Used Sterilization for sale (194)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Krotoszyn

Krotoszyn

1,434 km

Manifold with valves and regulators

Alfa Laval

Call

Condition: excellent (used), functionality: fully functional, Alfa Laval manifold with valves and regulators

Valve manufacturer: Alfa Laval

Number of valves: 14 pcs

Number of regulators: 8 pcs

Set dimensions: 1050 mm × 1000 mm × 1250 mm

The manifold (valve cluster) is equipped with 14 Alfa Laval valves and 8 flow regulators, designed for use in process installations requiring high levels of hygiene and precise flow control. The unit is constructed entirely from stainless steel, ensuring corrosion resistance and ease of cleaning.

Alfa Laval valves are recognized as a standard in the food and pharmaceutical industries – known for their durability, tightness, and ease of operation. The integrated regulators enable accurate control of pressure and flow rate, allowing the manifold to be seamlessly integrated with advanced process automation systems.

Applications:

- Process installations in the food and dairy industry

- Production lines in breweries, bottling plants, and processing facilities

Iodpfx Adjxvi Adedstb

- CIP/SIP systems (cleaning and sterilization in place)

- Dosing and distribution systems for process media

Listing

Krotoszyn

Krotoszyn

1,434 km

Manifold with valves and regulators

Alfa Laval

Call

Condition: excellent (used), functionality: fully functional, Manifold with Alfa Laval Valves and Regulators

Valve manufacturer: Alfa Laval

Number of valves: 11 pieces

Number of regulators: 6 pieces

Set dimensions: 800 mm × 550 mm × 1200 mm

Iodpfx Adjxviz Tsdotb

The manifold (valve assembly) is equipped with 11 Alfa Laval valves and 6 flow regulators. The unit is made of stainless steel, designed for use in hygienic process installations such as the food, dairy, brewing, or pharmaceutical industries.

Alfa Laval valves are renowned for their high reliability, precision operation, and ease of maintenance. The integrated regulators allow for precise control of pressure or media flow, ensuring efficient and safe operation of the entire system.

Applications:

- Production lines in the food and beverage industry

- CIP / SIP systems (Cleaning and Sterilization in Place)

- Process installations in dairy plants and breweries

- Flow control systems for process liquids

Listing

Freising

Freising

1,296 km

Sheet filter as a frame filter

Seitz - Werke GmbH

Call

Condition: used, Sterilizable universal filter for sterilization filtration. Stationary sheet filter with square filter elements in a vertical row arrangement, hydraulic filter sheet pressure. Hydraulic control from built-in electrical control panel.

Additional title: Sterilisation filter, years of manufacture 1979-2010

Capacity approx.: 750 hl/h Sheet filter - filtration area approx. 356 - 493m2

Operating pressure: 8 bar

Power: 6 kW

Voltage: 220/380 V

Frequency: 50 Hz

Length: 10100 mm

Width: 1320 mm

Height: 1750 mm

Formats: Square filter elements

Operation / Control: Vertical row arrangement

Material: Stainless steel

Position: Horizontal

Base construction: Frame

Ijdpfx Asxbn N Hjddotb

Features: Filter sheets; hydraulik filter plate compression; hose pump

Layer patterns: Vertical row arrangement

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Freinsheim

Freinsheim

1,023 km

Beverage machine

BertolasoType 63/40/6/6

Call

Condition: excellent (used), Year of construction: 2006, functionality: fully functional, General

- Bertolaso filling and capping plant, built in 2006

- Well-maintained system with annual inspection

- Left/right running direction

Itjdpfou A Imvox Addob

- Capacity up to 8,000 bottles/h

63-station clamp-type overhead rinser

- Ozone sterilization medium

- Fully automatic sterilization before filling begins

- Centrally adjustable inlet starwheels, easy inlet screw replacement

40-station vacuum filler

- With new gearbox

- Centrally adjustable inlet screws

- Easy inlet screw replacement

- Fully automatic damping

- Central height adjustment

6-station natural cork capper

- With separate cork supply

6-head screw capper for BVS 30/60 and MCA 28

- Central cap supply

- With central inspection station

- Automatic reject bottle ejection and collection station

- With fully automatic starwheel adjustment and easy screw replacement

The The filling and capping plant is available immediately and can be inspected at any time upon request.

-----

English version:

General Information

Filling and closing line Bertolaso, year 2006

- Well-maintained system with annual inspections

- Running direction: left/right

- Capacity up to 8,000 bottles/hour

- 63-station cap overhead inserter

Sterilization medium: ozone

- Fully automatic sterilization before filling starts

- Centrally adjustable feed stars, easy feed screw replacement

- 40-station vacuum filler

With new gearbox

- Centrally adjustable feed screws

- Easy feed screw replacement

- Fully automatic damping

- Central height adjustment

- 6-Station Natural Cork Closer

With separate cork supply

- 6-Head Screw Capper for BVS 30/60 and MCA 28

Central cap supply

- With central control station

- Automatic rejection of defective bottles and collection station

- Fully automatic star adjustment and easy screw replacement

- The filling and closing line is immediately available and can be inspected at any time upon request.

Used machinery for the beverage industry Hans Biedert

Listing

Germany

Germany

1,034 km

Pure Steam Generator

Finn Aqua500 H1

Call

Condition: ready for operation (used), Year of construction: 1986, Output at 45 PSIG: 440kg/h, max. pressure: 8bar, max. temperature: 121°C, material: stainless steel, steam: sterile, machine dimensions X/Y/Z: approx. 1200mm/800mm/2850mm. On-site inspection is possible.

