2019 and approximately 200 brews have been produced on it. The plant is currently in operation and functioning flawlessly. Dimensions can be found in the images.

Brew House

• 3-vessel brewhouse 20 hl – mash tun, lauter tun, and wort kettle

• 2 hot water tanks, each 20 hl

• Plate heat exchanger with dual-stage operation

• HopRocket for external hopping or fruit infusion

Fermentation and Storage Technology – All tanks with jacket cooling

• 2 fermentation vessels 25 hl – open fermentation with removable spray heads

• 10 storage tanks – cylindrical-conical, 22.5 hl, 3.0 bar pressure – with spray heads

Hnodpfx Aew Rph Rjadjh

• 2 pressure tanks 22 hl, 2.0 bar pressure – with spray heads

• Cooling unit – glycol system with 10 hl tank and pump – digital control

• CIP system with pump

• Grist mill 500 kg/h – mill, malt hopper, floor scale

• Steam generator by Loos – with softened water tank, heated by LPG – can also be operated with fuel oil

• Water softening system

Listing

Dublin

Dublin

291 km

35hl brewery

PSSvarious

Call

Condition: not inspected (used), Year of construction: 2018, functionality: unexamined, PSS 35hl brewery for sale including:

* Grain storage, milling and handling

* 35hl brewhouse comprising mash tun, lauter tun, wort kettle, whirlpool, HLT, CLT

* 18 - PSS FT-140HL fermentation vessels

* Yeast tanks

* 3-tank CIP plant

* Centec Degas 5hl/hr de-aeration system

Hnedpov Av Anefx Aadoh

* Romfil XFA8-B filtration unit

* Centec FlashPasto 25hl/hr flash pasteuriser

* 2 - 140hl bright beer tanks

* Services including Certuss TC1500 steam generator, RO plant, glycol system, compressed air plant

Equipment manufactured 2018, installation incomplete

Listing

Karczmiska Pierwsze

Karczmiska Pierwsze

1,742 km

FLOTTWEG fruit processing line, press

Call

Condition: excellent (used), Offer: Juice extraction line:

- Flottweg B-FRU-1500 LR press, year 2004

- mill/pulper

- apple washing tank

- mash pump

- box pallet tipper

Hodpfsyc D N Tex Aadsnh

- inclined conveyor to the mill

- pomace conveyor

- juice cooler

- Flottweg control cabinet

- juice tank

- juice tray

- juice pump (x2)

- slot filter for belt washing water

- water pump

- vibrating filter

- pulp pump

- citric acid tank

- secondary water tank

- water tank (x2)

- pump and valve station

- process cabinet

All machines and equipment are made of acid-resistant stainless steel.

The price is for the complete set of machines.

Listing

Wallern an der Trattnach

Wallern an der Trattnach

1,430 km

Puree compact line

KreuzmayrKPK 1000

Call

Year of construction: 2022, condition: new, Kreuzmayr puree compact system for pitting and straining various fruits.

2 pcs. destoning-passing machines mounted on the frame

Mash tube heater and pasteurizer for 1000 kg/h output

Hnedpfohx Ebysx Aadoh

Oil or gas burners can be added to the boiler as required

Listing

Wallern an der Trattnach

Wallern an der Trattnach

1,430 km

Brewing plant

TMCI PadovanCompact-Bräu 5 HL

Call

Year of construction: 2016, operating hours: 50 h, condition: like new (used), functionality: fully functional, Impiantinox Easybräu SCB 500 brewing system

consisting of mash/boiling kettle, lauter tun, hot water tank

Agitator in the mash tun

Chopper in the lauter tun

Electrically or steam heated

Electrical connection 40 kW

Steam condenser in the boiling kettle

Brewing volume from 3.5- 7 HL

Hodpfxsq H Azzj Aadsnh

Complete internal piping with pumps, electric heating Heat exchanger for wort cooling

Wort aerator

Listing

Freising

Freising

1,296 km

Pub brewery plant

Johann Albrecht (JBT)

Call

Condition: used, Complete brewery system, consisting of: - Grist mill (ROBIX) with plate weigher - 2-device brewhouse with a wort capacity of 10 hl. One vessel as mash/wort kettle with bottom heating and internal boiler. One vessel as lauter tun/whirlpool. Made by Joh. Albrecht Brautechnik. - Plate heat exchanger (SONDEX) as wort cooler - Wort aeration (Donaldson) with sterile filter - 17.75 hl hot water tank, steam-heated, with pump. Made by Joh. Albrecht Brautechnik. - 5 cylindroconical storage tanks, each with a volume of 27 hl. Made by Joh. Albrecht Brautechnik. - Various beer hoses - Diaphragm pumps (FLOJET) as booster pumps, driven by compressed air - Beer pump (SAWA) for conveying 5 m³/h - Cleaning lance for dispensing tanks - CO2 warning device (Beviclean) - Further accessories with pressure reducers, tap heads etc. - Electric steam generator (VEIT) with an output of 60 kW - Compressed air system (KAESER), air compressor with refrigeration dryer - Water treatment (PENTAIR) - Refrigeration system with compressor, buffer tank, equalising tank, refrigerant pump - Pipework

