Used Emulsion for sale (271)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wiefelstede

Wiefelstede

785 km

Exhaust air purification system 0.75 kW

ifsIF-Vario M 1600

Call

Condition: good (used), Year of construction: 2012, Exhaust gas filter system, exhaust gas filter system, exhaust filter, hot filter, industrial exhaust gas filter, exhaust air purification system, filter cleaning system, electrostatic precipitator, filter system, oil mist separator, oil mist separator, air filter, mist separator, oil and emulsion mist separator, particulate filter, industrial filter

-Manufacturer: ifs, exhaust air purification system industrial filter type IF-Vario M 1600

Nsdpswrcbnofx Afhewb

-Nominal power: 0.75 kW

-Suction power: 1600 m³/h

-Individual components: see photos

-Dimensions: 990/600/H660 mm

-Total weight: 100 kg

Listing

Wiefelstede

Wiefelstede

785 km

Paint pump

Stöber HEWR27-0000-110-4

Call

Condition: used, Paint pouring machine, paint pouring machine, paint pouring station, paint pump, emulsion pump, dosing pump

-Gearbox: Stöber Type R27-0000-110-4

Nsdpfx Ajfv H Aijfhowb

-Speed: 800 - 1820 rpm

-Engine: HEW type EEXF-S/4

-Power: 1.1 kW

-Dimensions: 300/400/H935mm

-Weight: 43kg

Listing

Duxford

Duxford

436 km

IKA Eurostar PWR CV Overhead Stirrer

IKAEurostar PWR CV

Call

Condition: used, This listing is for a IKA Eurostar PWR CV Overhead Stirrer.

The unit is in full working condition and is ready for immediate release.

The IKA Eurostar PWR CV Overhead Stirrer is an efficient laboratory device specifically designed for various stirring tasks, excelling in mixing both high and low viscosity substances. This stirrer is part of the comprehensive IKA Eurostar series, which offers diverse models tailored to different laboratory needs.

Key Features:

Nsdpfxexxz S Aj Afhswb

Speed Range:

Features a versatile speed range of rpm, with automatic adjustments made possible through advanced microprocessor-controlled technology.

Safety Circuits:

Equipped with built-in safety circuits that provide automatic cut-off in cases of anti-stall or overload conditions, ensuring user safety and equipment protection.

Constant Speed:

Maintains a steady speed regardless of viscosity changes in the sample, as it continuously compares the actual shaft speed with the set speed for optimal performance.

Stirring Quantity:

The EuroStar 20 model can handle a maximum stirring quantity of 15 litres (H2O), making it suitable for larger volumes.

Torque:

Delivers a maximum torque of 20 Ncm at the stirring shaft, providing sufficient power for effective mixing.

Stirring Element Fastening:

The stirring element is securely fastened using a chuck, ensuring stability during operation.

Applications:

Laboratory Use: Designed specifically for laboratory environments, making it ideal for routine stirring tasks.

Mixing Substances: Capable of efficiently mixing a wide range of substances, whether they are of high or low viscosity, catering to diverse experimental needs.

Intensive Mixing: Suitable for applications that demand intensive mixing, such as preparing emulsions or suspensions.

Listing

Duxford

Duxford

436 km

APV Gaulin T Series Homogenizer

APV GaulinT Series

Call

Condition: used, This listing is for the APV Gaulin T Series Homogenizer

The unit is in full working condition and is ready for immediate use

The Gaulin T Series homogenizers, developed by SPX FLOW under the APV brand, are high-pressure, positive displacement reciprocating plunger pumps designed for demanding applications in industries such as dairy, food and beverage, pharmaceuticals, chemicals, and cosmetics.

Nsdpfsxhf Tvex Afhjwb

Key Features

High Pressure Capability: Models like the Gaulin 132T and 125T can handle pressures up to 600 bar (approximately 8,700 psi), making them suitable for applications requiring intense homogenization.

Flow Rate: These homogenizers can process flow rates ranging from 1,000 to 25,000 liters per hour (LPH), accommodating various production scales.

Design Options: The Gaulin T Series offers both mono-block and three-piece valve housing designs, allowing for flexibility in maintenance and customization.

Hygienic Construction: Constructed with stainless steel or duplex materials, these homogenizers feature 3-A sanitary design, making them suitable for hygienic applications.

Maintenance-Friendly: The design includes features like hydraulic valve actuators, easy access to key components, and modular electrical controls, simplifying maintenance and reducing downtime.

Applications

Gaulin T Series homogenizers are ideal for applications such as:

Dairy Processing: Homogenization of milk, cream, and other dairy products.

Food and Beverage: Processing of sauces, dressings, and beverages.

Pharmaceuticals and Cosmetics: Manufacturing of emulsions, creams, and lotions.

Chemical Processing: Production of paints, coatings, and other chemical products

Listing

Wiefelstede

Wiefelstede

786 km

Oil-water separation system for compressors

Atlas CopcoOSW30

Call

Condition: used, Emulsion splitting plant Oil-water separation system

The inexpensive and permanently reliable

The solution to the problem is usually the oil/water

Separation for dispersed condensates. The

purified water meets the legal

Sewer discharge regulations

-Dimensions: 650/520/H1000 mm

Nedjdz Smpepfx Afhjwb

Discover more used machines

Listing

Wiefelstede

Wiefelstede

786 km

Oil-water separation system for compressors

KaeserÖl-Wasser-Trenner

Call

Condition: used, Emulsion splitting plant, oil-water separation system

Nwjdpjctlaqjfx Afhjb

-The cost-effective and permanently reliable solution to the problem is usually the oil/water separation for dispersed condensates. The purified water meets the legal requirements for sewer discharge.