Isdpfxeugmwfj Addjtb

Discover more used machines

Listing

Germany

Germany

1,034 km

Filling, Labelling and Packing Plant

Stork/Silmo/Robino & Galandrino/AdelskiVV-24/ST XII/Monoblocco Fenix 3/P2004 Longcap

Call

Year of construction: 2007, condition: ready for operation (used), A complete bottle filling, sterilizing, capping, labelling, cartoning and palletizing line for the wine industry is available. Bottle filling capacity: 4000 bottles/h, bottle format sets: 1l and 0.75l Schlegel/Bordeaux/Bugunder/0.5l/0.25l, sterilizer capacity: 4000 bottles/h, capper capacity: 8000 bottles/h, labelling capacity: 10000 bottles/h, capping capacity: 10000 bottles/h, carton formats: 12 and 6-bottle crates/12 and 6-bottle cartons, palletizing capacity: 1000 cartons/h. Line components: 1) Normpack Compact Form CF 670/980 carton folding machine, year of manufacture: 2000, output: approx. 650 cartons/h, 2) Stork VV-24 L.W. bottle filling machine, Year of manufacture: 1977, 3) Silmo ST XII/110 v ozone immersion bath sterilizer, year of manufacture: 1983, bottle formats: all standard wine bottles, 4) Miho LC 2000 caustic tester, year of manufacture: 2003, 5) Kapsler Robino & Galandrino Monoblocco Fenix 3, year of manufacture: 2002, 6) Syscona Unicount closure checker with counter for cork and metal closures, 7) Garnep Lebetta 4/3/18 1320 labeller, year of manufacture: 2017, including 2x wet gluing units, 3x SK units, camera system for rough alignment of bottles and domino laser for imprints, 8) Adelski PP2004 Longcap automatic capping machine, year of manufacture: 2007, 9) Adelski MCA PV 6541/1/210 AVM2104 automatic capping machine, year of manufacture: 1999, 10) Corker Bertolaso Delta, year of manufacture: 1977, 11) Carton sealing machine Normpack NCF-047, year of manufacture: 2001, including hot melt gluing unit, 12) Packaging machine Kettner Robot Junior Packer BE 2-T, year of manufacture: 1992, 13) Pallet loading machine Kettner Pressant Universal 1200, year of manufacture: 1992, 14) Crate labeling machine Weber Legi-Air 40XX, year of manufacture: 2004, 15) Dryer Okema T3, year of manufacture: 1999, 16) Carton printing machine Blum CompactLine 3. 0, number of heads: 8, printing options: double-sided, 17) Silmo 40g ozone generator, year of manufacture: 1983, 18) Schaberger glass lifting machine, year of manufacture: 1977, including new glass head, 12-bottle crate head and bottle table. Documentation available. On-site inspection is possible.

Itjdpfx Aevur Htjddjb

Listing

Freising

Freising

1,296 km

Capper

Marchesini

Call

Condition: used, Year of construction: 2004, Capper for twist-off caps. With lid storage container and lid sorting system for positioning and transporting lids to the capper. Injection of the lids with sterile steam.

Additional title: for twist-off caps

Capacity appr.: 6000 bo/h

Power: 4 kW

Current: 8 A

Voltage: 400 V

Frequency: 50 Hz

Compressed air: 6 bar, 80 NL/min

Formats: twist off caps, bottle diameter 18-80 mm, bottle height 35-200 mm

Itsdpfxjw Tmn Hs Addjb

Running direction: left -> right

Operation / Control: touch panel on switch cabinet

Features: switch cabinet with touch panel, storage container. Lid sorter (O.Z.A.F.), lid transport

Listing

Kraków

Kraków

1,669 km

Sweeper Aventurier Artist 1 SE

AventurierArtist 1 SE

Call

Condition: new, Year of construction: 2025, functionality: fully functional, working width: 400 mm, area performance: 1,200 m²/h, overall weight: 22 kg, warranty duration: 12 months, tank capacity: 4 l, water tank capacity: 4 l, I am offering the innovative Aventurier Artist 1 SE cleaning device, which combines effective scrubbing and debris collection in a single pass. This is a professional machine designed for daily cleanliness maintenance where precision, convenience, and operational efficiency are essential—ideal for schools, offices, clinics, hotels, restaurants, and small commercial spaces.

Key features:

• Rotating cleaning head – enables easy maneuvering and access to hard-to-reach areas: corners, edges, under furniture.

• Compact size and ergonomic design – adjustable tilt angle allows adaptation to the operator's height, ensuring comfort even during prolonged use.

• Intuitive operation – the touch control panel allows quick and easy adjustment of the operating mode to the specific task and surface type.

• Versatility – effectively removes dirt from all types of hard flooring, including porcelain tiles, concrete, stone, and vinyl panels.

• Quiet operation – perfect for use during opening hours and in noise-sensitive environments.

Technical specifications:

Theoretical performance: 1000–1200 m2/h

Working width: 40 cm

Brush pressure: 15 kg

Vacuum pressure: 8000 Pa

Brush rotation speed: 350 rpm

Average water consumption: 100–140 l/m2

Tank capacity: clean water – 4 l / dirty water – 4 l

Operating time: Eco mode 150 min / Turbo mode 120 min

Charging time: 100 min / per battery

Noise level: 60 dB (Eco mode) / 68 dB (Turbo mode)

Cleaning modes: Eco/Auto/Turbo/Sterilization/Deep clean

Dimensions: 110.4 x 43.9 x 34.6 cm

Gross weight: 22 kg

Device characteristics:

• Equipped with a HEPA filter for effective filtration and disinfection.

