Used Plastic processing machinery for sale (2,624)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Listing

Hattingen

Hattingen

834 km

Injection moulding machines

DEMAGERGOtech system 800-310

Call

Condition: good (used), Year of construction: 1998, Ref. no.: 17507

Hersteller: DEMAG

Type: ERGOtech system 800-310

Year of construction: 1998

Clamping unit

Clamping force: 80 ton

Djlq Nkqswgpw Es Sout

Opening stroke: 450 mm

Distance between tie bars: 370 x 370 mm

Mould height min.: 200 mm

Platen size (h x v): 600 x 600 mm

Injection unit

Screw diameter: 35 mm

Injection volume: 168 cm³

Shot weight: 149 g

Injection pressure: 2020 bar

Measurements and weight

Dimensions: 4,1 x 1,4 x 2,0 m

Machine weight: 3700 kg

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

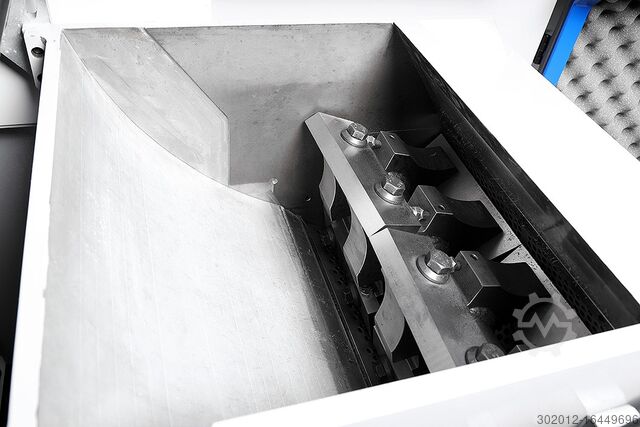

ZERMA GST250/450 granulator hollow body

ZERMAGST 250/450

Call

Year of construction: 2025, operating hours: 1 h, Condition: new, Functionality: fully functional, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

Duelq Nkqsum Rnvo Sot

98T8Mrx

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

Optional rear wall with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Listing

Mülheim an der Ruhr

Mülheim an der Ruhr

812 km

Injection molding machine

Demag Sumitomo100/420-310

Call

Condition: used, Year of construction: 2008, Functionality: fully functional, clamping force: 1,000 kN, screw diameter: 35 mm, displacement volume: 156 cm³, injection pressure: 2,180 bar, injection weight: 139 g, With Robotsystem

Djlqjwgc R Se Nkq Sjut

Listing

Eisenberg (Pfalz)

Eisenberg (Pfalz)

1,013 km

Foam adhesive welding machine

VeinasEPE Hot air Laminator

Call

Year of construction: 2019, Condition: used, Functionality: fully functional, Two foam boards (max. 800 x 600 mm) can be welded together here. Weight 1400 kg, dimensions 1900 x 1200 x 2625 mm

Duslq Nkev Icgwsq Sst

Listing

Sorcy-Saint-Martin

Sorcy-Saint-Martin

966 km

Injection press

BILLIONH260/90

Call

Condition: good (used), Year of construction: 1994, Hercules 90 tons injection press

Year : 1994

Injectable volume : 139cm3

Passage between columns: 445x445

Ejection stroke 110mm

Opening stroke : 380mm

Min. mould thickness: 180mm

Maximum thickness: 400mm

Dslq Nkqsizi Iro Sout

Diameter of centering ring : 125

Nozzle radius : 15.5mm

Ejection coupling in M16, 3 blowers, 1 programmable core, euromap interface for robot connection.