-Dimensions: 590/590/H1170 mm

-Weight: 58 kg

Listing

Germany

Germany

1,034 km

Milling Machining Center - Vertical

DECKEL MAHODMC 63V

Call

Condition: excellent (used), Year of construction: 1999, functionality: fully functional, Milling Machining Center - Vertical / Brand: DECKEL MAHO / Type: DMC 63V / Year of construction: 1999

The machine can be inspected by appointment under power.

Well-maintained and very good functional condition.

Spindle replacement: 18.03.2022

Spindle hours (03/13/2025): 51.206 h

The machine has a Lehmann A-axis and counter bearing (as new).

TECHNICAL DATA:

Working area:

- X-axis: 630 mm

- Y-axis: 500 mm

- Z-axis: 500 mm

Feed/axis drives:

- Advancing force X, Y, Z (100 % ED): 6.000 N

- Feed rate: 0 - 30.000 mm/min

- Rapid feed X, Y, Z: 30 m/min

- Diameter ball screw/pitch (X, Y, Z): 40/20 mm

Positioning accuracy:

- Pmax in X, Y, Z-axis to VDI/DGQ 3441: 0,015/0,010 mm

(indirect/direct measuring system)

Distance measuring system:

- Input unit: 0,001 mm

Working spindle:

- Drive power (40/100 % ED): 13/9 kW

- Torque (40/100 % ED): 83/57 Nm

Nodpfxov Nxbyo Afhswb

- Speed range: 1 - 10.000 rpm

- Tool holder DIN 69 871-A: SK40

- Tool clamping force: 12.000 N

Tool magazine:

- Tool changing system: Pick-up

- Number of magazine positions: 24

- max. Tool-Ø with vacant neighboring spaces: 80/140 mm

- max. Tool length: 300 mm

- max. Tool weight: 7 kg

- Chip-to-chip time: 6,5 sec

- Rotational speed/tool magazine: 47 rpm

- max. Maximum loading weight of the tool magazine (24 x 3 kg): 72 kg

Machine/Working table:

- Clamping surface with T-slots DIN 650-14: 800 x 500 mm

- Table load (set-up weight): 500 kg

- Loading height: 850 mm

- max. Workpiece height (at max. tool length): 240 mm

EQUIPMENT:

- CNC-Control: Siemens 810D powerline

- Lehmann A-axis and counter bearing (as new)

- Direct measuring system

- Internal cooling through the spindle, 15 bar

- Coolant system (emulsion)

- Electronic hand wheel

- Chip conveyor

- Documentation

- CE marking

There is no guarantee for correctness and completeness of the technical details and accessoires.

- Subject to prior sale -

Listing

Germany

Germany

1,148 km

1 used LTA AC 500 year 2010_ IntNr231258

LTAAC 500

Call

Condition: used, Year of construction: 2010, machine/vehicle number: IntNr231258, AC 500 solid

- low energy consumption thanks to pressure loss-free filter elements and energy-efficient blowers

· Filtration stages for the separation of coolant mist

· Filtration principle M (M = mechanical)

· Use for emulsion mist

· Direct attachment to machine possible

· Separation efficiency up to 99%

- Extraction capacity 800 m3/h (470cfm)

- Blower capacity 1950 m3 / 5 (1,147 cfm)

- Energy consumption 0.6 kW

- Voltage: 400V

- Dimensions: (LxWxH): 500x500x590 mm

- Weight: 48 KG

Subject to changes and errors in the technical data and information as well as prior sale!

AC 500 solid

- Low energy consumption thanks to pressure-loss-free filter elements and energy-efficient blowers

- Filtration stages for the separation of cooling lubricant mist

- Filtration principle M

- Use for emulsion mist

- Direct attachment to machine possible

- Separation efficiency up to 99

- Extraction capacity 800 m3/h (470cfm)

- Blower capacity 1950 m3 / 5 (1,147 cfm)

Nedjycu Tvspfx Afhewb

- Energy consumption 0.6 kW

- Voltage: 400V

- Dimensions: (LxWxH): 500x500x590 mm

- Weight: 48KG

Subject to changes and errors in the technical data and information as well as before sale!

Translated with (free version)

Listing

Germany

Germany

856 km

Machining Center - Vertical

YCMTV2110B

Call

Condition: used, Year of construction: 2012, x-travel 2100 mm

y-travel 1020 mm

z-travel 762 mm

Control Fanuc MXP-200FP

spindle speed 6000 U/min

spindle capacity ca. 22 kW

max. torque on the spindle ca. 550 Nm

tool taper SK 50

table surface area 2300 x 1020 mm

max. table load 3000 kg

T-slots 6 x 22 mm

T-slot - distance 150 mm

3-Axis CNC Machining Center

Equipment/Accessories:

- Automatic tool changer with chain magazine, 40 stations

- max. tool-Ø: 120/240 mm

- max. tool length: 350 mm

- coolant system with internal coolant supply and filter

- emulsion mist extraction

- electronic handwheel

Nedex Sr A Ujpfx Afhewb

- 2 pcs. magnetic clamping plates 800 x 400 mm

- various tool tapers SK50

- chip conveyor

Listing

Karben

Karben

999 km

Filter fleece system

HOFFMANNHydrostat HN 0,6

Call

Condition: good (used), functionality: fully functional, Year of construction: 2004, overall weight: 300 kg, input voltage: 400 V, input frequency: 50 Hz, HOFFMANN