• High-resolution LCD display + intelligent voice system

• Easy removal of the dirty water tank enables convenient cleaning, preventing unpleasant odors

• Clean water tank with dual inlets suitable for all types of faucets

• Extended battery run time – up to 2.5 hours on a single charge!

• Edge cleaning system

• Antibacterial body

Equipment included:

Battery

Disc brush

Squeegee blade

HEPA filter

Ijdpfewz Nr Eex Addstb

LED lighting

Wi-Fi

Listing

Скопје

Скопје

2,335 km

Asepsystems

Aseptic filler for drumsAsepsystems with 2 heads 1"plug

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 1996, Aseptic filler for drums Asepsystems with 2 heads 1" plug with homogenizer and sterilizer.

Ijdpfeq Rdhujx Addstb

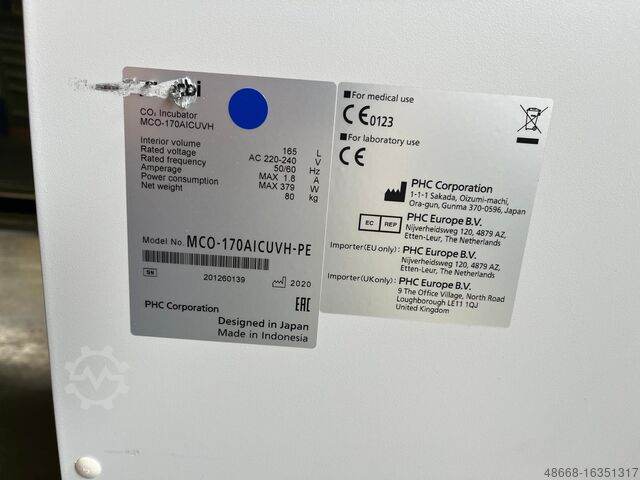

Listing

Wald

Wald

1,198 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2021, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2021

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions

Description has been adopted.

Iedpfx Adetxakxodotb

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

1,198 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

- Condensation control: this prevents unwanted condensation in the chamber and possible contamination.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

Itedpfetxaczox Addsb

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Wald

Wald

1,198 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

Iodpfx Adjtxarcodstb

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Freising

Freising

1,296 km

Tanks for yeast propagation system

Anton Steinecker Maschinenfabrik GmbH

Call

Year of construction: 1983, condition: used, Yeast cultivation with dampable wort sterilization tank designed for an operating pressure of 2 bar and a capacity of 2.47 hl, a second heatable and coolable wort sterilization tank designed for an operating pressure of 2 bar with a capacity of 12.7 hl, and a yeast propagation tank with a capacity of 55 hl, permissible operating pressure of 2 bar and jacket cooling in the lower third (without cone). All tanks are equipped with an agitator. Also includes a CIP tank. The plant is controlled via a Steinecker control cabinet (time-controlled). The tanks are also available individually

Iedsvcqt Uopfx Addetb

Additional title: with switch cabinet and CIP tank

Features: 2 tanks for wort sterilization with stirring unit (approx. 2,4 hl and approx. 12,7 hl), control cabinet, 1 cylindro-conical tank with stirrig unit, CIP system

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Pasteurizer

Tecnoindustria

Call

Condition: used, Year of construction: 2006, Tecnoindustria Used Pasteurizer Completely Overhauled

Tecnoindustria brand mesh pasteurizer all stainless steel with squared stainless steel mesh complete with water recycling tanks with relative pumps, infeed and outfeed belt for jars or boxes, blower for drying jars or boxes, steam modulating group, heat exchanger, various connecting pipes and all its accessories for operation.

The machine is totally overhauled

It is made up of two sectors of which:

first sector useful length 11450 mm

second sector useful length 7350 mm

overall dimensions:

Total length 18.70 meters without ribbons

Useful belt length axis by axis: 18.45 m

Useful net width 2.00 m.

Itedpfxevguhko Addsb

Overall width of the machine body 2.36 m

Overall width including trays 2.36 m + 0.65 m total 3.01 m

Total useful area of the machine sq.m. 36.90

Height 1400

Features by section

Sterilization length: mm. 7,700 useful

Pre-cooling length: mm. 3,300 useful

Length of warm water cooling + cooling: mm. 7,000 useful

Height mm 1400

Single track entry belt width: mm 200

Length: mm 3200

Single lane outfeed belt with Intralox belt width: mm 400

length: mm 3700 useful

Tecnoindustria Used Pasteurizer Completely Overhauled, The machine is totally overhauled, in excellent condition.

It is necessary to build the electrical panel, this is missing in this equipment.

Its construction is therefore carried out and created with the customer’s specifications, adapting the pasteurization areas to the production needs.

Its speed on the 65 diameter is approximately 18,000 pieces per hour, speaking of cylindrical containers.

This used tunnel pasteurizer is ideal for both tomato preserve jars and for tinplate and aluminum cans.

Both fruit juices and soft drinks and even tomato puree can be pasteurized.

The used tunnel pasteurizer has already been overhauled and is ready to be purchased and delivered to the end customer, we will follow all the issues related to its loading on trucks or containers included in the price.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Pasteurizer

PG

Call

Condition: used, Year of construction: 2004, operating hours: 2,000 h, Used Pasteurizer brand PG Completely Overhauled

Used Pasteurizer Completely Overhauled for jars or cans in d.b. PG brand, all stainless steel with squared stainless steel mesh, complete with 4 water recycling tanks with relative pumps.

Pasteurizer equipment for sale with inlet and outlet belt, blower for drying jars or boxes at the outlet, steam modulating group, shell and tube heat exchanger, various pipes connections, and all its accessories for operation.

