Used Small Brewery for sale (3,889)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Fântânele

Fântânele

2,196 km

Brewery equipment

Call

Condition: excellent (used), functionality: fully functional, Brewiks 700L batch + whirlpool

2X 1000L fermentation tank

1300L fermentation tank

3X 600L fermentation tank

Hfsdov A Rcpspfx Aadjc

Water filter

Robix Roppi 600 mill

Chiller 26 KW + 600L stainless steel tank

CIP

Can also be purchased separately

Seller is a private individual

Listing

Turkey

Turkey

2,976 km

Concrete mixing plant / concrete plant

CONSTMACH Concrete Mixing Plant30M3/H Small Mobil Concrete Mixing Plant

Call

Condition: new, functionality: fully functional, power: 47 kW (63.90 HP), color: other, Year of construction: 2025, Equipment: cabin, CONSTMACH MOBICOM 30 Mobile Concrete Plant is a concrete production facility designed specifically for projects seeking high mobility and low operating costs, standing out with its compact design. This system, manufactured to fit into a single 40 ft container, requires minimal setup on-site and eliminates the need for a mobile crane during assembly. The MOBICOM 30 can be easily transported between construction sites by truck and continues to operate in the same position during production. The mixer is positioned close to ground level, allowing the produced concrete to be conveniently transferred to the transmixer via a conveyor belt.

This compact plant carries all concrete production components except the cement silo. If cement is supplied in bags, production can be easily carried out using the blasting bunker and cement transfer system on the chassis. If desired, MOBICOM 30 can also be used with an external cement silo. It can be equipped with single-shaft, pan, or planetary mixer options according to production needs. The optimized aggregate bunker's low feed height allows the loader bucket to fill the aggregate directly from ground level. SIEMENS and SCHNEIDER branded electronic components, high-quality PLC, and user-friendly automation system make it easy to control all plant operations.

MOBICOM 30 - Mobile Concrete Mixing Plant Technical Specifications

Production Capacity: 30 m³/hour

Transport Dimensions: 8 (L) x 2.3 (W) x 2.5 (H) meters

Weight: 8.5 tons

Total Motor Power: 47 kW

Required Electric Generator: 70 kVA

Mixer Options: Pan – Single Shaft – Planetary

Aggregate Storage Bunker: 4 x 6 m³

Aggregate Weighing Bunker: 0.75 m³

Aggregate Transfer Belt: 800 x 15,250 mm

Mixer Wet Concrete Volume: 0.5 m³

Cement Weighing Bunker: 300 kg

Water Weighing Bunker: 200 liters

Additive Weighing Bin: 20 liters

Air Compressor: 300 liters, 4 kW

Cement Silo Capacity: 50 – 200 tons

Control Type: Fully Automatic

Working Area Requirement: 200 m²

Why Choose MOBICOM 30 | Mobile Concrete Batching Plant?

Developed by CONSTMACH, MOBICOM 30 is one of the most efficient solutions in its class in terms of both mobility and performance. Its compact design, which can be transported in a single container, low installation time, and high production capacity provide significant savings in time and cost. The automation system, supported by SIEMENS and SCHNEIDER components, guarantees long-lasting and uninterrupted operation. Manufactured with the CONSTMACH guarantee, MOBICOM 30 is an ideal investment for construction projects of all sizes thanks to its durability, easy transportability, and flexibility of use.

Hjdpfjxpg Abox Aadjfc

What Do We Do at Constmach?

Constmach is a leading machine manufacturer serving the construction and mining industries with a wide range of products tailored to their needs. Our product portfolio includes concrete block making machines, stationary and mobile concrete plants, stone crushing machines, stone crushing and screening plants, sand washing machines, sand making machines, asphalt plants, conveyor belt systems, jaw crushers, and mobile crushing plants. With its high quality standards, innovative production approach, and customer-focused solutions, Constmach stands out as a reliable brand in both national and international markets. Our products continue to be the preferred choice of industry professionals due to their durability, efficiency, and long-lasting performance.

Listing

Ankara

Ankara

3,165 km

Small occupied space balances complete p

Bodori76000W

Call

Condition: new, Year of construction: 2025, A compact design sheet fiber laser metal cutting machine with complete protection

Small occupied space balances complete protection and higher safety.

Each frame of the cutting machine bed is welded after mortise-and-tenon joint to achieve perfect mechanical property and better stability and firmness.

The pu

Convenient and fast open&close with one click; The laser cutter door is safe and reliable, by using rack-pinion transmission mode combined with self-locking cutting machine system

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Applicable Material: metal

Condition: New

Laser Type: Fiber Laser

Hsdpjhwmdrjfx Aadsfc

Laser Power: 1500W, 2000W, 3000W, 6000W, 12000W

Cutting Area: 3048*1524mm

Cutting Speed: 0-100m/min

Positioning accuracy: ±0.05mm

Repositioning accuracy: ±0.03mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Brazil

Brazil

8,977 km

Small Tube High Efficiency Laser Cutting

BodorQ0 Pro

Call

Condition: new, Year of construction: 2023, Expert High-speed Small Tube Processing

With features designed specifically for small tube processing, and a fully automated loading structure, the Q0 Pro significantly improves your production efficiency.