Listing

Hattingen

Hattingen

834 km

Multi-component injection moulding machines

ENGELVC 1050H/200W/200V(TOP4)/400 Combi-WP 6K

Call

Condition: good (used), Year of construction: 2008, Ref. no.: 171

Hersteller: ENGEL

Type: VC 1050H/200W/200V(TOP4)/400 Combi-WP 6K

Year of construction: 2008

Clamping unit

Clamping force: 400 ton

Opening width: 1008 mm

Platen size (h x v): 1300 x 1460 mm

Delq Njwgpwxekq Seut

Injection unit

Screw diameter: 50 mm

Injection volume: 422 cm³

Shot weight: 0 g

Injection pressure: 2322 + 00 + + + + bar

Measurements and weight

Machine weight: 22000 + 6600 kg

Dimensions LxWxH part 1: 5 x 2,3 x m

Dimensions LxWxH part 2: 3,9 x 2,3 x m

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM G 45 Cutting Mill

CrushmasterG 45

Call

Year of construction: 2025, Condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive capacity (hp) 15

Rotor blades (pieces) 3 x 1

Stator knives (rows) 2

Hopper opening (mm) 340 x 450

Total length (mm) 1207

Length machine (mm) 860

Width total (mm) 1020

Width machine (mm) 684

Height (mm) 1712

Dolqsp N Drxe Nkq Sout

Listing

Mülheim an der Ruhr

Mülheim an der Ruhr

812 km

Injection molding machine

Demag Somitomo IntElect100/470-340

Call

Condition: excellent (used), Year of construction: 2010, Functionality: fully functional, clamping force: 1,000 kN, screw diameter: 35 mm, clearance between the columns: 620 mm, displacement volume: 156 cm³, injection pressure: 2,180 bar, injection weight: 139 g, With Robotsystems

Duelqowgcx Aj Nkq Sot

Listing

Hattingen

Hattingen

834 km

Multi-component injection moulding machines

ENGELVC 1050H/200W/200V(TOP4)/400 Combi-WP 5K

Call

Condition: good (used), Year of construction: 2008, Ref. no.: 17147

Hersteller: ENGEL

Type: VC 1050H/200W/200V(TOP4)/400 Combi-WP 5K

Year of construction: 2008

Clamping unit

Clamping force: 400 ton

Opening stroke: 1008 mm

Platen size (h x v): 1360 x 1460 mm

Injection unit

Screw diameter: 60 mm

Injection volume: 608 cm³

Shot weight: 7 g

Injection pressure: 17 + + + + bar

Measurements and weight

Machine weight: 22.000 + 6.600 kg

Dimensions LxWxH part 1: 5 x 2,3 x m

Djlq Nkqjwgpwre Sjut

Dimensions LxWxH part 2: 3,9 x 2,3 x m

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

High speed granulator

ZERMA GST 250/300

Call

Year of construction: 2025, Condition: new, Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

Dslqjp Sr Ane Nkq Sjut

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive (kW) 7.5

Number of rotor blades 3 x 1

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 950

Feed opening (mm) 380 x 300

Feed opening option of M version (mm) 295 x 300

Listing

Mülheim an der Ruhr

Mülheim an der Ruhr

812 km

Injection molding machine

Demag Ergotech Systec 280/630-840

Call

Condition: used, Year of construction: 2008, operating hours: 75,000 h, Functionality: fully functional, clamping force: 2,800 kN, screw diameter: 45 mm, clearance between the columns: 630 mm, displacement volume: 368 cm³, injection pressure: 2,402 bar, injection weight: 320 g, opening stroke: 675 mm, plate width: 950 mm, plate height: 950 mm, installation height: 710 mm, total length: 6,620 mm, total width: 1,920 mm, total height: 2,250 mm, overall weight: 13,000 kg, Core pull 2-fold, 6-fold cascade, with robot

