Used Drilling Machinery for sale (75,020)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Certaldo

Certaldo

1,672 km

CNC drilling machinery

Maggi EngineeringBoring System 800 GT

Call

Condition: new, Year of construction: 2024, functionality: fully functional, overall weight: 1,060 kg, total height: 1,800 mm, total width: 1,830 mm, total length: 2,000 mm, feed length X-axis: 3,000 mm, feed length Y-axis: 800 mm, feed length Z-axis: 50 mm, spindle speed (max.): 3,200 rpm, workpiece weight (max.): 25 kg, power: 2.2 kW (2.99 HP), air demand: 750 m³/h, operating pressure: 6 bar, number of spindles: 12, empty load weight: 975 kg, warranty duration: 12 months, Easy programmamble through-feed boring machine with touch-easy-smart software, 3 controlled axis X,Y,Z, also performing grooving operations (optional) and working from above

Vacuum panel feeding

Machine manufactured according to EC standards

STANDARD EQUIPMENT

HEAD UNIT

Independent spindles

N.7 vertical

N.1 double horizontal -spindle TH1 (X axis) for back/ forth drilling

Manual SIDE-ALIGNER

PANEL EDGE-READER for perfect panel joints

Teleservice Software

Dust-collection nozzle

Wokring table with GENTLE BRUSHES to avoid storage of dust and shavings.

Working process can be in a cycle or back to the operator

HARDWARE & SOFTWARE

Codou U Hgispfx Abuopu

12" touch-screen - NO TEXT System, patented by Maggi

USB and Ethernet ports for file uploading, on-line assistance and system upgrades

System based on Linux Kernel

Up to 1.000 working programs storable

Package: on a wooden pallet (2200x2050x160 mm - Kg 123)

Listing

Great Britain

Great Britain

0 km

Food Packaging machinery

Record Packaging MachineryScorpion MD SP Flow Wrapper with Printer

Call

Year of construction: 2007, condition: excellent (used), REF: MM5765

1 x Record Packaging Machinery flow wrapper with Domino V230i thermal transfer overprinter and infeed conveyor. Fitted with an adjustable folding box, this unit is suitable for wrapping a variety of products in printed or clear film.

Model - Scorpion MD SP.

Date of manufacture - 2007.

Speed - between 20 to 120 packs/minute (depending on product size).

Sealing jaws - 350mm long.

Infeed conveyor - 185mm wide.

Outfeed conveyor - 220mm wide.

Previous use - for packing cereal bars and biscuits.

Overall dimensions - 4670mm L x 1350mm W.

Csdpfxsukw Nbj Abuspu

Listing

Great Britain

Great Britain

0 km

Food packaging machinery

Record Packaging MachineryScorpion Flow Wrapper

Call

Year of construction: 1999, condition: good (used), REF: MM5766

1 x Record Packaging Machinery flow wrapper with infeed conveyor. Fitted with an adjustable folding box, this unit is suitable for wrapping a variety of products in printed or clear film.

Model - Scorpion.

Date of manufacture - 1999.

Speed - between 20 to 80 packs/minute (depending on product size).

Sealing jaws - 240mm long.

Outfeed conveyor - 120mm wide.

Previous use - cereal bars.

Cjdpfx Aeukw Haobujpu

Overall dimensions - 3100mm L x 1350mm W.

*Please note* - 1. No inkjet printer will be supplied with the machine.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Derby

Derby

302 km

Continuous Milk Pasteurisers by Dairy Machinery UK

Dairy Machinery UKHTST DMUK

Call

Condition: used, Year of construction: 2025, The HTST (High-Temperature Short-Time) pasteuriser from Dairy Machinery UK is designed to provide efficient pasteurization of liquid dairy products while preserving their quality and safety. Here are some key features:

- Process Efficiency: HTST pasteurisation involves heating the dairy product to a high temperature (typically around 72°C and other temperatures on request ) for a short time (15-30 seconds and other timings on request ), which kills harmful bacteria and extends shelf life.

- Quality Preservation: This method retains the taste and nutritional value of the dairy products better than traditional pasteurization methods, minimizing the impact on flavor and color.

- Automated Control: Many HTST systems come with automated controls that monitor temperatures and flow rates, ensuring consistent pasteurisation and reducing human error.

- Compliance Standards: Designed to meet industry hygiene and safety standards, HTST pasteurisers help dairy producers comply with food safety regulations.

- Versatility: Suitable for various dairy products including milk, cream, cheese, and yogurt, making it a valuable asset for dairy processors.