Easy and Fast Operation

Hfodspvi Scjpfx Aadoc

Q0 Pro makes small tube cutting easy. With smart features and simple operations like full servo adjustment, over-edge protection, automatic focus, and lightning piercing, you’ll get fast and smooth cuts every time.

Revolutionary Processing Steps

Say goodbye to traditional processes like sawing, turning, punching, and drilling. With the Q0 Pro, you get everything in one automated cutting process and double your efficiency.

Versatile and Flexible Cutting

Our BodorThinker Tube system lets you keep up with customer design demands like never before. Plus, our sleek, compact design not only enhances your workspace but also ensures optimal space utilization.

Save Huge Manual Handling and Material Costs

Our automated cutting process, high-quality cutting results, and impressive short cutting tailings significantly reduce manual handling costs and leftover material costs. All you need to do is load your material, and let the Q0 Pro handle the rest.

Listing

Volkach

Volkach

1,106 km

Horizon CCR conveyor for smaller sizes

HorizonCCR

Call

Condition: used, offer consists of:

delivery unit

Hfsdpfx Aasu Stcnsdjc

Format: 16x18cm - 20x20cm

We can also organize the following for you:

packaging, loading, transport ( by ship or plane) including customs

Discover more used machines

Listing

Menslage

Menslage

797 km

Ca l'Arenys Microbrewery 800l Brewhouse (2012)

Ca l'ArenysSudhaus

Call

Condition: used, Year of construction: 2012, Overview This microbrewery had to cease operations in recently. The original plan was to continue operations, but as this did not happen for various reasons, the entire equipment is now being sold as a whole. Equipment Steam generator with gasoil burner and its tank. Three-phase mill for grain grinding. 800-liter brewhouse with steam jacket consisting of boiler, filter tank, lung, liquor tank, tubular cooler, accumulated osmotized water tank, and 3 necessary pumps for its operation. Industrial osmosis and descaling equipment. 4 atmospheric cylindrical-conical fermenters with refrigeration jacket and a capacity of 1000 liters. 3 atmospheric cylindrical-conical fermenters with refrigeration jacket and a capacity of 1300 liters. 1 cooling system for fermenters with temperature control panel by PLC. 1 cleaning pump. 1 transfer pump. Several hoses necessary for transfers and packaging. 1 atmospheric monoblock bottling and capping machine for 33 cl bottles with filling capacity of 1,200 containers/hour. 2 compressors necessary for the operation of the bottling machine. 1 manual 6-spout filler for emergencies and special bottles. Semi-automatic adhesive labeler. 1 compressor necessary for the labeler. Ribbon printer for adding variables to the labels, with rewinder. 1 pallet truck. 6m x 2.50m x 3m high refrigeration chamber. Industrial scale. Including all sandwich panels from which the production rooms are made

Hsdpfouzpipsx Aadefc

Listing

Volkach

Volkach

1,106 km

Horizon SPF-20 - gear for smaller sizes

HorizonSPF models

Call

Condition: used, offer consists of:

SPF-20 - gear / equipment for smaller sizes used

We can also organize the following for you:

Hfodsu Sr A Topfx Aadoc

packaging, loading, transport ( by ship or plane) including customs

Listing

Wächtersbach

Wächtersbach

1,027 km

Complete microbrewery

Pfanne: Schulz

Call

Year of construction: 2010, condition: excellent (used), Complete microbrewery for sale:

Brewhouse 10 HL:

High-quality brewing pan (Schulz), double-walled with smooth cooking process, lauter tun and whirlpool, complete piping, hoses. Automatic mashing with electrical pannel, control for hot water heating, malt mill, small appliances.

Fermentation cellar:

Wort cooler, ice water container, 5 open fermentation tanks 10HL, 5 storage tanks 20 HL, 3 serving tanks 10 HL. Wort pump, hoses, temperature control. Precoat filter, yeast pan.

Bottle cellar:

Fully automatic inline filler, 8 digits, soft wheel, round bottle cleaner

Lots of accessories, small parts, hoses, etc.

Hodpsf Ni Rvjfx Aadofc

For sale as build in. Cranes and loaders for free.

Listing

Freising

Freising

1,296 km

Microbrewery

Easybräu-Velo | TMCI Padovan

Call

Year of construction: 2019, condition: used, consisting of: - Malt milll - Mash-/Wortkettle/Whirlpool - Lauter tun - Warmwater vessel - Wort cooler - Wort aeration - Siemens touch screen - 4 x Fermenting vessel - 8 x Storage tanks with shell cooling surface - Icewater vessel - mobile beerpump - Steam boiler - 2 Bottle-filler + 1 Can-filler by Fillmatic - bottle filler A. Gruber

Additional title: 5 hl-Brewery, with Grist Mill, Compact-Brewhouse, Fermenting vats, Storage tanks

Cast out wort: 500 l

Capacity wort cooler: 750 l/h

Wort cooling time: 40 min.