Duolq Nkqjwgcmgs Sst

Listing

Hattingen

Hattingen

834 km

Multi-component injection moulding machines

ENGELES 750H/80W/(500V)/300HL-2F

Call

Condition: good (used), Year of construction: 2004, Ref. no.: 17146

Hersteller: ENGEL

Type: ES 750H/80W/(500V)/300HL-2F

Year of construction: 2004

Clamping unit

Clamping force: 300 ton

Opening stroke: 855 mm

Injection unit

Screw diameter: 50 + 25 mm

Injection volume: 393 + 49 cm³

Shot weight: 354 + 44 g

Injection pressure: 1917 + 1586 bar

Dolq Nowgpwljkq Sout

Measurements and weight

Dimensions: 6,5 x 2,3 x m

Machine weight: 21000 kg

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

High speed granulator

ZERMA GST 250/600

Call

Year of construction: 2025, Condition: new, Size reduction of large-volume blow molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with special emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths from 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material jams. As with all ZERMA granulators, the rotor and stator knives are adjustable outside the machine, reducing downtime for maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material pickup and minimizes the risk of jams.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling e.g. voluminous parts such as bottles, canisters, crates. Due to the low feeding height, the machines can be easily fed with material by hand or by a small conveyor belt. The low noise emission and the small footprint make the granulator a perfect solution for inline size reduction

Djlq Nep Sr Iaokq Ssut

Optional rear panel with higher stator knife M version:

The feed method with a higher positioned stator knife is better suited for thicker walled and more compact parts, such as injection molded parts, profiles, plates, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high quality regrind is obtained regardless of the material type or shape, such as injection molded parts, profiles, plates, etc.

Control system and control panel:

The integrated control system and control panel not only comply with all applicable safety regulations, but can also be customized to meet specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available that reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 er cyclone

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive (kW) 11

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 1450

Feed opening (mm) 380 x 600

Feed opening option of M version (mm) 295 x 600

Listing

Hattingen

Hattingen

834 km

Injection moulding machines

BATTENFELDEM 75-120 Unilog B4 All-electric

Call

Condition: good (used), Year of construction: 2005, Ref. no.: 16369

Hersteller: BATTENFELD

Type: EM 75-120 Unilog B4 All-electric

Year of construction: 2005

Clamping unit

Clamping force: 75 ton

Opening stroke: 800 mm

Distance between tie bars: 405 x 405 mm

Mould height min.: 150 mm

Mould height max.: 480 mm

Injection unit

Duelq Nswgpwfekq Set

Screw diameter: 18 mm

Injection volume: 30 cm³

Shot weight: 27 g

Injection pressure: 2440 bar

Measurements and weight

Dimensions: 4,5 x 1,7 x 2,0 m

Machine weight: 4500 kg

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

890 km

Shredding machine

ZermaGST 250/450

Call

Condition: new, Year of construction: 2024, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been integrated into a compact redesign, with particular emphasis on weight, handling and energy efficiency.

These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with 250 mm rotor diameters and widths of 300, 450 to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce maintenance downtime.

The highly tangential, curved rear wall of the cutting chamber combined with the aggressive open rotor design ensures reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are suitable for recycling voluminous parts such as bottles, canisters and crates. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the granulator the perfect solution for inline shredding

98T8Mrx

Optional rear panel with higher stator knife M version:

The feed method with a higher stator blade is better suited for thicker-walled and more compact parts, such as injection-molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, a high-quality regrind is achieved regardless of the material type or shape, e.g. injection molded parts, profiles, plates, etc.

Control system and control cabinet:

The integrated control and control panel not only complies with all applicable safety regulations, but can also be adapted to specific requirements. In addition, peripheral equipment such as feed conveyors, metal detection and unloading systems can be seamlessly integrated into the machine's control system. For improved efficiency, an optional intelligent energy saving function is also available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW and 400 cyclone

Dolq Nkjt Aagajq Ssut

Rotor diameter (mm) 250

Rotor width (mm) 450

Drive (kW) 7.5

Number of rotor blades 3 x 2

Number of stator knives 2

Screen perforation (mm) > 6

Weight approx. (kg) 700

Feed opening (mm) 380 x 450

Opening feed option of the M version (mm) 295 x 450

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM G 60 Cutting Mill

CrushmasterG 60

Call

Year of construction: 2025, Condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 250

Rotor width (mm) 600

Drive capacity (hp) 20

Duelep N Dtrsq Nkq Sjt

Rotor blades (pieces) 3 x 1

Stator knives (rows) 2

Hopper opening (mm) 340 x 600

Total length (mm) 1348

Length machine (mm) 1000

Width total (mm) 1165

Width machine (mm) 834

Height (mm) 1712

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM G 30 Cutting Mill

CrushmasterG 30

Call

Year of construction: 2025, Condition: new, The G and H series compact mills are primarily designed for

