Used Nitrogen for sale (344)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Bury St Edmunds

Bury St Edmunds

442 km

IQF freezer

PackoRotary drum IQF freezer ex cheese plant

Call

Condition: good (used), Similar in operation to Dohmeyer CryoRoll freezer. Packo developed these freezers to be used for high performance IQF freezing of small pieces of meat, seafood, cheese, pizza toppings, fruits and vegetables. The rotary drum is injected with CO2 down to -60 degrees C or nitrogen down to -110 degrees C.

This unit was used in a cheese manufacturing facility which has recently closed, they were running shredded and diced cheese through the machine. We have a large quantity of conveying and machinery available from this facility.

Rjdox Dcdkjpfx Abdep

Listing

Striegistal

Striegistal

1,208 km

Tempering furnace

AichelinKES-4

Call

Year of construction: 1973, condition: good (used), rust size: 700 x 650 x 1.100 mm

batch weight: 1.000 kg

Temperature: Max. 750 °C

connected load: 78 kW

Equipment: Incl. Control system (should be renewed) + Charging machine

Rjdeydld Ispfx Abdep

others: Furnace can be moved under nitrogen

Listing

Hauzenberg

Hauzenberg

1,386 km

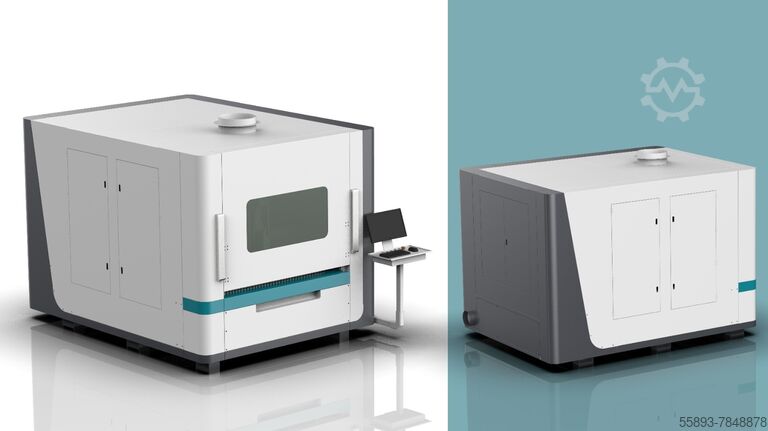

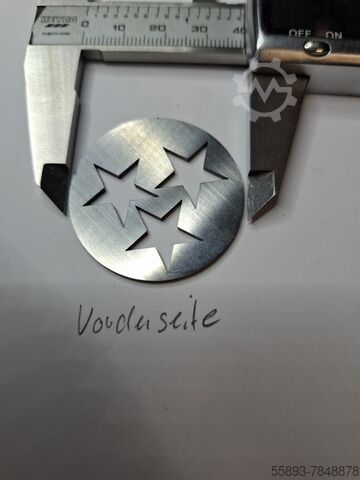

Laser cutting machine

LD-LaserLG-3015 20kW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, controller model: HypCut, laser type: fiber laser, laser source manufacturer: MaxPhotonic, laser power: 20,000 W, laser wavelength: 1,080 nm, sheet thickness (max.): 100 mm, sheet thickness steel (max.): 80 mm, sheet thickness stainless steel (max.): 100 mm, sheet thickness aluminum (max.): 60 mm, sheet thickness brass (max.): 20 mm, sheet thickness copper (max.): 12 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, input current: 110 A, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 20 bar, overall weight: 9,500 kg, warranty duration: 12 months, door opening width: 1,000 mm, door opening height: 2,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, nozzle changer, safety light barrier, New Laser Cutting Machine with 20 kW Fiber Laser

Our goal is to offer highly precise, long-term stable, and yet cost-effective laser machines. Our machines are ideal for workshops and repair businesses. The delivery includes a perfectly developed cutting parameter library as well as first-class service.

Please also check out our attractive leasing/leasing-purchase offers.

- Machine with automatic nozzle changer (optional)

and automatic nozzle centering (optional)

- Machine with automatic shuttle table

- Machine bed lined with graphite plates

- Machine measured and calibrated with Renishaw system (including measurement protocol)

- Space-saving design

- Extremely energy-efficient cutting system

- Requires only approx. 9.5 x 3.5 meters of installation space

- 20 kW MaxPhotonics laser source (G5 / German specification)

The following options are also available:

- Automatic nozzle changer (optional)

- Automatic nozzle centering (optional)

- Vision control (placement and nesting via camera system)

- Top quality – schedule a viewing today!

Rodpfsyhhnkox Abdsp

Cutting capacities:

- Steel sheet up to 80 mm

- Stainless steel sheet up to 100 mm

- Aluminum sheet up to 60 mm

- Travel: 1500 x 3000 mm

- Machine control in German language

- Safety light curtains for maximum operator protection

- Extensive collision protection measures for the cutting head

- Large laser safety windows on three sides for optimal monitoring of the cutting process

- Automatic, programmable 3-gas switching

(compressed air, nitrogen, oxygen)

- Comprehensive cutting parameter database

- Incl. nesting module

- Very user-friendly operation

- High-performance laser chiller

- Machine control in German

- Comprehensive service and warranty package

- High-performance laser chiller

- Optional filter extraction system

Sale exclusively to commercial customers.