Hfedpfx Ajvcqk Hjadoc

Material: Brewing vessel, hotwater tank, fermenting and storage tanks in stainless steel, 1.4301

Base construction: Brewhouse compact unit on stainless steel frame, vertical Fermenting vats on feet, horizontal storage tanks on two layer in a stainless steel frame.

Features: mobile grist mill, mash-/wortkettle, lauter tun, warm water tank, wort-cooling and aeration, 4 fermenting vats, 8 storage tanks with temperature control, pumps, hoses, bottle- and can-filler, bottle-washer, ice water tank, steam generator

Listing

Derby

Derby

302 km

New Batch Pasteurisers 300 Litres

Dairy Machinery UKBPT 300

Call

Condition: used, Year of construction: 2025, New Batch Pasteurisers custom made on request. offers new Batch pasteurisers for the Food and beverage industry. Our BPT Series is capable of Milk Pasteurisation, Ice cream mixing, Ice Cream Fermentation, Sauces, Brewery industry,etc.

Applications:

- Dairy Processing: Most commonly used in the dairy industry to pasteurise milk and milk products.

- Cheese Production: Used before cheese-making to ensure safety.

- Ice Cream Production: Pasteurises the base mixture before it is churned into ice cream.

Advantages of Batch Pasteurisation:

- Cost-Effective: Often less expensive than continuous pasteurisers for small to medium operations.

Hsdpfexl N H Ujx Aadjfc

- Flexibility: Suitable for small batches or varied products and recipes.

- Quality Control: Allows for greater control over the pasteurisation process.

Volume capabilities (litres): 300

Control panel: Stainless steel Control box, Controls, Thermometer Controller, ON/OFF Agitator, Chart Recorder; ;

Heating options: Heating Elements, Hot Water and Steam

Milk pasteurisation: 68-75c

Max temperatures: 95c

Cooling options: Connection to Ice Bank and Circulation Cold water through the Jacket; Plate Cooler Connection on the Outlet;

Heating time: Between 30m-1hr for BPT100 to BPT500 Series With Heating Elements; BPT600 -BPT2000 Heating by HOT water or Steam;

Cooling time: 30min to 45min Depending on Cooling Temperatures; Plate cooler at 30min Standard;

Structure: Stainless steel 316L & 304 Triple Jacket with Insulation; ;

Agitation: Slow Agitation with double props at two diferent levels; High Shear mixing for Ice Cream;

Cleaning: Spray ball internally for even cleaning by circulation of Hot water and chemicals used in the food industry; ;

Automation: We offer Full automation on our batch Pasteurisers that cover the full circle of heating down to cooling; Additional Costs will be added for automation;

Openings: Two Up Folding Covers for Easy Cleaning and Inspection; ;

Product outlet: DIN40-DIN50 On semi cone to make sure all product flows out; ;

Uasege: Milk Pasteurisation/ Ice Cream Mixing/ Ice Cream Fermentation/ Sauces/; ;

Lead time: 5-8 weeks from Order Delays may apply during COVID 19; ;

Finance Available: Pay Monthly, Ask For A Quote

Listing

Menslage

Menslage

797 km

González Trat. Firulais 6 Latas-Botellas Isobarometric Filler (2022)

González Trat.Druckfüller

Call

Condition: used, Year of construction: 2022, Overview This dual isobaric counter-pressure filling line for bottles and cans was manufactured in 2022 by the Spanish company González Tratamiento. The system includes a Firulais 6 Latas-Botellas filler and MPC-AS self-adhesive labeller, offering a compact and flexible solution for small and medium-sized breweries or beverage producers. The filler is still in operation and was maintained regularly. The owner is selling it because the equipment exceeds their current production capacity. Technical data Capacity: Up to 2,000 bph (operated between 500–1,000 bph) Filling System: Isobaric, counter-pressure Filling Valves: 5 Bottle Formats: 0.33 L and 0.75 L (adjustable) Can Formats: Standard 0.33 L Closure Systems: Integrated can seamer and crown capper Construction: Stainless steel Working Pressure: up to 3 bar CO₂ System: Pre-evacuation for cans, vacuum for bottles Controls: Touchscreen with adjustable parameters Mobility: On wheels with adjustable legs Condition: In use, regularly maintained Scope of Delivery Filler | González Tratamiento | Firulais 6 Latas-Botellas | 2022 | 5-valve isobaric filler with integrated can seamer and crown corker Labeling machine | González Tratamiento | MPC-AS | 2022 | Self-adhesive labeler, wrap-around, for various bottle sizes, incl. thermal printer for compliance and expiry date marking

Hedpfxjxn Uf Ij Aadsfc

Listing

Menslage

Menslage

797 km

Rizzolio RLV 2 ISO Isobarometric Filler (2015)

