Used Emulsion for sale (271)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Vilnius

Vilnius

1,821 km

Vertical machining center

HaasUMC-500

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, travel distance X-axis: 610 mm, travel distance Y-axis: 406 mm, travel distance Z-axis: 406 mm, workpiece weight (max.): 200 kg, table width: 500 mm, spindle speed (min.): 10,000 rpm, Equipment: chip conveyor, For sale: HAAS UMC-500 5-Axis Universal Machining Center

Condition: Absolutely brand new machine. Only one part was produced for test machining. The equipment has been unused and stored for 2 years.

Main technical specifications

Travel:

X-axis: 610 mm

Y-axis: 406 mm

Z-axis: 406 mm

Table:

Diameter: 500 mm

Maximum workpiece weight: 200 kg

5-axis rotary/trunnion table (trunnion type)

Spindle:

Inline direct-drive

10,000 rpm

30 HP (22.4 kW)

CAT 40 taper (40T)

Through-spindle coolant: 300 psi (21 bar)

Tool changer:

30 tool positions

Side-mount, high speed

Precision and compensation:

Temperature compensation

DWO/TCPC – Dynamic Work Offset and Tool Center Point Control

Rigid Tapping

Equipment and features:

Haas NGC CNC control (FANUC compatible)

1 GB memory

Ethernet connection, WiFi connectivity

USB port, color 15” LCD display

Early power-failure detection module

Memory lock (keyswitch)

Spindle coolant system

Protective enclosure with doors

Internal lighting

Centralized lubrication system

Top cover

Measurement and calibration equipment:

Renishaw WIPS wireless intuitive probing system

(Haas Visual Programming System, macros, spindle orientation, coordinate rotation and scaling)

Rotary-Axis calibration tool

Nodsxg Nd Njpfx Afhowb

RJH remote jog handle with color display

Chip and coolant systems:

Coolant tank – 95 gallons (360 L)

Initial fill with Blaser coolant emulsion

Chip conveyor (belt type – CONVEYOR-H)

High-pressure air system

Documentation:

Original machine documentation (in English)

Application

Haas UMC-500 is a compact yet powerful universal 5-axis machining center designed for the production of complex, multi-sided, and free-form surface parts. Suitable for simultaneous 5-axis machining as well as 3+2 machining, significantly reducing setup operations and ensuring high accuracy.

If you have further questions, we are happy to assist.

Listing

Coesfeld

Coesfeld

796 km

Vacuum tank truck

MERCEDES-BENZActros 2546 L 6x2 NEU ! KROLL Saug-Druck-Aufbau

Call

Condition: new, fuel type: diesel, overall weight: 26,000 kg, axle configuration: 3 axles, color: white, gearing type: semi-automatic, Year of construction: 2025, Equipment: ABS, electronic stability program (ESP), ++ RENT ++ BUY ++ RENT ++ BUY ++ RENT ++ BUY ++ RENT

Internal Number: #546

Mercedes-Benz Actros 2546 L 6x2 with Kroll ADR Vacuum/Pressure Tanker K 1.0-13.5/36PESP

Brand new KROLL ADR vacuum/pressure tank vehicle on Mercedes-Benz Actros chassis – engineered for the toughest applications from day one. Maximum suction performance, high-capacity high-pressure system, and premium ADR-L4BH technology make this vehicle a first-class choice for professional waste management and industrial operations.

Bodywork

• Manufacturer: KROLL

• Tank material: S355J2+N (St 52.3)

• ADR vacuum/pressure tank K 1.0–13.5/36PESP

• Air chamber volume: approx. 13,500 l

• Sludge volume: approx. 11,200 l

• Emulsion compartment: max. 4,589 l

• Rinse water (non-pressurized): approx. 1,000 l

Njdjv Nu Sbspfx Afhewb

• Discharge via ejector piston

Chassis

• Mercedes-Benz Actros 2546 L 6×2

• PowerShift 3 automatic transmission

• 460 HP / 338 kW

• EURO 6e

• Diesel tank: 400 l

• Cab color: Arctic White

• 2× LED beacons on the cab

• Reversing camera

• Navigation

• Air conditioning

Vacuum System

• CVS VacuStar W1300

• approx. 1,200 m³/h at 400 mbar

• Suction hose reel for approx. 50 m DN75 (mounted on tank cover, passes into tank)

• incl. 30 m plastic suction hose DN75

High-Pressure System

• Speck P45/85-160

• Delivery rate: 85 l/min at 160 bar

• Small hydraulic high-pressure hose reel for approx. 60 m DN13, hydraulic

• incl. 60 m high-pressure rubber hose DN13, hydraulic

Special features

• ADR version L4BH (incl. EX/II, EX/III, AT)

• Upper suction connection DN100, remote-controlled

• DN500 manhole on top with ladder & working platform

• High-pressure gun

• Sound insulation panels left & right in front of pumps

• LED perimeter lighting

• Radio remote control

• Tiltable debris container

• Ladder with mount & anchor points

• Advertisement boards left & right on the tank

Summary

An extremely robust, fully ADR-certified KROLL vacuum/pressure tank built on Mercedes-Benz Actros chassis – with a powerful W1300 vacuum system, high-performance high-pressure unit, and complete safety & comfort features. Ready for immediate operation by industrial clients, waste management companies, sewer service providers, and hazardous goods transport.