The pasteurizer equipment for sale is totally overhauled

Pasteurizer equipment is made up of two sectors of 9500 mm each

Overall dimensions of the Used Pasteurizer PG:

Total length 19.00 m

Useful belt length axis by axis: 18.60 ms

Useful net width 2.50 m.

Overall width 2.70 m machine body

Overall width including trays 3.30 m

Total useful area of the Used Pasteurizer Completely Overhauled sq.m. 46

Features by section:

Sterilization length: mm. 8,600

Pre-cooling length: mm. 2,500

Length of warm water cooling: mm. 5,000

Cooling length: mm 1900

Single track entry belt width: mm 150

Length: mm 3800

Outfeed belt with 4 lanes width: mm 350

Pasteurizer equipment for sell length: mm 3500

Services for pasteurizer equipment for sell:

We also offer the machinery reinstallation service at your company if you need it.

We will create a dedicated offer if you wish, only after receiving all the necessary information.

Upon request, we can also modulate the control panel and intervene on the machine’s PLC.

This is used to customize the functionality of the used pasteurizer for sale.

If requested, we also provide the packing service if the goods are destined abroad and with transport by ship.

One of our team of technicians will be at your service and will create a tailor-made project for your company.

We have many solutions available for this pasteurizer equipment for sell, contact us at the numbers on the site for more information and to receive a quote for one of our used bottling machines.

Additional information:

For this pasteurizer equipment for sell it is necessary to build the electrical panel, this is missing in this equipment.

Its construction is therefore carried out and created with the customer’s specifications, adapting the pasteurization areas to the production needs.

Its speed on the 65 diameter is approximately 18,000 pieces per hour, speaking of cylindrical containers.

This used tunnel pasteurizer is ideal for both tomato preserve jars and for tinplate and aluminum cans.

Itsdevguhwspfx Addob

Both fruit juices and soft drinks and even tomato puree can be pasteurized.

The used tunnel pasteurizer has already been overhauled and is ready to be purchased and delivered to the end customer, we will follow all the issues related to its loading on trucks or containers included in the price.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, Used aseptic filling line Tetra Pak A3 FLEX 200S up to 7000 l/h

The Used aseptic filling line Tetra Pak A3 FLEX 200S up to 7000 l/h provides an advanced solution for the aseptic bottling of dairy products and fruit juices. Consequently, this line fills 200 ml Slim Brick containers, ensuring high production efficiency and maintaining the sterility of the product throughout the entire packaging process.

Line Features of the Used aseptic filling line Tetra Pak A3 FLEX

The bottling line operates with a capacity of up to 7000 liters per hour, ensuring high standards of safety and quality. Furthermore, the aseptic system prevents bacterial contamination, making this solution ideal for packaging sensitive liquids. Additionally, the line includes a conveyor system that facilitates the smooth transfer of containers between different processing stages, ensuring an uninterrupted workflow.

Machines Included in the Line

Ijdpsv Ew Iqsfx Addotb

Tetra Pak A3 FLEX 200 ml Slim Filler (year 2006)

The Used aseptic filling line Tetra Pak A3 FLEX relies on the Tetra Pak A3 FLEX filler, which aseptically fills 200 ml Slim containers. Moreover, this machine utilizes an advanced sterilization system to guarantee the microbiological safety of the packaged product. The filling process ensures precision, thereby minimizing waste and maintaining accurate dosing.

Tetra Pak Straw Applicator 22 (year 2009)

The Tetra Pak Straw Applicator 22 automatically affixes straws to 200 ml Brick containers. As a result, its integration into the production line enables precise and fast application, improving the product’s ergonomics for the end consumer.

Flow Management and Buffering: Tetra Pak Accumulator ACHX30-0500-47M (year 2010)

The ACHX30-0500-47M accumulator optimizes production flow by regulating container transport between different processing stages. In addition, this component ensures a continuous workflow, preventing interruptions and maintaining a consistent production rate even when downstream machinery operates at variable speeds.

Tetra Pak Cardboard Packer 70 (year 2003)

The Tetra Pak Cardboard Packer 70 packages Brick containers into transport cartons. Consequently, the automated system enables fast and efficient packaging, protecting units during transportation and facilitating distribution logistics.

Aseptic Filling Process in the Used aseptic filling line Tetra Pak A3 FLEX

The entire system performs aseptic filling, a technology that maintains product sterility without requiring refrigeration. Specifically, the process sterilizes the container before filling, preventing bacterial contamination and ensuring an extended shelf life.

Safety and Compliance

The Used aseptic filling line Tetra Pak A3 FLEX incorporates advanced safety systems to protect both operators and the product during processing. Additionally, each machine complies with the sanitary and hygiene regulations required by the food industry, ensuring safe production in line with international standards.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, operating hours: 50,000 h, Used Bottling Line KRONES with Aseptic Filling 36000 bph

The used KRONES bottling line with aseptic filling 36000 bph provides a highly efficient solution for the beverage and dairy industries, meeting productivity and quality demands in high-capacity production environments. This system ensures the highest standard of sterilization, preserving the organoleptic properties and food safety of the bottled product. Furthermore, it is designed to offer consistent performance throughout long production runs.

Iodpfx Adsv Ew E Aedjtb

The process combines Blow-Fill-Seal (BFS) and wet aseptic technology, ensuring full aseptic integrity throughout the production flow.