Capacities: 500 Litres to 30,000 Litres per Hour

Heating: Electric, Hot water and Steam

Controls: Fully Automated PLC SIEMENS

CE Certified: Yes

Skid Mounted: Stainless steel Skid 316L

Safety valves: Yes

Non return Valve: Yes

Balance Tank: Yes

Product Pump: Yes

Water Pump: Yes

Regulating Valve for Hot water: Yes

Heavy Duty Construction: Yes

Temperatures: 73-75-80-85-90 Depending on Request

UHT Possibility: Yes

Finance: Available for UK Clients

Csdpfsxfr Smjx Abuepu

Listing

Derby

Derby

302 km

New Batch Pasteurisers 300 Litres

Dairy Machinery UKBPT 300

Call

Condition: used, Year of construction: 2025, New Batch Pasteurisers custom made on request. offers new Batch pasteurisers for the Food and beverage industry. Our BPT Series is capable of Milk Pasteurisation, Ice cream mixing, Ice Cream Fermentation, Sauces, Brewery industry,etc.

Applications:

- Dairy Processing: Most commonly used in the dairy industry to pasteurise milk and milk products.

- Cheese Production: Used before cheese-making to ensure safety.

- Ice Cream Production: Pasteurises the base mixture before it is churned into ice cream.

Advantages of Batch Pasteurisation:

- Cost-Effective: Often less expensive than continuous pasteurisers for small to medium operations.

- Flexibility: Suitable for small batches or varied products and recipes.

- Quality Control: Allows for greater control over the pasteurisation process.

Volume capabilities (litres): 300

Control panel: Stainless steel Control box, Controls, Thermometer Controller, ON/OFF Agitator, Chart Recorder; ;

Heating options: Heating Elements, Hot Water and Steam

Milk pasteurisation: 68-75c

Max temperatures: 95c

Cooling options: Connection to Ice Bank and Circulation Cold water through the Jacket; Plate Cooler Connection on the Outlet;

Heating time: Between 30m-1hr for BPT100 to BPT500 Series With Heating Elements; BPT600 -BPT2000 Heating by HOT water or Steam;

Cooling time: 30min to 45min Depending on Cooling Temperatures; Plate cooler at 30min Standard;

Structure: Stainless steel 316L & 304 Triple Jacket with Insulation; ;

Agitation: Slow Agitation with double props at two diferent levels; High Shear mixing for Ice Cream;

Cleaning: Spray ball internally for even cleaning by circulation of Hot water and chemicals used in the food industry; ;

Automation: We offer Full automation on our batch Pasteurisers that cover the full circle of heating down to cooling; Additional Costs will be added for automation;

Openings: Two Up Folding Covers for Easy Cleaning and Inspection; ;

Product outlet: DIN40-DIN50 On semi cone to make sure all product flows out; ;

Uasege: Milk Pasteurisation/ Ice Cream Mixing/ Ice Cream Fermentation/ Sauces/; ;

Lead time: 5-8 weeks from Order Delays may apply during COVID 19; ;

Codpfx Abexl N H Usuopu

Finance Available: Pay Monthly, Ask For A Quote

Discover more used machines

Listing

Derby

Derby

302 km

New Dairy Machinery UK BPT 600

Dairy Machinery UKBPT 600

Call

Condition: new, Year of construction: 2025, New Batch Pasteurisers custom made on request. offers new Batch pasteurisers for the Food and beverage industry. Our BPT Series is capable of Milk Pasteurisation, Ice cream mixing, Ice cream Fermentation, Sauces, Brewery industry, etc.

Applications:

- Dairy Processing: Most commonly used in the dairy industry to pasteurise milk and milk products.

- Cheese Production: Used before cheese-making to ensure safety.

- Ice Cream Production: Pasteurises the base mixture before it is churned into ice cream.

Advantages of Batch Pasteurisation:

Cpsdpjydlxrefx Abuju

- Cost-Effective: Often less expensive than continuous pasteurisers for small to medium operations.

- Flexibility: Suitable for small batches or varied products and recipes.

- Quality Control: Allows for greater control over the pasteurisation process.

Volume capabilities (litres): 600

Control panel: Stainless steel Control box, Controls, Thermometer Controller, ON/OFF Agitator, Chart Recorder; ;

Heating options: Heating Elements, Hot Water and Steam

Milk pasteurisation: 68-75c

Max temperatures: 95c

Cooling options: Connection to Ice Bank and Circulation Cold water through the Jacket; Plate Cooler Connection on the Outlet;

Heating time: Between 30m-1hr for BPT100 to BPT500 Series With Heating Elements; BPT600 -BPT2000 Heating by HOT water or Steam;

Cooling time: 30min to 45min Depending on Cooling Temperatures; Plate cooler at 30min Standard;

Structure: Stainless steel 316L & 304 Triple Jacket with Insulation; ;

Agitation: Slow Agitation with double props at two diferent levels; High Shear mixing for Ice Cream;

Cleaning: Spray ball internally for even cleaning by circulation of Hot water and chemicals used in the food industry; ;

Automation: We offer Full automation on our batch Pasteurisers that cover the full circle of heating down to cooling; Additional Costs will be added for automation;

Openings: Two Up Folding Covers for Easy Cleaning and Inspection; ;

Product outlet: DIN40-DIN50 On semi cone to make sure all product flows out; ;

Uasege: Milk Pasteurisation/ Ice Cream Mixing/ Ice Cream Fermentation/ Sauces/; ;

Lead time: 5-8 weeks from Order Delays may apply during COVID 19; ;

Finance Available: Pay Monthly, Ask For A Quote

Clickout

Göteborg

Göteborg

978 km

Cold Chamber Die Casting Line (Unused)

LK MachineryImpress Plus DCC 3500

Condition: like new (used), Year of construction: 2022, functionality: fully functional, total height: 3,100 mm, total width: 3,100 mm, stroke length: 950 mm, column diameter: 130 mm, mold height (min.): 900 mm, clamping force: 35,000 kN, pressure: 400 bar, Installed and commissioned with dry, test run only.

