Used Sawmill Alignment for sale (1,407)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Mikkeli

Mikkeli

1,892 km

Complete sawmill (stationary)

Heinola&Vislanda sawline

Call

Condition: reconditioned (used), functionality: fully functional, A chipper canter/4-band saw/rotary gang saw line with one edger is available for sale. All the mechnical parts will be checked by our professional team before delivery to a potential customer. Worldwide transportation can be arranged.

Nedpfx Ahoxaztvj Uelk

Listing

Debrecen

Debrecen

1,933 km

Complete sawmill (stationary)

Wood-MizerSLP2

Call

Condition: good (used), functionality: fully functional, Used, but fully operational complete line. The video shows the exact machine I am selling. New price starts at 337,605 USD without the upgrades. Please contact me for more details or pictures/videos.

Njdpfjvn Ei Usx Ah Uolk

Auction

Auction ended

Județul Iași

Județul Iași

2,262 km

Complete sawmill (stationary)

PrimultiniSägewerk

Condition: ready for operation (used), functionality: fully functional, workpiece length (max.): 7,500 mm, workpiece diameter (max.): 1,500 mm, No minimum price – guaranteed sale to the highest bidder!

Auction of a complete sawmill including sharpening workshop!

TECHNICAL DETAILS

Max. log diameter: 1.5 m

Max. log length: 7.5 m

Automatic separator: RG SX

Resaw: 1,300 RG

Trimmer: NO/5 single-blade

EQUIPMENT

Primultini model 460 sharpening machine for bandsaw blades

Primultini bandsaw blade beveling machine

Vollmer sharpening machine

Bandsaw blade end-welding device

Nedpfx Ahoxgg Sks Uolk

Additional sharpening machine

Many saws

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Grevesmühlen

Grevesmühlen

954 km

LBL Brenta canters for sawmills

Call

Year of construction: 2008, condition: excellent (used), LBL Brenta Canter CT 700

Max cutting depth = 150mm.

Max cutting height = 650mm

Njdpfsd Imuzex Ah Uelk

9 knife

Head and main piece of cast iron

Free Middle plate, overheating protection

Free space = 800 mm

Fast, precise positioning by brushless motor with additional role for forward and reverse cutting

Listing

Malax

Malax

1,639 km

Log cross conveyor for sawmills

RistikuljetinRundholzquerförderer 8.0

Call

Condition: good (used), Year of construction: 1985, functionality: fully functional, Heavy-duty log cross conveyor

( was behind a debarking line )

year of construction approx. 1985

4 conveyor lines, motorized

length approx. 8m

width 4,35m

Height approx. 1.8m

Nsdpfx Aeuthh Hoh Ujlk

( will be delivered disassembled )

in good condition

Discover more used machines

Listing

Wakefield

Wakefield

228 km

Slitting for business & playing cards

Rollem36” Jetslit + 30” Rollaway+ AutoCollator

Call

Condition: excellent (used), Year of construction: 2017, Ref: 11039 . 2017 Rollem 36” Jetslit + 30” Rollaway and Cassette AutoCollator Delivery

High volume print finishing system to maximizes finishing productivity for large volume producers

For greeting cards, photo books, direct mail, postcards, invoices, business cards, game cards and much more.

Features:

This flexible system takes full press sheets and converts them to finished products in one step, eliminating the need for guillotine cutting, excess manpower and paper movement.

100% accuracy of finished products is a key feature of the Jetslit.

Performs multiple print finishing steps with one system

Nljdpfx Ahoxyxttj Uek

Bi-directional slitting, cutting, creasing and perforating in one machine

Ideal for high volume production

Multiple-up layouts maximize press sheet

Decreases excess labour costs

Eliminates touch points and paper movement

Fully integrates with press via DFA communication system

Accepts sheets in-line from press or operates in a stand-alone near-line configuration

Process:

The system takes full printed sheets with multiple images and converts each sheet in two directions, as shown below:

1. Full sheets are fed into the JetSlit registration guide for perfect alignment.

2. The sheets are completely slit on the extreme edges and timed slit in-between with Rollem's patented strike-slit feature.

3. The sheets are turned 90 degrees and re-registered.

4. Final slits are made, removing the notched portions and leaving the final pieces.

Specification:

Speed: Up to 6,000 cut product sheets per hour

Format: Up to 36’’ (915mm)

Listing

London

London

492 km

Edgebander

OTTTOPEDGE DUO-MELT 80mm

Condition: reconditioned (used), Year of construction: 2014, functionality: fully functional, workpiece height (max.): 80 mm, edge thickness (max.): 15 mm, power of the milling unit: 3,000 W, overall weight: 7,000 kg, compressed air connection: 6 bar, height adjustment type: electric, space requirement length: 10,500 mm, year of last overhaul: 2023, Fully refurbished Topedge Duo-melt, year 2014

2 x 3Kw each Pre-milling motors

80 mm panel thickness

1 x Synchroflex top driven belt system

2 x Glue heads and tanks, Duo Melt system (For instant glue

colour changes)