Delivery / consultation / sales only within Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 8.5 m

Height: 2.3 m

Width: 3.5 m

Total weight: approx. 9500 kg

Need a different laser power, table shape, or table size?

No problem. I am happy to prepare a suitable offer.

E.g. 2 kW machine from €29,990 or

6 kW machine from €79,900

Not sure which laser power is right for your application? Just give us a call! Of course, I can perform cutting trials according to your requirements – many solutions are possible.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Berlin

Berlin

1,142 km

Resistance Annealing Machine

Tecno Induction

Call

Year of construction: 2016, condition: ready for operation (used), Suitable for stainless steel wire: 1.4301, 1.4310, 1.4401, wire diameter: 0.25-0.5mm with a strength up to 2400 N/mm², working speed: 75-80m/min, temperature range: 400-650°C, suitable for four wires at the same time with one temperature gauge (movable), shielding gas: forming gas grade 95/5 95%N2/5%H2, nitrogen gas, cooling: water-cooled tubes.

Rjdpfsn R Nhqjx Abdop

Listing

Great Britain

Great Britain

0 km

Full protected laser cutting machine

BodorP Series

Call

Condition: new, Year of construction: 2025, All-round sheet fiber laser metal cutting machine

Equipped with automatic functions of nozzle changing and one-click processing, P-Series is competent for all cutting demands.

Flake graphite in the cutting machine bed improves greatly the shock absorption and wear resistance, and residual stress almost disappears after age hardening, therefore, precision and lifetime of the equipment are improved, and costs saved.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Rodpohwaapsfx Abdep

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The fully closed-loop control adjusts according to feedback to ensure that the actual motion position is consistent with the theoretical input value.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Condition: New

Laser Type: Fiber Laser

Laser Power: 1500W - 30000W

Cutting Area: 3048*1524mm - 6100*2500mm

Cutting Speed: 0-169m/min

Positioning accuracy: ±0.03mm - ±0.05mm

Repositioning accuracy: ±0.02mm - ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Discover more used machines

Listing

Great Britain

Great Britain

0 km

Full protected laser cutting machine

BodorC Series

Call

Condition: new, Year of construction: 2025, Base sheet fiber laser metal cutting machine with full protection

Maximum cutting area reaches up to 12000mm*2500mm, suitable for a variety of cutting options.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The cutting process works even at the edge of thin sheets, and ensures no chatter marks.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Condition: New

Laser Type: Fiber Laser

Redpfehwaa Eex Abdsp

Laser Power: 1000W - 40000W

Cutting Area: 3048*1524mm - 12500*2600mm

Cutting Speed: 0-110m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Janville

Janville

878 km

Vacuum paddle dryer

ItalvacuumCosmodry System IHD 3200

Call

Condition: used, Year of construction: 2016, // Equipment dismantled and stored in our warehouse //

Manufacturer: Italvacuum

Model: Cosmodry System IHD 3200

Year: 2016

Type: horizontal vacuum paddle dryer

Application: drying wet powders

ATEX (Eex) unit: yes

Industries: Fine chemicals, pharmaceuticals (API), intermediates

A) Agitation: Concentric agitator with heated shaft, removable in several segments (double mechanical seal)

Transmission: (CEMP) - Power 30 kW + Gearbox + Chain

Agitation speed: 1.6 ÷ 8.1 rpm

Atex: explosion-proof ATEX II 2GD

Mounted with the dryer on a support structure (single SKID)

B) Drying chamber with discharge valve

Total volume : 3200 Liters

Useful volume : 30% - 80%

Internal pressure : -1 / 0,5 barg

Jacket pressure : 0 / 1,7 barg

Project temperature : -10 / +130°C

Maximum heating fluid temperature: +100°C

Best vacuum tightness: 4 mbar/h

EX-I absolute pressure transmitter

Rjdpfxjx R D Efj Abdop

PT100 Ex-i product temperature sensor

Nitrogen backwash system

Rotary chopper speed: 300 / 1200 rpm (not installed)

Material in contact with the product: AISI 316L - EN 1.4404

Vacuum seals: PTFE and FEP

Jacket material: AISI 304 - EN 1.4301

Heating fluid: Diathermic oil

Mirror-polished interior finish (Ra ≤ 0.4 µm)

Satin exterior finish (Ra ≤ 1.2 µm)

Inspection and Shut-off Valve DN.1650

Buffer Relief Valve DN 200/300

DN 250 Butterfly Loading Valve

Prepared for the installation of two choppers (lateral knives)

C) Process filter

D) Vacuum unit: SAURUS939 piston vacuum pump, model VVD

Pump support bench

ATEX: Ex-d-IIB-T4 – IP55

Power: 11 kW

Atmospheric pressure surface condenser, model VD200I

E) Vacuum condensing unit

- AISI 316L stainless steel with double cooling jacket in AISI 304 stainless steel.