RizzolioDruckfüller

Call

Condition: used, Year of construction: 2015, Overview This compact isobaric filler was manufactured in 2015 by Italian company Rizzolio. The Rizzolio RLV 2 ISO is designed for small breweries and artisanal beverage producers requiring precise CO₂ pre-injection and controlled filling of carbonated beverages such as beer. The machine has two filling heads and offers a robust, easy-to-maintain design. It is being sold because the owner purchased a larger filler. Recently, both electrical and mechanical parts were repaired. Technical data Capacity: Approx. 250 bph Formats: Adjustable for different bottle sizes Filling system: Isobaric with CO₂ pre-injection into filling bell Valves: 2 Max. working pressure: 5 bar Operation: Two manual levers for bottle lift and filling cycle; automatic gas compensation after first cycle Electrical supply: Single-phase, 220 V

Hjdsxd Ez Ejpfx Aadofc

Listing

Menslage

Menslage

797 km

GAI MLE 661 Isobarometric Filler (2018)

GAIDruckfüller

Call

Condition: used, Year of construction: 2018, Overview This glass bottle filler and capper was manufactured in 2018 by the Italian company GAI. The MLE 661 Bier model is a compact and precise filling monoblock designed for small to medium-sized breweries and beverage producers. It features Pick & Place technology for pilfer-proof aluminum screw caps (30x20 mm) and an electronic fill height adjustment system for easy format changes. With a capacity of up to 900 bottles per hour, the unit is suitable for bottles ranging from 0.25 L to 1.0 L. The machine is in very good condition and ready for operation. Technical data Filling system: Isobaric (for beer and other carbonated beverages) Capacity: 900 bottles/hour Bottle formats: 0.25 L – 1.0 L Closure type: Pilfer-proof aluminum screw caps (30x20 mm), Pick & Place system Electronic fill height adjustment Stainless steel construction

Hodpfx Aexn A R Ejadsfc

Listing

Menslage

Menslage

797 km

Cespedes, Anfara Sommer, Braumanufaktur Werk Brewhouse (2018)

Cespedes, AnfaraSudhaus

Call

Condition: used, Year of construction: 2018, Overview This complete brewing and packaging line was manufactured mainly in 2018 by Cespedes (Spain) and other European manufacturers such as Anfara, Sommer, and Braumanufaktur Werk. It includes brewhouse, fermentation, utilities, CIP, and filling equipment, all built in stainless steel AISI 304. With a brewhouse capacity of 1,500 L per batch and three 3,000 L fermenters, it is designed for small to medium-scale breweries. The line is in excellent condition and suitable for immediate use. Technical data Capacity: 1,500 L per batch (brewhouse), 3 × 3,000 L fermentation tanks Formats: Bottles and cans (330 ml, 440 ml, 500 ml) Brewing system: Steam-heated, fully stainless steel Filler: 6-head semi-automatic isobaric filler (bottles), modular semi-automatic filler and capper (cans, approx. 150 cph) Scope of Delivery Brewing kettle / whirlpool tank | Cespedes | - | 2018 | 1,500 L usable, double jacket, steam heating, fully insulated, stainless steel AISI 304 Mash/lauter tun | Cespedes | - | 2018 | 2. 000 L usable, motorized stirrer, insulated, stainless steel AISI 304 Hot water tank (HLT) | Cespedes | - | 2018 | 3,000 L, insulated, with heating jacket Fermentation/storage tanks (3 pieces) | Cespedes | - | 2018 | 3. 000 L usable, pressure vessel up to 3 bar, insulated, cooling jacket Control system | Cespedes | - | 2018 | Recipe management, temperature control, frequency converter Work platform with ladder | Cespedes | - | 2018 | Stainless steel, non-slip, with railing Connecting bench + piping | Cespedes | - | 2018 | Stainless steel, hygienic DIN valves, incl. Helicoidal pump Plate heat exchanger | - | UPF34/70 | - | stainless steel, for wort cooling Inline particle filter | - | - | 2018 | stainless steel AISI 304, slot width 0.2 mm Sight glass | - | - | - | stainless steel AISI 316, hygienic inline inspection window Steam generator | Anfara | AV-300 | 2018 | 300 kg/h, 5 bar, Oil burner, CE-certified CIP system | - | CDXM 70-5 | 2021 | flow rate 3.0-9.6 m³/h, 1.5 kW motor Semi-automatic bottle filler | Cespedes | ISO-6 | 2016 | 6 filling heads, isobaric, stainless steel Semi-automatic can filler + seamer | Braumanufaktur Werk | Fillmatic | 2021 | modular, formats 330-500 ml, approx. 150 cans/h Malt mill | Sommer Maschinenbau | Maltman | 2019 | up to 1,500 L batches, 2-roller mill Buffer/intermediate tank | - | - | - | 565 L

Hfsdpfx Aow U Tgxjadjc

Listing

Menslage

Menslage

797 km

EUROSTAR Canfill 5 ONE Isobarometric Filler (2020)