Njdpfsx Nbprex Ah Uslk

1 x rough trim station

1 x Bevel fine trim (can also be used for fine finishing wood in

“flat” setting - adjustable angle

1 x Radius trimming machine

1 x AKF station

1 x 4 position per side AZK4 radius scraper

1 x Flat scraper

1 x Cleaning spray, front, middle and back - LCM

1 x Buffing station

2 x free spaces

Infeed fence alignment for narrow panels

Nesting package

LCM iRelease cleaning system

BrushTec ES - not included

Listing

Wijchen

Wijchen

724 km

Car transporter

Mercedes-BenzAtego 816

Call

Condition: good (used), mileage: 363,076 km, power: 118 kW (160.44 HP), fuel type: diesel, axle configuration: 4x2, fuel: diesel, color: white, driver cabin: day cab, gearing type: automatic, emission class: euro6, suspension: other, Year of construction: 2016, Steering wheel placement: Left

Front axle: Suspension: parabolic suspension

Rear axle: Suspension: air suspension

Empty weight: 4.803 kg

Carrying capacity: 2.687 kg

GVW: 7.490 kg

Nodex H Slrepfx Ah Uslk

Technical condition: good

Visual appearance: good

Please contact Vink Machinery for more information

Mercedes Atego 816

* Top condition!

* Extra set of ramps for low vehicles

* Recently inspected and aligned by the dealer

* Winch

* Euro 6

Listing

Wellingborough

Wellingborough

385 km

CNC HEAVY DUTY PLASMA CUTTING MACHINE

VOORTMANV304

Call

Year of construction: 2013, condition: good (used), Plasma cutting and extraction table, dimensions 2.500 x 6.000 mm.

Gantry bridge.

Carriage with servo-drives (to position the gantry bridge in X-direction).

Machine track, length 8 m.

HEB450 profiles for the foundation of the machine track, 8 m.

Plasma cutting unit Hypertherm HPR 400XD, 1 pcs.

Plasma bevel cutting unit, including automatic height control system.

Fume extraction unit Filtercube 4H for plasma cutting unit.

Oxy-fuel cutting torch, 3 pcs.

Automatic height control system IHT M4000 CAP for oxy-fuel cutting unit, 3 pcs.

Torch suspension for oxy-fuel torch (motor driven).

Nsdjtp Dhpopfx Ah Ujlk

Torch suspension Single Drive for oxy-fuel torch, 2 pcs (automatic torch positioning).

Laser pointer (to align and position the torch).

Computer control system (consisting of an industrial PC and a control panel).

Control software 'VACAM Machine Edition' (including VaCad and VaNest software and online support).

Automatic nesting software Sigmanest "Powerpack" (including 3 days of training for max. 3 persons at Voortman Holland (excluding travel costs and board and lodging) and 1 day online-support).

Emergency stop with stop cord.

Year of build: 2013.

Listing

Deinze

Deinze

675 km

Turning gears - Positioners - Welding dericks & -pinchtables

Esab-Pemawelding rotator 450 ton

Call

Condition: ready for operation (used), self aligning set of welding rotators

one driven unit

one non-driven unit

max load capacity: 300 ton

max rolling capacity: 450 ton

speed range: 60 1200 mm/min

min diameter of workpiece: 1000 mm

max diameter of workpiece: 7800 mm

spare wheels included

Max weight on both supports: 450 ton

Number of wheels: 24 wheels

Dia x width wheels: dia 580 x 140 mm

Njdpfx Asx Enhysh Uolk

Coating material on wheels: steel

Listing

Germany

Germany

1,034 km

Wood Mill

EXCITECHMCA-03H-01-1225

Call

Year of construction: 2018, condition: ready for operation (used), This EXCITECH MCA-03H-01-1225 was manufactured in 2018. It features a refrigeration capacity of 300 W, a power supply of 50 Hz, and an input power of 250 W. Rated current stands at 1.1 A with a filling amount of 180 g. Consider the opportunity to buy this EXCITECH MCA-03H-01-1225 wood mill. Contact us for more information.

Nedpfjx Nr Ixsx Ah Uelk

Application Types

Milling (Wood)

Listing

Wakefield

Wakefield

228 km

Slitting for business & playing cards

Rollem36” Jetslit + 30” Rollaway and Cassette

Call

Condition: excellent (used), Year of construction: 2017, Ref: 11038 . 2017 Rollem 36” Jetslit + 30” Rollaway and Cassette Delivery

High volume print finishing system to maximizes finishing productivity for large volume producers

For greeting cards, photo books, direct mail, postcards, invoices, business cards, game cards and much more.

Features:

This flexible system takes full press sheets and converts them to finished products in one step, eliminating the need for guillotine cutting, excess manpower and paper movement.

100% accuracy of finished products is a key feature of the Jetslit.

Performs multiple print finishing steps with one system

Bi-directional slitting, cutting, creasing and perforating in one machine

Ideal for high volume production

Multiple-up layouts maximize press sheet

Decreases excess labour costs

Eliminates touch points and paper movement

Fully integrates with press via DFA communication system

Accepts sheets in-line from press or operates in a stand-alone near-line configuration

Process:

The system takes full printed sheets with multiple images and converts each sheet in two directions, as shown below:

Nsdpfxjxyxr No Ah Uslk

1. Full sheets are fed into the JetSlit registration guide for perfect alignment.

2. The sheets are completely slit on the extreme edges and timed slit in-between with Rollem's patented strike-slit feature.