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 250

Rotor width (mm) 300

Drive capacity (hp) 10

Rotor knives (pieces) 3 x 1

Stator knives (rows) 2

Chuck opening (mm) 340 x 300

Total length (mm) 1207

Length machine (mm) 860

Duolqjp N Dqts Nkq Set

Width total (mm) 870

Width machine (mm) 440

Height (mm) 1712

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Slow speed granulator

ZERMA GSL 300/800

Call

Year of construction: 2025, Condition: new, Direct driven staggered rotor

Special knife design makes adjustment unnecessary

Easy access for maintenance and cleaning

Slow rotor speed creates less noise and dust

Easily customizable to suit different applications

Rotor diameter (mm) 300

Duolen Hqv Djq Nkq Set

Rotor width (mm) 800

Rotor speed (rpm) 150

Drive capacity (kW) 18.5

Rotor knives (pcs) 66

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 1100

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM S 70 Granulator

CrushmasterS 70

Call

Year of construction: 2025, Condition: new, APPLICATIONS

The S-Series granulators are mainly used as large central granulators for

In-house recycling applications for processing large thick-walled parts in one

stage or as a second-stage granulator after a shredder to achieve higher results or throughput rates

GENERAL DESCRIPTION

The high-performance S-Series granulators offer widths from

600 to 1000 mm with diameters of 400 and 560 mm.

The all-welded heavy steel construction is designed to withstand

the most demanding and universal applications. Rotor bearings, blades

brackets and rotor shaft are oversized. The standard V-cut ensures a high

quality grind with a very low percentage of fines in the starting material.

The removable third stator blade (optional) acts as a deflection wedge

and allows the machine to be quickly adapted to different application

scenarios. Other standard equipment also includes easily adjustable blades

from the outside, reducing the risk of contamination.

S-SERIES - HIGH PERFORMANCE GRANULATORS ADVANTAGES:

"The easily removable deflector wedge acts as a third stator blade and can

Deljp N D Sboq Nkq Ssut

be used to adjust the aggressiveness of the rotor at the first cut point.

The V-Cut technology produces a high quality regrind, with simultaneous

reducing energy consumption and noise.

The high performance bearings are separated from the cutting chamber to prevent lubricant ingress and bearing failure to prevent material contamination.

"Both rotor and stator knives are externally adjusted.

Rotor diameter (mm) 560

Rotor width (mm) 700

Drive capacity (HP) 75

Rotor knives (pieces) 5 x 2

Stator knives (rows) 2 + 1

Hopper opening (mm) 700 x 650

Total length (mm) 2300

Length machine (mm) 2200

Width total (mm) 1600

Width machine (mm) 1060

Height (mm) 3509

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM S 60 Cutting Mill

CrushmasterS 60

Call

Year of construction: 2025, Condition: new, APPLICATIONS

The S-Series granulators are mainly used as large central granulators for

In-house recycling applications for processing large thick-walled parts in one

stage or as a second-stage granulator after a shredder to achieve higher results or throughput rates

GENERAL DESCRIPTION

The high-performance S-Series granulators offer widths from

600 to 1000 mm with diameters of 400 and 560 mm.

The all-welded heavy steel construction is designed to withstand

the most demanding and universal applications. Rotor bearings, blades

brackets and rotor shaft are oversized. The standard V-cut ensures a high

quality grind with a very low percentage of fines in the starting material.

The removable third stator blade (optional) acts as a deflection wedge

and allows the machine to be quickly adapted to different application

scenarios. Other standard equipment also includes easily adjustable blades

from the outside, reducing the risk of contamination.

S-SERIES - HIGH PERFORMANCE GRANULATORS ADVANTAGES:

"The easily removable deflector wedge acts as a third stator blade and can

be used to adjust the aggressiveness of the rotor at the first cut point.

The V-Cut technology produces a high quality regrind, with simultaneous

reducing energy consumption and noise.