For further details and/or pictures, please contact us directly. A wide selection of additional vehicles for SALE or RENT is available at:

Specifications, interim sales, and errors are subject to change. Buyers are obligated to verify the condition and equipment of the goods themselves. Sale exclusively under our General Terms and Conditions and with exclusion of any warranty.

Listing

Zdziechowice

Zdziechowice

1,523 km

Oil mist extractor, Donaldson separator

Donaldson ToritDRYFLO DMC-D2

Call

Condition: used, volume flow: 7,500 m³/h, Oil mist extractor for CNC machines, Donaldson Torit brand filter separator.

The unit is designed for filtration of oil mist (emulsions as well as pure oil),

vapors and fumes generated by various

metal cutting processes.

Nwodpfx Afsxd Ry Hohsb

Filtration efficiency reaches 99.97%

Model: DMC-D2

Fan power: 7.5 kW

Capacity: 7,500 m3/h

Filtration area: 40.8 m2

Filter cartridges in very good condition.

Stock no.: 1043

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Georgensgmünd

Georgensgmünd

1,198 km

Universal machining center

DMGDMU 100P douBLOCK

Call

Condition: ready for operation (used), Year of construction: 2004, operating hours: 46,810 h, functionality: fully functional, machine/vehicle number: 11450000153, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 1,000 mm, total height: 3,393 mm, overall weight: 11,670 kg, spindle speed (max.): 18,000 rpm, operating hours of spindle: 46,160 h, number of spindles: 1, number of slots in tool magazine: 60, Equipment: chip conveyor, Horizontal tool changer with double gripper

100-position tool magazine HSK63

Coolant tank 600 l

Chip conveyor

Rotating viewing window

3D path control Millplus IT

NC rotary table Ø 1100 mm x 900 mm, load capacity up to 2000 kg

Motor spindle HSK-A63, spindle speed up to 18,000 rpm

Universal milling head

Tool holder

Tool magazine

Heidenhain TS641 touch probe

Electronic handwheel

Oil and emulsion separation system

High-pressure coolant system

Spray gun with pump

Axis travel X/Y/Z each 1000 mm

Rotary table 0-360° (C-axis) and swiveling head -10 to 180° (B-axis)

Laser for tool measurement

Chain magazine with 60 tool positions

Band filter system with 980 liters

Chain magazine 1.9 tons

Repairs 2022:

- Replacement of the spindle at 34,661 operating hours

Njdpfjw A Nimex Afhjwb

Repairs 2019:

- Replacement of X/Z sliding plate including guides of the Z and X axes

- Replacement of ball screw drive of the Z axis

Defect 2025 - A hose has a crack (see picture in the gallery). Depending on further use, we can repair this if needed.

Hour meter 1: 117,755 h

Hour meter 2: 46,810 h

Listing

Rzeszów

Rzeszów

1,805 km

Bitumen Sprayer/Crack Sealing Machine

TICABBM Combo

Call

Condition: new, functionality: fully functional, gearing type: other, axle configuration: 2 axles, emission class: none, mast type: other, brakes: other, suspension: other, Year of construction: 2026, Equipment: low noise, TICAB BM Combo | Asphalt Repair & Road Maintenance Equipment

The TICAB BM Combo is a dual-function bitumen combination machine designed for professional road construction, asphalt repair, pothole patching, crack sealing, joint filling, surface dressing, tack coat application, and asphalt priming. This versatile machine integrates a 750 L bitumen emulsion sprayer and a 120 L crack sealing unit, providing efficient, precise, and reliable asphalt and bitumen application for contractors, municipalities, and industrial projects.

Key Features:

• Dual-function design: 750 L bitumen emulsion sprayer + 120 L crack sealing machine

• Diesel-powered engine with hydraulic pump and heating system for reliable operation

• High-precision spray system for even asphalt and bitumen coverage

• Mobile, trailer-mounted, and easy to operate

• Tanks equipped with automatic temperature control, hand wand, wide spray bar, and flushing system

• Suitable for municipal roads, highways, streets, parking lots, driveways, industrial areas, bike paths, and airport pavements

• Durable construction for long-term heavy-duty use

• Manufactured by TICAB – trusted European road equipment brand

Applications:

• Road and highway construction and maintenance

• Asphalt paving preparation and tack coat application

• Pothole repair, crack sealing, joint filling

• Surface dressing and asphalt waterproofing

• Municipal, industrial, and commercial asphalt projects

Nedpfxox U S Hlj Afhowb

Why Choose TICAB BM Combo:

The TICAB BM Combo delivers dual-function performance, combining bitumen emulsion spraying and crack sealing in a single, high-efficiency road maintenance machine. It reduces equipment costs, saves time, and ensures uniform, professional asphalt and bitumen application across a wide range of projects.

Contact us now for price, availability, delivery options, and technical specifications. Ready for immediate deployment!

Discover more used machines

Listing

Rzeszów

Rzeszów

1,805 km

Bitum sprayer/crack sealer

TICABBM-Combo

Call

Condition: new, functionality: fully functional, power: 10.4 kW (14.14 HP), gearing type: other, fuel type: diesel, color: green, axle configuration: 1 axle, emission class: none, brakes: other, Year of construction: 2026, Equipment: low noise, TICAB BM Combo | Asphalt Repair & Road Maintenance Equipment

The TICAB BM Combo is a dual-function bitumen combination machine designed for professional road construction, asphalt repair, pothole patching, crack sealing, joint filling, surface dressing, tack coat application, and asphalt priming. This versatile machine integrates a 750 L bitumen emulsion sprayer and a 120 L crack sealing unit, providing efficient, precise, and reliable asphalt and bitumen application for contractors, municipalities, and industrial projects.