Internal design pressure: -1 / 0.5 barg

Jacket design pressure: 0 / 3 barg

Design temperature: -10 / 40 °C

Maximum cooling liquid pressure: 2.5 bar

Exchange surface area: 8.5 m2

Condensate collection capacity: 900 litres

Level sensor

F) External safety filter

G) Temperature control system: Heating/Cooling

Steam liquid heater: Pressure 7 bar - Jacket temperature: 142°C - Surface area: 1.65 m2

Cooler, mounted on the heater: cold water or brine - Pipe jacket pressure: 12 barg - Jacket temperature: 142°C - Pipe temperature: -10°C /+ 99°C - Surface area: 3.42 m2

H) Command and Control System (Electrical Cabinet + HMI)

Complete technical file

Listing

Janville

Janville

878 km

Granulator / High shear mixer

Zanchetta (Romaco Group)Rotolab

Call

Condition: used, Year of construction: 1998, Manufacturer: Zanchetta (Romaco Group)

Model: Rotolab

Year : 1998

Type : High shear granulator mixer

Capacity : 2 Litres

Opening : lid

Rsdpjx R A Ifofx Abdjp

Double heating jacket

Crumbler = 1500 rpm

Variable mixing speed : 20 – 955 rpm

Heating integrated into the double jacket.

Max. Max. bowl temperature 85°C,

Heating jacket

Connection for vacuum and nitrogen (.),

Materials: Stainless steel

Operating pressure: 0.6 MPa

Becker vacuum pump: 1.25 KW

Listing

Janville

Janville

878 km

Cryogenic Cabinet Freezer

Packo Inox-

Call

Condition: used, Year of construction: 2011, Manufacturer : Packo Inov NV

Type: Cryofreezer / Batch freezer

Year of manufacture : 2011

Total volume : 950 L

Dimensions : 150 x 120 x 230 cm

Rodpfx Asx R A Apobdop

Supply voltage 3x400V + N – 50Hz

Minimum temperature set point: – 120°C

Weight : 600 Kg

Materials: 304 L stainless steel

Full technical file: available in digital version

Refrigerant : Liquid nitrogen

Previous use: 0.5 or 1L bottles containing Biological active ingredient.

0.5L bottle :

o Dimensions: 72 x 72 x 180 mm (WxDxH)

o Maximum capacity: 32 bottles

1.0L bottle :

o Dimensions: 90 x 90 x 220 mm (WxDxH)

o Maximum capacity: 32 bottles

Listing

Janville

Janville

878 km

Dryer

GlattTFO 100/150

Call

Condition: used, - Material: Stainless steel

- Pneumatic version / ADF - EX

Rodpfx Asx Rz Nbjbdjp

- 2 truncated 400L tanks on trolley (per dryer) model WSG120 / D.1200 / 900 X PF.500

- 1 tank turner common to both dryers

- Control cabinet

- Safety by 2 explosion membranes coupled to nitrogen gas cylinder

Listing

Germany

Germany

1,006 km

VOORTMAN V320

VOORTMANV320

Call

Condition: ready for operation (used), Year of construction: 2019, operating hours: 5,800 h, table load: 7,500 kg, This VOORTMAN V320 was manufactured in 2019. It features a Kjellberg Smart Focus 300 plasma source and a Donaldson DFPR06 extraction system. Capable of handling mild steel with a panel length range of 850 – 6,100 mm and thickness from 6 – 75 mm. It includes options for punch marking and countersinking, enhancing versatility. Consider the opportunity to buy this VOORTMAN V320 plasma cutting machine. Contact us for more information about this machine.

• Workpiece size

• Min./max. panel length: 850 – 6,100 mm

• Min./max. panel width: 200 – 2,050 mm

• Min./max. panel thickness: 6 – 75 mm

• Drilling unit: VD40

• Mounting: SK 40

• Axis speed: 0 – 2,500 rpm (continuously variable, servo motor)

• Drill diameter: 5 – 40 mm

• Threading: M6 – M30

• Countersinking: Yes

• Punch marking option: Yes

• Layout marking option (optional): Yes

• Automatic tool changer: 2 x VTC 5/40 (2 x 5 positions)

• Lubrication/cooling: Internal cooling, air/oil

• Hydraulic mounting: Yes

• Rated load: 30 kW

• Feeding and positioning: Synchronously driven servo motors, servo converter

Rsdpfx Abex D N Aajdop

• Cutting – Plasma (Smart Focus 300)

• Min./max. thickness: 3 – 80 mm

• Max. piercing capacity: 40 mm

• Virtually slag-free cutting: up to 35 mm

• Marking: Yes, with the same consumables

• Gases:

• Plasma gas for cutting mild steel: O2 (99.9% pure, clean, dry, oil-free)