3. The sheets are turned 90 degrees and re-registered.

4. Final slits are made, removing the notched portions and leaving the final pieces.

Specification:

Speed: Up to 6,000 cut product sheets per hour

Format: Up to 36’’ (915mm)

Listing

Finnentrop

Finnentrop

891 km

Heidenhain iTNC 530, internal cooling, glass scales

PinnacleLV 116

Call

Condition: ready for operation (used), Year of construction: 2012, operating hours: 10,799 h, functionality: fully functional, machine/vehicle number: 8P31127C4, travel distance X-axis: 1,145 mm, travel distance Y-axis: 615 mm, travel distance Z-axis: 615 mm, controller manufacturer: Heidenhain, controller model: iTNC 530, rotational speed (max.): 12,000 rpm, overall weight: 6,500 kg, spindle speed (max.): 12,000 rpm, operating hours of spindle: 10,799 h, coolant supply: 20 bar, spindle nose: SK-40 DIN69871, number of spindles: 1, Equipment: chip conveyor, rotational speed infinitely variable, Pinnacle LV 116

Control: Heidenhain iTNC 530

Travel X: 1145 mm

Travel Y: 615 mm

Travel Z: 615 mm

Table size: 1200 x 600 mm

Tool holder: SK-40 DIN69871

Tool positions: 30

Max. spindle speed: 12,000 rpm

Nledpfstphbzsx Ah Usk

Operating hours: 11,658 h (as of 20.06.2025, machine remains in use)

Rapid traverse: 30 m/min

Weight: 6.5 t

Equipment:

- Through-spindle coolant 20 bar with belt filter unit

- Mobile electronic handwheel

- Heidenhain iTNC 530

Payment terms: 100% prior to dismantling and loading

The spring disc pack for tool pull-in force was renewed in August 2024.

We are a toolmaking company reducing our production capacity.

The machine is powered up and in ongoing use.

Inspection and test operation are possible.

The machine can be handed over at short notice by arrangement.

In the event of purchase, we can additionally offer:

- Training of your personnel

- Cleaning of the machine

- Installation of transport locks

- Loading onto the truck

- Transport with our own truck

- Unloading at your site

- Placement of the machine at your premises

- Alignment of the machine

- Connection and commissioning

Listing

Liverpool

Liverpool

216 km

Automatic Crosscut Saw

CursalTRSI 8000

Call

Condition: used, Year of construction: 2018, Cursal TRSI 8000 AP Automatic Crosscut Saw With Integrated Pusher - 2018 CE

Durable and versatile automatic crosscut saw with exceptional speed and accuracy.

Impressive speed and accuracy

CNC programmable sequential cutting capabilities

Nledpfx Ahexxvqte Ujk

Optional loading and unloading

Specification :

6000 mm In feed capacity, push feed crosscut Saw

Single-block structure: the frame made of welded - worked steel

Pneumatic side-aligner installed before of the blade

Pneumatic blade-press with mobile casing: stroke 150 mm.

Breaking press-wheels with horizontal axis installed after blade

Cutting height on the guide: 120 mm.

Width of the boards: min. 40 - max. 250 (300) mm

Automatic cutting control managed by the computer

Vertical alternated blade movement: pneumatic system with totally controlled stroke

Saw blade HM steel with alternate teeth Ø 500 mm, hole Ø 35 mm - Z=120

Blade motor HP 7,5 with automatic brake

Cutting time: adjustable from 0.3 to 2 seconds

CNC unloading belt with 2 programmable ejectors

2018 CE

Listing

Möglingen

Möglingen

1,120 km

Laser cutting machine

TRUMPFTruLaser Cell 3000 (L34) 3000 Watt

Call

Condition: good (used), functionality: fully functional, Year of construction: 2013, control type: CNC control, laser type: fiber laser, laser power: 3,000 W, CNC Laser Cutting System TruLaser Cell 3000 (L34) fiber

X x Y x Z working area (max, mm): 800 x 600 x 400

Control: TRUMPF HMI based on Sinumerik 840 D solution line

Laser power: 3,000 watts

Operating hours: 31,875 h

Laser on time: 3,286 h

Machine

High-dynamic and precise CNC laser machine

Machine body made from mineral casting

Axis system in cantilever design

Axis travel range: 800 x 600 x 400 mm

X-Y axes with linear direct drives

Absolute measuring system with glass scales

Z-axis with linear guide and ball screw drive

Panel PC for process monitoring

Integrated electrical cabinet and water/air machine chiller

Protective enclosure active

Active, sensor-monitored safety system, laser protection class 1

for laser power > 1000 - 8000 W

- automatic lift door with personnel protection

- double-walled side protection doors

- safety window

Technology package CutLine Professional

Process adapter for cutting with gas supply

FocusLine

Focus diameter adjustment

ControlLine

Digital camera system for process monitoring

Cutting optics adjustment device

For aligning the cutting optics with the laser beam

Technology package WeldLine

- Welding functionality with FocusLine Professional

- Welding gas supply for 3 gases

Process adapter Welding f150 Crossjet

Swivel axis focusing optics

Torque axis for 3D processing with direct measuring system

Swivel angle optics ± 135°

Clamping frame with set of clamping bridges

Modular system for fixture mounting

Nedpfexur Iaox Ah Ujlk

Height adjustable 640-940 mm

1x clamping bridge each short/long

2D cutting table 800 x 600 mm

For cutting sheet metal up to 6 mm

Rotary axis C180 for machining rotationally symmetrical parts

3-jaw chuck d=125

Status lights

Multi-touch unit

MF-L1000 dust extractor

External dust extraction system with a volume flow of 1,000 m³/h

Filter system with automatic cleaning

Power supply and control via the laser machine

Function control MF-L1000

Reactive safety device for fire detection and suppression

TruDisk 3001

TruDisk 3001 laser unit (4 C)