FILTER FLEECE SYSTEM WITH REEL

TYPE: HYDROSTAT HN0.6

MACHINE NO.: 0405364

Nedpjx T Ah Djfx Afhowb

YEAR OF MANUFACTURE: 2004

Technical Data:

Operating Voltage: 400 V, 50 Hz

Footprint incl. sludge tank: approx. 2055 x 1560 mm

Filter area: 0.6 m²

Filtration capacity (based on emulsion): approx. 165 l/min

Inlet height: 488 mm

Paint finish: RAL 9002, textured lacquer

Weight: 300 kg

Equipment:

- Made of sheet steel, fully welded, base dimensions approx. 1500 x 1500 x 280 mm

Filling capacity: approx. 460 l

- 1 gear motor

- 1 reel for winding up used filter fleece

- 1 reel-disposal switch with “reel full” indicator

- 1 coolant level switch

- 2 pump mounts for user-supplied service pumps

- 1 roll of filter fleece, width 1000 mm

- 1 sludge tank

- 1 complete electrical control system in a dustproof control cabinet with all switching, control, and monitoring devices, motor protection switches for each drive, control transformer, function indicator lamps, filter system wiring according to VDE 0113

- Documentation, 2 copies, German

- EC Declaration of Conformity 98/37, Annex IIB

Listing

Germany

Germany

1,006 km

Sigma Leader 6

SigmaLeader 6

Call

Condition: ready for operation (used), Year of construction: 2007, controller manufacturer: HEIDENHAIN, This 3-axis Sigma Leader 6 vertical machining center was manufactured in 2007. It features extensive travel capabilities with X-axis at 1250 mm, Y-axis at 810 mm, and Z-axis at 630 mm. Rapid traverse rates reach up to 50 m/min, and it includes a high-capacity tool magazine with 40 positions. If you are looking to get high-quality milling capabilities, consider the Sigma Leader 6 machine we have for sale. Contact us for more information about this machine.

Nwedox D Nafopfx Afhjb

• Axes: 3 / current spindle hours: approximately 33000 / x-axis travel (longitudinal): ranges from 1250 mm to 2000 mm / y-axis travel (transverse): 810 mm / z-axis travel (vertical): 630 mm / b-axis travel (swivel): -60° to +105° / c-axis travel (rotary table): 360° / x/y/z rapid traverse: ranges from 40 m/min to 50 m/min / b/c rapid traverse: ranges from 40 rpm to 50 rpm / acceleration x/y/z: ranges from 5000 mm/sec² to 10000 mm/sec² / acceleration b/c: ranges from 3. 5 rad/sec² to 8. 8 rad/sec² / guides: linear with sliding block with triple circulation of preloaded balls / pallet changeover time: 3 seconds (5-axis)

• Power supply: 400v 50hz 3-phase line / power rating: ranges from 35 kw to 60 kw / rated current: ranges from 60 a to 105 a

• Compressed air pressure: 6 bar / compressed air consumption: 150 nm³/h

• Machine color: gray ral 7008 / protective cover color: yellow ral 1004 / workstation lighting: 2 or 4 / sound pressure level: 77 db(a) to 79 db(a) (standard, 15000 rpm)

• Tool holder: n. 40 din 69871, n. 40 din 69871 (bt40), hsk-a63 din 69893-1 / max. Available power: 27 kw / max. Available torque: 235 nm, 158 nm, 86 nm / programmable indexed spindle angle positions: electronic with 3600 positions

• Measuring system: heidenhain measuring system, electronic fold commutator / positioning accuracy (x/y/z): 0. 008 mm / positioning spread (x/y/z): 0. 006 mm / average reversal error (x/y/z): 0. 002 mm

• Magazine type: chain magazine with 2 directions / number of positions: 40 (standard) - 50 (optional) / tool selection: "random" / tool changer: double-gripper arm, electromechanically driven / min. Tool change time: 1. 5 seconds / chip-to-chip time: 4. 5 seconds / max. Tool weight: 8 kg / max. Tool diameter: 80 mm / max. Tool length: 350 mm / max. Tool dimensions: 300 mm

• At low pressure with oil emulsion: 10 nozzles around the spindle, max. 5 bar at 100 l/min / at high pressure with oil emulsion through the spindle (option): 15 bar at 15 l/min or 30 bar at 30 l/min / chip mixing: 2 parallel screws on the two long sides of the table and a side chip conveyor / cooling system filtration: 60μ filter system with 2 filter inserts and manual bypasscooling system filtration: 60μ filter system with 2 filter inserts and manual bypassinner cooling through spindle (IKZ)

Listing

Soltau

Soltau

905 km

Machining center

Röders TecRXP400DS/RXD5

Call

Condition: reconditioned (used), travel distance X-axis: 310 mm, travel distance Y-axis: 294 mm, travel distance Z-axis: 210 mm, overall weight: 3,000 kg, spindle speed (max.): 50,000 rpm, Used HSC machine RXP400DS/ RXD5

-overhauled-

The machine is completely overhauled, tested and measured in our company. The machine again meets the new machine tolerance!