Key Features:

• Dual-function design: 750 L bitumen emulsion sprayer + 120 L crack sealing machine

• Diesel-powered engine with hydraulic pump and heating system for reliable operation

• High-precision spray system for even asphalt and bitumen coverage

• Mobile, trailer-mounted, and easy to operate

• Tanks equipped with automatic temperature control, hand wand, wide spray bar, and flushing system

• Suitable for municipal roads, highways, streets, parking lots, driveways, industrial areas, bike paths, and airport pavements

• Durable construction for long-term heavy-duty use

Nwsdpfxjx U Am Ns Afhob

• Manufactured by TICAB – trusted European road equipment brand

Applications:

• Road and highway construction and maintenance

• Asphalt paving preparation and tack coat application

• Pothole repair, crack sealing, joint filling

• Surface dressing and asphalt waterproofing

• Municipal, industrial, and commercial asphalt projects

Why Choose TICAB BM Combo:

The TICAB BM Combo delivers dual-function performance, combining bitumen emulsion spraying and crack sealing in a single, high-efficiency road maintenance machine. It reduces equipment costs, saves time, and ensures uniform, professional asphalt and bitumen application across a wide range of projects.

Contact us now for price, availability, delivery options, and technical specifications. Ready for immediate deployment!

Listing

Rzeszów

Rzeszów

1,805 km

Asphalt recycler

TICABAsphalt recycler RA-800

Call

Condition: new, functionality: fully functional, power: 7.5 kW (10.20 HP), fuel type: diesel, color: green, empty load weight: 2,300 kg, operation weight: 3,100 kg, Year of construction: 2026, Equipment: additional headlights, hydraulics, The TICAB RA 800 Asphalt Recycler is a professional mini asphalt plant designed for hot mix asphalt production, asphalt recycling, pothole repair, crack filling, road resurfacing, patching, and pavement maintenance. This versatile unit reuses reclaimed asphalt pavement (RAP) to produce high-quality hot mix asphalt directly on-site, saving materials, energy, and costs. Ideal for municipalities, contractors, industrial sites, highways, parking lots, and urban road maintenance projects.

Key Features:

• Mini asphalt plant & asphalt recycler RA 800 for on-site hot mix asphalt production and RAP recycling

• Diesel-fired heating system with precise temperature control for consistent hot mix quality

• Output capacity: up to 800 kg/h for medium-scale repairs

• Compact, mobile, and easy to operate on construction sites, municipal roads, highways, parking areas, driveways, bike paths, and industrial pavements

• Supports bitumen emulsion, tack coat, and recycled asphalt pavement (RAP)

Njdpex Uxiasfx Afhjwb

• Durable, robust construction for long-term heavy-duty use

• Designed for road contractors, paving companies, municipalities, and civil engineering works

Applications:

• Asphalt recycling and RAP processing

• Hot mix asphalt production and transport

• Road repair, pothole patching, crack filling, and resurfacing

• Municipal streets, highways, parking lots, driveways, and industrial surfaces

Why Choose TICAB RA 800:

The TICAB RA 800 Asphalt Recycler combines mini asphalt plant capability with on-site recycling efficiency, allowing contractors and municipalities to produce high-quality hot mix asphalt, reduce material costs, and maintain durable road surfaces. Compact, reliable, and versatile, the RA 800 is the perfect choice for all asphalt repair, resurfacing, and pavement maintenance projects.

Contact us now for price, delivery options, and full technical specifications. Start producing and recycling asphalt efficiently today!

Listing

Rzeszów

Rzeszów

1,805 km

Asphalt recycler

TICABAsphalt recycler RA-800

Call

Condition: new, functionality: fully functional, power: 7.5 kW (10.20 HP), fuel type: diesel, color: green, empty load weight: 2,300 kg, emission class: none, mast type: other, brakes: other, Year of construction: 2026, Equipment: hydraulics, TICAB RA 800 | Mini Asphalt Plant & Asphalt Recycler – Hot Mix Asphalt Machine

The TICAB RA 800 is a compact asphalt recycler and mini asphalt plant for pothole repair, asphalt patching, crack filling, hot mix production, and road resurfacing. Perfect for municipal streets, highways, parking lots, driveways, and industrial pavements.

• Hot mix asphalt recycler for on-site RAP processing

• Output: up to 800 kg/h

• Diesel-fired heating system ensures uniform temperature

• Mobile, compact, and easy to operate

• Ideal for contractors, municipalities, paving companies, and road maintenance crews

Keywords: asphalt recycler, mini asphalt plant, RA 800, hot mix asphalt recycler, asphalt repair machine, pothole repair equipment, RAP processing, municipal asphalt equipment, TICAB RA 800

Key Features:

• Mini asphalt plant & asphalt recycler RA 800 for on-site hot mix asphalt production and RAP recycling

Nodpfx Aox Uqfyjfhjwb

• Diesel-fired heating system with precise temperature control for consistent hot mix quality

• Output capacity: up to 800 kg/h for medium-scale repairs

• Compact, mobile, and easy to operate on construction sites, municipal roads, highways, parking areas, driveways, bike paths, and industrial pavements

• Supports bitumen emulsion, tack coat, and recycled asphalt pavement (RAP)

• Durable, robust construction for long-term heavy-duty use

• Designed for road contractors, paving companies, municipalities, and civil engineering works

Applications:

• Asphalt recycling and RAP processing

• Hot mix asphalt production and transport

• Road repair, pothole patching, crack filling, and resurfacing

• Municipal streets, highways, parking lots, driveways, and industrial surfaces

Why Choose TICAB RA 800:

The TICAB RA 800 Asphalt Recycler combines mini asphalt plant capability with on-site recycling efficiency, allowing contractors and municipalities to produce high-quality hot mix asphalt, reduce material costs, and maintain durable road surfaces. Compact, reliable, and versatile, the RA 800 is the perfect choice for all asphalt repair, resurfacing, and pavement maintenance projects.