Diode-pumped disk laser with beam quality of 4 mm mrad

Laser power at workpiece: 3,000 W

Consists of:

- Laser with 1 cavity

- Integrated laser power supply and real-time capable controller for evaluation and visualization of operating data

- Fast laser power regulation

- TruControl 1000 controller:

- CPU with real-time operating system

- 2x USB interface

- 24x digital I/O interface, configurable as real-time interfaces

- Expandable with fieldbus interfaces

- Storage capability for 199 laser programs

- Intelligent water management (CLK) with water-to-water heat exchanger and operating status display on control panel

- Safety monitoring according to laser protection class 1, incl. central safety interlock

- Housing for max. 4 laser outputs

- Protection class: IP54

Control panel OP84

- Removable operating panel for laser unit control

- 8.4" touchscreen with rotary push knob

- Buttons: Emergency stop, power on/off

Beam guidance consisting of:

- Optical assembly for 1 laser light cable D

- Central safety interlock

- Switching time 50 ms

- Output 1 with 100% with safety interlock

- Pilot laser per laser light cable output incl. electrical control

Chiller unit

Listing

Nattheim

Nattheim

1,192 km

Edge banding machine with joining

StefaniSolution XD

Call

Condition: used, Year of construction: 2016, Industrial automatic edge bander SOLUTION XD MAIN FEATURES "E-TOUCH" CONTROL WITH AUTOMATIC PROGRAMMING: ONE "TOUCH" IS ENOUGH TO OPERATE THE MACHINE. STANDARD PRESSURE DEVICE WITH DRIVE BELT FOR OPTIMAL PANEL GUIDANCE. BANDING OF ROLLED MATERIAL, STRIPED EDGES, AND SOLID WOOD EDGES. GENERAL FEATURES: Single-sided edge bander in left-hand design for gluing rolled materials and strip edges using all conventional hot melt adhesives. The base frame consists of a sturdy, highly rigid steel welded stand, which provides optimal support for the processing units. The upper pressure consists of a thick-walled steel profile and a double trapezoidal drive belt that is automatically positioned to the panel thickness. Height adjustment with display on the top pressure and on the operator interface. Manual workpiece feeding system with a generously dimensioned work line and enlarged support surface facilitates the feeding of large workpieces. Adjustable infeed ruler for two positions with automatic selection for processing with or without pre-milling. Working units are attached to the pressure beam and mechanically connected to ensure automatic adjustment when changing panel thickness. Lower working units are attached to the machine frame or to the longitudinal beam for precise reference in relation to the panel. All high-frequency motors are powered by frequency converters (inverters). The unit is equipped with its own inverter for optimal flexibility and improved production times. The cleaning hood for all units positioned after the gluing unit is equipped with polycarbonate windows to ensure a good overview of the units during processing. The interior lighting of the cleaning hood is lined with sound-absorbing material for lower noise emissions during processing. The spacers on the infeed ruler allow the machine to be fed at the correct distance. The distance is automatically adjusted to the selected feed speed. The exhaust nozzles are arranged on the pivoting control panel, positioned in the infeed area, and are adjustable for ergonomic electrical installation in compliance with current regulations. The electrical component is housed in a metal casing, fixed to the machine frame and equipped with doors for easy access in case of any problems. The standard voltage is 400 V EU 50 Hz (with neutral). The material is fed by a feed chain with 80 mm wide chain plates made of rubberized nylon for optimal guidance and a high chain tension. The chain slides on two guides made of hardened and ground steel, one round and one flat, to ensure linear feed and prevent lateral misalignment. Automatic chain lubrication. The amount of lubricating oil is controlled by the control system according to the panels being processed. The storage roller conveyor is external and positioned along the entire length of the machine; it consists of an opening system that can be extended up to 650 mm (for panels with a maximum width of 1200 mm). E-TOUCHPC control system for quick and easy execution of the main functions which includes:– Editing of programs in Just in Time mode– Possibility of management via parts lists– Possibility of management by

Nodpsxy Tm Isfx Ah Uolk

Listing

Ireland

Ireland

501 km

Laser cutting machine

BLM AdigeLT712D

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2006, operating hours: 22,500 h, control type: CNC control, degree of automation: automatic, controller manufacturer: Siemens, controller model: Sinumerik 840D, laser type: CO₂ laser, laser source manufacturer: Rofin, laser source model: Sinar series DC K 2.5kW Laser source, laser power: 2,500 W, pipe diameter (max.): 140 mm, pipe length (max.): 8,500 mm, table length: 8,500 mm, working length: 8,500 mm, travel distance X-axis: 8,500 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 95 mm, workpiece weight (max.): 4,000 kg, type of input current: three-phase, compressed air connection: 6 bar, overall weight: 10,000 kg, total length: 17,536 mm, total width: 4,604 mm, total height: 2,237 mm, Equipment: CE marking, 2006 BLM Adige LT712D Tube Laser

Machine Manufacturer: BLM Adige

Machine Model: LT712D

Laser: Rofin Sinar series DC K 2.5kW Laser source.

Year: 2006

Infeed: 8,500mm

Outfeed: 4,500mm

Condition: Very Good

Hours: 22,500hrs

Available February or March 2026

This 2006 BLM Adige LT712D is a high-performance CNC tube laser cutting system designed for precision processing of mild steel, stainless steel, and aluminium tube profiles. Known for its reliability and accuracy, the LT712D is one of the most capable mid-range tube laser platforms, delivering clean, repeatable cuts with full automation from loading to unloading.