EUROSTARDruckfüller

Call

Condition: used, Year of construction: 2020, Overview This can filler and seamer was manufactured in 2020 by the Italian company Eurostar. The Canfill 5 One is a compact and efficient filling and closing system designed for small-scale beverage producers. Suitable for both carbonated and still drinks, it offers an ideal solution for breweries, cider producers, or craft beverage facilities looking for professional filling performance in a small footprint. The machine has seen very limited use — only about 1,500 cans have been filled — and is therefore in excellent, near-new condition. Technical data Capacity: 2,000 cans/hour at 0.33 L 1,500 cans/hour at 0.5 L Compatible formats: Standard and Sleek cans (not suitable for Slim cans) Filling system: Isobaric (for carbonated products) Product types: Beer, cider, soft drinks, or similar beverages Condition: Used – as new (only 1,500 cans filled)

Hsdjxnmv Eopfx Aadofc

Listing

Menslage

Menslage

797 km

Monoblock VVF14/3 Line Returnable Glass Bottles

H & KAbfülllinie für Glasflaschen (Mehrweg)

Call

Condition: used, Year of construction: 2016, Overview The filling line for glass bottles (non-refillable and refillable) was in operation at a small brewery in Germany until recently. The line is set up for 0.33l longneck bottles and can fill up to 2,500 bph. The machine is still in operation and can be inspected at any time after consultation. The bottle washer and the unpacker can also be purchased separately. Technical details Capacity: 2.500 bph Formats: set up for 0.33l longneck Filling temperature: 6°C Packaging: 0,33l Longneck in 24er folding box 0,33l Longneck in 24er modular box Individual machines / line components New glass lifter | Füllmeister | - | 2016 Filler + capper | H&K | VVF 14/3 | 1966 2016 general overhaul (with pre-evacuation - new rotary ball connection - new stainless steel table - new electrics - new valve control cabinet in stainless steel design - 0.33 liter guide set - Sihi vacuum pump.) Seals on lifting cylinders and filling valves renewed 2023 Vacuum and relief valves fitted with new seals and springs 2023 Bottle unpacker | Joha | - 1982 Packing head for 24 bottles in modular crate Bottle washer | Silmo | Praktika | 1983 Bottles per row: 12 Label discharger Labeler | Krones | Vinetta | 1999 Type 480-6-3-180 Labelling station for back labels Labelling station for breast labels and neck loops Three glue pallets and gripper sponges each Glue pallets, gripper sponges and sponge roller at bottle discharge new 2023 Glue pump Krones Unipump-H with glue heater Packer | Pexco | - | - 1 head for 24 bottles in module box 2016 new electrics installed and machine overhauled Residual liquid and finish control | Miho | LC2000 | Residual liquid detection from bottle cleaning machine Control of bottle mouth for crown cork/metal Incl. balancing screen from Silmo for visual control of the cleaned bottles Crate washer | Fleischer | - | - For cleaning of plastic empty crates, in longitudinal run Module size: 300x400mm Overhauled in 2016 Compressor | Alup | Allegro 19-10 | 2016 Oil-free 4897 operating hours Transport Bottle transport: various conveyor belts + 90° bends Crate transport/ roller conveyor: 2016 overhauled with stainless steel cheeks and feet

Hsdpfxel Hx Rpe Aadofc

Listing

Menslage

Menslage

797 km

Shandong Yuesheng 10HL Brewhouse (2020)

Shandong YueshengSudhaus

Call

Condition: used, Year of construction: 2020, Overview This brewhouse was manufactured in 2020 by Chinese company Shandong Yuesheng. It is a 10 hL two-vessel system designed for small to medium-sized breweries, equipped with mash/lauter tun, wort kettle, and an additional 20 hL hot water tank. The brewhouse includes steam heating, integrated pumps, and auxiliary equipment, offering a compact and professional solution for efficient beer production. The unit is in good condition and will be available by the end of April 2026. Reason of the replacement is that they will go to a new 20hl brewhouse. Technical data Capacity: 10 hL brewhouse, up to 2 batches per day Formats: Beer, up to 20° Plato initial density Vessels: 2 (mash/lauter + kettle/whirlpool) + 1 hot water tank (20 hL) Power supply: 5.5 kW Air supply: 6 bar Construction: SUS304 stainless steel, mirror surface treatment, PU insulation (100 mm), polished welding seams (Ra ≤ 0.4 μm) Heating: Steam Features: CIP rotary ball, sparging arm, thermowell, motor with frequency conversion, grain raker, top manhole with sight glass, laser-cut false bottom, side grain door and chute, adjustable legs Scope of Delivery Brewhouse 10 hL | Shandong Yuesheng | 1000L | 2020 | 2 vessels (mash/lauter, kettle/whirlpool) Hot water tank | Shandong Yuesheng | – | 2020 | 20 hL capacity Heat exchanger | Shandong Yuesheng | – | 2020 | 10 m² surface Pumps | Shandong Yuesheng | – | 2020 | 1 hot water pump, 1 wort pump Platform with access | Shandong Yuesheng | – | 2020 | Stainless steel construction Steam generator | Shandong Yuesheng | – | 2020 | 150 kg/h