The high performance bearings are separated from the cutting chamber to prevent lubricant ingress and bearing failure to prevent material contamination.

"Both rotor and stator knives are externally adjusted.

Rotor diameter (mm) 400

Rotor width (mm) 600

Drive capacity (HP) 50

Rotor knives (pieces) 5 x 2

Duslq Nkep N D N Sjq Sjt

stator knives (rows) 2 + 1

Hopper opening (mm) 630 x 600

Total length (mm) 1950

Length machine (mm) 1876

Width total (mm) 1359

Width machine (mm) 1000

Height (mm) 3040

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM H 100 Cutting Mill

CrushmasterH 100

Call

Year of construction: 2025, Condition: new, The G and H series compact mills are primarily designed for

Djlq Njp N Dv Hekq Sout

use in injection molding and blow molding applications for recycling voluminous product

parts such as bottles, canisters and crates, as well as flush blow molding

and injection channels. Their low height makes them ideal for use with

manual feeding of such parts. The low noise level and small footprint

This makes them perfect for inline recycling operations.

Advantages:

Compact design, small footprint.

All knives are adjusted outside the machine in a fixture

to reduce downtime for maintenance

Aggressive feed due to curved rear wall of the cutting chamber

Large screen area for high throughput rates

Advanced V-Cut technology produces a high quality grind

while reducing energy consumption and noise levels

Rotor diameter (mm) 400

Rotor width (mm) 1000

Drive capacity (hp) 40

Rotor blades (pieces) 3(5) x 1

Stator knives (rows) 2

Hopper opening (mm) 490 x 990

Total length (mm) 1348

Length machine (mm) 1120

Width total (mm) 1577

Width machine (mm) 1216

Height (mm) 1914

Trust Seal

Dealers certified through Machineseeker

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

CM S 100 Granulator

CrushmasterS 100

Call

Year of construction: 2025, Condition: new, APPLICATIONS

The S-Series granulators are mainly used as large central granulators for

In-house recycling applications for processing large thick-walled parts in one

stage or as a second-stage granulator after a shredder to achieve higher results or throughput rates

GENERAL DESCRIPTION

The high-performance S-Series granulators offer widths from

600 to 1000 mm with diameters of 400 and 560 mm.

The all-welded heavy steel construction is designed to withstand

the most demanding and universal applications. Rotor bearings, blades

brackets and rotor shaft are oversized. The standard V-cut ensures a high

quality grind with a very low percentage of fines in the starting material.

Duelop N D Tysq Nkq Sst

The removable third stator blade (optional) acts as a deflection wedge

and allows the machine to be quickly adapted to different application

scenarios. Other standard equipment also includes easily adjustable blades

from the outside, reducing the risk of contamination.

S-SERIES - HIGH PERFORMANCE GRANULATORS ADVANTAGES:

"The easily removable deflector wedge acts as a third stator blade and can

be used to adjust the aggressiveness of the rotor at the first cut point.

The V-Cut technology produces a high quality regrind, with simultaneous

reducing energy consumption and noise.

The high performance bearings are separated from the cutting chamber to prevent lubricant ingress and bearing failure to prevent material contamination.

"Both rotor and stator knives are externally adjusted.

Rotor diameter (mm) 560

Rotor width (mm) 1000

Drive capacity (HP) 100

Rotor knives (pieces) 5 x 2

stator knives (rows) 2 + 1

Hopper opening (mm) 1000 x 650

Total length (mm) 2310

Length machine (mm) 2200

Width total (mm) 1800

Width machine (mm) 1330

Height (mm) 3770

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Single shaft shredder

ZermaGST 400/600

Call

Condition: new, Year of construction: 2024, Functionality: fully functional, overall weight: 3,300 kg, rotor diameter: 400 mm, number of blades: 6, rotor length: 600 mm, rotor width: 400 mm, power: 22 kW (29.91 HP), filling opening width: 490 mm, filling opening length: 590 mm, warranty duration: 12 months, input voltage: 400 V, The compact inline granulators in the GST series are suitable for use in injection molding and blow molding plants. They are suitable for recycling voluminous parts such as bottles, canisters, crates, sprues and injection molded parts. Due to the low feed height, the machines can be easily fed with material by hand or a small conveyor belt. The low noise emission and small footprint make the GST series the perfect solution for inline shredding.