• Shielding gas for mild steel: O2 / Air (99.9% pure, clean, dry, oil-free)

• Marking gas: Argon; for >200 A, nitrogen

• Automatic gas console: Yes

• Automatic height adjustment: Yes

• Ignition: Automatic

• Cutting speed (mild steel):

• 6 mm: approx. 3,700 mm/min @ 90 A

• 12 mm: approx. 3,600 mm/min @ 200 A

• 25 mm: approx. 1,600 mm/min @ 300 A

• 40 mm: approx. 720 mm/min @ 300 A

• 50 mm: approx. 400 mm/min @ 300 A

• 80 mm: approx. 100 mm/min @ 300 A

• Cutting – Oxy-fuel (oxygen cutting unit)

• Nozzle type: Nozzle-mix

• Automatic height adjustment: Yes

• Gas supply: Magnetic valve with non-return valve

• Fuel gas: Propane (optional: Acetylene)

• Cutting gas: O2

• Max. thickness: 75 mm

• General/installation

• Working direction: Left to right

• Working height: 760 mm (+/- 25 mm)

• Ambient temperature: -10°C to +35°C, max. 95% relative humidity

• Voltage regulator: Not included

• Current transformer: Not included

Additional equipment

• Kjellberg Smart Focus 300 plasma source (included)

• Donaldson DFPR06 extraction system (included; last filter change January 2025)

Auction

Auction ended

Baden-Württemberg

Baden-Württemberg

1,132 km

Laser cutting machine

TrumpfTruLaser 1030

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2012, operating hours: 18,000 h, machine/vehicle number: A0215A0232, laser power: 2,500 W, sheet thickness (max.): 15 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, positioning accuracy: 0.1 mm, overall weight: 8,900 kg, TECHNICAL DETAILS

X-axis travel: 3,000 mm

Y-axis travel: 1,500 mm

Laser power: 2,500 W

Maximum sheet thickness (mild steel): 15 mm

Maximum sheet thickness (stainless steel): 6 mm

Maximum sheet thickness (aluminum): 5 mm

Axis speed: max. 60 m/min

Positioning accuracy: ±0.1 mm

MACHINE DETAILS

Dimensions & Weight

Dimensions (L × W × H): approx. 7,400 × 3,300 × 2,300 mm

Machine weight: 8,900 kg

Mains connection: 400 V / 50 Hz

Connected load: 65 kVA

Redpfxeyb Rzys Abdop

Control voltage: 24 V

Required fuse protection: 3 × 100 A

Compressed air connection: 7–14 bar

Nitrogen connection (N₂): 29 bar

Oxygen connection (O₂): 14 bar

Operating hours: approx. 18,000 h

EQUIPMENT

Automatic pallet changer

FocusLine laser technology

NitroLine laser technology

Maintenance-free AC servo drives

Listing

Bron

Bron

1,223 km

HEAT TREATMENT LINE (TTH)

CIEFFELL8

Call

Year of construction: 2004, condition: good (used), ATMOSPHERIC HEAT TREATMENT LINE (NITROGEN/METHANOL) comprising 3 high-temperature furnaces, 2 tempering furnaces at 450 °C, 1 industrial washer, 1 automatic loader, electrical cabinets, and a storage magazine.

Rsdpsyc Sm Tsfx Abdjp

Listing

Hauzenberg

Hauzenberg

1,386 km

Laser cutting machine

LD-LaserLG-1325 3kW Premium Line

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: Max Photonics, laser power: 3,000 W, laser wavelength: 1,080 nm, sheet thickness steel (max.): 22 mm, sheet thickness stainless steel (max.): 12 mm, sheet thickness aluminum (max.): 12 mm, table width: 1,300 mm, travel distance X-axis: 2,550 mm, travel distance Y-axis: 1,260 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 3,500 kg, door opening width: 2,600 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, new laser cutting machine with 3kW fiber laser

Our goal is to offer high-precision, long-term stable, and yet affordable laser machines. Our machines are ideal for workshops and repair businesses. A perfectly developed cutting parameter library is included, as is first-class service.

Please also take note of our attractive leasing and hire-purchase offers.

- Machine without automatic shuttle table

Redoxa Ahnspfx Abdjp

- Very space-saving design

- Extremely energy-efficient cutting system

- Only about 4 x 4 meters installation area required

- 3kW laser source from MaxPhotonics (G5/German configuration) – suitable for aluminum

- Top quality, schedule a viewing now!

Cutting capacities:

- Mild steel up to 22mm

- Stainless steel up to 12mm

- Aluminum up to 12mm

- Brass up to 5mm

- Travel range: 1260 x 2550mm (suitable for medium-size sheets)

- Machine control interface in German

- Safety light curtain for maximum operator protection

- Extensive collision protection for the cutting head

- Large laser protection window for process observation

- 3-gas selection (compressed air, nitrogen, oxygen)

- Extensive cutting parameters library

- Including nesting module

- Very easy to operate

- Powerful laser chiller

- German service and spare parts availability

- Extraction/filter system optionally available (5.5kW with frequency converter for exceptionally quiet operation)

Leasing and hire-purchase available via our financing partner

Sale exclusively to commercial customers. Delivery / consulting / sales only in Germany / Austria / Switzerland.