Listing

Schijndel

Schijndel

722 km

Vertical machining center

HERMLEC30 V (HSC - 40.000 RPM)

Call

Condition: like new (used), Year of construction: 2008, travel distance X-axis: 650 mm, travel distance Y-axis: 600 mm, travel distance Z-axis: 500 mm, rapid traverse X-axis: 45 m/min, rapid traverse Y-axis: 45 m/min, rapid traverse Z-axis: 45 m/min, controller model: Heidenhain iTNC530, table width: 960 mm, table length: 600 mm, overall weight: 9,000 kg, spindle speed (max.): 40,000 rpm, operating hours of spindle: 22,800 h, spindle nose: HSK E 40, number of spindles: 1, number of slots in tool magazine: 38, input voltage: 400 V, Equipment: documentation/manual, rotational speed infinitely variable, This machine has been used exclusively for copper processing. The coolant water supply is present but has not been used to date. In other words, a superb machine that has always done very light machining, has never seen coolant, and is equipped with a Weiss spindle running at 40,000 rpm.

The machine comes as standard including:

- Original documentation for the machine and the Weiss spindle

- BLUM tool laser

- Heidenhain TS-440 3D probe

- Spindle and emulsion cooler

- Lockable roof (harmonica style)

Njdpfsxgukbox Afhewb

The machine can be inspected under power by appointment.

Listing

Germany

Germany

1,086 km

Multispindle

INDEXMS 22-8

Call

Condition: excellent (used), Year of construction: 2021, functionality: fully functional, number of spindles: 6, bar diameter (max.): 22 mm, Equipment: rotational speed infinitely variable, 8-spindle

Double NCU

Slide unit 1.1: X-axis and Z-axis NC-controlled

Slide unit 1.2: X-axis and Z-axis NC-controlled

Slide unit 2.1: X-axis and Z-axis NC-controlled

Slide unit 2.2: X-axis and Z-axis NC-controlled

Slide unit 3.1: X-axis and Z-axis NC-controlled

Slide unit 3.2: X-axis and Z-axis NC-controlled

Slide unit 4.1: X-axis and Z-axis NC-controlled

Slide unit 4.2: X-axis and Z-axis NC-controlled

Slide unit 5.1: X-axis and Z-axis NC-controlled

Slide unit 5.2: X-axis and Z-axis NC-controlled

Slide unit 6.1: X-axis and Z-axis NC-controlled

Slide unit 6.2: X-axis and Z-axis NC-controlled

Slide unit 7.1: X-axis and Z-axis NC-controlled

Slide unit 7.2: Swivel axis and Z-axis NC-controlled

Slide unit 7.3: X-axis NC-controlled, Z-axis fixed

Slide unit 8.1: Swivel axis and Z-axis NC-controlled

Slide unit 8.2: X-axis and Z-axis NC-controlled

Slide unit 8.3: X-axis NC-controlled, Z-axis fixed

Synchronization device at position 7.2

Synchronization device at position 8.1

Rear-side machining at positions 7.3 and 8.3 possible with three fixed and two driven positions

Index loading magazine MBL228/3300 bundle loader

Njdoxur Srepfx Afhswb

Hinged belt chip conveyor

Three-jaw chuck Röhm for synchron spindle

Workpiece conveyor belt at spindle position 7

Workpiece conveyor belt at spindle position 8

Fire extinguishing system

Büchel coolant emulsion extraction system

Listing

Schijndel

Schijndel

722 km

Vertical machining center

HERMLEC40 V

Call

Condition: like new (used), Year of construction: 2008, functionality: fully functional, travel distance X-axis: 850 mm, travel distance Y-axis: 700 mm, travel distance Z-axis: 500 mm, rapid traverse X-axis: 45 m/min, rapid traverse Y-axis: 45 m/min, rapid traverse Z-axis: 45 m/min, controller model: Heidenhain iTNC530, table width: 1,070 mm, table length: 700 mm, overall weight: 10,000 kg, spindle speed (max.): 18,000 rpm, operating hours of spindle: 16,533 h, spindle nose: SK40, number of slots in tool magazine: 38, input voltage: 400 V, Equipment: documentation/manual, rotational speed infinitely variable, Once again, a very neat HERMLE C40V coming from a mold making workshop. The machine is in excellent condition and can also be viewed under power at our facility! This machine is standard equipped with: Blum tool laser, Heidenhain TS440 probe, custom-made coolant table, lockable roof (accordion style), original documentation, spindle and emulsion cooler.