Working area:

- X-axis: 200 mm

- Y-axis: 294 mm

- Z-axis: 200 mm

- Drives of the linear axes:

Linear motors in all axes.

- Drives of the rotary axes:

Highly dynamic direct drives with integrated cooling.

- Feed rates 0 - 40,000 mm/min in all linear axes.

- Network connection:

- Tool measuring laser:

Diameter and contour measurement, wear monitoring

and breakage control of the milling tools.

- Chuck control, 1st chuck

- Emulsion cooling with mechanical oil mist extraction

-RMS Main Job Manager

- Spindle max. 60,000 rpm HSK 25

- Tool changer 12-way row, optional tool changer conversion to chain

- High-precision option

- Remote maintenance via Teamviewer

- Transport dimensions of machine:

W 2,425 x L 1,925 x H 2,140 mm

- Weight: Approx. 3,000 kg

Nodpelzhhcsfx Afhswb

A viewing of the machine in operational condition is possible at any time. You are also welcome to find out more about the type and scope of our overhauled machines on our website or on our Hüttmann YouTube channel.

Listing

Soltau

Soltau

905 km

5 axis vertical machining centre

YCM5-Achsen UV650

Call

Condition: as good as new (ex-display), Year of construction: 2023, operating hours: 15 h, YCM UV650

Spindle: SK40 / 15.000 rpm, 17kW

toolchanger places: 60

control: Heidenhain TNC640

travel: X:620mm Y:520mm Z:460mm B:-50 / +110 C:360

spindle cooling system

Blum laser for tool length measurement

3D probe

el. hand wheel

Emulsion cooling ICS 20bar

outer cooling

Nwedpsuxbciofx Afheb

cooling gun

chip conveyor

machine dimensions:

L:4250mm W:2310mm H:2.560mm

weight:

appr. 12.500kg

Listing

Soltau

Soltau

905 km

Vertical machining center

RödersRXP600DSH

Call

Condition: reconditioned (used), Year of construction: 2012, functionality: fully functional, Equipment: chip conveyor, documentation/manual, Röders RXP600DSH

- HSK63F spindle max. 30,000 rpm

- 24-position tool changer

- Emulsion cooling with 40 bar internal coolant supply (IKZ)

- Extraction system

Nwodpfex I A Imsx Afhob

- Laser tool measurement

- 3D probe

- Thermal package

- Prepared for automation

The machine is already at our facility in Soltau. We will upload pictures shortly.

Listing

Soltau

Soltau

905 km

5-axis milling machine

RödersTecRXP500DSC

Call

Condition: refurbished (used), Year of construction: 2010, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 240 mm, overall weight: 6,000 kg, spindle speed (max.): 42,000 rpm, 5-axis HSC milling machine Röders RXP500DSC with linear direct drives in all axes and torque drives in the rotary axes.

Travels: X450mm, Y400mm, Z240mm

Spindle / table distance: approx. 315mm

- Linear direct drives in all axes - wear-free

Specification:

- Tool changer places: 19

Njdpfett Argjx Afhowb

- Cooling unit for drives, motors, spindle and cable cabinet

- Measuring laser for the fully automatic measuring of milling tools (length / diameter / contour / cone angle) as well as wear monitoring including tool cleaning before measuring

- Handbox

- Remote maintenance

- Automatic 3D probe including calibration ball in the tool changer

- Minimal quantity lubrication

- emulsion cooling

- Spindle HSK40E with max. 42.000 rpm

- Spindle compensation

- Zero point clamping system Erowa integrated in the machine table

- manual operating of chuck clamping

- Automation package for retrofitting the machine with a pallet changer

- Handbox

The machine is overhauled in our house and is now in almost new condition. The machine can be inspected and tested under power after completion at our site. Please make an appointment with us!

Listing

Germany

Germany

1,006 km

HEDELIUS T8 - 2300

HEDELIUST8 - 2300

Call

Condition: ready for operation (used), Year of construction: 2006, operating hours: 7,647 h, travel distance X-axis: 2,300 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 850 mm, controller manufacturer: HEIDENHAIN, controller model: iTNC 530, overall weight: 18,500 kg, spindle speed (max.): 12,000 rpm, spindle motor power: 26,500 W, tool weight: 10,000 g, number of axes: 5, This 5-axis HEDELIUS T8 - 2300 was manufactured in 2006, featuring a robust vertical machining center design. It boasts a large travel range of 2300/800/850 mm and a high spindle speed up to 12,000 rpm. The machine includes a B-axis NC swivel head, a 40-position tool magazine, and supports a maximum workpiece weight of 2500 kg. Consider the opportunity to buy this HEDELIUS T8 - 2300 vertical machining center. Contact us for more information.