Machine dimensions approx.:

Length: 4.0m

Height: 2.3m

Width: 4.0m

Total weight: approx. 3500kg

Need different laser power, table configuration, or table size?

No problem. I am happy to prepare a tailored offer.

Example: 2kW machine from €29,990

Not sure which laser power is right for your application? Of course, I can perform cutting trials according to your requirements. There is a wide range of possibilities.

Listing

Hauzenberg

Hauzenberg

1,386 km

Laser cutting machine

LD-LaserLG-1313 eco-line 1,5 kW Laser

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 1,500 W, sheet thickness steel (max.): 15 mm, sheet thickness stainless steel (max.): 6 mm, sheet thickness aluminum (max.): 6 mm, sheet thickness brass (max.): 4 mm, input frequency: 50 Hz, type of input current: three-phase, type of cooling: water, compressed air connection: 8 bar, overall weight: 2,800 kg, Equipment: CE marking, centralized greasing system, cooling unit, dust extraction, emergency stop, fume extraction, safety light barrier, Laser Cutting Machine with 1500 W Fiber Laser Ecoline

Our commitment is to offer highly precise, long-term stable, yet affordable laser machines.

Our machines are ideal for workshops and repair businesses. Included in delivery is a perfectly optimized cutting parameter library as well as first-class service support.

Please also take note of our attractive leasing and hire-purchase offers.

Cost-effective Entry Into Laser Cutting Technology

- High-quality MaxPhotonics laser source

- Extremely energy-efficient cutting system

- Requires only approximately 3.0 x 3.0 meters of installation space

- Top quality – schedule a viewing now!

Cutting capacity:

- Mild steel sheet up to 15mm

- Stainless steel sheet up to 5mm

- Aluminum sheet up to 5mm

- Travel range: approx. 1300 x 1300mm

- Support table size: approx. 1300 x 2500mm (allows for full mid-format sheet loading)

- Machine control in German

- Manual front door

- Comprehensive collision protection measures

- Large front viewing window for monitoring the cutting process

- Automatic, programmable dual-gas switching (compressed air/nitrogen, oxygen)

- Extensive cutting parameter database

- Incl. nesting module

- CypCut1000 cutting software

- Raytools 240 cutting head

- Very easy to operate

- Powerful laser chiller

Sale exclusively to commercial customers.

Delivery / consulting / sales only within Germany / Austria / Switzerland.

Machine dimensions (approx.):

Width: 3.2 m

Rsdjitu Srjpfx Abdop

Height: 2.3 m

Length: 3.3 m

Total weight: approx. 2,800 kg

Need a different laser power, table design, or table size?

No problem. I am happy to provide a customized quotation.

Not sure which laser power is suitable for your application?

We are happy to conduct test cuts based on your requirements. Wide range available – from 0.5 kW up to 20 kW laser power.

Listing

Hauzenberg

Hauzenberg

1,386 km

Laser cutting machine

LD-LaserLG-3015 6kW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser power: 6,000 W, laser wavelength: 1,080 nm, sheet thickness (max.): 30 mm, sheet thickness steel (max.): 30 mm, sheet thickness stainless steel (max.): 15 mm, sheet thickness aluminum (max.): 15 mm, table width: 1,500 mm, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 120 mm, input voltage: 400 V, type of cooling: water, overall weight: 2,500 kg, door opening width: 1,000 mm, door opening height: 1,000 mm, Equipment: CE marking, cabin, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, New laser cutting machine with 6kW fiber laser

Our aim is to offer highly precise, long-term stable, and yet attractively priced laser machines. Our machines are ideal for workshops and repair businesses. A fully developed cutting parameter library is included with every machine, as well as first-class service.

We also offer attractive leasing and hire purchase options.

- Machine with automatic shuttle table

- Very space-saving design

- Extremely energy-efficient cutting system

- Only approx. 9 x 3.5 meters installation footprint

- 6kW laser source from MaxPhotonics (G5 / German version)

- Top quality – schedule a viewing now!

Cutting capability:

- Steel sheet up to 25mm (max. 30mm)

- Stainless steel sheet up to 15mm

- Aluminum sheet up to 15mm

- Brass sheet up to 12mm

- Travel range: 1500 x 3000mm

- Machine control system in German

- Safety light curtain for maximum operator protection

- Comprehensive collision protection measures for the cutting head

- Large laser-protection windows on three sides for monitoring the cutting process

- Automatic, programmable 3-gas switching (compressed air, nitrogen, oxygen)

- Extensive cutting parameter file included

- Includes nesting module

- Very user-friendly operation

- High-performance laser chiller

- Machine control system in German

Rodpfx Abshncfcedep

- German service and spare parts support

- High-performance laser chiller

- Optional fume extraction system

Leasing or hire purchase is available through our financing partner.