Hodpexb S A Defx Aadofc

Listing

Menslage

Menslage

797 km

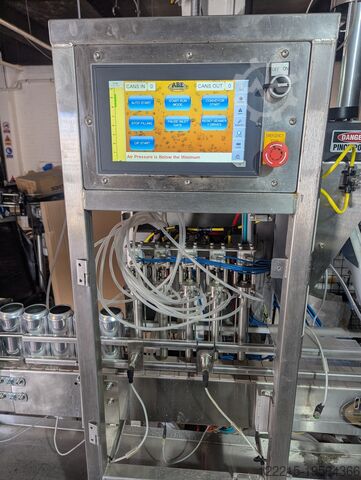

ABE / Vigo UK CraftCan35 Atmospheric filler (2017)

ABE / Vigo UKAtmosphärischer Füller

Call

Condition: used, Year of construction: 2017, Overview This CraftCan35 can filling machine was manufactured in 2017 by the British company Vigo UK (ABE). The machine has been overhauled, is currently cleaned, dismantled and safely stored and is available for immediate use. It is particularly suitable for small to medium-sized breweries that want to process 330 ml and 440 ml standard cans (202 ends). A viewing can be organized by arrangement. Technical details Output: up to approx. 35 cans per minute (depending on product) Formats: 330 ml & 440 ml standard cans (202) Filling system: 6-head filler Closure: double seam seamer for 202 ends Voltage / power supply: not specified Special features: Retrofitted rinser and dryer (Vigo UK) Pneumatics converted to metric connections Original operating instructions available Scope of delivery 1 × Can filling line | ABE | CraftCan35 | 2017 Incl. rinser and dryer (retrofitted) Optional: Stainless steel rotary table (pack-out table) and 3 m single-track conveyor belt Some acrylic protective cladding (some replacement required)

Hjdpfx Aowzb Irjadsfc

Listing

Menslage

Menslage

797 km

Speidel, Spagni, Sommer Maltmann, 500l (5hl) Brewhouse (2016)

Speidel, Spagni,Sudhaus

Call

Condition: used, Year of construction: 2016, Overview This complete 500 L brewhouse package was manufactured between 2016 and 2017 by leading European companies, including Speidel, Spagni, Skrlj, Sommer, and MTA IT. Designed as a turnkey solution for small to medium-sized breweries, it includes all key equipment for mashing, fermentation, chilling, capping, labelling, and malt processing. The system was previously operating at 600 bph and can be adapted for up to 900–1,000 bph. It is offered for sale as the brewery has ceased operations and is immediately available. Technical Details Brewhouse capacity: 500 L (Braumeister 500 L, atmospheric) Fermentation capacity: 4 × 625 L (total 2,500 L) Formats: 26 mm crown caps (adaptable to 29 mm) Labeller type: Self-adhesive, semi-automatic, for cylindrical bottles Malt mill capacity: 150 kg/h Chiller: MTA TAEevo TECH 015, 3.8 kW, refrigerant R410A Production speed: 600 bph (adaptable to 900–1,000 bph) Electrical connection (brewhouse): 230/400 V, 32 A, 50/60 Hz, IP43 Scope of Supply Speidel Braumeister 500 L brewhouse (2017) 4 × Speidel 625 L fermentation tanks (2017) Spagni Aircorona 26/29 FE pneumatic crown capper (2017) Skrlj E03 180 semi-automatic labeller (2017) Sommer Maltman 110 malt mill (2017) MTA TAEevo TECH 015 process chiller (2016) Additional equipment: crane, manual filler, air compressors, sugar mixer tank, transfer pumps

Hfedpfsw Nk Ezox Aadjc

Listing

Menslage

Menslage

797 km

SIFA Idrokeg 21 KEG Washer (2020)

SIFAKEG Wascher

Call

Condition: used, Year of construction: 2020, Overview This semi-automatic keg washer was manufactured in 2020 by Italian company SIFA. The Idrokeg 21 is equipped with two cleaning heads and designed for efficient steam-heated keg washing. With a capacity of up to 12 kegs per hour, it is suitable for small to medium-sized breweries. The unit is in very good condition, ready for immediate use, and comes with dedicated tanks, pumps, and cleaning features. Technical data Capacity: 12 kegs/hour Cleaning stations: 2 Heating: Steam Formats: S-type kegs

Hfsdpjxcul Djfx Aadec

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Filling Monoblock

AlfatekMBC 7/1 LP ELVIRA

Call

Condition: used, Year of construction: 2014, Used filling monoblock ALFATEK MBC 7/1 LP ELVIRA for re-fermented beer year 2014

This filling monoblock offers a compact and efficient solution for bottling re-fermented beer in glass containers. Consequently, Alfatek manufactured this machine with a gravity filling system to ensure a stable process that meets industry standards.

Hsdpfxsv N Dcio Aadsfc

Technical Features of the Used filling monoblock ALFATEK ELVIRA for re-fermented beer

The ALFATEK MBC 7/1 LP ELVIRA filling monoblock for beer year 2014 includes 7 fixed filling valves, specifically designed to process beer in 0.33 L and 0.75 L glass bottles. Moreover, the gravity filling prevents organoleptic alterations, and significantly reduces the risk of foam formation during filling.

In addition, the integrated capper features 1 capping head for 29 mm crown caps, ensuring a secure and effective seal. Furthermore, this capping system works in synergy with the gravity filling process to maintain the internal pressure stability of the bottles.