- Two‑platen machine

Cpsdjygxr Rspfx Abusu

- Max locking force: 35,000kN

- Injection force: Approx. 390–420kN (varies by plunger size)

- Plunger diameter: Ø130mm

- Plunger stroke: 950mm

- Shot weight (Al): 6.5–8.5kg, depending on plunger

- Projected area at 400 bar: 8,750–9,000cm² (calculated from 35,000kN clamping force)

- Platen size (H × W): 3100× 3100mm

- Distance between tie bars (H × W): 1950×1950mm

- Die height (min / max): 900/1350mm

- Die opening stroke: 1200mm

Støtek melting system with

- Støtek SMG 3.0_7.0 two chamber gas fired melting shaft furnace with ingot charging elevator, furnace melting capacity approx. 1.5t/h

- Støtek DTI 6020 holding furnace with Fuco-Heg MBS 2000 molten metal treatment/rinsing station

- Støtek AMET 1700 dosing furnace

LK Impress Plus DCC 3500 die casting machine with

- Siemens PLC S7-1500 controls

- ABB IRB 6650S die release agent spray robot

- Wollin OSA 15-2-C die release agent supply system and spray head

- AED 181-080 die lubrication dilution system

- Fondarex Highvac Premium 2C 200 die casting vacuum system with air tank and vacuum pumps

- 5x IECI PFN 330 2-Z oil temperature control units

- 5x IECI PF-ZH 1802-Z water temperature control units

- KMA Ultravent UV 20000EE fume extraction and filter system

- ABB IRB 7600 robot for die casting machine unload, trim press load/unload and cooling station load

- LK WB-100 1,000kN trim press with trim conveyor

- ABB robot for cooling station unload, laser marking and outfeed

- Keyence MD-X 1500C 3 axis laser marking system

- Outfeed conveyor with cooling tunnel

A quantity of spare parts is available with the line.

Listing

Germany

Germany

1,148 km

Citizen A32 with FMB, year of manufacture 2015, internal number 231480

Citizen MachineryA32 (A232-VIIPL)

Call

Condition: used, Year of construction: 2015, operating hours: 10,680 h, machine/vehicle number: IntNr231480, CNC Swiss-Type Lathe Citizen A32 (A232-VIIPL)

Year of Manufacture: 2015

Control System: Cincom Mitsubishi Meldas M70

TECHNICAL DATA

Number of axes: 7

Number of spindles: 2

MAIN SPINDLE

Maximum bar diameter: 32 mm

Maximum machining length: 320 mm

Travel: 325 mm

Spindle speed: 200 – 8,000 rpm

Spindle drive power: 5.5 / 7.5 kW

Minimum C-axis resolution: 0.001°

SUB SPINDLE

Maximum bar diameter: 32 mm

Z-axis travel: 290 mm

X-axis travel: 370 mm

Spindle speed: 200 – 8,000 rpm

Spindle drive power: 2.7 / 3.7 kW

Minimum C-axis resolution: 0.001°

Driven tools for rear-side machining

ACCESSORIES

Instruction manuals and documentation

Parts conveyor belt

LNS chip conveyor

Codpfxjyg Nq Do Abuepu

Bar feeder FMB Turbo 3-36 / 3200

WEIGHT AND DIMENSIONS

Footprint (L×W×H): 2,520 × 1,300 × 2,229 mm

Machine weight: approx. 3,500 kg

The machine can be inspected by appointment.

Technical data and information are subject to change and error. Prior sale reserved.

Listing

Great Britain

Great Britain

0 km

Flow wrapper

Adpak Machinery Systems LtdGSP 65 Flow Wrapper with Thermal Printer

Call

Condition: excellent (used), REF: MM5767

1 x Adpak Machinery Systems Ltd stainless steel flow wrapper fitted with an ICE Zodiac Hawk thermal transfer printer and a fixed folding box.

Model - GSP 65.

Date of manufacture - 2009 approx, refurbished by Midas Motion in 2020.

Sealing jaws - 300mm long.

Fixed folding box - 40mm wide.

Came out of production in 2023, this unit was previously used to individually wrap ice lollies.