Sale to commercial customers only.

Delivery / Consultation / Sale only within Germany / Austria / Switzerland

Machine dimensions approx.:

Length: 9.0m

Height: 2.3m

Width: 3.5m

Total weight: approx. 6500kg

Need a different laser power, different table style, or table size?

No problem.

I would be happy to create a suitable quote for you.

For example: 1kW machine from €29,990 or 3kW machine from €32,900

Not sure which laser power suits your application?

Naturally, I can carry out cutting trials based on your requirements. Many options are available.

Listing

Bury St Edmunds

Bury St Edmunds

442 km

Meat processing machine

PackoRotary drum IQF freezer

Call

Condition: good (used), Similar in operation to Dohmeyer CryoRoll freezer. Packo developed these freezers to be used for high performance IQF freezing of small pieces of meat, seafood, cheese, pizza toppings, fruits and vegetables. The rotary drum is injected with CO2 down to -60 degrees C or nitrogen down to -110 degrees C.

This unit was used in a cheese manufacturing facility which has recently closed, they were running shredded and diced cheese through the machine. We have a large quantity of conveying and machinery available from this facility.

Rodpfx Abexz E Ndsdop

Listing

Germany

Germany

1,034 km

Full protected laser cutting machine

BodorC Series

Call

Condition: new, Year of construction: 2025, Base sheet fiber laser metal cutting machine with full protection

Maximum cutting area reaches up to 12000mm*2500mm, suitable for a variety of cutting options.

The special fiber laser nozzle and cutting process ensure faster carbon steel oxygen cutting, more gas-saving low-pressure stainless steel nitrogen cutting, and better-quality carbon steel air cutting.

Cutting performance and efficiency are improved by maintaining gas flow steady with little turbulence.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

The cutting process works even at the edge of thin sheets, and ensures no chatter marks.

With One-click Processing, one laser cutter is able to process multiple sheets in batches with a one-off setup, achieving batch processing.

Condition: New

Laser Type: Fiber Laser

Laser Power: 1000W - 40000W

Cutting Area: 3048*1524mm - 12500*2600mm

Rodshv U Tiopfx Abdop

Cutting Speed: 0-110m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Lübbecke

Lübbecke

860 km

Laser cutting machine

SAN LaserSA-AT1530 12kW

Call

Condition: like new (used), functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: hydraulic, laser type: fiber laser, laser source manufacturer: MAX Photonics, laser source model: MAX 12kW mit CE, laser power: 12,000 W, sheet thickness (max.): 40 mm, sheet thickness steel (max.): 40 mm, sheet thickness stainless steel (max.): 30 mm, sheet thickness aluminum (max.): 20 mm, sheet thickness brass (max.): 15 mm, sheet thickness copper (max.): 15 mm, table length: 3,000 mm, table width: 1,500 mm, working length: 3,000 mm, working width: 1,500 mm, positioning accuracy: 0.03 mm, repeat accuracy: 0.03 mm, power: 12,000 kW (16,315.44 HP), input voltage: 380 V, input frequency: 50 Hz, type of input current: AC, type of cooling: water, overall weight: 8,000 kg, total length: 8,500 mm, total width: 3,500 mm, warranty duration: 12 months, Equipment: CE marking, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, Fiber Laser Cutting Machine 1530, 12 kW – Overview

Safety & Protection

Fully enclosed metal safety cabin with radiation-protected doors and windows.

Environmentally friendly and safe for operators.

Work Platform

Parallel platform design with upper and lower levels:

Front section: Laser cutting.

Rear section: Loading and unloading.

No interference between operations → increased work efficiency.

Machine Structure

10 kW bed design:

Segmented, time-controlled dust extraction.

Excellent heat dissipation, thermal resistance.

Rodpfx Absycfuwedop

Industrial auxiliary equipment: Air conditioner, special cooling system, constant temperature & humidity → stable performance & extended service life.

Precision Guarantee:

Bed processed with a large gantry milling machine.

Industrial linear guides, gears, and screw drives.

Full servo control, dual-sided double drive.

High industrial quality and precision.

German assembly techniques:

Precision laser interferometer calibration

Fine craftsmanship, easier maintenance.

Control & Software

FSCUT 6000 control system (included).

FSCUT software package:

Industry-standard, safe, and user-friendly software.

Supports intelligent networking.

Professional nesting software: CypNest (included).

Core Components

Laser cutting head: BOCI BLT442

Laser source: MAX 12 kW, CE certified

Water chiller: HANLI 12 kW

Linear guides: TAIWAN DTX 30+20+20

Frame: TAIWAN JT

Reducer: Germany Techmach

Cameras: 2 units

Servo motor: BOCHU

Proportional valve: Felton

Electronic components: SCHNEIDER

Triple air inlets: nitrogen, oxygen, air

Lubrication system: Automatic oil supply system

Accessories

30 protective lenses, 30 nozzles, toolbox.