• NC swivel head B-axis: +92° / -92°

• Max pendulum operation: 2 × 850 mm

Nwjdpfx Afex E Ebwjheb

• Rapid traverse: 60 m/min

• Feed force: X/Y 5000 N, Z 9000 N

• Spindle:

• Max torque: 158 Nm

• Front spindle bearing diameter: 70 mm

• Tool clamping (pull-in force): 12 kN

• Tool magazine/changing:

• Tool positions (standard): 40

• Tool positions (Magnum): 80

• Max tool diameter: 125 mm (180 mm with adjacent positions empty)

• Max tool length: 330 mm

• Tool change time (approx.): 3.5 s

• Chip-to-chip time: vertical 6.0 s / horizontal 6.5 s

• Table/capacity:

• Fixed table (L×W): 2000 × 920 mm

• T-slots: 6 × 18 H12

• Rotary table: 1 × 18 H8

• Max. workpiece weight: 2500 kg

• Machining capacities:

• Drilling in St 52 with carbide: 40 mm

• Tapping: M24

• Milling in St 52: 500 cm³/min

• Distances (reference):

• Z travel vertical (L2): 850 mm

• Spindle nose to swivel axis (L3): 300 mm

• Spindle nose to table surface (L4): 40 mm

• Z travel horizontal (L5): 1000 mm

• Spindle axis to table surface (L6): 210 mm

• Y travel (L7): 800 mm

• Table center to travel start/end (L8/L9): 400 / 400 mm

• Power/weights:

• Total connected load: 25 kVA

• Machine weight (standard): approx. 17,000–17,500 kg

• Hours:

• Operating hours: 21,100 h

• Spindle hours: 7,647 h

Additional equipment

• Chip conveyor

• Internal coolant through spindle, 40 bar

• Paper belt filter

• Oil and emulsion mist separator

• Rotating viewing windows (2)

• Cleaning guns (2)

• Renishaw touch probe

Technical Specification

Taper Size SK 40

Listing

Janville

Janville

878 km

Vacuum mixer

Romaco – FrymakorumaDinex Lab

Call

Condition: used, Year of construction: 2009, Manufacturer: Romaco - Frymakoruma

Model: Dinex Lab

Year: 2009

Type: Vacuum mixer for R&D or small-scale production

Application: liquid and/or viscous (semi-liquid) products = dispersion, homogenization, emulsion, grinding, and pumping of the product

Tank:

Pressure: -1 / 0 bar

Volume: 18 L

Temperature: 130°C

Jacket:

Pressure: 6 bar

Volume: 2 L

Temperature: 180°C

Homogenizer: high-speed agitation

2 modes = Pumping with discharge / Dispersion with high shear force

Tool size: 100 mm

Nwedpjx R D Elefx Afheb

Rotor: 20 x 4 mm

Stator: 30 x 4 mm

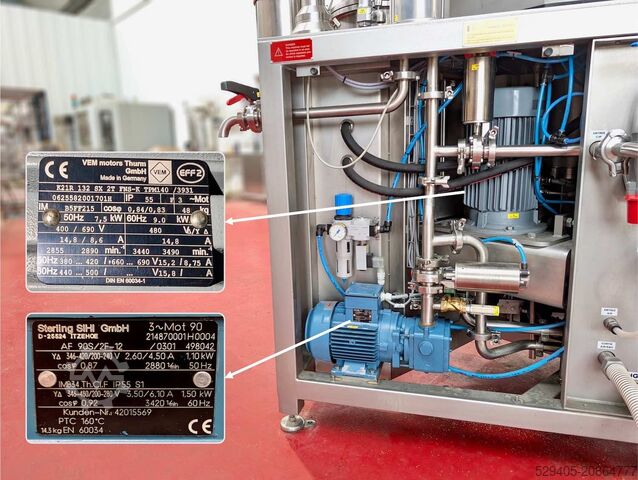

VEM motor 7.5 kW / 2890 RPM

Scraper mixer: slow agitation

SEW 0.37 KW motor

Sterling SIHI LEMA 25 liquid ring vacuum pump

Power 1.1 KW - Max. 16 m³/h.

CIP (clean in place)

2 x feed hoppers, 1 of which is connected to the jacket with its piping

Air pressure: 6 bar

Water pressure: 6 bar

Temperature control regulator

Single-acting seal: reconditioned by Burgmann

Paper documentation

Weight: 750 kg

Listing

Janville

Janville

878 km

Vacuum mixer

VMI RayneriTrimix (TXR) 10 litres

Call

Condition: used, Year of construction: 1998, Manufacturer : VMI Rayneri

Model Trimix (TXR) 10 litres

Year : 1998

Type : Vacuum mixer

Application : Dispersion, dissolution, homogenisation, deaeration, heat exchange > gels, creams, pomades, …

Total volume : 10 Litres

Empty weight : 300 kg

Power : 3.5 KW

Power supply: 230 V

Pressure : 2 bars

Temperature : 120°C

Nsdpfjx R Di Dox Afhewb

Jacket + insulation

Mixing :

– Anchor blade with scrapers: 0 – 60 rpm

– Counter agitation: 0 – 180 rpm

– Dispersion/emulsion turbine: 200 – 3000 rpm

Sold with water temperature controller :

Manufacturer : SOLEV

Model : RE 50-3-SC-R-20-2D

Year : 1998

Heating capacity : 3 KW

Documentation available

Listing

Warstein

Warstein

891 km

Vertical machining center

StarragCWK 400D

Call

Condition: good (used), Year of construction: 2005, operating hours: 32,099 h, functionality: fully functional, travel distance X-axis: 625 mm, travel distance Y-axis: 650 mm, travel distance Z-axis: 650 mm, controller manufacturer: Siemens, controller model: Sinumerik 840D, total length: 5,800 mm, total width: 4,800 mm, table width: 400 mm, table length: 500 mm, overall weight: 12,800 kg, spindle speed (max.): 10,000 rpm, operating hours of spindle: 3,648 h, coolant supply: 50 bar, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, For sale is a 4-axis horizontal machining center from the manufacturer Starrag.