Additional title: 10 hl brewhouse with storage tanks and supply technology, largely built in 2019

Hnsdpfx Aasxwyzaodjh

Cast wort capacity: 1000 l

Material: Brewhouse from stainless steel

Features: Mash/wort kettle, lauter tun, whirlpool, wort cooling, wort aeration, hot water tank, 5 x cylindroconical storage tank, booster pump, beer pump, CO2 warning device; cleaning lance, pressure reducer, tap heads, hoses, refrigeration system, compressed air system, electric steam generator, water treatment, pipework

Listing

Rīga

Rīga

1,704 km

Milk & dairy production

Alistar EuropeS40 500kg/h cheese 2.2kW

Call

Condition: new, Year of construction: 2026, functionality: fully functional, High performance soft and hard cheese grater. The 2.2kW motor will easily grate any cheese. By changing blades you can get vegetable slicer with the same machine.

General Features:

• Productivity 500-1000 kg/h;

• High quality, long lasting stainless steel cutting knives (up to 100 tons between sharpening);

• Disc diameter of 40 cm, grants, that you can put whole or cut in half small cabbage heads;

• The universal cutting machine, very good for slicing, grating, mashing, julienne stick cutting;

• Compact size can be equipped with wheels and easily transported;

• Easy to clean, can be washed with low-pressure water;

• All food contact elements made of stainless steel;

• Powder painted frame, three-layer lacquer in the standard version, or full stainless steel version(picture);

• Machine motors can be adjusted as required up to 2200 W.

• Electric connection 400/220/120 Volts, 50-60 Hz. For different connections, please, ask;

Hnjdpfx Aaedv Ec Ujdjh

Listing

Rīga

Rīga

1,704 km

Vegetable processor S40 500kg/h

Alistar EuropeS40

Call

Year of construction: 2026, condition: new, machine/vehicle number: Al160, Compact size, high productivity food processing machine:

Vegetable processor is a productive, compact-sized commercial cabbage shredding machine that is intended for cabbage shredding, slicing, grating, as well as beets, carrots grating, and julienne cutting. High productivity 500-1000 kg/h, high-quality materials as food-grade stainless steel AISI 304. Made for small and medium-sized producing companies.

General Features:

• Productivity 500-1000 kg/h;

• High quality, longlasting stainless steel cutting knives (up to 100 tons between sharpening);

• Disc diameter of 40 cm, grants, that you can put whole or cut in half small cabbage heads;

• The universal cutting machine, very good for slicing, grating, mashing, julienne stick cutting;

• Compact size can be equipped with wheels and easily transported;

• Easy to clean, can be washed with low-pressure water;

• All food contact elements made of stainless steel;

• Powder-painted frame, three-layer lacquer in the standard version, or full stainless steel version

Hnododwfdqjpfx Aadsh

• Machine motors can be adjusted as required up to 2200 W.

• Electric connection 400/220/120 Volts, 50-60 Hz. For different connections, please ask;

Listing

Rīga

Rīga

1,704 km

Vegetable/Cheese processor

Alistar EuropeS40 food processor

Call

Year of construction: 2026, condition: new, functionality: fully functional, machine/vehicle number: S40Basic, Compact size, high productivity vegetable processing machine:

The commercial vegetable processing machine, cabbage shredder S40 is a productive, compact size commercial food processing machine that is intended for cabbage shredding, slicing, High productivity 500-1000 kg/h, high-quality materials as food-grade stainless steel AISI 304. Made for small and middle-size producing companies.

General Features:

Productivity 500-1000 kg/h;

High quality, long-lasting stainless steel cutting knives (up to 100 tons

between sharpening);

Disc diameter of 40 cm, grants, that you can cut small cabbage heads that are sliced in half.

Hjdpfxsffwgvs Aadonh

Universal cutting machine, very good for slicing, grating, mashing,

julienne stick cutting; (additional attachments)

Compact size, can be equipped with wheels and easily transported;

Easy to clean, can be washed with low-pressure water;

All food contact elements made of stainless steel;

Powder painted frame, three-layer lacquer in the standard version, or full stainless steel version(additional option)

Machine motors 0.75kW in the standard version

Electric connection 400/220/120 Volts, 50-60 Hz. For different connections, please, ask

Trust Seal

Dealers certified through Machineseeker

Listing

Delmenhorst

Delmenhorst

829 km

Stainless steel bowl with anchor agitator

Call

Condition: new, total length: 9,900 mm, total width: 8,450 mm, total height: 1,580 mm, Brand new stainless steel agitator tank with anchor agitator

Application: Stirring mustard mash

Type: CILC200BRWAA4

Item number: 10760

Hnodpfx Asq Rc Egsadsh

Volume: 221L

Type: Upright design on reinforced feet with castors

Design: Single-walled

Material (wetted parts): 1.4404 stainless steel V4A

Surface: Satin finish outside, IIId inside

Internal weld seams: Pickled, passivated and brushed

Operating pressure: Atmospheric

Top shelf: Central crossbar with two hinged lid halves

Underbody: Conical base with DN32 DIN11851 pipe pulled forward

Tank dimensions:

Tank diameter: 650mm

Total height: 1580mm

Cylinder height: 650mm

Height of feet: 460mm

Equipment:

- Central crossbar with two hinged lid halves, sheet metal grids as protection against access, screwed, removable

- Latching function for hinged lid

-1 x outlet valve DN32 ball valve DIN11851, EPDM/PTFE seal

Agitator:

Anchor agitator

Make: Schwarzer Rührtechnik GmbH

Type: SRTGMK/0,37-21

Power: 0,37KW

Speed: 21UPM (infinitely variable)

Operating voltage: 1PH 230V

-Motor and gear unit in the latest aluminum technology, manufactured by Getriebebau NORD

Food-approved oil filling

-Massive agitator shaft attached to the agitator motor with sleeve coupling, removable

-Stirrer shaft balanced for concentricity in the speed range

-1 piece space-saving anchor agitator, welded design, weld seams ground

-Stainless steel flange with shaft seal, EPDM

Agitator control unit:

CEE plug switch on the container, on/off switch, emergency stop, phase inverter, zero-voltage release

Infinitely variable speed control

of the agitator motor by means of a compact frequency inverter mounted on the motor, manufactured by Getriebebau NORD.

Incl. potentiometer.

Pre-programmed for agitator operation.

Operating voltage 1PH 230V

Drive power is increased to 0.37KW by this position

Listing

Domaszek

Domaszek

1,924 km

MK 1000 STONER

Maurer GépMK 1000

Call

Year of construction: 2026, condition: new, The machine is suitable for stoning of stone fruit. The chopped fruit can be delivered to a container, a pasteurizer, a jam extractor, suitable for use with a screw pump or collector handle with manual force.

Specifications:

- Performance: 1-5000 kg/h

- Electric demands: 5,5 kW, 400 V, 16 A, monophase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 860x1820x1350 mm

- Weight: 190 kg

- IP65 certified electronics

- Tiltable work surface, adjustable height

Easy to clean, with massive food industrial conveyor belt, steplessly adjustable speed in both ways, with 2pcs rotating, 2pcs fix wheels.

It requires minimal maintenance.

Available options:

Ribbed texture belt: it helps to prevent the fruits rolling down in case of working on an angled surface.

With feed screw in the input hopper. With 2 pcs rotating, 2 pcs fix wheels, or 4 pcs vibration-free feet.

It requires minimal maintenance. Sieves can be changed easily and quickly.

One choosable diameter sieve is inclusive in the list price

Available options:

- Inverter: speed control for the rotor

Sieves:

- 0,8 mm diameter sieve: berries, pulps

- 1,5 mm diameter sieve: berries, pulps

- 3 mm diameter sieve: apple, pear mash

- 5 mm diameter sieve: cherry

- 8 mm diameter sieve: plum, apricots

- 10 mm diameter sieve: peach, mango

- Custom diameter sieve

Hsdpfx Aefd Iixoadenh

Listing

Domaszék

Domaszék

1,925 km

MK 500 STONER

Maurer GépMK 500

Call

Year of construction: 2026, condition: new, The machine is suitable for stoning of stone fruit. The chopped fruit can be delivered to a container, a pasteurizer, a jam extractor, suitable for use with a screw pump or collector handle with manual force.

- quick sieve change

- low upkeep

- perfect for mash seed removing

Specifications:

- Performance: 500-1000 kg/h

- Electric demand: 2,2 kW, 400 V, 6 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 650x1100x1140 mm

- Weight: 100 kg

- IP65 certified electronics

- Input height: 1050 mm

- Output height: 380 mm

- Food industrial rotor rubbers

- Adjustable distance between the sieve and rotors

- With feed screw in the input hopper. With 2pcs rotating, 2pcs fix wheels, or 4 pcs vibration-free feet.

It requires minimal maintenance. Sieves can be changed easily and quickly.

One choosable diameter sieve is inclusive in the list price

Available options:

- DN 65 connection for the outlet

- Inverter: speed control for the rotor

- Sieves:

Hodpfod Aqy Rsx Aadenh

- 0,8 mm diameter sieve: berries, pulps

- 1,5 mm diameter sieve: berries, pulps

- 3 mm diameter sieve: apple, pear mash

- 5 mm diameter sieve: cherry

- 8 mm diameter sieve: plum, apricots

- 10 mm diameter sieve: peach, mango

- Custom diameter sieve

Listing

Domaszék

Domaszék

1,925 km

TANK BLOCK

Maurer Gép3X200L

Call

Year of construction: 2026, condition: new, machine/vehicle number: 1234, Designed to accumulate mash before the packaging operation. The accumulation option allows the entire line to run continuously without stopping, independently of the packaging machine.

Hnodpfxeiu Hy To Aadeh

- Capacity: 600 L

- Material: Wnr. 1.4301, AISI 304 Stainless steel

- Weight: 60 kg

- With floating lid

- With level indicator

Dimensions:

D - diameter: 565 mm

H - total height: 1095 mm

h1 - tank height without legs: 845 mm

h2 - height of legs: 250 mm

We make it easier for you to find: "mash"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Mash (117)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you