Optional: ARS-30HP-XF-1.6 MPA air compressor, 7.5 kW dust collector.

Listing

Babenhausen

Babenhausen

1,030 km

Standard tractor unit

SCANIAR 460*SPITZER SILO*WENIG KM*ACC*KOMPRESSOR*TOP

Call

Condition: used, mileage: 186,000 km, power: 338 kW (459.55 HP), first registration: 07/2023, fuel type: diesel, overall weight: 18,000 kg, axle configuration: 2 axles, next inspection (TÜV): 09/2025, brakes: retarder, color: green, gearing type: automatic, Year of construction: 2023, Equipment: ABS, air conditioning, compressor, electronic stability program (ESP), navigation system, parking heater, soot filter, SCANIA R 460 | SPITZER SILO | LOW KM | ACC | PTO | EXCELLENT CONDITION

----VEHICLE HISTORY

* 1 OWNER

* GERMAN VEHICLE

* MAINTENANCE CONTRACT WITH SCANIA

* VIDEO AVAILABLE ON REQUEST

----VEHICLE EQUIPMENT

----GENERAL DATA

* EXCELLENT CONDITION

* OPERATING HOURS: 4,300 H

----AXLES

AXLE 1:

* TIRES: 385/65R22.5

* SCANIA AXLES

Rjdpfx Abjxpbn Sedep

* ALCOA DURA BRIGHT EVO

* LEAF SUSPENSION

AXLE 2:

* TIRES: 315/70R22.5

* AIR SUSPENSION

* ALCOA ULTRA ONE DURA BRIGHT EVO

----DRIVELINE & TECHNOLOGY

* RETARDER

* COMPRESSOR

* PTO (POWER TAKE-OFF)

* AUTOMATIC TRANSMISSION

* DIFFERENTIAL LOCK

* TRACTION CONTROL (TC)

* HILL START ASSIST

* HILL DESCENT CONTROL

----TANK & BRAKES

* 1X DIESEL TANK 440 LITERS

----ASSISTANCE SYSTEMS

* ACC (ADAPTIVE CRUISE CONTROL)

* LANE KEEP ASSIST

----COMFORT & INTERIOR

* SCANIA ENTERTAINMENT PREMIUM

* STATIONARY AIR CONDITIONING

* PARKING HEATER

* AUTOMATIC CLIMATE CONTROL

* 1 BED

* 1 FRIDGE

----DRIVER'S SEAT

* SEAT HEATING

* SEAT VENTILATION

----SPECIAL FEATURES

* NAVIGATION SYSTEM

* ELECTRIC WINDOWS

* HEATED SIDE MIRRORS

----TRAILER

SPITZER | CEMENT SILO

* 1 OWNER

* GERMAN VEHICLE

----GENERAL DATA

* MANUFACTURER: SPITZER

* MODEL: S11037

* FIRST REGISTRATION: 11/2023

* YEAR OF MANUFACTURE: 2023

* UNLADEN WEIGHT: 4,475 KG

* GROSS WEIGHT: 37,000 KG

* COMPARTMENT 1: 34,000 LITERS

* PERMISSIBLE TEMPERATURE: -40°C TO +80°C

----AXLES & CHASSIS

* 3-AXLE

* TIRES: 385/65 R22.5

* FULL AIR SUSPENSION

* BPW AXLES

* LIFT AXLE

* ALCOA DURA BRIGHT EVO

----TECHNOLOGY & EQUIPMENT

* TOP LOADING

* NITROGEN INLET REAR

---- EXPORT SALES ONLY WITH DEPOSIT MIN. €500 - €2,000

----CUSTOMS EXPORT DECLARATION EXW IN 10 MIN. (APPROVED EXPORTER) 5 DAY, 30 DAY TEMPORARY GERMAN PLATE AND 17 - 21 DAY AUSTRIAN PLATE EURO 1

RESERVATIONS ONLY VIA EMAIL FUNCTION

VERBAL RESERVATIONS ARE NOT VALID!

A deposit of at least €500.00 / €1,000.00 will be charged for sales to EU & third countries.

Subject to change, errors, and prior sale.

Find more vehicles on our homepage:

Sale is strictly according to our General Terms and Conditions – see homepage.

Important note – Important information: Despite carefully checking all details in our offer, errors may occur. These may be caused by transmission errors in the systems of various platform providers. Therefore, all information is given without guarantee and does not constitute a legal claim.

Legal: This sales advertisement does not constitute an offer in the sense of §145 BGB. It serves solely as information to initiate a contract. The details provided are without obligation and do not represent guaranteed characteristics.