Delsvgncujq Nkq Seut

All machines in the GST series have a compact, sound-insulated machine housing and a sound-insulated hopper. The feed hopper can be opened and closed by means of a gas pressure damper. The compact granulators are available with two rotor diameters (250 mm, 400 mm) and in rotor widths from 300 to 1000 mm. The smaller machines have an open F-rotor, the larger machines are equipped with the heavier S-rotors. The curved rear wall of the cutting chamber ensures aggressive material feed and prevents material jams. Thanks to the modular design of the granulator, it can be easily expanded with additional options such as replaceable wear plates. As with all ZERMA granulators, the rotor and stator knives can be adjusted outside the machine to reduce downtime during maintenance. The setting gauge is included in the scope of delivery. The control cabinet is permanently mounted on the outside of the noise protection box, the complete cabling is inside the machine.

Rotor diameter (mm) 400

Rotor width (mm) 600

Drive (kW) 22

Rotor blades (rows) 3 x 2

Stator knives (rows) 2

Screen perforation (mm) > 6

Cutter housing (mm x mm) 400 x 600

Weight (approx. kg) 3300

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Granulator

ZERMAGSL 300/600

Call

Year of construction: 2025, Condition: new, GSL - Slow speed granulator GSL 300

Rotor diameter (mm) 300

Rotor width (mm) 600

Rotor speed (rpm) 150

Drive capacity (kW) 11

Rotor knives (pcs) 48

Stator blades (rows) 2

Screen size (mm) > 6

Weight approx. (kg) 950

The slow speed granulators in the GSL range are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues. The machines can be used for rejected products in the inline recycling process as well. Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots.

Driven by gear motor

Unique knife design eliminates adjustment after resharpening.

Duslq Nji Hpf Njkq Sjt

Simple tool less access for maintenance and cleaning

Customizable hopper and base frame

The slow speed granulators in the GSL 300 range feature a staggered 300 mm diameter rotor with widths ranging from 400 to 800 mm.

The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding.

The special design knives of the GSL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound absorbing feed hopper that can be tailored to fit various applications and feeding ways.

Depending on the requirements the machines can be fitted with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters.

Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy.

Applications

The GSL slow speed granulators of the 300 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues.

But they can be used as low noise central granulators for small throughput requirements as well.

The stronger design of the 300 series GSLs allow them to be used for stronger and thicker materials while offering the same advantages regarding low noise and dust as the smaller GSL machines.

All GSL models can be equipped with a built in blower system in case a vacuum loading system is not available, or to transport the ground material to bags for storage.

Listing

Buchholz in der Nordheide

Buchholz in der Nordheide

891 km

Shredding machine

ZERMAGSL 180/300

Call

Condition: new, Year of construction: 2025, Slow-running mill for storage

Rotor diameter (mm) 180

Rotor width (mm) 300

Rotor speed (rpm) 150

Drive (kW) 4

Number of rotor blades 30

Number of stator blades 2

Screen perforation (mm) >5

Approx. weight (kg) 180

Dolq Nst Aam Hskq Seut

The slow-running mills of the GSL 180 series have a rotor diameter of 180 mm and working widths from 120 to 430 mm.

The rotor is driven directly by a gear motor. The low rotor speed ensures a pleasant noise level and a high-quality product.

The special rotor blades can be resharpened several times, eliminating the need for complex adjustment work. The mills are fed via a noise-reducing sandwich-type hopper. Depending on the task, the machines can be equipped with various hopper variants.

Low and high base frames are available as options. The ground material is either vacuumed or filled into bags or a plastic container.

Good accessibility for simple and quick maintenance work is ensured by the Quick Snap locking system.

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Plastic processing machinery (2,624)

Search Machineseeker now with more than 200,000 used machines:This may be of interest to you