With only 22,500 operating hours, this machine is in very good condition and has been maintained to OEM standards. It offers exceptional value for fabrication companies, structural steel specialists, subcontractors and manufacturers looking for a high-precision tube laser with proven durability.

⭐ Key Machine Specifications

Working Capacity & Tube Dimensions

Minimum tube length: 3,200 mm

Maximum tube length: 8,500 mm

Round tube diameter: Ø12 – Ø140 mm

Square tube: 12 – 120 mm side dimension

Rectangular / flat-oval: up to 170 mm circumscribed circle, min. side 10 mm, max. side 140–150 mm

Max bar weight:

Linear: 15 kg/m

Total (L=8500 loader): 130 kg

Machine Dimensions & Weight

System footprint (L=6500 version):

17,536 × 4,604 × 2,237 mm (complete system)

13,595 × 4,604 × 2,237 mm (machine body)

Machine weight: approx.10000 daN (= 10 tonnes)

Laser, CNC & Automation

CNC Control: Siemens Sinumerik 840D

Laser Source: Rofin DC-K Series

Cutting Head: Autofocus head with capacitance sensor + collision protection

Working Axes:

X travel: 8,500 mm

Y travel: 400 mm

Z travel: 95 mm

A-axis: spindle rotation

A1-axis: steady rest rotation

V-axis: Bar support on the machining line (90mm)

W-axis: Unload piece support (85mm)

X1-axis: steady rest travel (610 mm)

Loader & Unloader

Automatic bundle loader with alignment, measuring & singularisation system

Scimitar-style tube transfer system for smooth transition to machining line

CNC-controlled tube support system with 5 active support groups

Intelligent cut-piece unloader with conveyor belt for short parts up to 300 mm

Extraction & Cooling Systems

Fume extraction: 2,000 m³/hr with high-efficiency filtration system

Cooling: MTA TAE 121 chiller, 260-litre cooling circuit reserve

Hydraulics: 25-litre tank, 25 L/min pump, 70 bar system pressure

Nljdpfx Ahox Ddags Uek

🟢 Condition & Availability

Year: 2006

Hours: 22,500 (very low for a tube laser)

Condition: Very Good – well maintained, clean, fully operational

Availability: February–March 2026

Includes: Full machine, loader, unloader, chiller, documentation supplied.

Why the LT712D Is a Top Choice

The BLM Adige LT series is widely regarded as the benchmark for tube laser systems. This LT712D stands out thanks to:

✔ Exceptional tube cutting accuracy

✔ Reliable automatic loading & unloading

✔ High-quality Rofin laser source

✔ Full CNC control of every movement

✔ Capability to handle a wide range of profiles

✔ Heavy-duty industrial build quality (10 tonnes of rigidity)

For fabricators looking to increase productivity, quality, and automation, the LT712D is an ideal investment.

Notes: *Specifications are given in good faith but not guaranteed*

Clickout

Fulda

Fulda

1,028 km

Hexagonal bead winding machine (1)

Gadsden, Davis, ABB

Condition: used, Year of construction: 2001, functionality: fully functional, 1. Bead Winder – Gadsden

• Enclosed winding machines with yellow safety covers

• Multiple rotating winding discs and wire guides

• Integrated control panels with push buttons, indicator lights, and emergency stop switches

• Mechanical winding stations mounted on heavy steel frames

• Visible wire feeding pathways and guiding elements

2. Bead Extruder – Davis

• Extruder assemblies with screw and barrel sections

• Downstream guiding and forming components

• Control cabinets and local operator panels

• Auxiliary equipment including heating/control units and material conveying components

• Safety devices integrated into the system

3. Carousel and Loader Robots

• Articulated industrial robot arm from ABB (orange)

• Rotary carousel stations with multiple indexed holders

• Safety fences enclosing robot work areas

• Integrated control panels next to the robot cell

4. Coil Winding Equipment

Nledpfx Ajx Itzqjh Usk

• Multiple wire pay-off and take-up reels aligned in series

• Tension and guide rollers

• Winding stations mounted on steel frames

• Clearly separated parallel winding positions

Listing

Wasbek

Wasbek

869 km

Guillotine Shear - KMT M 1303

KnuthKMT M 1303 mit Standardmessersatz

Call

Condition: as good as new (ex-display), The KMT M 1303 Guillotine Shear from KNUTH is engineered for precise and reliable cutting, making it an essential tool in the Sheet Metal Processing category. Featuring a robust solid steel construction, this modern plate shear is equipped with a powerful drive motor that allows for efficient operation. With its straight cutter angle, it minimizes workpiece torsion during cutting while providing a high-precision manually adjustable back gauge for exact positioning. The dual-sided reversible upper cutters and four-edge lower cutters enhance the lifespan and versatility of the machine. Ergonomically designed, the bright LED illumination of the cut line and a clear view from above ensure accurate alignment. A mobile foot switch offers operators the flexibility to manage the workpiece safely, while essential features such as a cut counter and accessible lubrication points promote efficient maintenance. This reliable and powerful Guillotine Shear is perfect for your workshop needs—request a quote today to enhance your Sheet Metal Processing capabilities with the KMT M 1303.