Listing

La Ràpita

La Ràpita

1,670 km

Vacuum cleaner

WIELANDVacTrailer S-4

Call

Condition: new, Year of construction: 2023, operating hours: 60 h, functionality: fully functional, machine/vehicle number: 13943/08, overall weight: 1,660 kg, tank capacity: 500 l, Equipment: CE marking, The S-4, manufactured in series production, is a very compact mobile suction unit. Its impressive suction power allows conveyed material to be transported at considerable transfer speeds over long distances using flexible hoses with an 80 or 100 mm diameter. The high-tech filtration system, featuring three-stage serial separation and a pneumatic AirShock® filter cleaning device, ensures constant high suction performance even with challenging dust types. The collection container is hydraulically raised to its working position and discharges the extracted material into BigBags or open containers. Special versions are available with ATEX-compliant explosion protection and nitrogen cooler for catalyst handling. The S-4: the compact unit with exceptionally high suction power, produced with series production quality.

Rsdsxyq Ngjpfx Abdop

Trust Seal

Dealers certified through Machineseeker

Listing

Köln

Köln

852 km

LNG Methan Gas Semi-trailer

M1 EngineeringLNG Methan Gas Cryogenic Semi-trailer

Call

Condition: excellent (used), Year of construction: 1999, LNG Methan Gas Cryogenic Semi-trailer M1 Engineering

Hersteller: M1 Engineering

Rsdpfewp Iq Aox Abdsp

Baujahr: 1999

Volume: 49 m3

Working pressure: 8 bar.

Tare 15435 kg

Pump

Flowmetter

We also have other tankers, tanks, vessels for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, LNG, Hydrogen, Methane

We will be glad to answer your questions via Phone and E-mail

Listing

Breitenbach

Breitenbach

1,167 km

Material testing machine

ZwickRoell, Schenk-TrebelRME 250 kN

Call

Year of construction: 1985, condition: repair required (used), functionality: limited functionality, Schenk-Trebel Materials Testing Machine Type RME 250 kN

• Load frame and drive by Schenk Trebel, year of construction 1985, total height approx. 3.3 m; traverse stroke approx. 2 m

• Modernization around the end of 2003: equipped with the ZwickRoell "testControl" control electronics

• Retrofit in 2010: MultiXtens universal extensometer system by ZwickRoell, with swiveling device and two pairs of measuring sensors (photo), and new testControl module

• Note: The testControl module functions together with the current "testXpert III" software from ZwickRoell (software is not included in this offer)

• Temperature chamber (photo) insertable into the test space of the machine, built in 2006 by RS-Simulatoren Prüf- & Messtechnik, heatable up to approx. 200°C; coolable down to approx. –40°C with liquid nitrogen

• Load cells: 250 kN and 50 kN (currently installed, see machine photo); additionally: 5 kN, 1 kN, and 500 N (photo)

• 2 wedge specimen grips (photo)

Rodpfx Aoyhb Rljbdsp

Condition of the machine

The machine was in use for testing until early 2026. The 50 kN load cell and the traverse displacement sensor were used (both sensors last calibrated on 06.05.2024 incl. standard inspection). A defect in the servo amplifier for the drive (component in the testControl module) has resulted, since autumn 2025, in frequent connection losses to the software and halt of the drive until hardware/software reboot. The servo amplifier or the entire testControl module need to be replaced (cost details available from the supplier).

The 250 kN load cell was last calibrated on 11.02.2021, but has not been used since then.

The other load cells, MultiXtens system, and temperature chamber have not been used or calibrated in recent years.

The two hydraulic clamping units shown installed in the machine on the pictures will be removed and remain with the supplier.

Listing

Düsseldorf

Düsseldorf

817 km

CONTINUOUS BRAZING

WMUCONTINUOUS BRAZING LINE FOR STAINLESS ST

Call

Year of construction: 2003, condition: used, functionality: fully functional, CONTINUOUS HUMP BACK BRAZING LINE FOR STAINLESS STEEL

TECHNICAL INFORMATIONS:

- Type: Hump Back Mesh Melt Continuous Furnace Line

Rjdpfxex Ux Sbs Abdop

- Process : Brazing (Stainless steel)

- Total Length : 28.800mm

- Heating Zone : 5200mm

- Band width : 650mm

- Band speed : Max. 1200mm/min

Min : 100mm/min

- Capcity : 420kg/h netto

- Heating : With Natural gas

- Total Heating Power : 400kW Brut

- Heating Elements : x10 WS Burners

- Controlled zone : 4

- Max Temp. : 1130 C

- Athmosphere : Nitrogen / Hydrogen

- Control : Demig / Siemens

Listing

Bad Hönningen

Bad Hönningen

900 km

Tanker truck Scania transport argon

Orca Scania8,2 m3 tank gas argon cryogenic

Call

Condition: excellent (used), Year of construction: 2016, Orca 8,2 m3 tank gas argon cryogenic

Manufacturer:Scania

Year: 2016

Mileage: 425000 km

Capacity:8,2 m3

We also have other tankers, tanks, vessels for LIN, LOX, LAR, LNG and CO2, argon, oxygen, nitrogen and carbon dioxide, LNG, Hydrogen, Methane

We will be glad to answer your questions via Phone and E-mail

Rodpju Snghefx Abdep

We make it easier for you to find: "nitrogen"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Nitrogen (344)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month