Cjdpfoulc Sqjx Abuepu

Listing

Niederlangen

Niederlangen

753 km

Pillar Drilling Machine

HM MACHINERYSBM 28 F

Call

Condition: new, bore capacity in steel (diameter) 28 mm

throat 250 mm

bore stroke 130 mm

morse taper 3 MK

Cjdpfxoprfbuj Abuopu

table: 380 x 380 mm

turning speeds 75 - 3200 U/min

thread M16 ST60

column diameter 98 mm

engine output 1,1 kW

dimensions 800 x 500 x 2000 mm

weight 210 kg

- automatic drill feeds (magnetic clutch)

- Height adjustable and angle adjustable table

- Movable work table

- Integrated cooling system

- Powerful engine

- 3 hand levers for drilling feed

- Safety shield with limit switch

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Niederlangen

Niederlangen

753 km

Pillar Drilling Machine

HM MACHINERYSBM 32 F AUT

Call

Condition: new, bore capacity in steel (diameter) 32 mm

throat 300 mm

bore stroke 160 mm

morse taper 4 MK

table: 460 x 460 mm

turning speeds 75 - 3200 U/min

engine output 1,5 kW

column diameter 125 mm

thread M16 ST60

feed 0,10/0,18/0,26 mm/U

dimensions 800 x 500 x 2200 mm

weight 350 kg

- automatic drill feeds (magnetic clutch)

- Height adjustable and angle adjustable table

- Movable work table

- Integrated cooling system

- Powerful engine

- 3 hand levers for drilling feed

Codpfx Askahu Rsbuspu

- Safety shield with limit switch

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Niederlangen

Niederlangen

753 km

Pillar Drilling Machine

HM MACHINERY TischbohrmaschineSBM 28 B

Call

Condition: new, bore capacity in steel (diameter) 28 mm

throat 250 mm

bore stroke 130 mm

morse taper 3 MK

table: 380 x 380 mm

turning speeds 75 - 3000 U/min

engine output 1,1 kW

Cjdpfx Ajkahu Usbuopu

column diameter 98 mm

thread M16 ST60

dimensions 700 x 450 x 1500 mm

weight 200 kg

- Height adjustable and angle adjustable table

- Movable work table

- Prepared for cooling system

- Powerful engine

- 3 hand levers for drilling feed

- Safety shield with limit switch

- Separate emergency stop

- Built-in working lights

- Incl. drill chuck 16mm - B16

- Built-in automatic thread cutting.

Listing

Soltau

Soltau

905 km

CNC - turning center

Yeong Chin Machinery Industries Co. Ltd. (YCM)NTC2000LSY

Call

Condition: as good as new (ex-display), Year of construction: 2023, CNC - turning center

YCM NTC2000LSY

control : Fanuc TXP100FBTXP100FB+

main spindle : A2-6 / 5.000 rpm, hole through spindle: Ø80mm, hole through draw bar: Ø66mm

sub spindle : A2-5 / 6.000 rpm, hole through spindle: Ø55mm, hole through draw bar: Ø45mm

Cpedpfx Abstt Dhveuou

Turret Capacity: 12

Max. Turning Diameter : Ø310 mm

Max. Turning Length : 570 mm

X travel: 160mm

Z travel: 570mm

Y travel: 90mm (-50 / +40mm)

LSY (Y axis, BMT55 turret 12T

High performance coolant pump 8 bar

coolant gun

interface for bar feeder

automatic Renishaw HPMA tool length measuring system

main spindle

Parts collection system

Counter spindle

Listing

Bakkeveen

Bakkeveen

681 km

Finger Jointer

Marinus MachineryPowermax Finger Jointer & Defect Saw

Call

Condition: new, Year of construction: 2026, pressing force: 25 t, Equipment: double-sided, The Marinus Powermax Finger Jointer Line profiles horizontally, applies adhesive, cuts out defects, presses and cuts to length. The unique process creates a clean joint that does not require post-processing.

Cpsdop R Iwhjpfx Abuou

About the Finger Jointer

When feeding wood into the machine, it is possible to mark defects, such as knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines. For instance, to get cladding or paneling without knots or holes. Before the profiling and also before the pressing, the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. This results in a highly accurate connection of the finger joint, with a flat surface at the joint and a straight end-product. Because of this precision (for most purposes) the wood does not need to be planed or sanded afterwards. The adhesive applicator is mounted to the carriage with the profile cutters. In the returning stroke of the profiling carriage the adhesive is applied. The use of PU adhesive ensures a very strong bond, suitable for outdoor use and in wet environments. While most other finger jointers move the wood transversely (right-angled) past the profiling heads, the Marinus Finger Jointer moves the wood longitudinally (lengthwise) through the machine. This enables feeding in long lengths of 6 meters or even longer. As a result, the machine can process all the wood, including longer lengths, and use it all (except for the defects) for the jointed end-product. This way, there is no good wood turned into short pieces of scrap. Where other finger jointers focus on re-using short pieces of scrap wood, the Marinus eliminates the production of scrap wood. The Marinus Finger Jointer contributes to an efficient and sustainable production process.