Nedpfjxd U N Sox Afhjwb

Listing

Rzeszów

Rzeszów

1,805 km

Mastic asphalt mixer

TICABSelf-propelled BitumenSprayer BS-1000 SP

Call

Condition: new, Year of construction: 2025, SELF-PROPELLED BITUMEN EMULSION SPRAYER BS-1000SP

TM TICAB self-propelled Bitumen Emulsion Sprayer BS-1000-SP is the most powerfull mini bitumen emulsion sprayer among all TICAB mini sprayers. Spray bar 1,5m (7 nozzles) covers up to 2000 sq.m per hour. Tank 1000 L. Repair work in the shortest possible time both on small areas (household areas, alleys) and on the bigger areas. Self-propelled system fits any trailer. Car is needed just to move the BS-1000-SP sprayer to the construction side. It makes using the sprayer much easier and increases its maneuverability. Operate remotely using a joystick.

Specifications:

Gasoline engine – 16 hp; Productivity – 30 l/min; Spraying width – 1.7 m;

Nwjdpfovpg Izsx Afheb

System cleaning – 3-level, diesel fuel; Self-pumping function of the tank;

Installation on a frame or on a trailer at the customer's request; Heating system of the emulsion tank; Tank – 1000 l;

Possibility of connecting an extra compressor for spraying bar cleaning; Thermal sensor – mechanical;

Burner – propane;

Hand spraying rod; Self-propelled traction hydraulic wheel.

Listing

Buchholz

Buchholz

890 km

COBARON | Mechanical air filter

ISI Gruppe -COB 23 TR – 2050 m³/h – 400 V

Call

Condition: new, Extraction capacity of filter unit at spigot*: 2050 m³/h

Total power consumption*: 1.04 kW

Operating voltage: 400 V, 50/60 Hz,3Ph+PE

Noise level*: 69 db(A)

Dimensions L/W/H in mm: L 1290 / W 588 /H 595

Colour: RAL 7035

Weight: 113 kg

Manufacturer: ISI Industrieprodukte GmbH

*Depending on filter equipment

Special voltage or special colour on request

Application:

Separation of emulsion mist, for medium to very large machine workrooms.

Your advantages of the COBARON series:

Nodpfsh Rfbxex Afhswb

- 15 unit variants available

- Direct from the manufacturer

- ISI-TRONIC as standard (digitalised filter control)

- Electronically controlled EC fan as standard

- Adjustable speed and air flow rate

- Available with a wide range of filters

- High-quality filter media in the pre-filter and main filter area

- Separation rates of up to 99.95

- Large range of mounting and connection accessories

- Flexibly adaptable to the application

- Optimum service life

- Quality Made in Germany

With COBARON, we offer a filter system that meets today's diverse processing possibilities and the resulting pollutant profiles. In the standard programme alone, the COBARON combination filter system offers various filter equipment variants and can thus be variably configured for many applications.

The various configuration levels of the COBARON series were specially developed for applications that were borderline cases for many filter systems (mechanical or electrostatic). The combination of both proven filter principles in the appropriate application increases the effectiveness of the air filter and extends the service life.

COBARON can be operated as a purely mechanical filter unit with different filter stages - or additionally configured with an electrostatic filter cell. Our filter units are already digitalised as standard and can be controlled with a laptop, for example.

Listing

Buchholz

Buchholz

890 km

ELBARON | Electrostatic air cleaner

ISI Gruppe - NEUE SERIE -E-RON 4 STR – 2600 m³/h – 400 V

Call

Condition: new, Year of construction: 2023, Extraction capacity of filter unit at spigot*: 2600 m³/h (free-eye)

Total power consumption*: 0.62 kW

Operating voltage: 400 V, 50/60 Hz,3Ph+PE

Noise level*: 65 db(A)

Dimensions L/W/H in mm: L 975 / W 508 /H 545

Colour: RAL 7035

Weight: 90 kg

Manufacturer: ISI Industrieprodukte GmbH

*Depending on filter equipment

Special voltage or special colour on request

Application:

Extraction of oil mist, emulsion mist (for emulsions with higher oil contents) and smoke, for small to very large machine workrooms | Oil mist separator.

Your advantages of the ELBARON series:

- 18 unit variants available

- Direct from the manufacturer

- ISI-TRONIC as standard (digitalised filter control)

- Electronically controlled EC fan as standard

- Speed and air flow rate adjustable

- Simplex (single-stage) or duplex (two-stage) available

- Wide range of air flow rates available

- Adaptable to pollutant load and air performance requirements

- Large range of mounting and connection accessories

- Quality Made in Germany

We have developed the ELBARON® filter series for use in machining operations with pure oil or for separating oil mist and smoke (oil mist separator). For many years now, the digital electrostatic air filters of the ELBARON® series have been among the most efficient filter units on the market and are in use worldwide. Our filter units are already digitalised as Option and can be controlled, for example, with a laptop.

The ELBARON® unit series comprises 18 unit variants and can be optimally designed for your application in terms of size and performance. ELBARON® units impress with their long service life and absolute functional reliability. Our electrostatic filter cells are dimensioned in such a way that the best possible filter efficiencies, service lives and trouble-free operation are achieved under economic aspects.