The machine is used, has been regularly maintained, and is in fully functional condition.

Machine Details

- Manufacturer: Starrag

- Model: CWK 400D

- Year of manufacture: 2005

- Operating hours: 32,099

- Control: Siemens Sinumerik 840D

- Machine weight: 12,800 kg

- Footprint (LxW): 5.8 x 4.8 m

Technical Data

Travel paths:

- X = 625 mm

- Y = 650 mm

- Z = 650 mm

- B axis: 360° (0.001° increments) / 100 rpm

- Spindle speed: 50 – 10,000 rpm (stepless)

- Motor power: 24 kW / 37 kW

- Torque: 250 Nm / 350 Nm

Table & Pallets

- 2 pallets, each 500 x 400 mm

- T-slots to DIN 55201

- Load capacity: 400 kg

- Pallet changer included (changeover time 8 s / 5 s)

Tool Data

Nsdpfxex Ib T Io Afhjwb

- Interface: DIN 69893-HSK-A63

- Chain magazine with 60 tool positions

- Tool diameter: 80 mm (up to 160 mm with adjacent pockets free)

- Max. tool length: 350 mm

- Max. tool weight: 10 kg

- Total tool weight: 200 kg

Equipment & Extras

- Coolant system (emulsion, internal & external supply, approx. 1100 L)

- Knoll coolant unit with fleece filter (30, 40, 50 bar)

- Measuring probe: Renishaw

- Tool breakage monitoring in magazine

- Chip conveyor

- Flood wash, paper band filter, cleaning gun at setup station

- Fully enclosed working area to UVV safety standards

- Pallet sequence mode

- Network connectivity, Ethernet interface

- Technical documentation & layout plan included

Maintenance

- Carried out regularly

- Machine is fully functional

All details have been prepared to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

Listing

Warstein

Warstein

891 km

Horizontal machining center

UNISIGNUnivers4

Call

Condition: used, Year of construction: 2004, operating hours: 19,357 h, functionality: fully functional, travel distance X-axis: 1,600 mm, travel distance Y-axis: 400 mm, travel distance Z-axis: 400 mm, controller manufacturer: Siemens 810 D, total length: 6,500 mm, total width: 3,500 mm, overall weight: 9,000 kg, spindle speed (max.): 9,000 rpm, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, For sale is a 4-axis vertical machining center from Unisign, model Univers 4, year of manufacture 2004. The machine is used but in good condition, fully functional, and has been regularly maintained.

Special feature: second milling spindle (replacement spindle included).

Operating hours: 19,357

Technical Data

-Traverse paths: X = 1600 mm / Y = 400 mm / Z = 400 mm

-B axis: A axis (360° x 0.001°) 20 rpm

-Spindle speed: 0 – 9000 rpm

-Control: Siemens Sinumerik 810D

Nedpfxox Iputs Afhowb

-Table size: 1 bridge with 4 sides, L 1800 mm, 4 x 113 mm

-Table load capacity: approx. 150 kg

-Working feed rate: 5 – 28,000 mm/min

-Rapid traverse (X/Y/Z): 28,000 mm/min

Tool & Magazine

-Tool holder: DIN 69871-SK40

-Chain magazine with 44 stations

-Tool diameter: approx. 70 mm (up to 200 mm with free adjacent slots)

-Max. tool length: approx. 240 mm

-Max. tool weight: 5 kg

-Max. total weight of tool magazine: approx. 200 kg

-Tool change time: approx. 8 sec

Machine Requirements & Dimensions

-Total power requirement: 14 kW

-Machine weight: approx. 9000 kg

-Footprint (LxW): approx. 6.5 x 3.5 m

Equipment & Accessories

-Coolant system (approx. 480 L, internal & external emulsion)

-Clefil RBF-E100 20 bar pump unit

-Chip conveyor

-Rinse gun in machining area

-Hydraulic/pneumatic clamping options in machining area

-Enclosed work area cover in accordance with safety regulations (UVV)

-Röhmheld hydraulic aggregate (max. 500 bar)

-Automatic probe RWP20.00

-Various SK40 holders

-Technical documentation & floor plan available

Maintenance

-Regular maintenance performed

-Hydraulic and pneumatic hoses partially renewed

-LT module replaced in control cabinet

The machine is immediately available and ready for operation.

If interested or if you have any questions, please get in touch!

All information provided to the best of our knowledge and belief. Subject to change, error, and prior sale.

Listing

Baienfurt

Baienfurt

1,232 km

Portal milling machine

F. ZimmermannFZ 33 compact

Call

Condition: excellent (used), Year of construction: 2014, First commissioning: 2014

Control: Heidenhain iTNC 530 HSCI including HR 520 handwheel

Machine hours

Power-on hours: approx. 90,000 h

Spindle hours: approx. 38,000 h

Current milling spindle hours: approx. 900 h

Travel distances

X-axis: approx. 2,500 mm

Y-axis: approx. 3,000 mm

Z-axis: approx. 1,250 mm

A-axis: ± 110°

C-axis: ± 300°

Clamping table

Clamping surface: approx. 2,500 x 3,250 x 600 mm

2-axis milling head VH30

Spindle power: 60 kW

Spindle speed: max. 22,000 rpm

Torque: 95 Nm

Tool holder: HSK 63A

Tool clamping: hydraulic

Coolant supply: external and internal

Linear axis drives

Feed speed X/Y/Z-axis: up to 60 m/min

Axis acceleration X/Y/Z-axis: up to 5 m/s²

Electrical specifications

Connected load: 190 kVA

Main fuse: approx. 315 A

Dimensions, weights

Space requirement (machine with peripherals): approx. 10,000 x 8,000 x 5,650 mm

Total weight: approx. 63,000 kg

Colour

Enclosure, portal, control cabinet: RAL 7035 light grey

Milling head and applications: RAL 6038 luminous green

Description:

Additional equipment

- Coolant supply with belt filter system

- 50-position chain-type tool changer

- Work area enclosure

- Chip conveyor

- Emulsion mist extraction system from LTA

Optional at extra cost:

- Renishaw RMP60 wireless measuring probe

- BLUM Control NT

Nsdpjwywcisfx Afhewb

Condition of the machine

Fully functional, in excellent condition and available for inspection under power!

Images are sample photos from a new machine of this type. Original images to follow shortly!

Trust Seal

Dealers certified through Machineseeker

Listing

Baienfurt

Baienfurt

1,232 km

Briquetting press including chip shredder

StyrotecMSP 120 ZK

Call

Condition: like new (used), The MSP 120 ZK is ideally suited for crushing and subsequent briquetting of various types of metal chips.

The MSP 120 ZK briquetting press with integrated shredder is composed of a hydraulic chip press paired with an upstream shredder, both perfectly matched to each other. This system enables the crushing and compaction of chips generated during turning and milling operations. The volume is significantly reduced, and the briquettes are separated from the coolant lubricants (emulsion, oil) absorbed during earlier machining processes.

The system consists of a feed hopper for loading the material to be processed and a shredder inside the hopper, which reduces chip length. A conveyor system moves the shredded chips continuously and stepwise via a conveyor belt into the chip press hopper. There, two augers feed the material into the compaction chamber.

The system is equipped with a monitored liquid collection tank and pump, allowing coolants to be returned to the production process.

Cycle control is managed by a PLC and an electronic level sensor for the monitoring of the hopper fill level.

Optionally, a tipping device can be added for manual loading of the unit.

Briquetting Press:

Throughput (Aluminum): 15–20 kg/h

Throughput (Steel, Copper): 45–60 kg/h

Briquette diameter: 60 mm

Nsdsw R Ranepfx Afhewb

Productivity: 120–180 pcs/h

Specific pressure on briquette: 1,050 kg/cm³

Motor pump power: 7 kW

Total installed power: 10 kW

Voltage: 400V / 50 Hz

Oil tank: 80 l

Dimensions: 1,400 x 1,200 x 1,050 mm

Weight: 800 kg

Shredder:

Number of knife shafts: 1 pc

Motor power: 5.5 kW

Number of knives: 16 pcs

Exchangeable knives: Yes

Knife size: 25 mm

Knife material: Hardened steel

Shaft length: 400 mm

Screen mesh size: 20 mm

Hopper inner diameter: 1,000 mm

Hopper volume: 1 m³

Weight: 280 kg

Power supply: 380V

Overall system dimensions: 2,820 x 1,862 x 2,065 mm

Colour: Textured paint, RAL 7035 light grey

Listing

Germany

Germany

1,148 km

Used AR Filtrazioni model ARNO 2VFA_YB, year 2018 (internal no. 231086)

AR FILTRATIONIARNO 2

Call

Condition: like new (used), Year of construction: 2018, machine/vehicle number: IntNr231086, Int. No. 231086

1449 Oil/Emulsion Mist Extraction System

AR FILTRATIONI S.R.L.

Nodpfxox U Dhuj Afhowb

Extraction Series ARNO 2:

Mechanical AR 5-stage air purifier for emulsion mist/oil smoke

Air flow rate: 2600 m³/h (1.5 kW)

Voltage/frequency: 230/400 V, 50 Hz

Noise level: approx. 70 dBA

Stage 1 – Centrifugal condenser, self-cleaning

Stage 2 – Metal mesh filter, washable

Stage 3 – Pocket filter

Stage 4 – Fine filter mat, washable

Stage 5 – HEPA ultra-fine filter

Overall unit filtration efficiency: up to 99.97%

- Quick and easy maintenance, once per year, high operational reliability

- Sturdy construction, minimal space required

- Recovery of up to 80% of condensed coolant lubricant

- Design and performance in compliance with current standards

- Approx. €415.00 in energy savings per air purifier

- Reduction of emissions by 9,000 kg CO2/year/unit

- Protects sensitive machine tool components

- Protects both the environment and personnel

Dimensions: approx. 990 x 570 x 1400 mm

Weight: approx. 120 kg

Short delivery times available by arrangement.

The machine can be inspected under power by appointment.

Subject to technical modifications, errors, and interim sale!