Line Speed and Capacity

The Used aseptic line KRONES processes 36000 bottles per hour (bph), on the format 500 ml, making it suitable for high-capacity production. It handles PET containers and supports various formats, including 0.3 L, 0.4 L, 0.5 L, and 1.0 L. Moreover, the system can adapt from 250 ml up to 1.5 L bottles, offering a broad production flexibility. In addition, this versatility makes the line ideal for different applications in the beverage industry, including milk, juices, tea, and flavored water. As a result, the line adapts easily to various markets and production demands by configuring different container sizes. Therefore, it offers flexibility for a range of product types.

Aseptic Filling Technology in the Used aseptic line KRONES

The line’s aseptic filling system eliminates microbiological contamination. Moreover, the sterilization and filling processes occur while keeping the product sealed in aseptic conditions, minimizing preservatives and ensuring a long shelf life without refrigeration. This process is critical for handling sensitive products like milk and fruit juices, which require advanced sterilization to maintain their nutrients and natural properties. Consequently, the line ensures that all products meet stringent quality and safety standards.

The aseptic filling technology includes electronic volumetric filling valves with an accuracy of ±0.3%, supporting both cold filling at 20 °C and ambient temperature filling.

The system uses a wet sterilization method with peracetic acid (PAA) or hydrogen peroxide, achieving contact times of less than 8 seconds and leaving residuals below 0.1 ppm.

Additionally, the filling environment is maintained at ISO Class 5 cleanliness, using HEPA filtration and positive pressure control, ensuring the highest standards of contamination prevention.

Key Components of the Line

The system manages sterilization with a STORK machine, available in two units. In addition, the system also handles product homogenization with a STORK homogenizer (available in two units). These devices ensure consistent product quality, especially for beverages like milk and juices. As a result, the system achieves uniformity in the final product, improving consumer satisfaction.

The UHT system (Ultra High Temperature) uses the VarioDose Krones to treat the product at high temperatures, eliminating bacteria and microorganisms without compromising quality.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, Used Aseptic Filling Line Tetra Pak A3 FLEX 1000S up to 9000 l h

The Used aseptic filling line Tetra Pak A3 FLEX 1000S up to 9000 l h provides an advanced solution for aseptic bottling of liquid products. Specifically, it can reach a production capacity of 9000 liters per hour. This line ensures maximum efficiency and reliability when filling dairy products and juices. Moreover, its fully integrated aseptic process preserves the organoleptic and microbiological characteristics of the product.

Main Components of the Aseptic A3 Flex 1000S line

Homogenizer and Sterilizer – 12 tons per hourThe homogenization and sterilization system of the Used aseptic filling line Tetra pak A3 FLEX 1000S up to 9000 l/h stabilizes the product and eliminates microorganisms through controlled thermal treatment. Furthermore, its 12 tons per hour capacity allows it to handle large volumes while maintaining product quality and safety.

Alsafe Tank – AsepticThe Tetra Alsafe tank stores products aseptically before filling. As a result, its food grade certified materials ensure complete isolation and prevent contamination risks.

Tetra Pak CIP System The Cleaning In Place CIP system automates line sanitation. Consequently, it cleans all product contact parts internally, reducing downtime and improving operational efficiency.

Tetra Pak A3 FLEX 1000S Filling MachineThe A3 FLEX 1000S filling machine forms the core of the Used aseptic filling line Tetra Pak A3 FLEX 1000S up to 9000 l h. Specifically, it fills dairy products and juices aseptically in carton containers. In addition, it ensures high dosing precision, thereby minimizing waste and guaranteeing excellent packaging quality.

CAP21 Capping MachineThe CAP21 capping machine seals containers hermetically, thus preventing contamination and extending shelf life. Additionally, its seamless integration with the filling machine maintains an uninterrupted workflow.

Itjdpfx Adev Ai Haodeb

ACHX30 Accumulator 47 metersThe ACHX30 accumulation system optimizes package flow along the production line. Consequently, it reduces downtime and enhances overall bottling efficiency.

Tetra Pak Film Wrapper 67 Shrink WrapperThe Film Wrapper 67 shrink wrapper of the Used aseptic filling line Tetra pak A3 FLEX 1000S up to 9000 l/h provides secondary packaging by wrapping products in plastic film. In turn, this step improves logistics and distribution efficiency while ensuring greater protection and stability during transportation.

Filling Line Features of the line

The Used aseptic filling line Tetra Pak A3 FLEX 1000S up to 9000 l h uses aseptic filling technology, which prevents bacterial contamination without preservatives. Furthermore, it supports various liquid products, especially milk, dairy products, fruit juices, and plant based beverages.

By integrating advanced technologies and automated sanitation management, this line delivers high quality standards with optimal production efficiency.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Filling Machine

BertolasoSuprema 48

Call

Condition: used, Year of construction: 2021, Used isobaric filler Machine Bertolaso 11000 bph

year of the remark of isobaric filler 2021

suitable for bottling sparkling and semi-sparkling wines

entrance on the left

completely overhauled isobaric filler in all its parts with original Bertolaso spare parts (documentable)

bottle sizes 85, 88, 90, 112

6 sets of channels with isobaric filler to make the levels

the electrical panel of the Used Isobaric Filling Machine according to CE standards

use and maintenance manual, spare parts manual available for this isobaric filler

the production speed of isobaric filler is 9000 BPH with the sparkling wine

the production speed is 7000 BPH with spumante.

Ijdpfxsvguv Ue Addjtb

This isobaric filler is immediately available and delivered in case of purchase. We can assist the buyer in each step of the commissioning and testing operation of the Used Isobaric Filling Machine.

How to build one isobaric triblock:

The isobaric filler can be connected either to an automatic rinsing machine or to one or more cappers.

We have 40 Bertolaso SBR grippers and two series of Bertolaso mushroom and satin cappers.

