Used hydraulic presses double column / Four column presses for sale (320)

Gelsenkirchen

Gelsenkirchen Hydraulic Double-Column (Drawing) Press

Hidrobrasil160 T Heizpresse

Gelsenkirchen

Gelsenkirchen Hydraulic Double-Column (Drawing) Press

Hidralmac200 T Doppelständerpresse

Gelsenkirchen

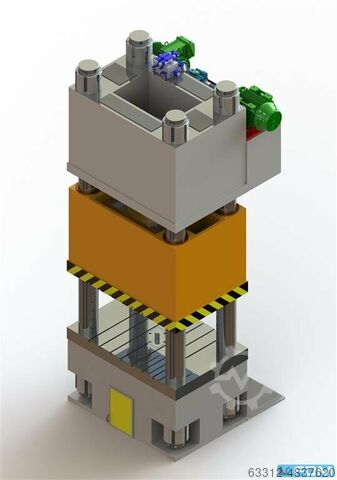

Gelsenkirchen Four Column Press - Hydraulic

Hidralmac160 T Viersäulenpresse

Gelsenkirchen

Gelsenkirchen Four Column Press - Hydraulic

Hidralmac60 To Viersäulenpresse Tiefziehkissen

Gelsenkirchen

Gelsenkirchen Straightening Press - Double Column

Hidralmac400T Portal-Richtpresse

Discover more used machines

Gelsenkirchen

Gelsenkirchen Four Column Press - Hydraulic

Hidrobrasil4 Säulenpresse 250T

Cestona

Cestona HYDRAULIC DOUBLE COLUMN PRESS

CAMP250 TN

Ennepetal

Ennepetal Four Column Press - Hydraulic

SORG500 To Viersäulenpresse S 500-2K

Ennepetal

Ennepetal Single Column Press - Hydraulic

Calende220 To Viersäulenpresse Auflagetisch

Ennepetal

Ennepetal Four Column Press - Hydraulic

Hidrobrasil1000 Tonnen Viersäulenpresse

Ennepetal

Ennepetal Four Column Press - Hydraulic

Hidrobrasil110 Tonnen 4-Säulenpresse

Ennepetal

Ennepetal Four Column Press - Hydraulic

DUNKES200 T Doppelständerpresse

Ennepetal

Ennepetal Four Column Press - Hydraulic

Hidralmac500T Säulenpresse

Ennepetal

Ennepetal Four Column Press - Hydraulic

Hidrobrasil350 Tonnen Viersäulenpresse

Ennepetal

Ennepetal Hydraulic Press

Hidrobrasil20 Tonnen Viersäulenpresse

Ennepetal

Ennepetal Four Column Press - Hydraulic

Hidrobrasil160 T Doppelständerpresse

Ennepetal

Ennepetal Hydraulic Double-Column (Drawing) Press

Hidralmac200 T Viersäulenpresse

Hessisch Lichtenau

Hessisch Lichtenau Double-column hydraulic press

SCHÖNUTE/B 50

Gelsenkirchen

Gelsenkirchen Hydraulic press

Hidrobrasil40 Tonnen Doppelständerpresse

Gelsenkirchen

Gelsenkirchen Hydraulic 400 to column press

Hidrobrasil400 Tonnen Viersäulenpresse

Gelsenkirchen

Gelsenkirchen Double column press 20 T

Hidrobrasil20 Tonnen Doppelständerpresse

Gelsenkirchen

Gelsenkirchen Hydraulic Double-Column (Drawing) Press

400t 4 Säulenpresse Tiefziehkissen 250t

Birmingham

Birmingham Hydraulic Press

SchulerEB 2-500

Birmingham

Birmingham Hydraulic Press

HounselH Frame

Birmingham

Birmingham Hydraulic Press

Hugh Smith1000ton

Used hydraulic presses double column / Four column presses (320)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you