Nodjh Rdxnspfx Afhowb

Listing

Neckartailfingen

Neckartailfingen

1,148 km

Briquetting press, briquette press

RUF4/3700/60x40

Call

Condition: as good as new (ex-display), Year of construction: 2022, Briquetting press for aluminium or steel chips

Extremely high pressing force of 3,700 kg/cm²

Large storage silo

Briquette size: 60 x 40 mm

Throughput:

Aluminium chips – up to approx. 70 kg/h

Steel chips – up to approx. 100 kg/h

Brass chips – up to approx. 100 kg/h

*depending on feedstock

Included:

- Emulsion tray

- Emulsion pump

Njdpfx Afsw Ig Sushewb

- Oil cooler

Listing

Neckartailfingen

Neckartailfingen

1,148 km

Briquetting press Briquetting press aluminum

mütekMPP NEM 90

Call

Condition: reconditioned (used), Year of construction: 2023, All wear parts new

only 704 operating hours

Special price for a low-hour demonstration unit

Base machine: €29,990 net

Optional extras (for an additional charge):

- Cooling unit: €3,995 net

- Emulsion tray: €3,990 net

The hydraulic briquetting presses of the MPP NEM series compact materials such as aluminum, copper, brass, bronze, graphite, and other non-ferrous metals into dimensionally stable cylindrical briquettes. These machines are distinguished by their robust construction, ensuring consistent briquette quality during continuous operation. The pressing process does not require any binding agents – compaction is achieved solely through hydraulic pressing force. Depending on material, the feedstock volume can be reduced by up to 90%.

Throughput capacity: maximum 70 kg/h (depending on material)

Briquette diameter: Ø 50 mm

Motor: 5.5 kW

400 Volt / 50 Hz / 3-phase

Pump: 40 liters

Maximum briquette length: 50 mm

Optimal briquette length: 40 mm

Silo diameter: 1,000 mm

Oil tank: 110 liters

Dimensions: 1750 x 1130 x 1100 mm (L x W x H)

Nwodpfod N Dnhjx Afheb

Weight: 950 kg

Hydraulic pre-compaction via slide

Main press cylinder

Vertical cylinder

Fill level sensor: yes

Feed material requirements:

- Max. chip length: 15 mm

- Installation room temperature: heated space, at least +5°C

- Max. load on agitator: 150 kg

- Feed material must be free from magnetic metals and mineral contaminants such as sand, stones, etc. Damage to pressing tools and/or increased wear may otherwise occur.

Listing

Gerstetten

Gerstetten

1,187 km

Universal machining center

DMG MORIDMU 60evo

Call

Condition: excellent (used), Year of construction: 2014, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 500 mm, travel distance Z-axis: 500 mm, Equipment: chip conveyor, rotational speed infinitely variable, DMG-MORI DMU 60 EVO linear Year 2014

Travel X/Y/Z: 600 mm x 500 mm x 500 mm

Motor spindle SK40 with 18,000 rpm

NC tilting rotary table, B and C axes

Tool magazine with 60 stations

Nwjdexvhrwopfx Afhsb

Heat exchanger for spindle and table

Dynamic package

Control: Siemens 840 D SL with Shop-Mill

Infrared probe Heidenhain TS 649

Blum laser tool measurement

Scraper belt conveyor, HPC with paper band filter and 80 bar

Oil mist emulsion separator

Programmable coolant nozzles

Electronic handwheel, mode 4

Turning and milling cycle

Listing

Slovenia

Slovenia

1,646 km

Vertical Machining Centre

DOOSANDNM 4500

Call

Condition: ready for operation (used), Year of construction: 2020, operating hours: 2,850 h, General Data

Measurements width 2615 mm

Measurements depth 2158 mm

Measurements height 2985 mm

Machine weight 5000 kg

Control Unit

Brand SIEMENS

Main Drive

Nwedpfx Afsx D E H Ijhob

Number of axis 3

Movement

X-Axis Movement 800 mm

X-Axis Rapid Traverse 36 m/min

Y-Axis Movement 450 mm

Y-Axis Rapid Traverse 36 m/min

Z-Axis Movement 510 mm

Z-Axis Rapid Traverse 30 m/min

Workpiece

Workpiece weight 600 kg

Tools

Slots in storage 30

Max weight 8 kg

Max tool diameter 125 mm/80 mm

Max tool length 300 mm

Type of tool holder BT 40

Media

Chip conveyor Yes

Additional Equipment

Electronic Handwheel

Chip conveyor

Oil skimmer

Emulsion flushing gun

2 x Hydraulic vice

25 x Clamping chuck BT40

This 3-axis DOOSAN DNM 4500 vertical machining center was manufactured in 2020. It features a SIEMENS 828 D CNC controller, with X-axis travel of 800 mm, Y-axis travel of 450 mm, and Z-axis travel of 510 mm. The spindle operates at 12,000 rpm with a drive power of 16.5 kW. It includes a tool magazine with 30 slots and additional equipment like a chip conveyor and an electronic handwheel. Contact us for more information about this machine.

Application Types

Milling

Listing

Tönisvorst

Tönisvorst

797 km

Coolant mixing device

Nimatec

Call

Condition: excellent (used), Coolant mixer

Emulsion mixer

Nimatec

Njdpfx Aswf Ht Iofhewb

Stock number (28599)

1/2-inch water supply connection

Listing

Gütersloh

Gütersloh

873 km

Universal machining center

ReidenRX10-5X

Call

Condition: excellent (used), 5-Axis Machining Center

with swivel milling head, pallet station, tool calibration, thermal compensation, work area extraction system, and much more.