One has 6 heads and reaches 9.000b / h, and one has 10 heads and reaches 14.000 BPH

We can introduce all the machines in a sterile clean room with a filtration system.

You can have the performance of an isobaric triblock with a Used Isobaric Filling Machine for natural cork and mushroom.

Productivity can be from 11,000 to 14,000 BPH.

It is possible to foresee a periodic maintenance program for isobaric filler to always have excellent efficiency. This involves both having spare parts in stock and foreseeing machine stops for a week/10 days.

In case of purchase of the isobaric filler triblock, at least 9.00 meters by 2.50 meters, H 4.00 meters are required. The creation of a clean room guarantees the absence of contamination in the bottling phase.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Filling Monoblock

GaldiRG260A

Call

Condition: used, Year of construction: 2010, Used Filling Monoblock Galdi Up to 6000 BPH

Introduction to Advanced Bottling Technology

Initially, the Galdi RG260A, a high-performance filling monoblock from 2010, stands as a cornerstone of modern bottling operations. Having been recently overhauled, it showcases unmatched efficiency and reliability. Consequently, achieving speeds of up to 6,000 bottles per hour, this machine sets a benchmark in the industry. Specifically, it is engineered for Pure-Pak Daimond Standard Curve B-style T-Bottom containers. Moreover, it utilizes 36mm Elocap caps, demonstrating its versatility and adaptability to various packaging needs.

Ensuring Uncompromised Product Safety of the Filling monoblock Galdi

Importantly, one of the critical aspects of the Galdi RG260A is its disinfection killing rate. With up to LOG5, it guarantees the highest levels of product safety. This capability is especially crucial in today’s market, where consumer health and safety are paramount. Therefore, the machine’s design and operational protocols are aligned with strict hygiene standards, offering peace of mind for producers.

Adaptable to a Wide Range of Products

Ijdpfx Aovgt N Heddstb

Furthermore, the machine’s flexibility is highlighted by its capacity to handle multiple packaging cross-sections. From 500 ml to 1000 ml, it accommodates various product volumes. This adaptability extends to the machine’s ability to process a diverse array of products. Whether dealing with dairy, juice, liquid food, or high-viscosity substances, the Galdi RG260A stands ready. Additionally, its design supports products containing particles and fibers, ensuring smooth operation without compromising quality.

Customization and Efficiency in Chilled Distribution

Moreover, tailored to meet specific customer requirements, the machine features a 36 mm XE cap applicator. It also includes a cap feeding system, enhancing operational efficiency. The inclusion of a CIP return pump underscores the machine’s commitment to hygiene and easy maintenance. By employing gravity or light depression filling, it ensures accurate and gentle handling of products.

Technological Excellence for Optimal Performance

Additionally, the Galdi RG260A is equipped with advanced technological components. These include a double indexing magazine and a LOG5 killing rate sterilization system. Sterile air filters and a servo-driven cross cap applicator contribute to its superior performance. The aseptic double diaphragm filler, with specialized intake and discharge valves, ensures hermetic sealing from external environments.

Innovative Filling Solutions of the Filling monoblock Galdi

Furthermore, the machine employs a bottom-up filling system, designed to reduce splash and foam. This approach is critical for maintaining product integrity and appearance. A special closed filling box for the aseptic filling room and automatic CIP-SIP system further enhance sanitary conditions.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, Used Bottling Line for ESL MILK up to 2500 bph

We present a used bottling line engineered for maximum efficiency and reliability in packaging ESL milk. Furthermore, this line is optimized to ensure continuous and high-quality production, with a nominal capacity of 2500 bottles per hour (bph).

Nominal Capacity and Configuration of the Bottling Line for ESL Milk

The nominal capacity of 2500 bph arises from a precise arrangement of the main components. Firstly, the line includes 12 filling heads and 1 capping head, ensuring a smooth and uniform flow during the bottling process. Moreover, it handles round PET bottles with a standard format of 1000 ml.

Product and Packaging Specifications

This line is designed for round PET bottles, with a standard format of 1000 ml. It accommodates both pasteurized and ESL pasteurized milk, ensuring maximum versatility in production.

Power Feeding and Distribution Features

The line requires an electrical supply of 400 Volts at 50 Hz and is configured for a three-phase distribution system with separate neutral and ground. Additionally, it requires a minimum pressure of 7 bar for the low-pressure compressed air system.

Filling Environment and Blow Molding

Itodpfxovgvr Re Addjb

The filling process occurs in an ultra-clean environment at a temperature of 4°C, ensuring maximum product quality and freshness. Moreover, the used blow molder, a Kosme KSB 4 L model, optimizes PET bottles of various sizes, with a production speed of up to 6800 bottles per hour.

Energy and Water Consumption

The line is designed for optimized energy and water consumption. It consumes an average of 36 kW of electricity, with an installed power of 56 kW. Additionally, it necessitates a cooling water flow of 6.6m3/h at a temperature of 5-7°C.

Performance and Efficiency

The line achieves a maximum output of 1700 bottles per hour per mold unit, thanks to pneumatic preform separation and precise servo motor controls. Moreover, it features short deaeration times, ensuring optimal use of blow molding time.

Additional Components

In addition to the blow molder and filling line, we specifically include the AVE mod. 12/12/1 MLK automatic monoblock for packaging fresh milk in 1000 ml PET bottles, complete with rinsing, filling, and capping systems. Furthermore, a SIMAC 2500BPH labeler and Mariani FS-T10 automatic shrink wrapper provide a comprehensive and automated packaging solution.

Optional upgrade of the ESL Monoblock

If needed the Monoblock present in the Used Bottling line for ESL milk can be complemented by some elements to enhance its functionality.