Nodpfsww Uaasx Ah Uelk

Auction

Ends in

d

h

min

s

Auction ended

Bayern

Bayern

1,171 km

Indoor crane

KonecranesCXT40410040A36FCL0S

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2017, machine/vehicle number: 11690446, load capacity: 4,000 kg, lifting height: 6,530 mm, TECHNICAL DETAILS

Span: 9.9 m

Crane lifting capacity: 4,000 kg

Lifting height: 6.53 m

Lifting speed at full load: 3.2 m/min

Lifting speed at partial load: min. 3.0 m/min up to max. 7.5 m/min

Trolley travel speed: 20 m/min

Crane travel speed: 40 m/min

Nljdjx Nvpgopfx Ah Usk

MACHINE DETAILS

Weights

Trolley weight: 390 kg

Crane weight without trolley: 1,750 kg

Classification

Crane class: 3U4/Q2, EN 13001-1

Hoist mechanism group: 4.3 + 4.4 m / ISO M6

Crane girder mechanism group: 16 m / M5

Electrical data

Power supply: 400 / 48 V / 50 Hz

Rated output: 3.3 kW

EQUIPMENT

Radio control

Overload protection

Load spectrum memory

Pre- and end-limit switches for crane and trolley travel

Remote control type “Mini Joystick”

Spare transmitter

Storage cabinet

Spare battery

Charging station

Signal horn

Hook collision protection

Hook center-of-gravity alignment

Manual crane hook tracking

Safety conductor line incl. main disconnect switch and power supply

Clampable holding brackets

Riser cable (fixed installation) to be provided by customer

Listing

Möglingen

Möglingen

1,120 km

Punching laser machine

TRUMPFTruMatic 6000 (K05M) 2700 Watt FMC

Call

Condition: good (used), functionality: fully functional, Year of construction: 2013, laser power: 2,700 W, X working area max.: 2500 mm

Y working area max.: 1250 mm

Control system: Rexroth IndraMotion MTX (basic version)

Laser power: 2700 Watt

Standard Equipment

Machine

- Sturdy, easily accessible C-frame

- Coordinate guide system for high-precision machining

- Linear magazine with 23 tool stations and 2 clamps

- Maintenance-free three-phase drive motors

- Repositioning unit with programmable hold-down device

- Foot pedal for clamp closing

- Alignment pin (right inside)

- Ball tables

- 2 parts flaps 500 x 500 mm incl. sensor for parts ejection

- Two good parts containers

- NitroLine

- Focus Line

- FastLine

- FlyLine

- Slag cone detection

- Ejector cylinder for laser parts

TRUMPF Laser

- TruFlow 2000 laser with LensLine and optimized standby mode

- High-frequency excitation

- Cooling unit

- Laser control

- Enclosed beam guidance

- Fine filtration of compressed air for beam tube ventilation

Cutting Head

- Lens cutting head with 170 mm focal length

- Universal cutting head quick-change system UTI with bus connection

- ControlLine

Punching Station

- Electro-hydraulic punching head

- Rotatable mono-tool holder

- Tool length compensation

- Programmable hold-down device with manually adjustable holding force

- Stroke counter for punch and thread-forming

- Punch spray lubrication

- Punch slug extraction

- Measurement of fill level in punching console

- Level monitoring for thread-forming and tool lubrication

Control

- TRUMPF control based on Rexroth IndraMotion MTX

- Operating panel with 17" touch screen

- Integrated technology data

- Teleservice via internet

- Programmable cutting gas pressure

- Automatic shutdown incl. wake-up mode

- Program management

- Production scheduling

Data Transfer

- Network connection RJ45 and USB interface

Safety

- CE marking

- Two-beam light curtain

- Monitoring system for gas pressure, temperature, and cooling water

- Emergency stop

- Protection against stray radiation

- Compact extraction unit

+ Brush tables

+ Lowerable die

+ MultiTool function

+ Softpunch function

+ Marking function

+ Chip conveyor with tilting container

+ Roll technology functions: roll knurling, roll deburring, roll shearing, roll offsetting, roll bead forming, roll cutting

+ Die spray lubrication

+ Blow-off device for small parts

+ 1 pc. additional clamp

+ Smart Punch Monitoring (punch breakage monitoring)

+ Vibration-damped installation

+ Repositioning cylinder

+ Warping detection

+ Parts conveyor belt in punching area

+ Parts conveyor belt in laser area

+ GripMaster (2500x1250)

+ Scissor lift table

+ Scrap grid pallet

+ SheetMaster (2500x1250) (AK04)