Specifications:

Infeed Lenghts: 450 - 6000+ mm

Infeed Widths: 50 - 300 mm

Infeed Thicknesses: 8 - 50 mm

Length modes: Variable / Fixed

Capacity: Up to 8 joints/min

This machinery is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machinery is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

681 km

Powermax Chevron + Angular Saw

Marinus MachineryPowermax Chevronline

Call

Condition: new, Year of construction: 2026, functionality: fully functional, working width: 200 mm, The Marinus Powermax Chevron is an advanced machine line for head-end machining tongue and groove on Hungarian-point (Chevron) and herringbone parquet.

Several wooden parquet boards can be loaded into the infeed cassette, after which the process runs automatically. First the boards are pre-cut to the corresponding length and angle in the cross cut saw unit, then they go via conveyor to the Chevron machine. Before the profiling takes place the wood is brought to a stationary position, fixed sideways and clamped to an accurate reference surface above. Resulting in high profile accuracy with no noticeable edge on the top side when the boards are fitted together.

The two arms on which the profiling heads slide back and forth are sturdy built and driven by servo motors, which guarantees that all the boards have exactly the same length and angle. The lengths and angles are stepless adjustable via the user friendly touch screen panel.

This clamping system combined with two pre-cut aluminium backing blocks effectively prevents blow-outs and splintering.

Lengths: 350 - 1200 mm

Widths: 50 - 200 mm

Thicknesses: 8 - 22 mm

Angle: -45° to +45°

Capacity: Up to 10 boards per minute

Length modes: Fixed lengths

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

Codsiv R Hhepfx Abuopu

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Bakkeveen

Bakkeveen

681 km

Powermax 300 Endmatcher and defect saw

Marinus MachineryPowermax 300

Call

Condition: new, Year of construction: 2026, The Marinus Powermax Endmatcher is designed for head-end machining tongue and groove on parquet floorboards, decking and cladding, producing fixed and variable lengths. It can be used for any type of wood; hardwood, softwood, or engineered wood. The machine can cut to length, cut out defects, and do head-end profiling, all in a single pass of the wood through the machine. When feeding wood into the machine, it is possible to mark defects, like knots or cracks, with a luminescent crayon. The machine will cut out these defects, including the crayon lines.

Cpedpfx Abof Hkgpeuju

Lengths: 450 - 6000+ mm

Widths: 50 - 300 mm (optional width of 400mm or 500mm)

Thicknesses: 8 - 45 mm

Capacity: up to 20 pc/min

Length modes: Variable / Fixed / Round.

This machine is engineered and built in our company in The Netherlands and will be delivered new from our factory. This machine is equipped with an online remote support system. We provide customer support worldwide.

This listing on Machineseeker is also made by us: Marinus Machinery.

Listing

Markneukirchen

Markneukirchen

1,197 km

Milling machine

Buffalo MachineryCV-850

Call

Condition: used, Year of construction: 2002, functionality: fully functional, travel distance X-axis: 850 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 1,200 rpm, spindle speed (min.): 30 rpm, table width: 530 mm, table length: 900 mm, type of input current: three-phase, input voltage: 380 V, controller manufacturer: Fagor, controller model: 8055/FL 1 Jahr alt, Equipment: documentation/manual, Microcut / Buffalo Machinery Company Limited CV-850

Cpodpfeyhbw Esx Abueu

Year of manufacture: 2002

Control: Fagor 8055/FL, 1 year old

Travel paths:

X – 850

Y – 500

Z – 450

Voltage: 400V

Power: 56 kW

Spindle speed: 30 – 1200

Table size: 900x530 mm

T-slots: 14 mm wide, spaced at 60 mm

Table load capacity: max. 400 kg

A wide range of tool holders and tools included!

Price is net plus VAT:

Listing

Janville

Janville

878 km

Wall mounted mixer

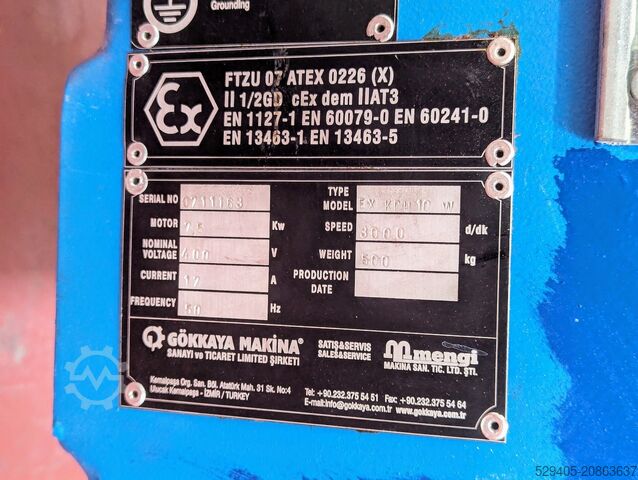

Gökkaya MachineryAKO®WALL EX KDH 10W

Call

Condition: used, Year of construction: 2007, Manufacturer: Gökkaya Machinery

Model: AKO®WALL EX KDH 10W

Year : 2007

Type: Wall-mounted dissolver

ATEX classification: Ex 1/2GD cEx dem IIAT3

Weight: 500 Kg

Diameter of mixing rotor: Ø 200 mm

Shaft length : 985 mm

Up/down stroke: 1150 mm

Cpsdpfx Asx R Ayzebusu

Raise/lower: hydraulic

Sew Eurodrive unit: 1.5 Kw

Loher motor: 7.5 KW

Listing

Suffolk

Suffolk

442 km

Ribbon blender 75 litres

Prism Pharma MachineryPRB 50

Call

Condition: excellent (used), Prism Pharma Maxhinery ribbon blender. Vacuum option. Lovely condition. Direct from test facility.

Csdpfx Aex Axbcebuepu

Listing

Quakenbrück

Quakenbrück

802 km

High-Pressure Pasteurization Unit

Hiperbaric Machinery EquipmentWAVE 6000/55

Call

Year of construction: 2007, operating hours: 2,000 h, condition: used, functionality: fully functional, cylinder diameter: 200 mm, pressure (max.): 6,000 bar, machine/vehicle number: 600/55, High-Pressure Food Processing Machine (HPP System) – Wave 6000/55

This high-pressure food pasteurization system (HPP) is a unit designed for batch processing of packaged food using hydrostatic pressure. The machine is fully operational, well maintained, and suitable for research, product development, and low-to-medium volume industrial production.

High-pressure processing (HPP) offers significant advantages for food manufacturers seeking to improve product safety, quality, and shelf life without the use of heat or preservatives. By applying up to 600 MPa of hydrostatic pressure to already packaged products, HPP inactivates harmful pathogens such as Listeria monocytogenes, Salmonella, and E. coli while preserving the natural taste, texture, nutrients, and color of the food. This makes HPP an attractive technology for clean-label formulations. In addition, the process typically doubles or even triples the shelf life of many refrigerated foods, reducing waste and improving distribution flexibility. Because HPP is a post-packaging treatment, recontamination risks are minimized, enabling manufacturers to meet stringent food safety standards in domestic and export markets. The technology is suitable for a wide range of products, including meat, seafood, juices, plant-based foods, ready-to-eat meals, and high-value chilled items.

Cpsdpfex E Utiox Abusu

The system offers a treatment chamber volume of 55 L, reaching pressures up to 6,000 bar (600 MPa), with automatic basket loading/unloading and an integrated intensifier. It is ideal for enhancing food safety, extending shelf life, and enabling clean-label product concepts.

Technical Details

Model: Wave 6000/55

Chamber layout: Horizontal

Chamber dimensions: Ø 200 mm × 2,000 mm

Chamber volume: 55 L

Total equipment length: 8,020 mm

Maximum working pressure: 6,000 bar (600 MPa)

Pressure medium: Water, free of additives

Processing water temperature: +5 °C to +30 °C

Pressure-build time (0–6,000 bar): 3.9 min

Intensifiers: 1 integrated

Electrical power: 47 kW (50 Hz)

Loading/unloading system: Automatic

Total weight: ~20,000 kg

Condition and Use Cases

The machine is in very good condition and suitable for:

Meat, seafood, ready-to-eat meals

Dairy, beverages, plant-based products

Shelf-life extension and pathogen reduction

R&D, validation trials, pilot production

Cycles completed (as of Jan 2025): 20,000

Included with the High Pressure Food Processor WAVE 6000/55:

High-pressure vessel made of stainless steel, wire-wound with high-resistance cable; horizontal layout with 55 L useful volume

Yoke constructed from high-quality steel layers, double-primed and painted

Stainless steel vessel plugs

Support beds

Hydraulic power unit with vessel opening/closing mechanisms

Integrated intensifier (1 unit)

High-pressure stainless steel piping for intensifier–vessel connection

Water filtration system (5 µm)

Temperature probe for monitoring processing water via the client fluid circuit

Tactile touch screen for automatic and manual operation (interface in German)

Electrical control cabinet

SCADA system for control and data recording

Internet communication module for remote service

Instruction manual

The machine has been used for reasearch purposes and has only done ~20.000 cycles. It is assumed the average cycle length is 6minutes = 2,000 hours

All technical specifications and details are provided without guarantee. Subject to prior sale and possible errors or omissions.