An H2O2 an H2O2 hydrogen peroxide injection system can be installed to sanitize the bottles.

An inlet screw would allow 1 ml of H2O2 to be nebulized, while a UV lamp on the capper would ensure the sterilization of the caps. A compressed air microfiltration system and a pressurized environment with HEPA filters would ensure a sterile environment.

Trust Seal

Dealers certified through Machineseeker

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, Used UHT Milk Preparation Room Tetra Pak 6600 L/h

Technical Overview of the System

The Used UHT Milk Preparation Room Tetra Pak 6600 L/h provides a complete solution for the aseptic preparation of UHT milk, drinking yoghurt, juices, and flavored beverages. Currently in storage and ready for reinstallation, the system delivers high thermal and microbiological efficiency. Moreover, its modular design allows it to operate at 2640 L/h, 3850 L/h, and up to 6600 L/h in full configuration. Therefore, it adapts well to varying production demands.

Homogenization Section

At the core of the Used UHT Milk Preparation Room Tetra Pak 6600 L/h lies a Tetra Pak homogenizer, model Tetra Alex, which ensures effective fat globule size reduction and consistent product texture. As a result, it stabilizes complex emulsions such as flavored milk or drinking yoghurt and prevents phase separation during storage. Importantly, this homogenizer is non-aseptic and operates upstream of the UHT sterilization process, which eliminates any microbial load introduced during homogenization. Furthermore, the homogenizer supports high working pressures and simplifies maintenance. In addition, the robust construction ensures long-term reliability.

Itodswqxhhopfx Addeb

Integrated Deaeration System

The system includes a Tetra Pak deaerator (2005) equipped with an auxiliary pump and tank. Specifically, this component removes dissolved oxygen and unwanted gases from the product before thermal processing. Consequently, it improves product stability and reduces oxidation. Additionally, the vertical configuration ensures efficient gas separation. Meanwhile, the design minimizes product loss and guarantees a continuous flow to the next stage.

High-Performance Tubular UHT Module

Thermal sterilization occurs through a tubular UHT heat exchanger, manufactured by Tetra Pak and model Tetra Therm Aseptic. In particular, this component sterilizes products via indirect heat exchange while preserving organoleptic properties. Importantly, the module includes a holding coil to maintain temperature over a defined time span. Thus, it complies with food safety regulations and ensures microbiological safety. Similarly, its modular design allows for easy integration into existing lines.

Electronic Control and Automation

The line features an electrical control panel, a Siemens PLC, and operator panels for precise management of each phase. Notably, it includes detailed electrical schematics, Festo pneumatic valves, and Danfoss inverters to dynamically control pumps and heat exchangers. As such, the automation enables continuous processing. Besides, it optimizes the CIP cycles, reduces downtime, and enhances traceability. Above all, it ensures reliable performance across diverse operating conditions.

Conclusion

In summary, the Used UHT Milk Preparation Room Tetra Pak 6600 L/h offers a complete, high-efficiency system for preparing UHT milk and beverages. Thanks to its top-tier components and scalable design, this line stands as an ideal choice for dairy producers. Whether the goal is reliability, hygiene, or adaptability, this solution meets strict industry standards. Finally, the system remains in storage and is available for immediate installation.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, operating hours: 4,800 h, Used SIG Combibloc – like new

Aseptic line for dairy and juice – advanced technical configuration

The used SIG Combibloc processes dairy products and juices in 65 ml, 125 ml, and 200 ml formats. Notably, the line achieves a nominal output of 26,500 packs per hour. Furthermore, the manufacturer has fully packed the line for immediate shipment, and it has only completed 4800 working hours. It is in near-new condition. Therefore, this line presents an excellent opportunity for rapid deployment.

Sterilization and aseptic filling system

The line features a hydrogen peroxide (H₂O₂) supply and concentration control system, installed in 2023. This unit plays a crucial role: it sterilizes the carton packs before filling, ensuring that aseptic conditions are met according to the strictest standards.

Immediately following sterilization, the process continues with the SIG Combibloc CFA 1224 aseptic filling machine, also installed in 2023. This machine includes all original accessories. In 2024, the operator added a conversion kit, which significantly increases the filler’s speed while still maintaining sterility and reliability. As a result, the line performs at higher throughput without sacrificing safety.

These two modules together form the technical core of the Used line like new brand SIG Combibloc. Consequently, they deliver consistent, controlled, and efficient operation across multiple formats.

Accessory application and primary packaging

After filling, the system proceeds to the Geyssel 533 automatic straw applicator (2023), which applies straws to the packs. This function is especially important for consumer-oriented formats, particularly those designed for children or on-the-go consumption.

Next, the line transfers products to the Meurer tray packer for SIG formats (2023). This machine groups the filled packs into stable trays for handling and distribution. Subsequently, the process reaches the HTW450 double stacker tray packer by SIG Combibloc, installed in 2024, which stacks trays in two levels. Thanks to this configuration, the system maximizes storage efficiency and simplifies palletizing.

Altogether, these machines ensure smooth downstream flow, as well as effective primary and secondary packaging.

Flow management and conveying

In addition, the line includes a Meurer HSP 4 – S KF accumulator (2023), which regulates product flow between modules and prevents bottlenecks. This feature proves essential during high-speed operations or brief downstream interruptions.

Iedpfswc Ucrjx Addetb

Likewise, the Meurer conveyor system (2023) transfers packs smoothly between each station. Since all modules are synchronized, the line operates without unplanned downtime. Moreover, this modular architecture allows for future upgrades if production requirements increase.