Year of manufacture: 2016

Nwsdpfxjxhg Die Afheb

Spindle hours approx. 1,500 h (after spindle replacement at the beginning of 2025)

Control System:

- Heidenhain iTNC 530 HSCI

- Heidenhain DCM Collision Monitoring

- Heidenhain HR 410 electronic handwheel

- Swiveling console with 19" monitor

- Teleservice via LAN/WLAN

Travel Range:

- Travel X 1,000 mm, Y 1,100 mm, Z 810 mm

- NC rotary table D 1,000 x 800 mm, swing diameter 1,350 mm

Milling Head:

- Automatic horizontal/vertical swivel milling head

- Fully-fledged stepless NC axis from -1° to +90°

- Blowing air through the spindle

- External coolant supply via nozzle ring

Drive power: 38 kW (100% duty cycle)

Speed: 16,000 rpm

Torque: 135 Nm at 40% duty cycle

Spindle interface: HSK 63-A

Media Supply:

- Internal coolant feed: 50 bar - capacity 28 l/min

- Paper belt filter with additional fine filter

- Individual tool pressure regulation during program operation

Tool Changer:

- Rack magazine with 73 stations (expandable with additional racks)

- Swiveling dialog operation panel

- Drawer for loading and unloading tools from tool racks

Tool Measurement:

- 3D wireless touch probe m&h 20.00-Multi, software adapted for HSK 63-A

- Including Kinematics-Opt, compatible with iTNC control, and calibration sphere on magnetic stand

Pallet Changer:

- Double palletizing unit, pallet diameter 1,000 x 800 mm, hole grid 100mm x 100mm, hardened drill bushes D 16mm

- Rotary table unit including zero-point clamping system, loading station accessible by crane

- Pallet changer unit protected with enclosure

Special Equipment:

- Micro-Epsilon sensor

- For detection and dynamic compensation of thermal spindle growth

Chip Conveyor:

- Scraper belt conveyor along machine bed

- Chip ejection height 1,100 mm

Machine Enclosure:

- Full-area protective enclosure with large angle door for crane loading and a quick-access door

- Easy removal of swarf from the workspace

Extraction System:

- Oil and emulsion mist extraction, mechanical air filter, extraction capacity 1,800 m³/h

Rotating View Window:

- Viewing window integrated into the cabin door for workspace observation

Camera in Work Area:

- Monitor and keyboard at the operator console—allows monitoring of rear-side machining operations

Machine Data:

- Space requirement (without service area): approx. LxWxH 4,791 mm x 4,100 mm x 4,791 mm (including extraction system)

- Machine weight approx. 19,700 kg

- Total weight with all equipment plus maximum workpiece load, full tool magazine, and all operating materials: approx. 27,730 kg

- Connected load: 50 kVA, 400V, 50/60 Hz

This machining center, featuring an exceptionally good and practical configuration, is in very good condition. It operates with the renowned "Swiss precision." There is no service or repair backlog—in fact, the opposite. With an almost new milling spindle, the REIDEN RX 10 5X is well positioned for long-term use.

Technical modifications and errors excepted.

Auction

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

839 km

Process plant

FrymaVME 400

Year of construction: 1988, condition: ready for operation (used), functionality: fully functional, usable tank capacity: 400 l, rotational speed (max.): 3,000 rpm, Process plant for the production of emulsions, creams, ointments, pastes, lotions, suppository masses. The plant consists of the following components:

- Heatable stainless steel vessel with double jacket

- Lifting column for hydraulic raising and lowering of the lid

- Swiveling control panel

- Steel housing with hydraulic and vacuum pump for water circulation

- Discharge device for the jacket

TECHNICAL DETAILS

Usable volume: 400 l

Total volume: 480 l

Minimum volume: 105 l

Mixing unit speeds

Anchor scraper agitator (1.5 kW): 20 rpm

Toothed colloid mill (5.5 kW): 3,000 rpm

Dissolver (5.5 kW): 1,500 rpm

Disc diameter: 250 mm

Connection diameter: NW 32 mm

MACHINE DETAILS

Motor power hydraulic pump: 1.1 kW

Motor power SIHI vacuum pump: 1.5 kW

EQUIPMENT

- Thermostats and solenoid valves for temperature control

- Fryma type PK 84/25 discharge pump

- Sight glass with lighting and wiper

- Diaphragm vacuum gauge

- Connection for external compressed air supply

- Ventilation device

Nwodpfx Aext E Iqofhjb

- Cleaning wash nozzles

Trust Seal

Dealers certified through Machineseeker

Listing

Lithuania

Lithuania

1,813 km

Meat processing machine

HyShprizHySpriz RK50U 3-in-1 Forming System for

Call

Condition: new, Year of construction: 2025, total length: 600 mm, total width: 600 mm, total height: 1,400 mm, warranty duration: 12 months, overall weight: 300 kg, input voltage: 400 V, power: 1.5 kW (2.04 HP), pressure: 9.8 bar, tank capacity: 50 l, HySpriz RK50U 3-in-1 Forming System for Meat Snacks, Pet Sticks & Mini Salami | Up to 1500kg/shift

Made in Ukraine. 18 month full warranty. RK50U — universal casing-free forming system for meat sticks, jerky & sausage production

HydroShpriz RK50U is a powerful piston-driven filling and forming machine engineered for small and mid-size manufacturers starting production of meat sticks, salami snacks, pet food, kibbeh, fruit bars, and more. Ideal for dry-cured snacks without alginate casing. Strong, compact, and easy to operate — it’s the perfect choice to start your line and grow with Trade-In options.