Listing

Wiesbaden

Wiesbaden

987 km

Machining center

Yeong Chin Machinery Industries Co. Ltd. (YCM)NXV-1020A

Call

Condition: new, Year of construction: 2023, travel distance X-axis: 1,020 mm, travel distance Y-axis: 520 mm, travel distance Z-axis: 540 mm, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 48 m/min, rapid traverse Z-axis: 32 m/min, feed rate X-axis: 20 m/min, feed rate Y-axis: 20 m/min, feed rate Z-axis: 20 m/min, workpiece weight (max.): 6 kg, table load: 500 kg, spindle speed (max.): 12,000 rpm, YCM vertical machining center model NXV-1020A

Fanuc control MXP-300FB+

Screen size 15"

12,000 revolutions

30 tools

20 bar internal cooling

Hinged belt chip conveyor

Spindle oil cooler

Oil separator

Steep taper 40 - DIN-69871A or BBT-40

Machine-side cable preparation for 4th axis connection

Demonstration machine at a special price

Cpjderfdckepfx Abusu

Sale only possible in Germany and Austria

Trust Seal

Dealers certified through Machineseeker

Listing

Almelo

Almelo

738 km

Laser cutting machine

DMA Machinery BVDMA-A1530 Fiber Laser NEW

Call

Condition: new, functionality: fully functional, Year of construction: 2026, control type: CNC control, degree of automation: automatic, actuation type: electric, laser type: fiber laser, laser source manufacturer: BOCHI, laser power: 6,000 W, sheet thickness (max.): 15 mm, warranty duration: 24 months, Equipment: CE marking, centralized greasing system, cooling unit, documentation/manual, dust extraction, emergency stop, fume extraction, safety light barrier, FREE> Installation, commissioning, and training service

FREE> Lifetime 24/7 online after-sales engineering support

Blazing Fast & Razor Sharp: CNC Fiber Lasers

Cut steel, stainless steel, and aluminum with unparalleled speed and precision – so clean that no post-processing is required.

With Danmar Machines' CNC Fiber Laser cutting machines, elevate your metalworking to the next level!

🔥 Lightning-fast production speed

🔥 Extremely low energy and maintenance costs

🔥 Perfect cuts and engravings down to the smallest detail

🔥 Power up to 6kW and flexible working areas

More output, lower costs, higher quality.

Best of all? Financial leasing available on exceptionally favorable terms!

Ready to leave your competition behind?

Request a quote now.

Specifications:

Power support: 3kW–12kW

Working area: 1530×3050mm

Type: Single enclosed working table

Table pull method: Fully automatic; entire working table can be extended

Table loading capacity: 900kg

Max acceleration: 1.0G

Maximum linkage speed: 120m/min

Machine dimensions: 4649×2260×1950mm

4649×4000mm (with table extended)

Machine weight: 3600kg

Machine type: Single Enclosed Working Table

Laser generator: MAX

Cutting system + cutting head: Model-dependent

Bochu FSCUT2000E + Boci BLT310 (1.5–4kW);

Bochu FSCUT4000E + Boci BLT421S (6kW);

Bochu FSCUT6000 + BLT442 (12kW);

Servo motor: Veichi Bus High-Speed

Cpedpsx Srnkofx Abuju

Reducer: High-quality Chinese manufacture

Water chiller: S&A / Hanli

Zoned dust extraction as standard

Exhaust fan included as standard

Power supply: 3-phase, 380V, 50Hz

FiberLasers:

Fairly priced for professionals who can manage their own setup.

Pay for steel, not service. Our CNC machines are for the resourceful, self-sufficient business owner.

Focus on functionality: Your machine, your management, our lowest price.

Opt for self-installation and save tens of thousands of euros on your new CNC machine.

Experience the power of CNC automation without the overhead costs. For technically skilled professionals.

24-Month Warranty:

· Parts delivery: If a malfunction occurs within 12 months, parts are provided free of charge after diagnosis (photo/video required).

· Labor not included: Replacement of parts to be performed by you or outsourced at your discretion.

· Designed for low maintenance

· Digital setup: Direct online service via app or TeamViewer, often eliminating the need for technician visits—saving time and costs

· Online service: 24/7

Digital Support as an Alternative

· Video guides: clips for calibrating or replacing components

· Exploded view diagrams: Instantly identify the exact replacement part

Focus on functionality: Your machine, your management, our lowest price.

You pay only: machine, travel costs, hotel, and meals!

The Best Solution 2026

Listing

Germany

Germany

1,148 km

Citizen Miyano BNE-51MSY, year 2018, internal number 231432

Citizen MachineryBNE-51 MSY

Call

Condition: used, Year of construction: 2018, machine/vehicle number: IntNr231432, CNC short turning machine – Citizen Miyano BNE-51MSY

Year of manufacture: 2018

Condition: Very good, fully operational

Cpodex Tg Sgjpfx Abueu

Availability: At short notice

Brief description

For sale is a Citizen Miyano BNE-51MSY CNC short turning lathe in MSY configuration featuring main and counter spindles, as well as a Y-axis. This machine is ideal for precise and cost-effective complete machining of complex turned and milled parts in series production.