Listing

Coesfeld

Coesfeld

796 km

Vacuum tank truck

MERCEDES-BENZAROCS 3545 L 8x4 B13 - Kroll ADR Sauger, 1,0 - 1

Call

Condition: used, mileage: 1,000 km, power: 375 kW (509.86 HP), first registration: 10/2025, fuel type: diesel, overall weight: 32,000 kg, axle configuration: > 3 axles, gearing type: automatic, emission class: euro6, total width: 2,550 mm, total height: 3,800 mm, Year of construction: 2025, Equipment: ABS, air conditioning, electronic stability program (ESP), navigation system, ++ RENT ++ BUY ++ RENT ++ BUY ++ RENT ++ BUY ++ RENT

Internal number: #391

Mercedes-Benz AROCS 3545 L 8x4 B13 Kroll K 1.0-18.0 /36PESP, Suction Unit

This Mercedes-Benz Arocs 3545 L 8x4 is equipped with a powerful KROLL suction/pressure tank superstructure of ADR class L4BH. With a tank capacity of 18,000 liters, VacuStar W1600, Speck P52/100-150, and hydraulic tank equipment for 18,000 L, this vehicle is ideal for demanding industrial, sewer, and emulsion suction applications. A robust suction system for professional operations.

Superstructure

* Manufacturer: KROLL

* Tank Material: S355J2+N (St 52.3)

* ADR Suction/Pressure Tank K 1.0–18.0 / 36PESP

* Tank Volume: 18,000 L (air volume)

* Sludge Volume: 15,000 L

* Emulsion Chamber: 3,000 L

* Rinse Water Chamber: 1,000 L, non-pressurised

* Discharge via robust ejection piston

Vacuum System

* CVS VacuStar W1600 – approx. 1,550 m³/h at 400 mbar

* Approx. 30 m DN80 suction hose mounted on the tank lid, can be fully cleaned through

High-Pressure System

* Speck P52/100-150 – 100 L/min at 400 bar

* Small hydraulic HD hose reel for 60 m DN13

* Equipped with approx. 60 m cleaning hose DN13

Special Features

* ADR L4BH, incl. EX/II, EX/III & AT

* Remote-controlled suction inlet for pre-chamber DN100

* Manhole DN500 (left side)

* High-pressure gun

* Soundproofing enclosure left and right in front of the pumps

* Removable, swiveling halogen work lights

* LED perimeter lighting

* Radio remote control (including 2 batteries)

* Tiltable scrap box

* Reversing camera

* Ladder with bracket and anchor points

* Advertising boards left and right on the tank

Technical Data

* Gross vehicle weight: 32,000 kg

* Length: 10,700 mm

* Height: 3,800 mm

* Width: 2,550 mm

* Wheelbase: 3,900 mm

Nwsdpfjx Egx Usx Afhob

Conclusion

A high-performance Mercedes-Benz Arocs 3545 L 8x4 with large 18,000 L KROLL suction body, VacuStar W1600 and Speck P52 high-pressure system. Ideal for industrial, sewer, and emulsion suction projects requiring high durability and reliable technology.

For further detailed information and pictures, please contact us directly. A wide selection of other vehicles for PURCHASE or RENT can be found at:

Subject to change, prior sale, and errors. The buyer is obliged to independently verify the condition and equipment of the goods. Sale is made exclusively on our general terms and conditions and under exclusion of any warranty.

Listing

Oberweis

Oberweis

1,443 km

Travelling column milling machine

UrbanAP 6500 F

Call

Condition: used, Year of construction: 2007, Urban AP 6500 F - travelling column milling machine

- Heidenhain path control iTNC 530, control panel can be moved over the entire machining length

- robust basic structure as a welded frame construction

- ball rail guides on all axes

- milling spindle unit: 80 - 6000 rpm, tool holder SK30

- X-axis with rack and pinion drive (30 m/min)

- Y-/Z-axis with recirculating ball screw (20 m/min)

- 6 chip drawers

- swivel clamping device for 6200 mm workpiece length

- 12 pneumatic workpiece clamps

- manually operated central lubrication

- moving plate tool changer for 8 tools

- micro spray

- cooling emulsion pump

- machine light

- safety fence

- safety bumper

- safety light grid

- machine protection hood opens pneumatically vertically

- control on: 33922 h

- Program run: 9847 h

- Spindle on: 7221 h

- Year of manufacture 2007

Technical data

- Travel paths X/Y/Z: 6500 / 275 / 310 mm

- Working area X/Y/Z with swivel device: 6200 / 155 / 110 mm

- Rapid traverse X/Y/Z: 30 / 10 / 10 m/min

- Continuous feed: 0 - 5000 mm/min

- Tool change: Disc changer with 8 tool positions

- Tool holder: SK30

- Tool clamping: pneumatic

- Coolant system: Micro-spray for flow drilling, cooling emulsion

- Spindle speed: 80 - 6000 rpm

- Speed correction: 80 - 120 %

- Drilling capacity in St60/Alu Ø: up to 18 / 20 mm

Nwjdju Awm Sjpfx Afhsb

- Thread cutting capacity: up to M14 / M16

- Position measuring system: rotary encoder

- Positioning accuracy: 0.05 mm

- Repeatability: 0.025 mm

- Machining accuracy tolerance: ± 0.2 mm

- Compressed air connection: R 3/8" / 6 bar

- Device connection: R 1/4"

- Operating pressure: approx. 6 bar

- Air consumption per cycle: approx. 600 l/min at 6 bar

- Noise emission: 79 dBA

- Motor power: 15 kW

- Electrical connection: 3x 400 V ± 5% / 50-60 Hz

- Pre-fuse: max. 25 A

- Power consumption: approx. 13 kVA

- Control voltage: 24 V DC

- Space requirement with safety fence: approx. 34 m² (11.4 x 3 m)

- Machine weight with accessories: approx. 5000 kg

We make it easier for you to find: "emulsion"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Emulsion (271)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you