Technical conclusion of the Used line like new brand SIG Combibloc

In summary, the Used line like new brand SIG Combibloc offers a comprehensive aseptic packaging solution for both dairy and juice products.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, Used aseptic filling line Tetra Pak A3 FLEX 1000SQ 7000 l/h

General description of the line

The Used aseptic filling line Tetra Pak A3 FLEX 1000SQ 7000 l/h provides an industrial configuration specifically designed for the sterile filling of liquid food products. It particularly suits sensitive items such as UHT milk and fruit juices, which require controlled processing environments. Moreover, the system operates with 1-liter square containers and reaches a production capacity of 7,000 liters per hour. As a result, it ensures high microbiological quality standards. In this configuration, each machine plays a critical role in maintaining aseptic conditions from filling to final packaging.

Aseptic filler Tetra Pak A3 FLEX

At the heart of the Used aseptic filling line Tetra Pak A3 FLEX 1000SQ 7000 l/h, the Tetra Pak A3 FLEX filler (version 100V), manufactured in 2004, performs aseptic filling using an integrated sterilization system, microbial barrier, and precise dosing mechanisms. Consequently, it processes pasteurized or sterilized products intended for extended shelf life and keeps them intact without requiring refrigeration. Furthermore, the filler maintains a sterile environment throughout the entire cycle. In addition, it ensures consistent product dosing and eliminates variability in filling performance. As a result, manufacturers can rely on this equipment to meet strict food safety requirements.

Aseptic capper Tetra Pak TCA88

The line also includes the Tetra Pak TCA88 capper, built in 2006. This module applies plastic caps to filled containers using induction or mechanical systems that ensure hermetic sealing in an aseptic environment. Moreover, the capper synchronizes precisely with the filler to ensure uninterrupted operation. In contrast to conventional systems, this integration significantly reduces the risk of contamination after filling. In the same way, the TCA88 includes built-in quality control functions that verify each cap’s position and torque. Meanwhile, Tetra Pak designed the unit with safety features such as interlocked guards and error monitoring systems, ensuring full compliance with industry standards.

Cardboard packer TCBP70 in this used aseptic filling line Tetra Pak

The Tetra Pak TCBP70 packer, manufactured in 2007, manages secondary packaging. This automatic system forms and fills corrugated cartons using wrap-around or preformed box configurations. Similarly, it operates with fully electronic controls that allow real-time adjustment and monitoring. Therefore, the machine supports flexible packaging layouts and rapid format changes. In addition, the TCBP70 includes safety systems such as light curtains and emergency stop devices. For example, if an operator enters the guarded zone, the system halts automatically to prevent accidents. As a result, the packaging process remains both efficient and secure.

Industrial applications and operational benefits

Itedpfx Adswkux Njdeb

The Used aseptic filling line Tetra Pak A3 FLEX 1000SQ 7000 l/h targets producers in the dairy and beverage industries who require aseptic packaging capabilities.

Listing

Fumane (Verona)

Fumane (Verona)

1,487 km

Complete Bottling Line

Call

Condition: used, operating hours: 1,800 h, Used Bottling Line for champagne, sparkling and still wine 4000 bph

Product Compatibility and Filling Technology

This bottling line processes still wine, sparkling wine, and champagne with high efficiency. Specifically, it handles only glass bottles and uses an isobaric filling system, which ensures precise control when filling pressurized liquids, such as sparkling products. As a result, wineries that produce multiple wine types with different physical and chemical properties can rely on this line for consistent, adaptable operation. In other words, the system addresses diverse product demands without compromising output quality.

Performance Output by Bottle Format

Depending on the bottle format, the line delivers different outputs. It processes both 0.20l and 0,375l bottles at 4,500 bottles per hour. Meanwhile, it handles 0,75l bottles at 4,000 bottles per hour and 1.5l bottles at 2,000 bottles per hour. Therefore, this production speed suits medium-scale wineries that require flexibility while maintaining industrial performance.

Commissioning, Runtime, and Immediate Availability

Technicians installed the line in 2022. Since that time, it has operated for 1,800 hours and produced approximately 2,400,000 bottles. The system continues to run in production, which means it remains in good operational condition. Furthermore, its immediate availability offers an advantage to wineries needing rapid deployment. Because of this, buyers can integrate the equipment without significant downtime.

Ijdswgw Dgspfx Addstb

Primary Bottling Block: Depalletizing, Rinsing, Filling, and Capping

The process starts with a Duetti Packaging depalletizer, model M, which automatically feeds empty bottles into the system. Subsequently, the GAI monoblock, model 4033RES-HP-A01, performs rinsing, filling, and capping in a single integrated unit. The dual-stage rinser (water + gas) uses 16 grippers to sanitize bottles. A high-pressure electropneumatic filler with 24 valves carries out isobaric filling. Notably, the 3-head rotary corker applies straight corks, champagne-style mushroom corks, plastic closures, and aluminum screw caps. Moreover, the monoblock includes multi-format screws, motorized guide adjustments, dummy bottles for internal rinser sterilization, and a solenoid valve kit to switch between gas and cleaning liquid inputs. Altogether, this configuration provides high precision, minimal changeover time, and excellent bottle handling.

CIP and Quality Control: Cleaning and Inspection Systems

To maintain hygiene, the WIN&TECH CIP unit, model Win&Guard C 23.05, manages automatic cleaning via a steam-water heat exchanger and a three-stage filtration system across two independent circuits. Additionally, this system allows operators to sanitize the internal components between production runs without disassembly. At the same time, the CMP inspection unit, model CV-MUF108, performs continuous quality control.

We make it easier for you to find: "sterilization"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sterilization (194)

Search Machineseeker now with more than 200,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month