+ Peeling system

+ Automatic clamp closing

+ HZP loading/unloading

Njdpfx Ahex Aq Axs Uslk

+ TwinCarts loading station with toothed belt drive

+ TwinCarts unloading station with toothed belt drive

Trust Seal

Dealers certified through Machineseeker

Listing

Nattheim

Nattheim

1,192 km

Edge banding machine

SCMOlimpic K 800

Call

Condition: used, Year of construction: 2012, Basic machine Olimpic K 800 "T-ERL" (47) 1 pc. BASIC EQUIPMENT: - Ribbed steel machine frame with tubular reinforcements for optimal work unit support - Pivoting control panel - Support roller conveyor with ball bushing guides along the entire machine length - Protective and sound-absorbing hood with separate doors between the gluing and finishing units - Extractor nozzles located on the sound-absorbing hood - Electrical system with lockable main switch - Emergency/stop buttons at the inlet and outlet - Inverter for electric spindles. PLATE FEED SYSTEM - Feed chain with rubber glide shoes, mounted on a 1 1/4-inch industrial chain with a high friction coefficient - The chain slides on two guides made of hardened and ground steel, one round and one flat, to guarantee straight feed and protect against lateral misalignment. --- Automatic central lubrication of the feed chain - The upper pressure beam is made of thick-walled steel construction. Complete with double rows of bearing rollers and protective device for the printing rollers - manual lifting of the printing unit with automatic working unit positioning when changing the plate thickness - mech. Digital display for checking the selected panel thickness. ORION 100 CONTROL SYSTEM. Control device complete with PLC, allows fast, easy, and error-free execution of custom processing programs (max. 60 programs). Manages the pneumatic positioning of the units, if present on the machine. (The control system does not include pneumatic positioning). - Alphanumeric keyboard and display - Function keys for quick control of the processing units - Ambient temperature range from 0 to +45° C. MAIN FUNCTIONS - Control of the processing units and automatic activation of the motors - Control and regulation of the glue pot temperature - Selection of longitudinal and transverse processing without program change - Simple and guided diagnostics for easy troubleshooting - Statistics on absolute data and individual processing: number of pieces, edge consumption, total chain feed distance - Unit of measurement selectable in mm or inches. Technical data OLIMPIC K800 T-ER L Edge thickness: 0.4 to 8 mm Max. gluing thickness of the roll edge: 3 mmFeed speed: 12/18 m/minWorking height: 8 to 60 mmMax. dimensions of the edge cut: 135 mm²Turntable diameter: 780 mmMax. oversize compared to the panel thickness: 4 (2+2) mmMin. panel width (with 210 mm min. length): 55 mmMin. panel length (with 100 mm min. width) - with strip or roll edges max. 3 mm: 140 mm - with solid wood edges: 200 mmMin. distance between consecutive panels at 11 (16) m/min: 750 (850) Standard equipment - Pre-milling unit in the infeed RT-E- Gluing station VC-800- Trimming unit KSEL- Flush trimming unit, tiltable RI/800- Rounding unit ROUND K- Scraper unit RAS-V- ½ free space for surface scraper- 1 S free space for surface scraper or Universal milling or buffing unit - 1 free space for air nozzle unit. European safety regulations (C.E. mark). 1 unit. Voltage 400 EU. 1 unit. Frequency 50 Hz. 1 unit. "Autoset" for ER2, T-ERS, and T-ERL models. 1 unit. Allows all necessary adjustments to be made from the control panel for each machining change. Includes: - time-controlled pressure unit - pneumatic and independent pivoting of the mitre saw blades (front/rear) - pneumatic remote adjustment for the RI/800 flush trimming unit.

Njdpfoxq Apgsx Ah Uslk

Listing

Essen

Essen

814 km

Low loader semitrailer

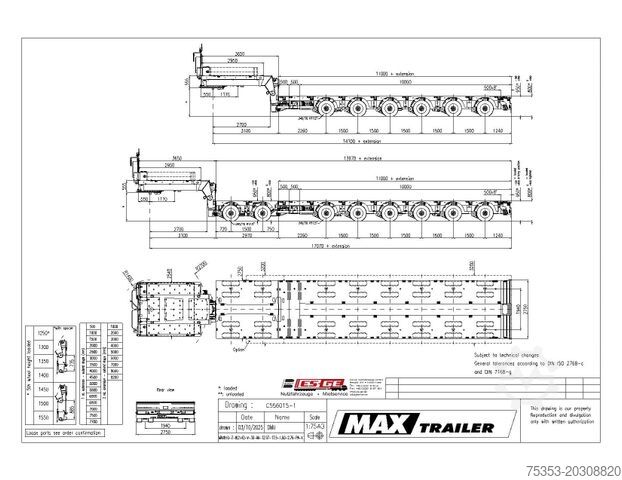

FAYMONVILLEMAX Trailer MAX810 Semi-Tieflader 2+6 PA-X

Call

Condition: new, maximum load weight: 96,590 kg, overall weight: 126,000 kg, axle configuration: > 3 axles, total width: 2,750 mm, Equipment: ABS, You can find our complete vehicle inventory, including vehicles available for immediate or short-term delivery, on our website.

Excerpt from the equipment specification. Full specification available upon request.

Gooseneck:

* Gooseneck hydraulically liftable/lowerable as well as detachable. Length approx. 3,650 mm

* 2 pairs of folding lashing rings to the outside (LC 5,000 daN)

* 2 pairs of lashing rings on the gooseneck (LC 10,600 daN)

* 1 pair of lashing rings in the middle section of the gooseneck (LC 10,600 daN)

* For tractor unit: 6x4 or 8x4

2-axle front bogie:

* Pin-eye coupling front and rear. Length: approx. 2,970 mm

* Chassis width: approx. 2,750 mm

* 1 pair of lashing rings (LC 10,000 daN) in the outer frame

* 2 pairs of lashing rings (LC 10,000 daN) on the central beam

Loading platform:

* 6-axle double telescopic loading platform with pin-eye coupling at the front and chamfering approx. 500 mm x 8° at the rear, length approx. 11,000 mm

* Technically extendable by: approx. 8,200 + 7,700 mm

* Axle spacing: approx. 1,500 mm

* 7 pairs of lashing rings along the central beam (LC 10,000 daN)

Pendulum axle 2-axle front bogie:

* PENDULUM AXLE, all axles hydro-mechanically forced steered

* Hose rupture valve on the axle compensation cylinder with automatic reset function

* Hydraulic cylinder with shut-off valves and safety pins for securing in the raised position

* Technical axle load: 13,740 kg each (30 km/h)

Nodpfxjxn E Iye Ah Uelk

* Hydraulic axle compensation

Pendulum axle 6-axle loading platform:

* PENDULUM AXLE, all axles hydro-mechanically forced steered

* Hose rupture valve on the axle compensation cylinder with automatic reset function

* Hydraulic cylinder with shut-off valves and safety pins for securing in the raised position

* Technical axle load: 13,740 kg each (30 km/h)

* Hydraulic axle compensation

Tyres:

* 24x brand of our choice (M+S) 245/70 R17.5 load index 143/141L (146/146F)

Paintwork:

* HRM metallisation of the entire vehicle chassis with ZINACOR 850 (85% zinc / 15% aluminium) to ensure maximum corrosion protection

* Final paintwork with 2 coats of 2K topcoat, single colour in RAL 3002 Carmine Red

* Rear section metallised and painted RAL 9010 (Pure White)

Options included:

* Truck hydraulic connection with flow controller (20 l/min), including support arm for supply lines, tractor unit tank must be at least 80 L

* with MAX Trailer coupling pieces, otherwise coupling pieces to be supplied free ex works by the customer

* 3.5 inch king pin

* Steel front wall, approx. 400 mm high

* Removable ALU side boards and rear wall on the gooseneck, approx. 400 mm high, anodised finish

* Socket for remote steering operation on the gooseneck with cable remote control and push buttons including single-wheel tracking alignment (without installation in the tractor unit)

* Control lever on the gooseneck protected by a foldable cover

* Illuminated gooseneck control area with on/off switch

* BEKA-MAX central lubrication system for a gooseneck with standard grease NLGI-2

* Hydraulic connections from gooseneck to lowbed with screw couplings

* BEKA-MAX central lubrication system for a 2-axle bogie with standard grease NLGI-2

* Stake pocket strips mounted transversely in the load floor for plug-in stakes approx. 100 x 50 mm

* Chassis surface finished with sand coating for anti-slip protection

* Hydraulic coupling pin

* BEKA-MAX central lubrication system for the loading platform with standard grease NLGI-2

* Surface of the loading platform finished with

Listing

Großbettlingen

Großbettlingen

1,152 km

Internal and surface grinding machine

TSCHUDIN HTG 610I

Call

Condition: refurbished (used), Year of construction: 2025, functionality: fully functional, center height: 150 mm, total length: 620 mm, Mechanics:

All wear parts of the machine are replaced, including the infeed spindle in the X-axis. All assemblies are restored to as-new condition. After the overhaul, the machine is comparable to a new machine.

Geometry:

The machine is completely dismantled down to the guides. Before the geometry of the individual tables and assemblies can be restored, both guides of the X and Z axes are scraped by hand and restored to as-new condition. After completion, the machine receives a measurement report in accordance with the manufacturer's specifications.

Painting:

Once the geometry of the machine has been restored, it is prepared for repainting. All housings, tables and the machine bed are stripped of old paint, cleaned and repainted.

Hydraulics:

The entire lubrication system, including the lubrication unit, is replaced. The hydraulic unit is also completely overhauled.

Conventional internal cylindrical grinding machine TSCHUDIN HTG 610I

Equipment of the machine:

Technical data:

Center height: 150 mm

Center width: 680 mm

Grinding length: 620 mm

Weight and space requirement of the machine:

2500kg // 2340x1445x1900 mm

Machine equipment (standard):

Njdpeurw Uyefx Ah Ujlk

1 pc. Workpiece headstock MK5

1 pc. Control panel

1 pc. Holder for internal grinding spindle

1 pc. Speed control unit for belt spindle (UJ50 / UJ80) FISCHER

1 pc. Hydraulic unit

Optional:

- Digital measuring system 2-axis

- Freely adjustable speed (1-800 rpm) incl. soft start (higher speeds are optionally possible after clarification of technical details)

- Separate low speed for part alignment

Listing

Schweiz

Schweiz

1,251 km

Band saw

CanaliML 1100 TWIN F.L. 30 H.S.

Call

Year of construction: 1981, condition: excellent (used), functionality: fully functional, Canali Resaw Bandsaw including Transport and Conveyor System

Resaw Bandsaw

Manufacturer: Canali KG Maschinenfabrik

Manufacturer Location: Speyer am Rhein, Germany

Machine Type: ML 1100 TWIN F.L. 30 H.S.

Year of Manufacture: 1981

Key Technical Data – Resaw Bandsaw

Machine Type: ML 1100

Design: Twin Bandsaw (Dual-configuration)

Cutting Type: Resaw bandsaw, diagonal cuts possible

Saw Blade Length:

max. 6,500 mm

min. 6,350 mm

Saw Blade Width:

max. 120 mm

min. 90 mm

Saw Blade Tensioning

Pneumatic saw blade tensioning

Configured according to manufacturer specifications depending on blade width and thickness

Operating Note:

The saw blade must be released at every machine standstill to prevent material fatigue and saw blade damage.

Transport and Conveyor System

Cross and longitudinal conveyors for automated infeed and outfeed of timber

Process-secure transfer to the saw unit

Removal of cut workpieces without backlog

Functional Description

Canali resaw bandsaw with two bandsaws in twin configuration

Suitable for parallel and flexible cutting processes

Nljdpfxox N D Rfo Ah Ujk

Control system for operation, monitoring, and process management

The machine unit is designed for continuous industrial operation and enables precise, reproducible resaw cuts in industrial applications.

We make it easier for you to find: "sawmill alignment"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sawmill Alignment (1,407)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month