Equipment / Highlights

- Fixed headstock (short turning)

- Main spindle + counter spindle

- Y-axis

- 2 tool turrets, each with 12 stations

- Driven tools

- Simultaneous machining capability

- High rigidity and process reliability

Technical data

- Max. bar capacity: Ø 51 mm

- Max. turning diameter: approx. 165 mm

- Max. turning length: approx. 380 mm

- Main spindle speed: up to approx. 5,000 rpm

- Counter spindle speed: up to approx. 5,000 rpm

- Control: Mitsubishi MELDAS

- Machine weight: approx. 8,000 kg

The machine is fully functional, both electrically and mechanically.

Complete technical documentation available.

The machine can be inspected under power by prior appointment.

Subject to technical changes, errors, and prior sale!

Listing

Wysoka

Wysoka

1,350 km

Double wide belt sander

Qindao Haohailong Woodworking MachineryBSG2613C

Call

Condition: excellent (used), Year of construction: 2019, Double-sided grinder

Production date: 07.2019

New not used.

1) Net weight: 15000 kg

2) Dimensions: 2200 x 3100 x 3050 mm

3) Higher grinding speed

Cjdpfot Dmmcsx Abuopu

4) High precision

Technical specifications

1) Grinding width (max): 1300 mm

2) Grinding thickness: 5-150 mm

3) Grinding length:> 700 mm

4) Abrasive belt speed: 25 m/s

5) Abrasive belt dimension: 1350 x 2800 mm

6) Total motor power: 163.25 kW

7) Grinding head motor: 75 kW x 2

8) Motor for feeding: 11KW

9) Lift motor: 0.75 kW

10) Brush motor: 0.75 kW x 2

11) Feeding speed: 10-30 M/min

12) Power supply: 380 V 50 Hz

13) Working pressure: 0.6-0.8 MPa

14) Extraction capacity: 24000m³/h

a. Thickness of sanding boards in large range: 5-150mm.

b. Machining plate thicknesses greater than 25mm with good quality.

c. The upper and lower conveyor pressure roller adopts double power transmission, so that the transmission efficiency is increased and smooth operation is maintained. It can ensure grinding with high accuracy and good surface quality.

d. To meet the needs of different plate processing, they used variable frequency and adjustable speed system and variable speed motor for conveying.

e. Siemens electrical parts were selected as the main parts with long service life.

Listing

Almelo

Almelo

738 km

Machining center

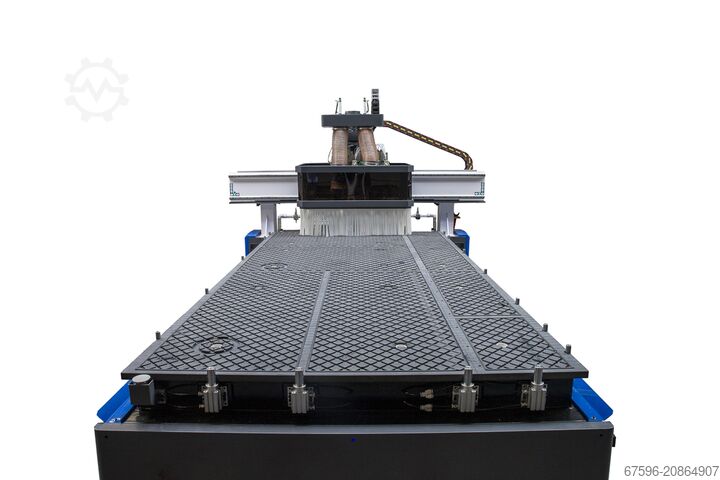

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Call

Condition: new, Year of construction: 2026, functionality: fully functional, travel distance X-axis: 2,600 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 200 mm, rapid traverse X-axis: 40 m/min, rapid traverse Y-axis: 40 m/min, rapid traverse Z-axis: 15 m/min, workpiece height (max.): 350 mm, total length: 3,500 mm, total width: 2,100 mm, rotational speed (min.): 1,000 rpm, rotational speed (max.): 24,000 rpm, overall weight: 2,460 kg, input voltage: 400 V, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, CNC Nesting Machine

The EXPRESS-ROUTER CNC milling machine is the new customized machining center for those who demand precision and reliability. Designed and assembled in the Netherlands according to the strictest European standards. This machine is built for small and medium-sized businesses.

With a robust welded steel chassis, servo drive, automatic tool changer, and smart software integration, this is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Suitable for processing: wood, plastic, aluminum, acrylic, foam, plastic, …etc

- Unlimited possibilities

- No licenses required

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Fairly priced, for the skilled professional who can do it themselves.

Pay for steel, not for service. Our CNCs for the smart, self-reliant entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Cjdpfsx R D Rnox Abuopu

Choose to do it yourself and save tens of thousands of euros on your new CNC machine.

The power of CNC without overhead costs. For professionals with technical knowledge.

We make it easier for you to find: "drilling machinery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Drilling Machinery (75,020)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Cnc Drilling Machine

- Core Drilling Machine

- Deep Drilling Machine

- Drill Grinder Machine

- Drill Grinding Machine

- Drill Machine

- Drill Mill Machine

- Drill Tap Machine

- Drilling And Milling Machine

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month