⸻

Technical specifications

• Drive: hydraulic piston

• Piston force: 94 kN

• Power: 1.5 kW, 380 V, 50 Hz

• External dimensions: 1050×550×950 mm

• Weight: approx. 300 kg

• Material: full stainless steel, food-grade

• Certification: CE certified, built for continuous 8-hour production cycles

⸻

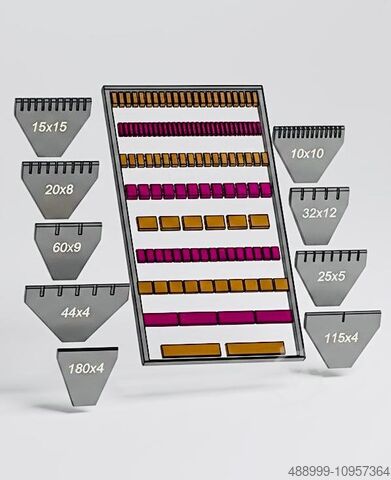

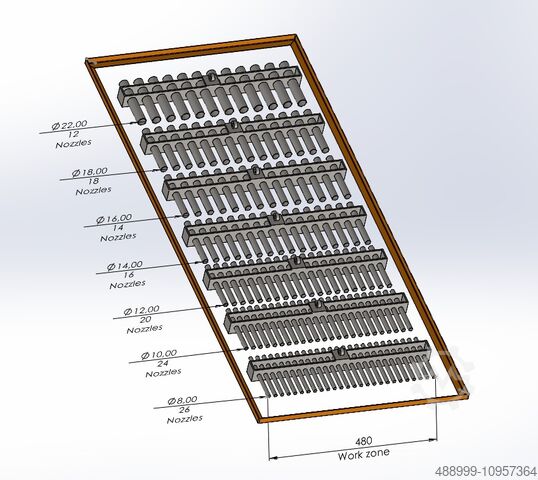

Configuration & possibilities

• Gearbox-driven filler for thick and sticky emulsions down to –2 °C

• Multi-nozzle head: up to 25 lanes simultaneously

• Round nozzle set: 8 mm to 22 mm for meat or fish sticks

• Flat nozzle set: 25 mm to 200 mm width, 3–5 mm height — ideal for jerky/strips

• Sausage stuffing set: for traditional casing sausages

• Overhead tray holder: for direct forming onto drying racks

• Trolley integration: fits perfectly with our 30-row drying racks (60 trays)

• Integrated time-based portioning unit with ±8% accuracy

• 24V remote signal: compatible with automatic clippers (PolyClip, Compa, etc.)

• Optional vacuum connection: for better product density and shelf-life

⸻

Production capacity

• From 20 kg to 1,600 kg per 8 hours depending on product shape, tray format and nozzle type

⸻

Availability

✔️ In stock at official distributors in:

• Austria

• Poland

• United Kingdom

• Lithuania

• Australia

• South Africa

• United States

Delivery worldwide. Training, test batch, and spare parts included.

⸻

Made in Ukraine. CE sertified industrial forming system

• meat snack production

• pet food production

• jerky, salami, kebab machine

• food processing equipment

Nwedpfjmrpvyex Afhob

Listing

Győr

Győr

1,683 km

Industrial Vacuum Cleaner

NilfiskT40W

Call

Condition: used, functionality: fully functional, Nilfisk T40W 3 Phase Industrial Vacuum Cleaner.

Brand: Nilfisk

Model Name/Number :Nilfisk T40 L100

Nodpfx Ajv Rg U Refhewb

Phase:3 Phase

Power: 4.3 kW

Voltage: 400 V

Weight: 135 Kg

Container Capacity: 100 Ltr

Model T40 is a powerful threephase industrial vacuum. It offers great vacuum and is ideal to collect wet or dry heavy material.

The version with liquid cut-off system is perfect for companies that have to collect chips mixed with oil and emulsions. The accessories box, the cable holder and the supports for the hoses make model T40 really ergonomic, making easier the daily work of the operator.

Good working condition. Please check out our other listings as well.

Listing

Lorquí

Lorquí

1,931 km

S/S KRAMER+GREBE 200 L Cutter

KRAMER GREBE

Call

Condition: like new (used), The Kramer + Grebe SM 200 cutter (also known as a bowl cutter) is an industrial machine mainly used in the meat industry for cutting, mixing, and emulsifying meat and other ingredients.

Nedpox S Ih Tjfx Afhswb

Main function:

- It features a bowl with an approximate capacity of 200 litres.

- The blades rotate at high speeds to cut meat, fat, ice, spices, etc.

- Cutting while the bowl rotates produces a fine emulsion, resulting in a homogeneous texture in products such as sausages, pâtés, frankfurters, and more.

Listing

Lorquí

Lorquí

1,931 km

Mixer line for juices with homogenizer

Call

Condition: like new (used), This equipment is ideal for sterilising various types of juices, fresh milk, beverages, wines, and other liquid products. It is also suitable for soya milk and animal feed liquids. When used in combination with a homogeniser, it is capable of processing high-viscosity materials such as sweetened condensed milk, among others. The high-pressure homogeniser is a type of ultra-fine grinding and emulsification equipment. It operates by subjecting the suspension to high pressure, then passing it through a unified decompression zone. Bulging, implosion, shearing, and high-speed impact occur in an adjustable flow-restriction gap. This pulverises particles and oil droplets in the liquid to a very fine size, resulting in an ideal emulsion and a homogeneously dispersed liquid. This process integrates the effects of ultrasonic atomisation, colloid milling, ball milling, and jet milling. Homogenisation enables improvements in product stability, consistency, mixing properties, absorption, nutritional value, shelf life, flavour, colour, and palatability.

Nwedpfxjx S E E Aj Afhob

We make it easier for you to find: "emulsion"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Emulsion (271)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month