Operational Specifications

Notably, the monoblock fills up to 1,000 bottles per hour, making it ideal for small to medium-sized production lines. As a result, bottles move through the system with a clockwise rotation, thereby optimizing workflow efficiency.

Along with the monoblock, the conveyors are also included in the sale. They have the following dimensions: 1.80 m in length, maximum width 52.5 cm, minimum width 25 cm.

Regarding electrical specifications, the Used filling monoblock ALFATEK ELVIRA for re-fermented beer operates at 415V and 50Hz. Therefore, it remains compatible with most industrial plants.

Safety and Structure of the Used filling monoblock ALFATEK ELVIRA for re-fermented beer

Importantly, the machine includes safety devices that protect the operator during operation. Additionally, its compact structure measures 1,190 mm in width, 1,900 mm in length, and 2,330 mm in height, allowing seamless integration into existing production lines without major modifications.

Current Condition and Availability

At present, the Used filling monoblock ALFATEK ELVIRA for re-fermented beer remains in storage. Thus, it is ready for inspection and installation in a new production facility. Given its robust structure and advanced technical features, it presents a reliable choice for breweries looking for a high-performance and tested machine.

Ultimately, this monoblock provides a valuable opportunity to improve production efficiency. Likewise, it represents a strategic investment in a well-maintained used system. Consequently, breweries can optimize their operations while reducing acquisition costs. Additionally, its compatibility with industry standards ensures smooth integration into various production setups. Therefore, this machine offers both efficiency and reliability, making it a practical choice for modern bottling facilities.

Trust Seal

Dealers certified through Machineseeker

Listing

Oradea

Oradea

1,980 km

Vacuum pump

VerderflexDURA 35

Call

Condition: like new (used), Year of construction: 2024, operating hours: 200 h, functionality: fully functional, machine/vehicle number: 159422, Verderflex Dura 35 peristaltic pump, serial number: 159422, MFG: 2024

For demanding applications, the Verderflex Dura 35 provides:

Maximum flow rate: 5,292 L/hr

Maximum pressure: 16 bar

Maximum medium temperature: 80 ºC

Compressible solid size: 8.75 mm

Suction lift: 9.5 mWc

Certification: ATEX, FDA and EC/1935

Pump Housing made from cast iron (GG25)

Front Cover made from carbon steel with plexiglass inspection window

Rotor made from cast iron (GG25)

Drive Shaft EN24T Steel

Mounting Frame made from carbon steel

Torque Arm made from carbon steel

Bearing made from bearing steel

Flow 11/hr

Pump speed 35 PM

Installed motor power 25W

Max turndown at 5 Bar discharge pressure 101

Verderflex peristaltic pumps are the ideal low cost life cycle solution for the transfer and dosing of difficult to pump fluids such as viscous, abrasive or high solid content liquids such as slurry and sludge. Sizes range from small models such as OEM pump modules, precision and industrial style tube pumps to the world's largest hose pumps, used in the most demanding applications. These include water treatment, biotechnology, food & drink production, mineral processing and chemical manufacturing.

Features :

• Peristaltic pumps are excellent problem solving pumps and offer the following benefits:

• Abrasion Resistant

• No moving parts in the liquid stream

Hfedpewdtbcsfx Aadsc

• Accurate Dosing

• Self Priming

• Can pump liquids containing up to 80%

• inorganic solids (fines)

• Aseptic pumping

• smooth liquid passage

• Easy and completely cleanable without disassembly

• Suitable for handling shear sensitive products

• Can run dry

• Low cost of ownership

• High suction capability of up to

• 95% vacuum or a 9.5 mWc

• No seals

• Reversible rotation, empties line or blockages

• Can pump

• abrasive, very viscous or

• high density fluids

Application for abrasive fluids : Lime mixing, Kieselguhr, circulation and dosing

Application for corrosive fluids : Ferric Chloride, Copper Sulphate and similar Activators, process chemicals, Acids, including Alkalis

Application for shear sensitive fluids : Coagulants, Flocculants and bacterial remediation treatments

Application for mining industry : Dosing Process Reagents, Thickener Underflow, polymers and slurry transfer

Application for water treatment : Dosing Lime, Hypochlorite, Silicate, Polymer, Ferric Chloride, sludge transfer and filter press feeds

Application for chemical Industry : Corrosive Acids, Bases and Hydrocarbons

Application for Printing and packaging : Inks (including water based inks), Paints, Dyes and Glue

Application for Battery Filling, Chemical Cleaning, Equipment Sterilising, Seed Coating : Biocides, Hydrogen Peroxide, Sodium Hypochlorite, Caustic Soda

Application for Laboratory Systems : Biological Broths to polluted streams

Application for Agriculture : Feed Additives, Animal Vaccines and Waste Transfer

Application for Paper and Pulp : Pulp and Dyes

Food and Beverage : Breweries, Diatomaceous Earth, wineries, dairies, sugar refining, abattoirs

The pump is in excellent condition, like new.

Price Euro 4.500 Euro + VAT, negotiable, FCA: Oradea/Romania

Irrtum, Anderungen und Zwischenverkauf vorbehalten /

Subject to errors, changes and prior sale /

Ne rezervăm dreptul la greșeli, modificări și vânzare prealabila.

We speak English. /Wir sprechen Deutsch./ Beszélünk magyarul. /Nous parlons français/Vorbim romana

Auction

Ends in

d

h

min

s

Auction ended

Thüringen

Thüringen

1,080 km

Industrial robot

KUKAKR 10 R900-2 / SEL (7x)

Condition: ready for operation (used), Year of construction: 2021, functionality: fully functional, overall weight: 37 kg, load capacity: 10 kg, arm reach: 901 mm, positioning accuracy: 0.03 mm, Auction of a set of 7 KUKA KR 10 R900-2 robots!

TECHNICAL SPECIFICATIONS

Payload: 10 kg

Arm reach: 901 mm

Repeatability: 0.03 mm

MACHINE DETAILS

Hfjdpfxoyft U Ds Aadjc

Controller: KRC4 compact

Net weight: 37 kg

Areas of application: Handling, assembly, packaging, machine tending, small-lot production

Protection class: IP65

SCOPE OF DELIVERY (per robot)

KUKA industrial robot KR 10 R900-2

KUKA control unit KRC4 compact

KUKA SmartPad (operator panel)

Set of connection cables

Auction

Ends in

d

h

min

s

Auction ended

Czech Republic

Czech Republic

1,414 km

Laser cutting machine

TRUMPFTruLaser Tube 5000 (T05)

Condition: ready for operation (used), functionality: fully functional, Year of construction: 2014, operating hours: 8,416 h, laser power: 3,200 W, sheet thickness steel (max.): 10 mm, sheet thickness aluminum (max.): 4 mm, pipe diameter (max.): 152 mm, working length: 6,500 mm, TRUMPF Tube Laser Cutting System with LoadMaster Tube 6.5 m and extensive additional equipment!

TECHNICAL DETAILS

Maximum tube diameter: 152 mm

Maximum working length: 6,500 mm

Material thickness (steel): 10 mm

Material thickness (stainless steel): 5 mm

Material thickness (aluminum): 4 mm

Laser power: 3,200 W

MACHINE DETAILS

Control system: SIEMENS Sinumerik 840D SL

Operating hours: 24,428 / 8,416 h

EQUIPMENT

- LoadMaster Tube 6.5 m with bundle magazine

- Robust machine frame with integrated laser unit

- Feed station with self-centering clamping jaws

- Raw material tube support with automatically retractable pipe rests

- Through-feed chuck with self-centering parallel clamping rollers

- High-precision drives

- Discharge station for finished workpieces up to 3 m in length

- Tube support for finished parts with extendable guide rollers

- Scrap conveyor with collection bin

- Enclosed beam guide

- NitroLine

- FocusLine

- Laser power control

- Programmable cutting gas pressure

- Automatic power on/off

- Ergonomic control panel with touch color screen

- Work area illumination

- High-frequency excitation

- Maintenance-free turbo radial blower

- TASC 3 laser control

Hodpfx Asygu Tkjadsfc

- Laser logbook function

- Cooling unit

- Single cutting head strategy

- Lens cutting head, 155 mm focal length

- ControlLine

- Simple operation

- Online support

- Diagnostic functions

- Integrated technology data

- Remote service via internet

- RJ45 network interface and USB port

- CE marking

- Multi-beam light barriers

- Monitoring system for gas pressure, temperature, and cooling water, among others

- Compact dust extraction system

- Protective enclosure with polycarbonate (Makrolon) panels

- Jaw sets with clamping range 20–85 mm and 85–152 mm

- Quick-change forming shells for round tubes up to 152 mm

- Quick-change forming shells for rectangular tubes (up to a circumscribed circle of 85 mm)

- Quick-change forming shells for rectangular tubes (up to a circumscribed circle of 170 mm)

- Guide rollers for round and rectangular tubes

- SeamLine Tube with inner seam detection

- Adaptive clamping technology – feed station, small circumscribed circle

- Adaptive clamping technology – feed station, large circumscribed circle

- Adaptive clamping technology – through-feed chuck, small circumscribed circle

- Adaptive clamping technology – through-feed chuck, large circumscribed circle

Note: The machine will be dismantled on 02/03/2026 and can be inspected under power until then.

Listing

Newton Aycliffe

Newton Aycliffe

147 km

Westfalia MSD 20-06-076 Stainless Steel Centrifuge

WESTFALIAMSD 20-06-076

Call

Condition: used, Used Westfalia model MSD 20-06-076 stainless steel milk centrifuge, clarifier design. Driven by Loher 11,0kW/50Hz/400V el. motor. Ideal for small cheese plant wanting to remove cheese solids from whey. Capacity up to 10,000lt per hour on whey. New 2002. Transport dimension: 1,5x0,9m - 1,3m high.

Hjdpfxjyh Ncyj Aadefc

We make it easier for you to find: "small brewery"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Small Brewery (3,889)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month